INTRODUCTION

A Vortex A/C enclosure cooler is designed to use ltered

compressed air to cool industrial control cabinets without the

use of any refrigerants. Hot air in the cabinet is vented to the

surroundings through a built-in vent in the Vortex A/C. Noise

generated by the Vortex A/C is comparable to normal speech

levels. The Vortex A/C has a built-in mechanical thermostat that

requires no electricity. To operate, simply install on your enclosure

and connect the compressed air source.

COMPRESSED AIR SUPPLY

The compressed air supply must be ltered (5 micron maximum)

to remove water and dirt. A 5 micron lter is supplied for this

purpose (Vortec model 701S-24A or 701S-36A). If oil is present

in the compressed air supply, remove the oil using an optional

0.01 micron coalescing lter (Vortec model 701S-48 or 701S-54).

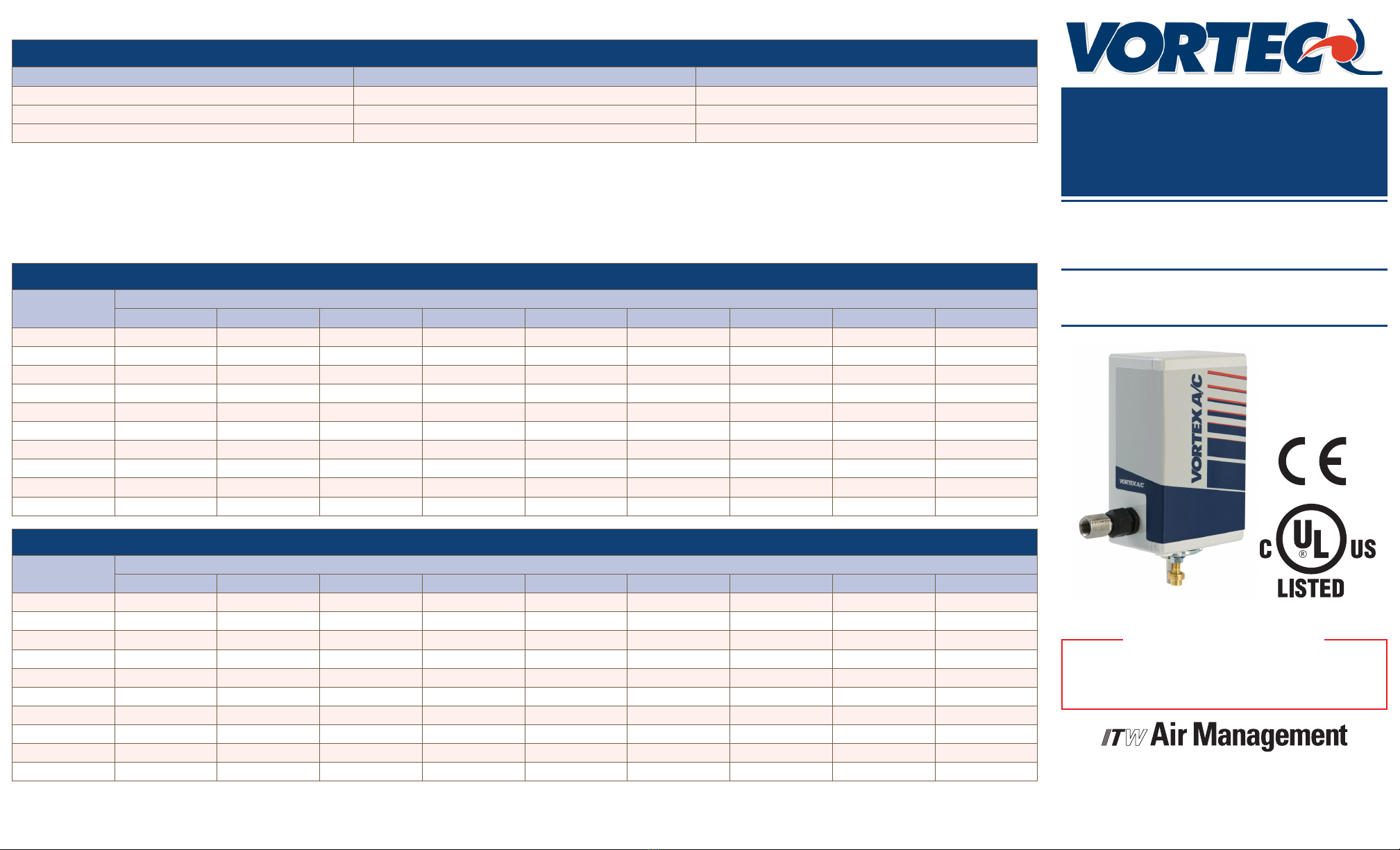

Filter recommendations are given in Table 1.

If an oil removal lter is necessary, install it downstream of

the 5 micron lter. Change the lter elements as needed (see

Maintenance).

The appropriate size of compressed air supply line should be

selected to ensure optimal performance of the Vortec product.

Please refer to Table 2 to determine what supply line size is

recommended for your application. Contact Vortec at 1-800-441-

7475 for further assistance.

INTERNAL CABINET PRESSURE

The Vortex A/C, when operating at 100 psig (6.9 bar), will maintain

the internal enclosure pressure at approximately 35” (889 mm)

of water column. When the Vortex A/C is not cooling (when the

thermostat senses acceptable temperatures), the Vortex A/C is

not pressuring the enclosure. If you desire a constant positive

internal enclosure pressure, even when the Vortex A/C is not

cooling, this may be accomplished by removing a set screw

that is adjacent to the mechanical thermostat on the bottom of

the unit. By removing this set screw with a 3/32” (2 mm) hex

key), a small amount of air (3 cfm or 85 lpm) will pressurize the

sealed enclosure to approximately 1.5” (38 mm) water column.

This “pressurization air” will run continuously, regardless of the

thermostat operation, until the set screw is re-installed.

MAINTENANCE

The only maintenance involved with the Vortex A/C is normal

element changes to the compressed air lter. The lter element

should be changed when there is a noticeable decrease in

performance or when pressure drop across the lter exceeds

5 psig (0.3 bar). The Vortex A/C has only one moving part (the

mechanical thermostat/valve) which is not serviceable in the

eld. Do not disturb the setting of the thermostat. Evidence of

tampering with the thermostat may void the warranty.

If it is suspected that the compressed air lter has not been

maintained after an extended period of operation, there may be

dirt in the Vortex A/C. If the Vortex A/C is not cooling sufficiently,

there may be debris in the “generator” of the unit. To check, pull

the 1/2” (13 mm) inside diameter vinyl tubing off the cold air

outlet of the Vortex A/C and unscrew (with a 1” (25 mm) open

end wrench) the cold air outlet. Remove the O-ring. Remove the

white nylon washer(s). Then remove the red (model 7615) or the

blue (model 7625) or the brown (model 7635) generator. Inspect

the six slots in the generator for dirt and clean if necessary. Clean

the cavity in the Vortex A/C that the generator was located in

if necessary. Reassemble in reverse order. Tighten the cold air

outlet to 100 inch-pounds (11 newton meters) torque. Be sure to

supply clean (ltered to 5 micron) and oil free compressed air to

the Vortex A/C.

INSTALLATION

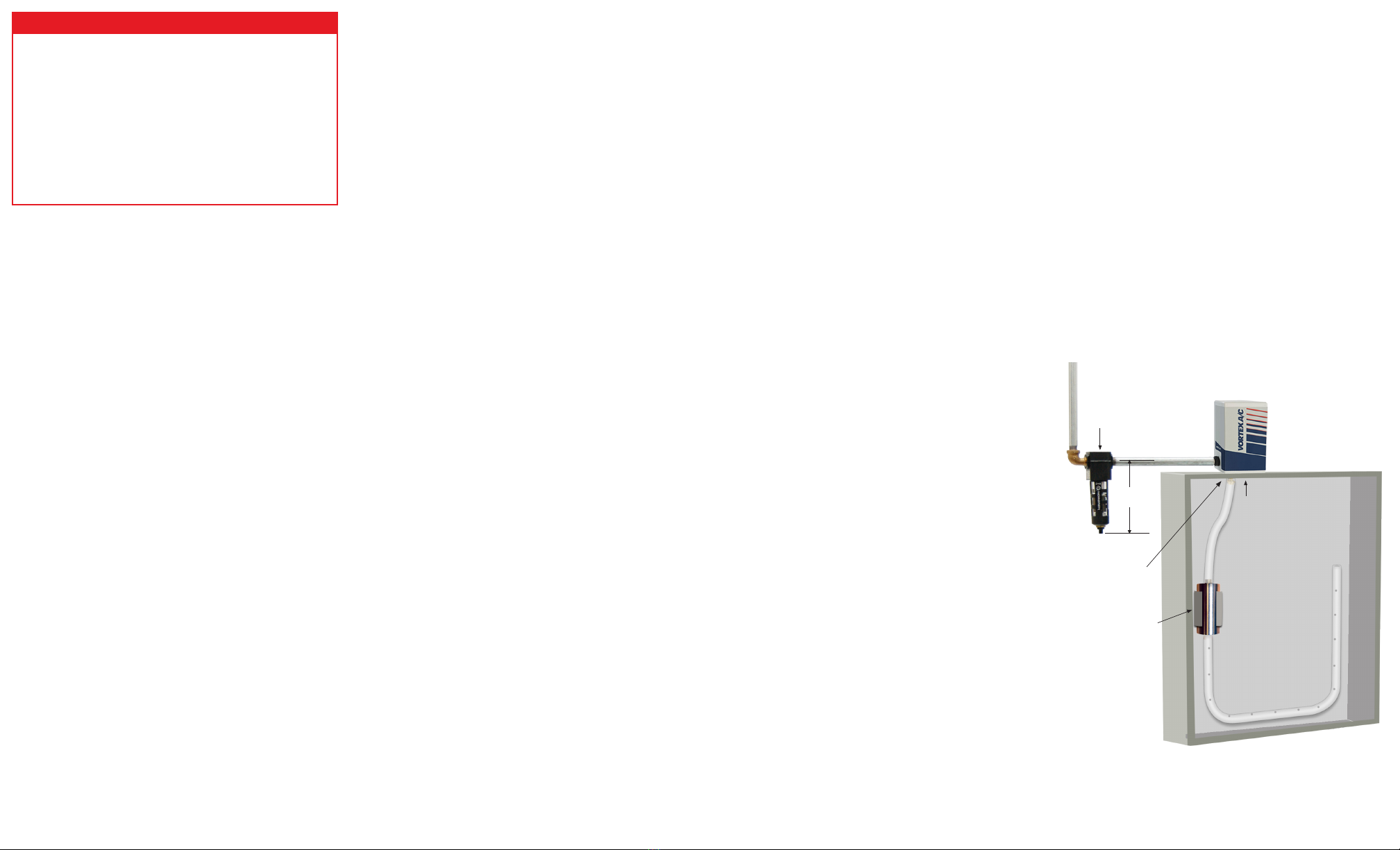

To maintain the UL Type 12 rating, the Vortex A/C MUST be

installed in one of the following congurations on a UL Type 12

enclosure:

a. Top mounted in an upright and vertical orientation, on

a at horizontal surface (as shown)

b. Side mounted, on a at vertical surface of the

enclosure, with the compressed air inlet pointing

upward. When side mounted, rotate the aluminum

louvered outlet on the back of the Vortex A/C so the

louvers point downward to the oor.

1. Position the Vortex A/C on the top or side of your enclosure

so that there is sufficient clearance for the internal mechanical

thermostat and cold air outlet, and, so that the entire mounting

“footprint” of the Vortex A/C is supported by the enclosure. (A

4-3/4” wide x 3-3/8” deep (121 mm wide x 86 mm deep) area).

Position the unit so that the louvered outlet on the back of the

Vortex A/C is away from personnel, if possible. Also, position

so that no internal enclosure components obstruct air ow

around the mechanical thermostat.

2. Cut a 1-15/16” (49 mm) diameter hole (1-1/2” knockout size)

in the selected location on the enclosure. De-burr any sharp

edges around this hole.

3. Remove the 1-1/2” electrical locknut from the Vortex A/C.

Insert the threaded portion of the Vortex A/C into the 1-15/16”

(49 mm) hole in the enclosure. (Be careful not to damage the

mechanical thermostat during installation.)

4. From inside the enclosure, screw the electrical locknut onto

the threads of the Vortex A/C. Tighten the locknut securely

to compress the 1/8” (3 mm) thick sealing gasket that is

positioned between the enclosure and the Vortex A/C.

5. Determine a suitable location for the Cold Air Muffler inside the

enclosure that is close to the cold air outlet of the Vortex A/C.

(You will need a surface area of approximately 2” x 9” (50 mm

x 229 mm) to mount the muffler. The Muffler can be mounted

in any orientation, horizontal or vertical.) Using the supplied

Muffler Mounting Clamp (with double sided tape), attach this

Clamp at the desired location. Clean the mounting surfaces

so that the double sided tape bonds securely. If desired, this

Clamp can be permanently mounted to the enclosure using

the supplied mounting hardware. Two 5/32” (4 mm) diameter

holes positioned on 3/4” (19 mm) centers must be drilled to

mount the Muffler Clamp. Use the plastic snap rivets to secure

the Muffler Clamp to the panel.

6. Snap the Cold Air Muffler into the Mounting Clamp.

7. Cut a sufficient length of the 1/2” (13 mm) inside diameter

vinyl tubing from the supplied #701M-43 Cold Air Ducting Kit

to connect the cold air outlet of the Vortex A/C to one of the

hose barbs on the Cold Air Muffler. Attach this length of vinyl

tubing so that it is free of sharp bends and kinks. Direction of

cold air ow through the Muffler is not important.

8. Attach all (or a portion of) the remaining supplied vinyl tubing

of the #701M-43 Cold Air Ducting Kit to the opposite hose barb

connection on the Cold Air Muffler. Holes can be punched

or drilled into this 1/2” (13 mm) tubing to distribute the cold

air evenly inside your enclosure, or, the entire cold air output

can be directed to a heat sensitive component. If the end of

the 1/2” (13 mm) vinyl tubing is plugged, at least sixteen 1/8”

(3 mm) diameter holes should be punched into the tubing to

allow the cold air to escape. Use the nine self adhesive tubing

clips provided in the kit to mount the tubing.

9. Connect the compressed air lter (model 701S-24A or

701S-36A) to the compressed air inlet on the side of the

Vortex A/C with a length of 3/8” pipe. Install the compressed

air lter as close as possible to the Vortex A/C, in a location

where the temperature does not exceed 125oF (52oC). Allow

the lter to hang at the side of the enclosure as shown in

the installation drawing. Use a 13/16” (21 mm) wrench to hold

the air tting on the side of the Vortex A/C stationary while

tightening the pipe connections. Note the air ow direction

arrow on top of the lter.

10. Connect the compressed air supply to the inlet of the air lter.

See “Compressed Air Supply”.

OPERATION

Operate the Vortex A/C at 90 to 100 psig (6.2 to 6.9 bar)

compressed air pressure. Do not operate at pressures above 150

psig. (10.3 bar) Operation at pressures less than 90 psig (6.2

bar) and above 100 psig (6.9 bar) can affect the “on” and “off”

temperatures at which the unit cycles. The Vortex A/C will cycle

on and off to maintain temperatures between 80oto 90oF (27oto

32oC). The Vortex A/C will not work properly at pressures below

70 psig (4.8 bar).

CAUTION: The louvered outlet on the back of the Vortex A/C

becomes hot during operation and can remain hot for a period of

time after the unit has cycled off. Note warning label precaution,

and avoid direct contact with this area of the unit during or after

operation.

TROUBLESHOOTING

Insufficient cooling may be caused by the following:

1. Undersized compressed air line size.

2. Compressed air pressure at the product is too low.

3. Partial or complete blockage of internal compressed air paths,

due to dirt.

4. Water vapor in the compressed air supply.

5. Loose cold air outlet tting. This may occur if not tightened

properly after being disassembled for cleaning.

If trouble persists, please contact Vortec at 1-800-441-7475.

LIMITED WARRANTY

Vortex A/C compressed air enclosure cooling products

manufactured by ITW Air Management will be replaced or

repaired if found to be defective due to manufacture within ten

years from the date of invoice. Refer to our website www.vortec.

com for full warranty details and limitations. ITW Air Management

makes no specic warranty of merchantability or warrant of

tness for a particular purpose.

GENERAL SAFETY CONSIDERATIONS

1. Do not operate a Vortex A/C at compressed air pressures

above 150 psig (10.3 bar).

2. Do not operate a Vortex A/C at line temperatures above

110 oF (43oC).

3. Avoid direct contact with compressed air.

4. Do not direct compressed air at any person.

5. When using compressed air, wear safety glasses with

side shields.

WARNING: COMPRESSED AIR COULD CAUSE DEATH,

BLINDNESS OR INJURY.

VORTEX A/C TYPE 12

(SHOWN TOP MOUNTED ON CUSTOMER’S ENCLOSURE)

Hole 1-15/16” (49 mm)

1-3/4” (44 mm) diameter

x 3-19/32” (91 mm) long

muffler and mounting

clamps

Vent Air

Filter

5-7/8”

(149 mm)