SensorIQEasy2.0EX_UM_GB_V2_0 2

TABLE OF CONTENTS

Preface............................................................................................................................................... 4

Explanation of symbols....................................................................................................................... 4

1 Introduction..................................................................................................................................... 5

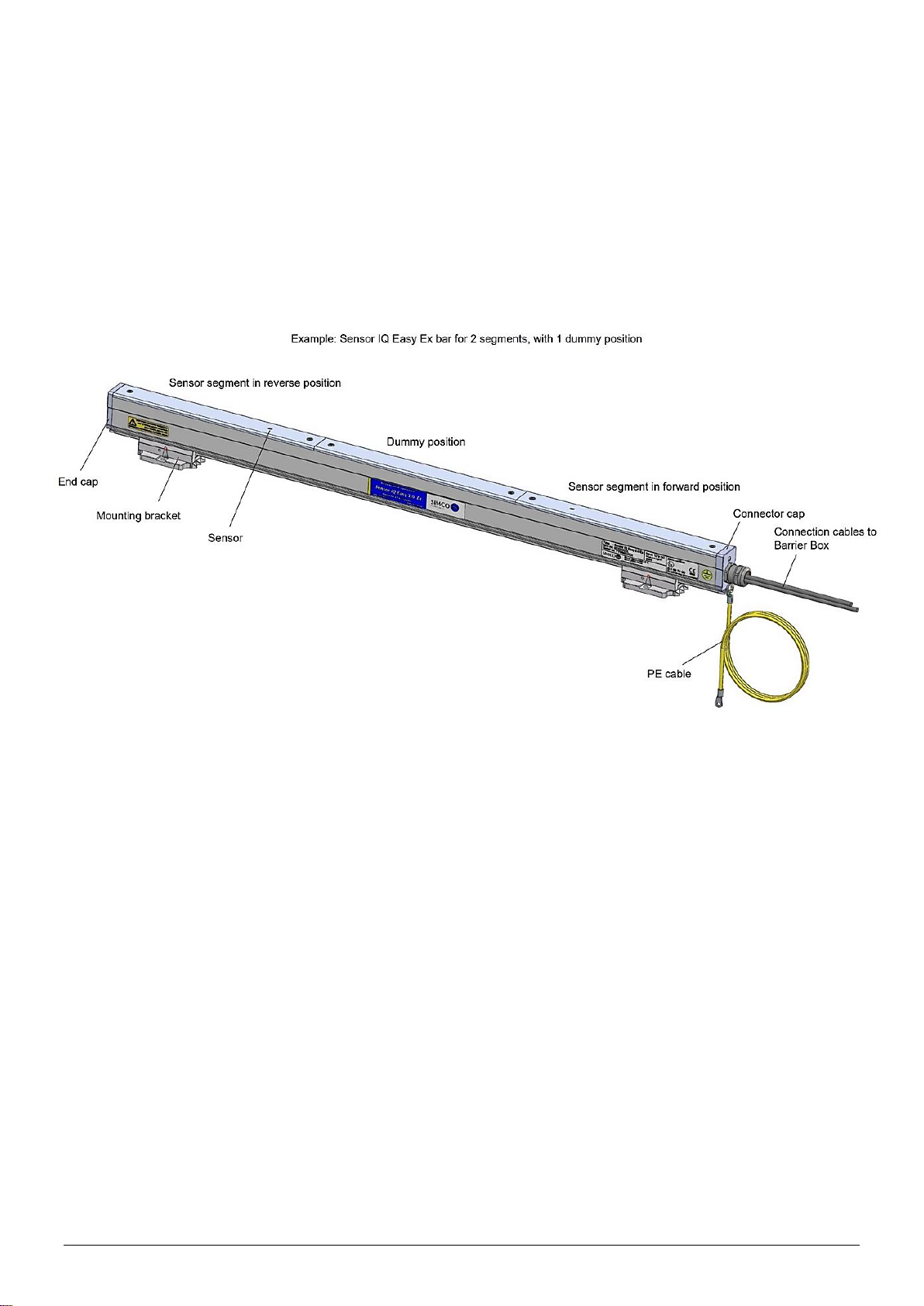

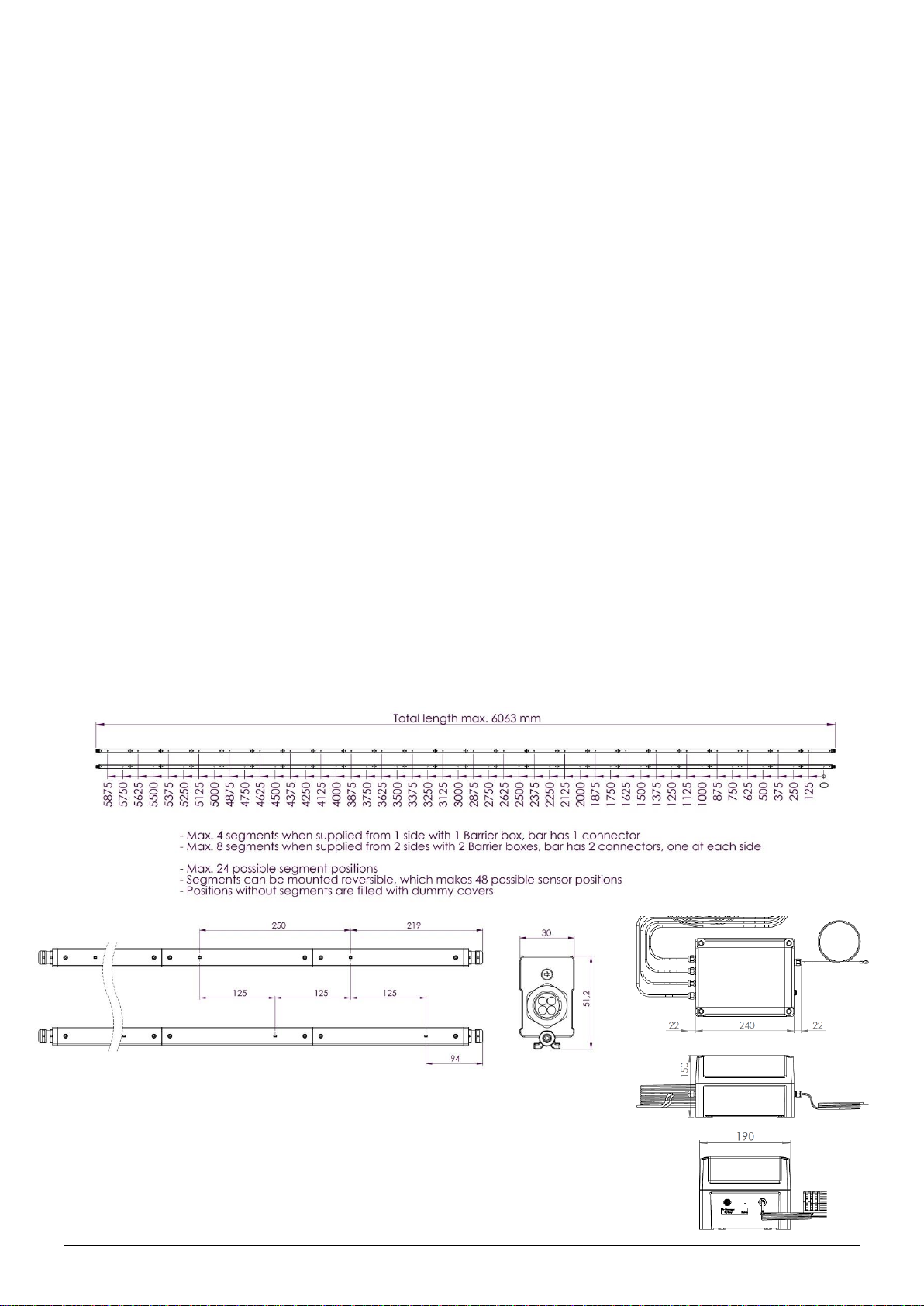

2 Description and operation................................................................................................................ 6

3 Safety.............................................................................................................................................. 8

4 Technical specifications.................................................................................................................... 9

5 Installation .................................................................................................................................... 11

5.1 Checks .................................................................................................................................................11

5.2 Installing segment units in the Sensor IQ Easy 2.0 EX bar.......................................................................11

5.3 Shortening the cable(s) between the Barrier Box and a Sensor IQ Easy 2.0 EX bar ..................................11

5.4 Placing the Sensor IQ Easy 2.0 EX..........................................................................................................13

5.5 Mounting bracket ................................................................................................................................14

5.6 Mounting Sensor IQ Easy 2.0 EX (slide bracket).....................................................................................15

5.7 Dismantling Sensor IQ Easy 2.0 EX (slide bracket)..................................................................................16

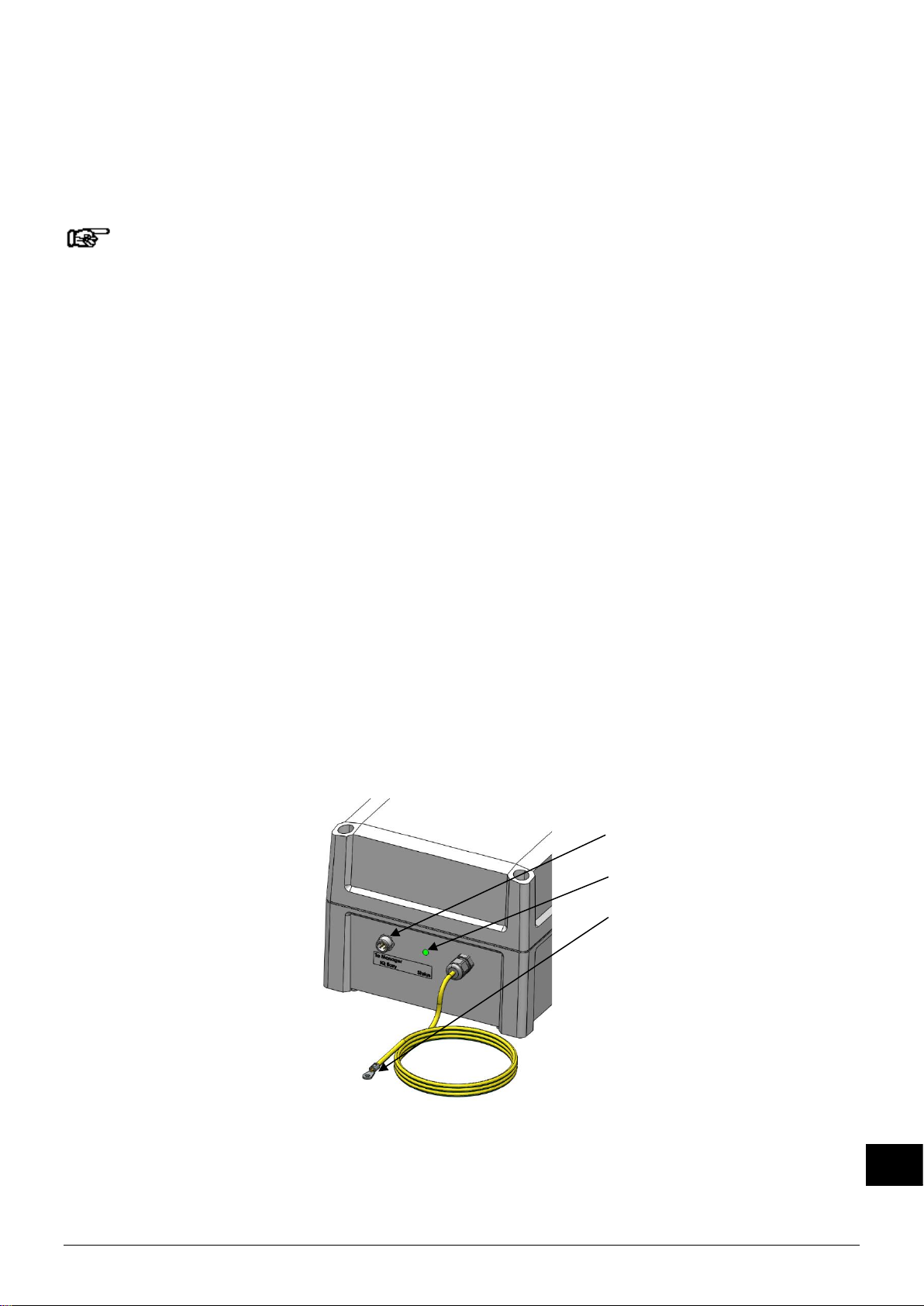

5.8 Connecting the Barrier Box...................................................................................................................16

6 Commissioning .............................................................................................................................. 17

6.1 Commissioning the Sensor IQ Easy 2.0 EX using the IQ Easy Platform.....................................................17

6.2 Selecting EXPERT mode for setting parameters or allowing for maintenance .........................................17

6.3 Selecting mounting distance Sensor IQ Easy 2.0 EX (expert mode) ........................................................18

6.4 Set the warning maximum level (expert mode).....................................................................................18

6.4.1 Set the warning minimum level (expert mode)...................................................................................19

6.5 Setting the alarm maximum level (expert mode)...................................................................................19

6.5.1 Set the alarm minimum level (expert mode) ......................................................................................19

6.6 Setting warning/alarm error delay (expert mode) .................................................................................19

6.7 Sensor IQ Easy 2.0 EX Standby & Active ................................................................................................19

6.8 Setting bar information parameters (expert mode) ...............................................................................20

6.9 (De)activating active segments (expert mode) ......................................................................................20

6.10 (De)activating Datalogging (expert mode)...........................................................................................20

6.11 Switching the bar on/off remotely through the remote on/off input on the manager or using fieldbus

(expert mode) (will be implemented in the software later) .........................................................................20

7 Functional check ............................................................................................................................ 21

7.1 Functional check ..................................................................................................................................21

7.2 Functional check via the Manager IQ Easy.............................................................................................21

7.2.1 Information tab..........................................................................................................................................................21

7.2.2 Graphics tab...............................................................................................................................................................22

7.2.3 Action log tab.............................................................................................................................................................22

7.2.4 Data log tab................................................................................................................................................................22