Grounding resistance check

Measure the resistance between the casing of static neutralizer, machine frame and the

Power unit. The meter should read less than 100 .Ω

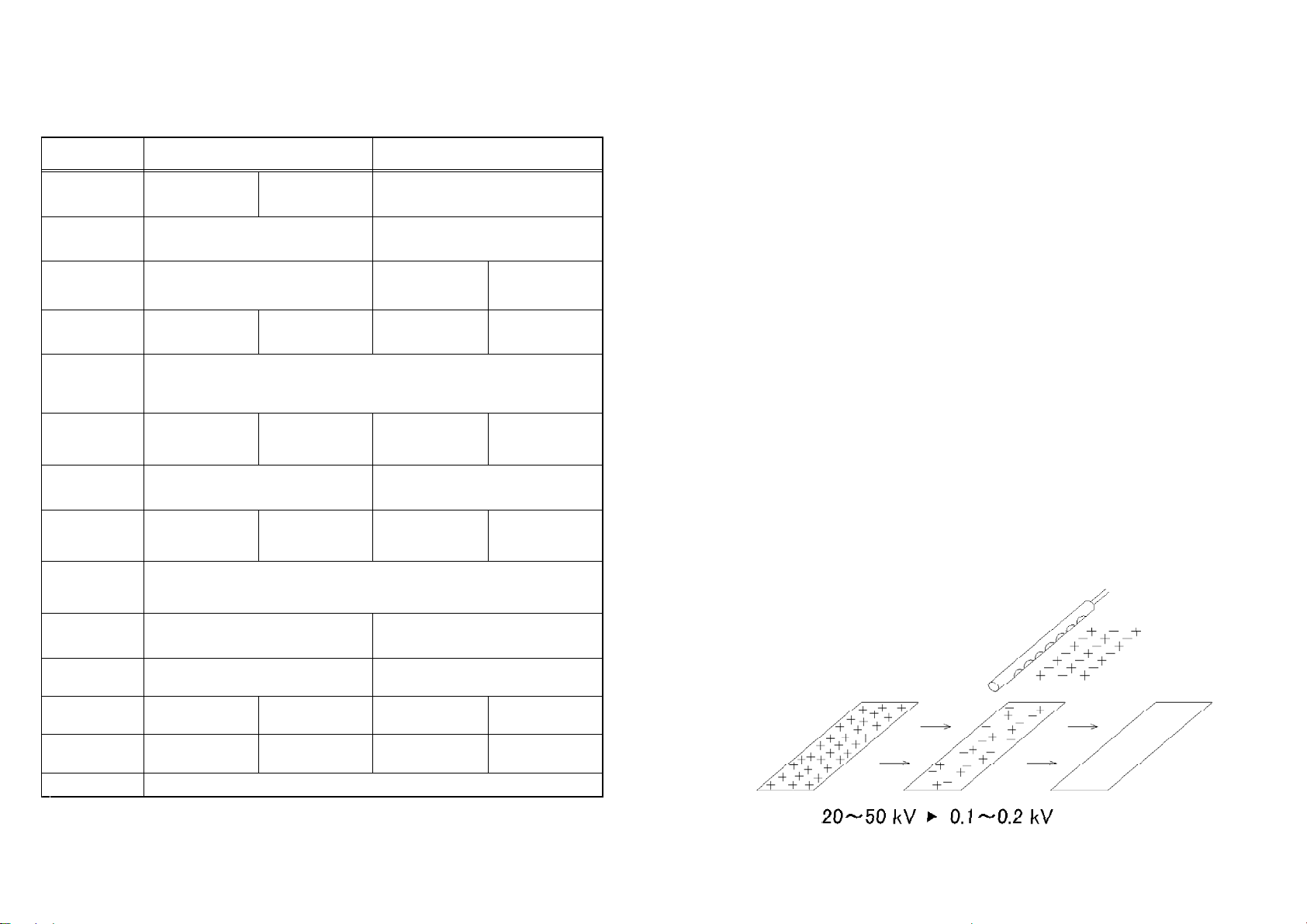

Neutralizing performance check

This test should be done periodically. The neutralization performance should be measured

with an electrostatic fieldmeter.

Measure the initial voltage of the charged object.・Turn the static bar on and use it to neutralize a charged object.・Measure the final voltage using the fieldmeter.・

If there is efficient neutralization, the voltage should decrease quickly (see Fig.1). Please

note that for efficient neutralization, the static bar should be located close to the charged

object as mentioned earlier.

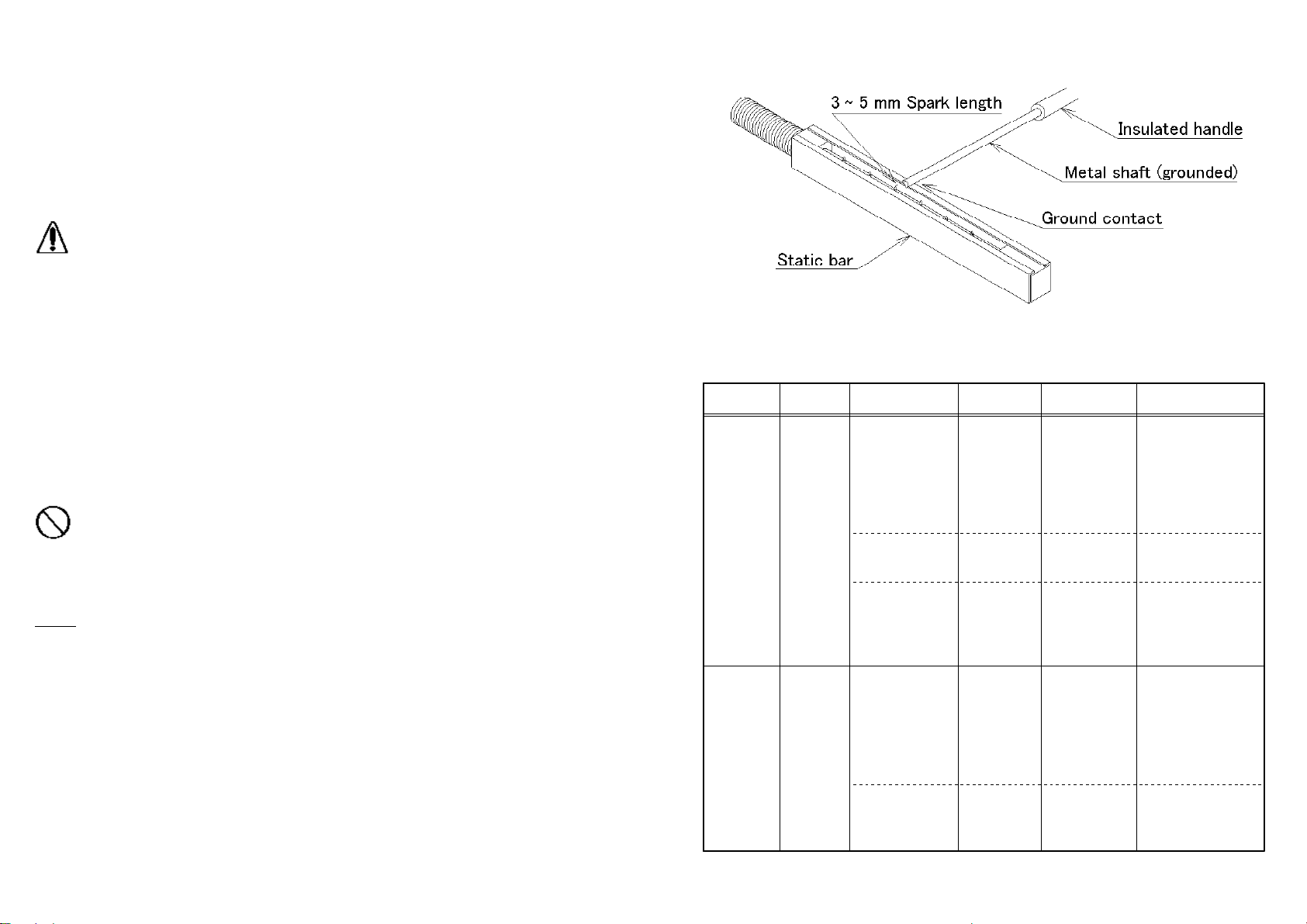

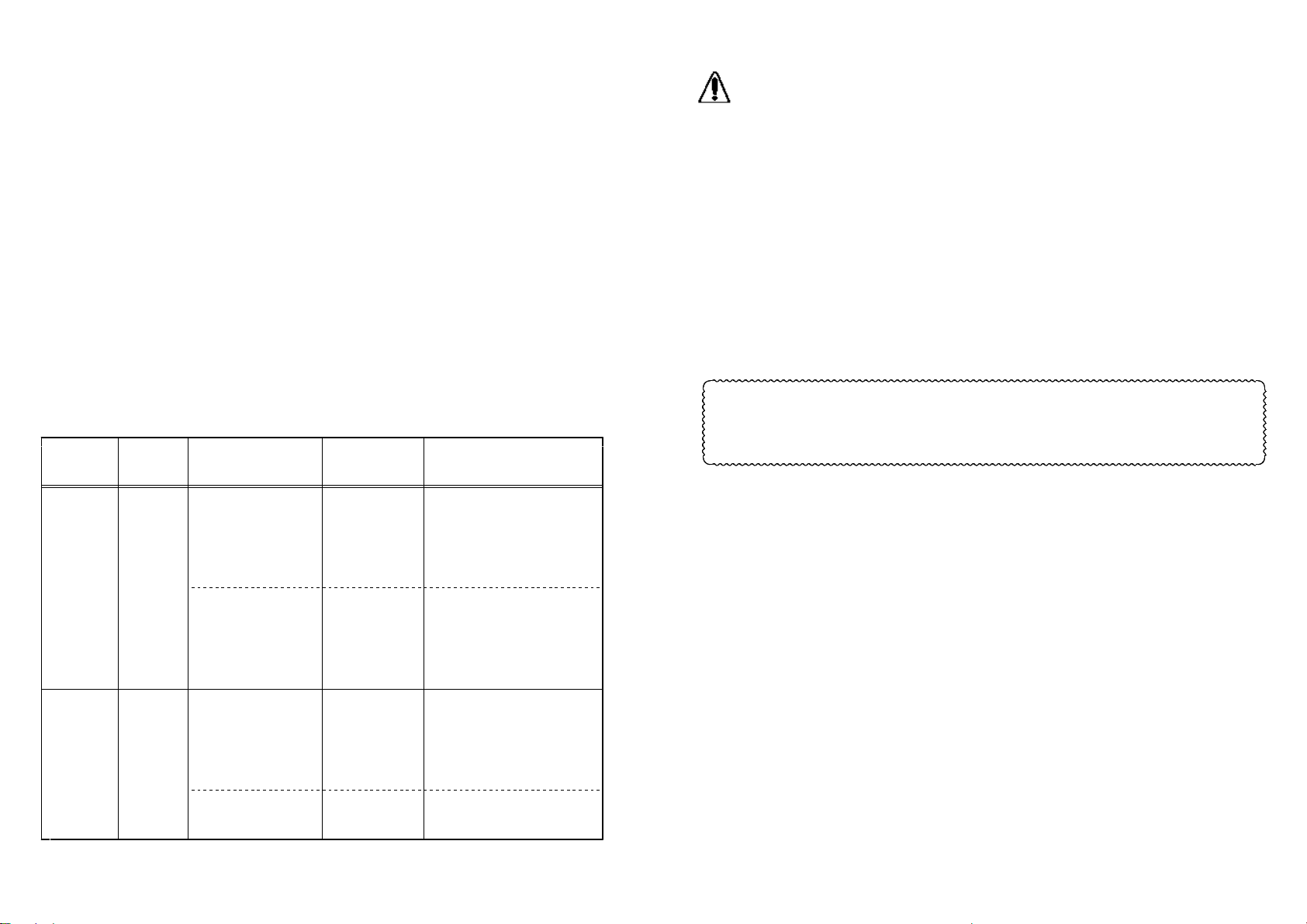

Insulation resistance

If spark test and neutralization performance are found unsatisfactory, the insulation

resistance of the bar should be checked. The following table provides the course of action

to be taken depending on the insulation resistance.

Bar type Model Measuring points Equipment Comments

used

Shockless MEB Needle - HV cable 1 G : OKDC 1,000 V ≧Ω

end 1 G ~ 100 M : barmeggar ΩΩ

needs to be cleaned

100 M : bar needs to<Ω

be replaced.

HV cable end - DC 10,000 V 10 G : OK≧Ω

grounding meggar 10 G ~ 100 M : barΩΩ

e l e c t r o d e needs to be cleaned.

connected to 100 M : bar needs to<Ω

ground be replaced.

Non- SS-50 HV cable end - DC 1,000 V 1 G : OK≧Ω

shockless grounding meggar 1 G ~ 100 M : barΩΩ

hot e l e c t r o d e needs to be cleaned.() connected to 100 M : bar needs to<Ω

ground be replaced.

Needle - HV cable Tester 10 : OK≦Ω

end 10 : replace bar.>Ω

-page 16-

ATTENTION

Each needle electrode in shockless bars is insulated. During insulation・resistance measurements, each needle should be tested separately. In hot

bar all needle electrodes are directly connected to high voltage.

Disconnect the cable at the Power unit end while carrying out the・resistance measurements.

In insulation resistance measurements above, high voltage cable-end refers・to the spring belonging to the connectors, such as in A3030 etc..

If, even after cleaning, the insulation resistance of the bar does not become・normal, it might need replacement.

Even if the insulation resistance values are normal, regular cleaning of the・needles is necessary.

If a 10,000 V meggar is not available, a 1,000 V meggar can be used. The・same criteria of success or failure as for other 1,000 V meggar tests can be

accepted in this case.

In case a repair is needed, please contact Simco Japan's sales division or an

authorized agent in your area with the details of the defects, test results,

observations etc. and ask for an estimate. Any inspection and repair will be

treated in accordance with the warranty provided at the end of this manual.

SECTION 7. Abnormal conditions

7.1 Spark from an ionizing needle electrode

During normal operation, there should be no visible spark. If spark is observed, the bar

should be cleaned properly see section 6.1 . If the sparking continues even after()

cleaning, please switch off the Power unit and contact us directly or an authorized agent

in your area.

7.2 Other abnormalities

In case the following abnormalities are observed, please switch off the Power unit and

contact us directly or an authorized agent in your area.

a Sparking from any part of a static bar or high voltage cable)

b Change in shape of a static bar)

c Melting or burning of high voltage cable)

-page 17-