Table of Contents

1 Safety precautions

1.1 Lockable safety switch .............................................................................4

1.2 Inspection doors ...........................................................................................4

1.3 Electrical connection ..................................................................................4

1.4 Compressor section ...................................................................................4

2 General

2.1 Intended use ....................................................................................................5

2.2 Manufacturer ....................................................................................................5

2.3 Designations ....................................................................................................5

2.4 CE marking and EU Declaration of Conformity ......................6

2.5 Maintenance .....................................................................................................6

2.6 Handling of refrigerant ..............................................................................6

2.7 Extended warranty .......................................................................................7

2.8 Spare parts ........................................................................................................7

2.9 Dismantling and decommissioning .................................................7

3 Technical description

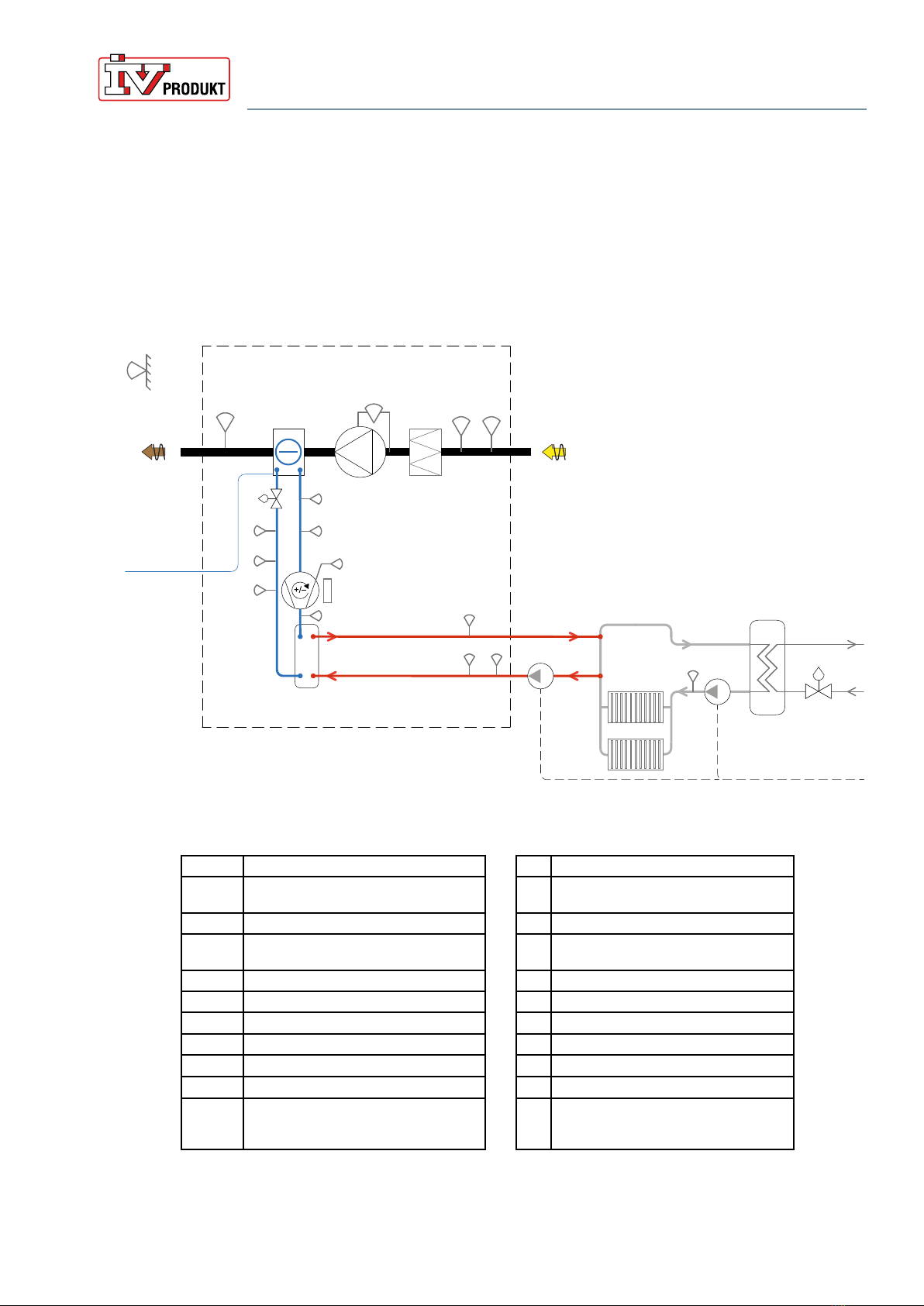

3.1 Design ...................................................................................................................8

3.2 Function ...............................................................................................................9

4 Wiring instructions and fuse protection

4.1 Wiring diagrams ..........................................................................................12

4.2 Recommended fuse protection and power supply ..........12

4.3 Wiring instructions ....................................................................................13

5 Operation

5.1 Commissioning ...........................................................................................14

5.2 Commissioning combustion gas bypass .................................15

6 Maintenance instructions

6.1 Service schedule ........................................................................................16

6.2 Filters (code ELEF) ....................................................................................17

6.3 Fan unit (code ENF) ..................................................................................20

6.4 Damper (code EMT-01) .........................................................................23

6.5 Combustion gas bypass (code EHP-B) .....................................24

6.6 Sound attenuator (code EMT-02) ...................................................25

6.7 Compressor section (code EHP-C) ..............................................26

7 Troubleshooting

7.1 Troubleshooting in the event of an alarm .................................28

7.2 Troubleshooting via symptoms and status message ......29

7.3 Alarm reset .....................................................................................................30