LIT0152

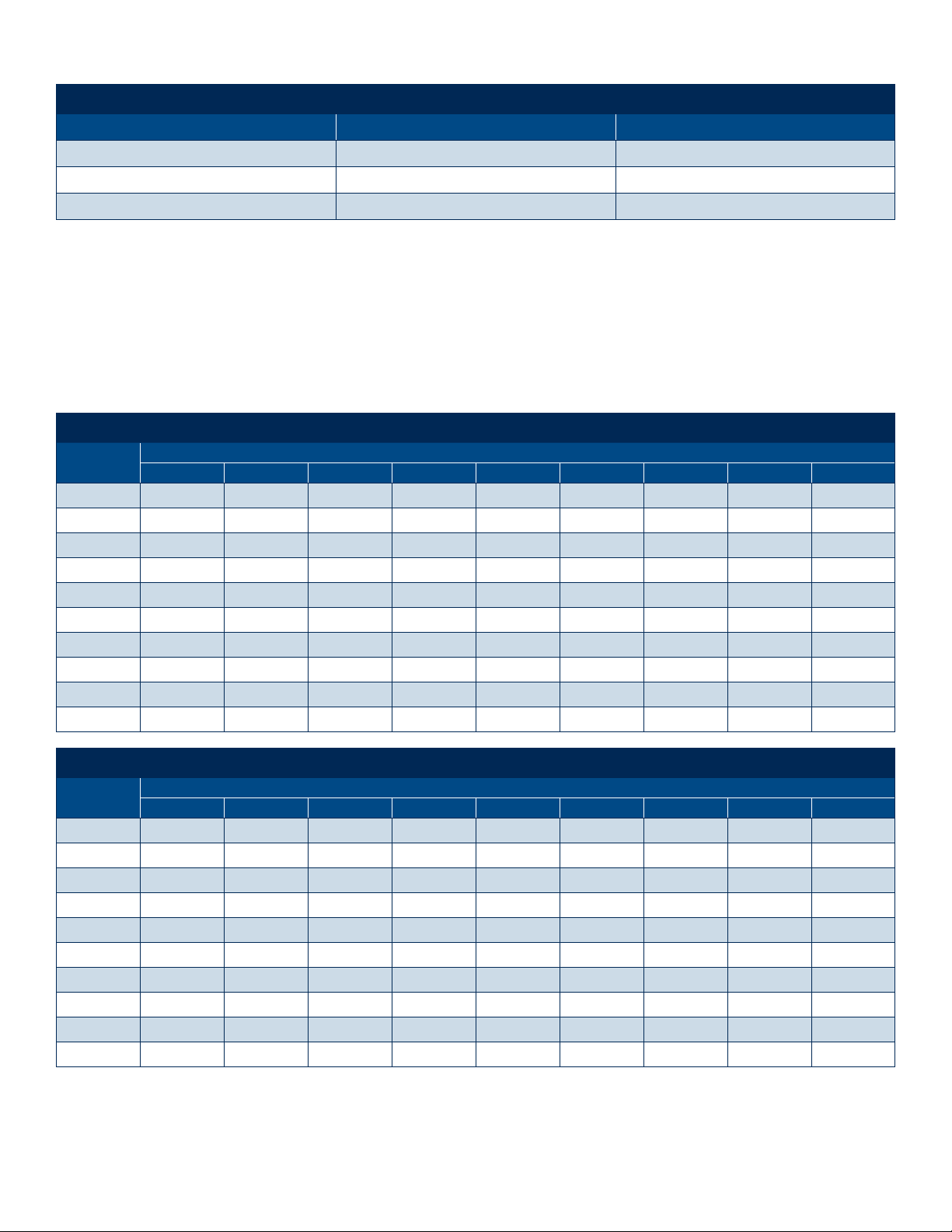

FILTER AND REPLACEMENT PART ITEM NUMBERS

Vortec Model Oil Removal Filter Replacement Generator Kits (5 pcs)

701, 770 701S-48 208GK-25H

701-15H, 770-15H 701S-48 208GK-15H

701-35H, 770-35H 701S-48 208GK-35H

Table 1: Filter Recommendations

Table 2: Determining Compressed Air Line Size

1. Calculate total product compressed air consumption (SCFM, SLPM).

2. Determine length of compressed air line required for connection to main supply.

3. Locate pipe length in left column and read to the right to nd the compressed air requirements.

4. Locate pipe size at top of column.

MAXIMUM AIRFLOW (SCFM) THROUGH PIPE AT 5 PSIG PRESSURE DROP (100 PSIG AND 70OF)

Pipe Length

(Feet)

Pipe Size (Nominal) - Schedule 40

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2

10 29 65 120 254 480 978 1483 2863 4536

20 21 46 85 180 340 692 1049 2024 3208

30 17 37 70 147 277 565 856 1653 2619

40 15 32 60 127 240 489 792 1431 2268

50 13 29 54 114 215 437 663 1280 2029

60 12 26 49 104 196 399 606 1169 1852

70 11 25 46 96 181 370 561 1082 1715

80 10 23 43 90 170 346 524 1012 1604

90 10 22 40 85 160 326 494 954 1512

100 9 21 38 80 152 309 469 905 1435

MAXIMUM AIRFLOW (SLPM) THROUGH PIPE AT 0.3 BAR PRESSURE DROP (6.9 BAR AND 21OC)

Pipe Length

(Meters)

Pipe Size (Nominal) - Schedule 40

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2

3 821 1840 3396 7188 13584 27677 42117 81023 128369

6 594 1302 2406 5094 9622 19584 29687 57279 90786

9 481 1047 1981 4160 7839 15990 24225 46780 74188

12 425 906 1698 3594 6792 13839 20999 40497 64184

15 368 821 1528 3226 6085 12367 18763 36224 57421

18 340 736 1387 2943 5547 11292 17150 33083 52412

21 311 708 1302 2717 5122 10471 15877 30621 48535

24 283 651 1217 2547 4811 9792 14829 28640 45393

27 269 623 1132 2406 4528 9226 13980 26998 42790

31 255 594 1075 2264 4302 8745 13273 25612 40611

Rubber hose maximum airow rating: 1/2” I.D. rubber hose = 3/8” pipe; 3/4” I.D. rubber hose = 1/2” pipe