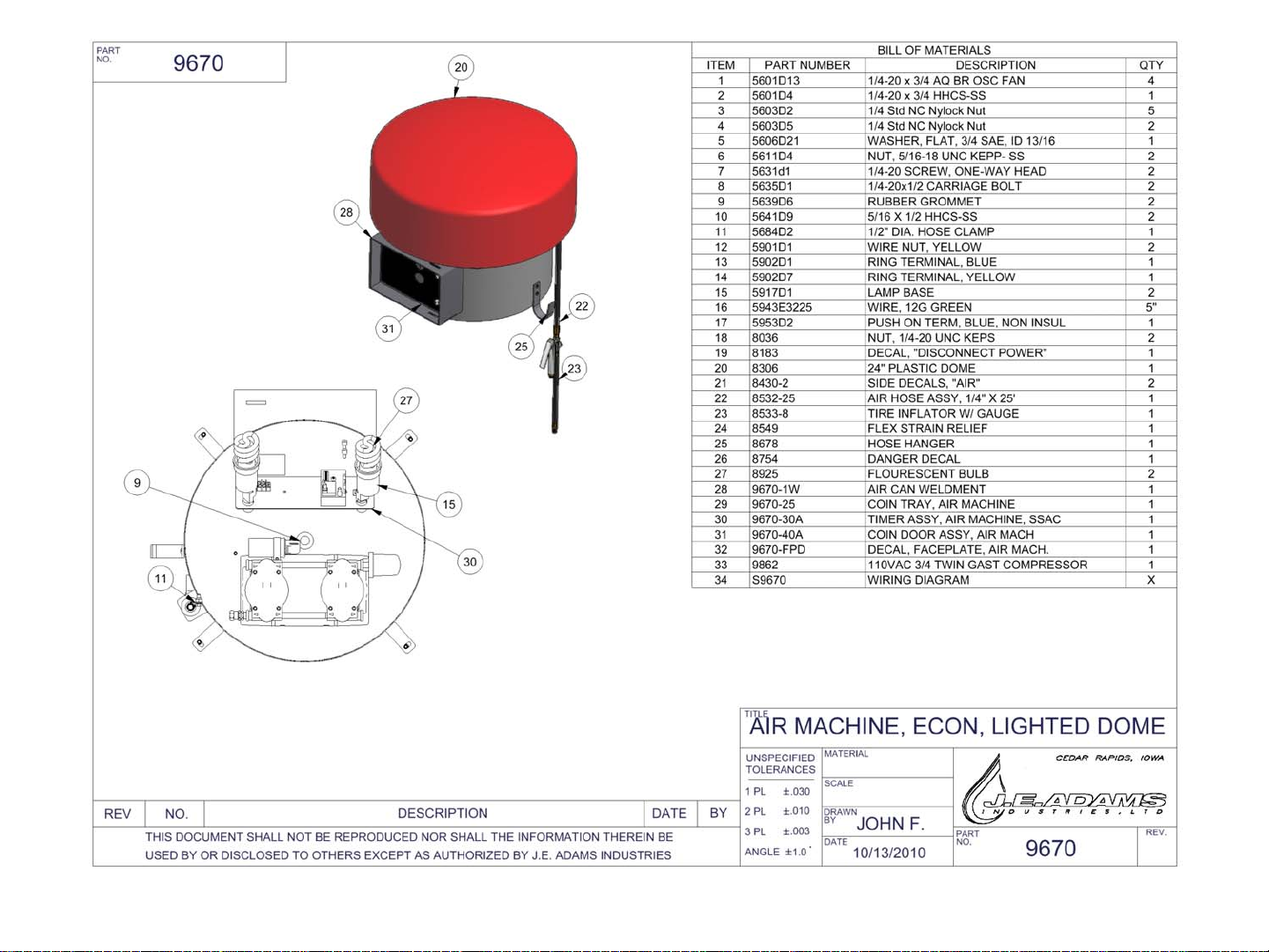

J.E. Adams 9670 User manual

REV A 8-26-20111

Models - 9670, 9670-F

Page 2 Product Information

Page 3 Specifications

Page 4 Important Safety Instructions

Page 5 Product Dimensions

Page 6-8 Installation

Page 9 Timer Set-Up

Page 10 Operating Instructions & Maintenance

Page 11 Troubleshooting

Page 12-13 Parts List & Wiring Diagrams

REV A 8-26-20112

PRODUCT INFORMATION

Please take a moment to fill out the information below in order to aid us with any future sales

or service inquiries. Model number and serial number information can be found on the

serial tag located inside the control box and/or on the lower exterior of the can. Key

number can be found on the tag that comes attached to the keys. There may be more than

one key number depending on unit.

Please keep this information with your records.

MODEL#:____________________________

SERIAL#:____________________________

KEY NUMBER(S):_____________________

DATE PURCHASED:___________________

DISTRIBUTOR:_______________________

J.E. Adams Industries

1025 63rd Ave. S.W.

Cedar Rapids, IA 52404

1-800-553-8861

www.jeadams.com

REV A 8-26-20113

Specifications

Unit specifications: 9670, 9670-F

Voltage: 120vac, 60hz

Amperage: (1) 10 amp service is required for this unit

Compressor: ¾ hp, twin cylinder

Timer: SSAC

Weight: 68lbs with dome

Locks: (2) High Security Medeco cam lock

DUTY CYCLE: 4 minutes on, 4 minutes off. Optional accessories:

NOTE: “UNIT INTENDED FOR COMMECIAL USE ONLY”

Wall mount

pedestal

8819-60

Lock bar kit

9670-24A

Floor mount

pedestal

8819-50

REV A 8-26-20114

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING (THIS APPLIANCE)

WARNING – To reduce the risk of fire, electric shock, or injury:

• Use only as described in manual. Use only manufactures recommended attachments.

• Do not allow to be used as a toy. Close attention is necessary when used by or near children.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dirt and anything that may reduce

flow.

• Keep hair, loose clothing, fingers, and all parts of body away from openings and moving parts.

• Do not use near flammable or combustible liquids, such as gasoline, or use in areas where they may be present.

• Do not use near anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

SAVE THESE INSTRUCTIONS

• Installation Instructions:

• Determine location to mount unit (“DANGER” “THIS EQUIPMENT INCORPORATES PARTS SUCH AS SWITCHES,

MOTORS, OR THE LIKE THAT TEND TO PRODUCE ARCS OR SPARKS THAT CAN CAUSE AN EXPLOSION.

WHEN LOCATED IN GASOLINE-DISPENSING AND SERVICE STATIONS INSTALL AND USE AT LEAST 20 FEET (6

M) HORIZONTALLY FROM THE EXTERIOR ENCLOSURE OF ANY DISPENSING PUMP AND AT LEAST 18 INCHES

(450 MM) ABOVE A DRIVEWAY OR GROUND LEVEL.”

• Run electrical service to that location (NOTE UNIT HAS WIRE PROVIDED UNDERNEATH DOME TO CONNECT

INCOMING POWER SUPPLY)

• Grounding Instructions: This appliance must be connected to a grounded metal, permanent wiring system; or an

equipment-grounding conductor must be run with the circuit conductors and connected to the equipment-grounding

terminal or lead on the appliance.

• All local and national electric codes must be followed for installation and use.

• Licensed electricians are recommended for installation.

REV A 8-26-20115

PRODUCT DIMENSIONS

.

Wall mount

pedestal

option.

Floor mount

pedestal

option.

REV A 8-26-20116

Pedestal mounting information:

Installation bolt

pattern. If mounting

to hollow concrete

block, proper

hardware must be

used (5/16"). Ex –

split sleeve wall

anchor, toggle bolts,

etc. Solid concrete

can use red-head

type anchors.

Floor

mount

pedestal

Wall

mount

pedestal

REV A 8-26-20117

.

Route electrical through

pedestal and up through center

of machine. Allow enough extra

wire on top to tie into the factory

wiring pictured on next page.

Once pedestal is

mounted, set air

machine onto

pedestal and open

door to access inside

of machine.

Bolts will line up

through bottom of

cabinet. Attach

with supplied

hardware

(4 nuts).

REV A 8-26-20118

NOTE: AIR MACHINE SHOULD BE INSTALLED PER LOCAL ELECTRICAL CODES BY QUALIFIED

ELECTRICIAN.

Wire nut 120VAC black to black, white

to white.

Add green ground wire to stud

provided.

REV A 8-26-20119

Programming:

The below timer pictured is the standard SSAC model that allows the end user to select the "coins to start" and

the "time per coin" by settings series of dip switches. The number of "coins to start" dip switch is how many

quarters are needed to make the machine come on. In the below example, the "one coin" dip is selected which

makes the unit come on with one coin. The "time per coins" will then need to be set, but a good rule of thumb

would be 4 minutes which requires dip switches 3.2 and .8 to be set to on. This scenario means 1 quarter will

provide 4 minutes of vacuum time. The time per coin setting can be modified as desired by simply adding or

subtracting time. If the operator would later decide to increase the cost of the unit to "2" quarters, the 2 dip

switch would need to be in the on position (all other off) and the time dip switches would need to have the 1.6

and 0.4 dips selected. This would allow 2 minutes of time for each quarter for a total of 4 minutes for two

quarters. Time in minutes/per coin dip switch settings:

0.1 = 6 seconds

0.2 = 12 seconds

0.4 = 24 seconds

0.8 = 48 seconds

1.6 = 96 seconds

3.2 = 192 seconds

6.4 = 384 seconds

REV A 8-26-201110

Machine Operating Instructions:

1) Read safety instructions on previous pages.

2) Insert coins to start.

4) Compressor will start.

5) For best results, remove valve stem covers on all tires before depositing money.

6) Hang hose up when finished.

Maintenance:

• All servicing of machine should be conducted by an authorized service representative!

• Periodically inspect hose, chuck, and chuck washer for wear or fatigue.

• Every month remove filter from compressor and clean.

• Periodically inspect electrical wires and connections for wear or fatigue.

• Clean canister with a stainless steel cleaner as needed.

• Decals can be cleaned with mild soap and water.

• Replacement parts can be ordered through JE Adams or your nearest dealer.

WHEN PERFORMING MAINTENANCE OR TROUBLE-SHOOTING, TURN POWER OFF! QUALIFIED

PERSONNEL ONLY!

REV A 8-26-201111

Troubleshooting:

Problem Possible cause Solution

Breaker inside fuse panel is not in the on position. Turn breaker on.

No power to machine. Check incoming power line voltage.

Machine power switch is not on. Remove dome and flip switch.

Loose connection. Check incoming power connection.

Air is leaking from unit somewhere. Turn power off to unit, apply chuck to air

source with at least 30lbs of pressure and

listen carefully for leaks inside cabinet or air

hose.

Chuck washer is worn out? Replace rubber washer inside chuck with JE

Adams PN 8533-3CW.

Wrong size breaker or other components running on

same circuit. Install correct breaker for compressor and

make sure line is a dedicated power source.

Compressor or timer might be shorted out? Isolate problem component and replace if

necessary.

Check key components to isolate failure:

Timer: Verify proper input voltage. Activate

timer. If no output voltage is present when

timer should be active, replace timer.

Coin mech: If using a mechanical coin mech,

remove the wires leading to the timer from the

coin mech and tap the together one time for

each coin necessary to start the timer. If

machine starts, replace the coin mech.

Unit is not powered.

Unit keeps tripping

breaker from

incoming power

source

Unit runs but will not

inflate tire.

Unit will not start Possible component failure

ALWAYS DISCONNECT POWER BEFORE TROUBLESHOOTING!!

REV A 8-26-201112

REV A 8-26-201113

This manual suits for next models

1

Table of contents

Other J.E. Adams Dehumidifier manuals