Jacka Industries JackaJay User manual

Installation Guide

JackaJay

Version 4.0

Jacka Industries Pty Ltd – 468 Hawksbury Rd, Winmalee, NSW, 2777– 1300 052052 –

www.jackaindustries.com

© 2018 Jacka Industries Pty Ltd. All rights reserved.

468 Hawkesbury Road, Winmalee, 2777, NSW, Australia

1300 052 052

www.jackaindustries.com

Trademarks / Patents

Jacka Industries Pty Ltd are the proprietary owners of all associated registered trademarks and

pending patents.

Patent Pending No. - 2019903079

Trademark No. - 1998805

Disclaimer

The information provided in this document is provided "as is" without warranty of any kind. Jacka

Industries Pty Ltd disclaims all warranties, either express or implied, including the warranties of

merchantability and fitness for a particular purpose. In no event shall Jacka Industries Pty Ltd be liable

for any damages whatsoever including direct, indirect, incidental, consequential, loss of business

profits or special damages, even if Jacka Industries Pty Ltd or its suppliers have been advised of the

possibility of such damages.

Document Lifetime

Jacka Industries Pty Ltd may occasionally update online documentation between releases of the

related software. Consequently, if this document was not downloaded recently, it may not contain the

most up-to-date information. Please refer to www.jackaindustries.com or make contact via email at

enquires@jackaindustries.com for the most current information.

From the Web site, you may also download and refresh this document if it has been updated, as

indicated by a change in this date: [Date].

Where to get help

Jacka Industries Pty support, product, and licensing information can be obtained as follows.

Product information — Documentation, release notes, software updates, and information about

Jacka Industries Pty products, licensing, and service, are at Jacka Industries Pty website at:

http://www.jackaindustries.com

Technical support — Go to http://www.jackaindsutries.com and contact a representative by the

provided means.

Your comments

Your suggestions will help us continue to improve the accuracy, organization, and overall quality of the

user publications. Please send your opinion of this document to:

enquires@jackaindustries.com

If you have issues, comments, or questions about specific information or procedures, please include

the title and, if available, the part number, the revision, the page numbers, and any other details that

will help us locate the subject that you are addressing.

Jacka Industries Pty Ltd JackaJay Installation Manual

Version 3.0

© Company 2021. All rights reserved. Page 3 of 36

Table of Contents

1

Introduction ............................................................................................................ 5

1.1

P

URPOSE OF THIS DOCUMENT

............................................................................................................ 5

1.2

I

MPORTANT POINTS TO BE OBSERVED THROUGHOUT THE

G

UIDE

.......................................................... 5

1.3

I

DENTIFICATION

................................................................................................................................. 5

1.4

R

EFERENCE INFORMATION

................................................................................................................ 6

1.5

P

OINTS OF

C

ONTACT

......................................................................................................................... 6

1.6

W

ARRANTY

....................................................................................................................................... 6

2

Installation Plan ...................................................................................................... 7

2.1

M

AIN

T

ASKS AND

I

NSTALLATION

S

TEPS

.............................................................................................. 7

2.2

E

NVIRONMENT

.................................................................................................................................. 8

2.3

E

QUIPMENT

...................................................................................................................................... 8

3

Installation Setup .................................................................................................. 10

3.1

O

PEN

JACKAJAY

KIT AND READ ALL

U

SER AND

I

NSTALLATION GUIDES

. ............................................ 10

3.2

I

DENTIFY A FLAT AND LEVEL LOCATION

.............................................................................................. 10

3.3

I

DENTIFY CORRECT OPERATION OF THE MANUAL WINCH SYSTEM

........................................................ 11

3.4

E

XPOSE MANUAL WINCH SYSTEM

. .................................................................................................... 11

3.5

S

ET ROOF HEIGHT AND INSTALL CORNER SUPPORTS

. ........................................................................ 12

3.6

R

EMOVE THE MANUAL WINCH SYSTEM

. ............................................................................................. 14

4

Installation of JACKAJAY lift system .................................................................... 16

4.1

C

ORNER

B

END

I

NSTALLATION

.......................................................................................................... 16

4.2

F

LEXIBLE PUSHRODS

....................................................................................................................... 17

4.3

C

OLOURED SQUARE DRIVE TUBES AND MOTOR ASSEMBLIES

.............................................................. 17

4.4

F

IXING

D

OWN OF ALL COMPONENTS

................................................................................................. 20

4.5

INSTALLING

CONTROLLER

&

HARNESSES ............................................................................. 23

4.6

I

NSTALLATION CLEAN UP

. ................................................................................................................. 27

5

Commissioning ..................................................................................................... 29

5.1

P

OWERING UP THE

C

ONTROLLER

..................................................................................................... 29

C

USTOM

I

NSTALLATION

............................................................................................................................... 31

6

Post Installation Care and Maintenance ............................................................... 32

Jacka Industries Pty Ltd JackaJay Installation Manual

Version 3.0

© Company 2021. All rights reserved. Page 4 of 36

6.1

Y

EARLY

C

HECKS

............................................................................................................................. 32

7

Troubleshooting .................................................................................................... 33

8

Documentation Feedback .................................................................................... 36

Jacka Industries Pty Ltd JackaJay Installation Manual

Version 3.0

© Company 2021. All rights reserved. Page 5 of 36

1 Introduction

This Installation guide is design to assist the installer by guiding through progressive

recommend steps and important check points to achieve a successful and fully operative

JackaJay Electric Lift System.

1.1 Purpose of this document

This installation guide covers the installation of the JackaJay lift system and all its

related components, for the benefit of removing the manual winch lift system and upgrading to a

fully automatic electric lift system.

1.2 Important points to be observed throughout the

Guide

IMPORTANT NOTE

This box is designed to highlight important information that is relevant to the current

steps.

STOP CHECK POINT

This is a Box / Highlight to enforce the importance of doing a detailed check and

confirmation that the works / items that are being directed is completed.

DANGER: This note is designed to issue a WARNING to the installer of any

impending DANGER / EVENT that has the potential to cause injury or death if

directives are not followed.

1.3 Identification

The JackaJay lift system and all related information regarding installation and operation

guide directives are only applicable for Jayco related camper trailers. Please contact Jacka

Industries for approval and directives for any application of the JackaJay product outside of

this documents guideline.

Jacka Industries Pty Ltd JackaJay Installation Manual

Version 3.0

© Company 2021. All rights reserved. Page 6 of 36

1.4 Reference information

Please also refer to the User Operation guide for JackaJay System operation and ensure

that all documents have been read and understood prior to carrying out the installation.

1.5 Points of Contact

For all queries, please contact Jacka Industries Pty Ltd or authorised distributor for your

area.

1.6 Warranty

Recreational warranty 5 years from purchase date. See Appendix A for definition.

Commercial warranty 1 year from purchase date. See Appendix A for definition.

Jacka Industry Pty Ltd goods come with guarantees that cannot be excluded under the

Australian Consumers Law (ACL). You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonable and foreseeable loss or damage. You

are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure.

Any operation or installation of the JackaJay lift system, other than as directed, will void any

warranty claims.

Any unintended use / residue, regarding extreme conditions including but not limited to, the

submerging of any components of the camper trailer, not including wheels, in water will void

all warranty claims.

Any major water leaks or insurance claims will need to be registered with Jacka Industries

Pty Ltd to maintain current Warranty offer.

Any warranty claims will need to be inspected by authorized personnel and deemed

claimable within Jacka Industries Pty Ltd procedures.

Jacka Industries Pty Ltd JackaJay Installation Manual

Version 3.0

© Company 2021. All rights reserved. Page 7 of 36

2 Preparation

The scope for the Installation Plan is to provide a definitive guide to the installer, to

enable a smooth removal of the manual winch system and installation of the JackaJay lift

system.

It is important that you have checked that you have all the necessary componentry in the

JackaJay kit, all required associated tools and equipment, and fully understand all aspects and

CHECKS that MUST be conducted during the installation process. This will assist you in a

successful installation and not void any warranty

.

2.1 Main Tasks and Installation Steps

The installation guide is broken up in to 7 areas to progress through. Please familiarise yourself

with relevant terminology and all aspects of the below steps prior to beginning the installation.

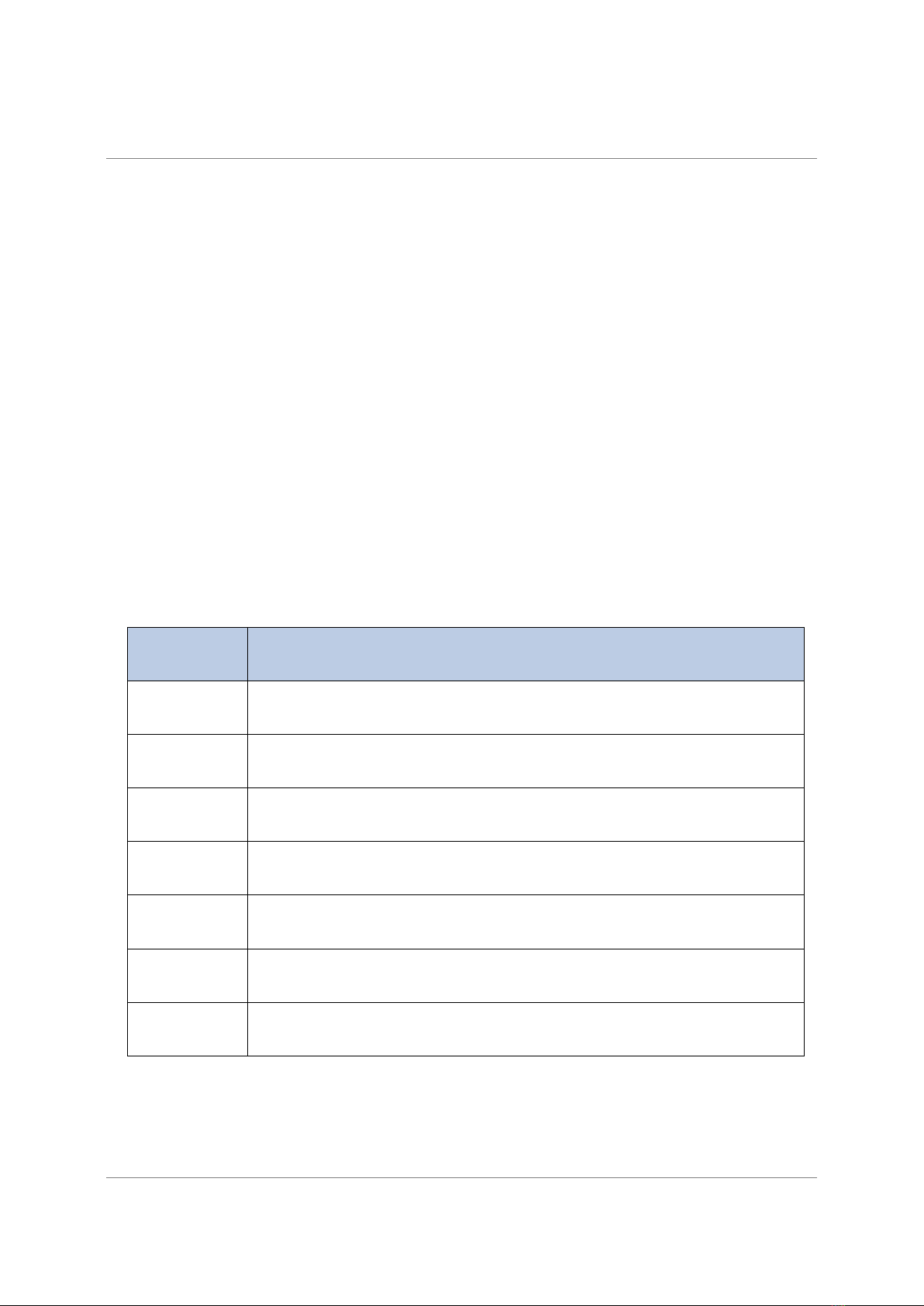

Section Task

1.0 Introduction

2.0 Preparation

3.0 Installation Setup – Set Roof Height and Remove old Winch system

4.0 Install the JackaJay lift system

5.0 Test and commission the JackaJay lift system.

6.0 Post Installation care and Maintenance

7.0 Troubleshooting Guide

Jacka Industries Pty Ltd JackaJay Installation Manual

Version 3.0

© Company 2021. All rights reserved. Page 8 of 36

2.2 Environment

During the installation it is important to ensure that no equipment gets wet, dropped,

or damaged and all care is taken to carry out a successful installation.

Ensure that a dry and secure site is chosen and if inclement weather is forecast or

moves in, ensure that all equipment is kept dry. Any water damage or indication of

heavy drops will void the warranty of that component.

Ensure that all personal effects are removed from the van and placed in a clean and

dry location.

Ensure the camper trailer is in a clean and tidy condition.

Ensure that all the cabinetry is empty, and access is not hindered, ready for

installation.

Unzip the top 200mm of all windows for air flow and place all the curtains in behind

the window. This will ensure that they are up and out the way when moving greased

and soiled components around the van.

2.3 Equipment

During the installation there is a requirement for multiple tools and JackaJay kit

componentry that should be sourced prior to beginning the installation. Please see

the below list in this section.

2.3.1 Tools

Battery Drill

Screw Drivers. 3/8”

90* Drill (optional)

32mm Hole saw

Small Bolt Cutters

Hammer

Allen Keys - 2.0mm & 2.5mm

Framing timber (Advise 90mm x 35mm)

Framing / window shims

General Spanners, sockets, and drill bits

Marking Pen

Jacka Industries Pty Ltd JackaJay Installation Manual

Version 3.0

© Company 2021. All rights reserved. Page 9 of 36

2.3.2 JackaJay Kit componentry

2.3.2.1 HARDWARE

4 x Motor Assemblies (1 x Red, 1 x Blue, 1 x Yellow, 1 x Green)

4 x Tube Assemblies (1 x Red, 1 x Blue, 1 x Yellow, 1 x Green)

4 x Corner Elbows (Black)

4 x Flexible Springs/ Pushrods.

4 x Motor covers

2 x Saddles (securing harnesses near controller)

1 x JACKAJAY Badge – plate

2.3.2.2 ELECTRICAL

1 x Rear Harness (Long with Large Plug)

1 x Front Harness (Short with large Plug)

1 x Power Harness (Smaller Plug)

1 x Jumper Harness (Smaller plug and alligator clamps)

1 x Control Box

2.3.2.3 MOUNTING KIT

20 x 14G – 10 x 42mm Hex head self-drilling metal screws (corner Elbows)

16 x 14G – 10 x 25mm Hex head self-drilling timber screws (motor Assemblies)

16 x M6 x 25mm Cap head bolts, nuts, and washers (general Use)

4 x M4 x 18 self-drilling screws (control box)

8 x M4 x 6mm self-drilling timber screws (saddle)

4 x 8G x30mm black screws (JackaJay plaque)

2.3.2.4 GENERAL

1 x Grease (small Tub)

16 x Sticky tabs

1 x Packet of Cable ties

Jacka Industries Pty Ltd JackaJay Installation Manual

Version 3.0

© Company 2021. All rights reserved. Page 10 of 36

3 Installation Setup

Please note that this Chapter is for guide purposes only. There may be individual circumstances

/ layout / equipment that may require you go carry outside of this guide. For any queries please

contact your local provider or Jacka Industries Pty Ltd.

3.1 Open JackaJay kit and read all User and Installation

guides.

Take the time to open the JackaJay kit, layout all the components and understand the

location and use for each piece, this will assist in ensuring that no pieces are missing and

when referred to in this guide, you will understand what is required.

STOP POINT 1

Ensure that all componentry is accounted for in the JackaJay kit.

3.2 Identify a flat and level location

It is critical, as when always putting up a camper trailer to ensure that you have a flat and

level location and if required, use the levelling legs to prop the camper into position.

STOP POINT 2

Ensure Camper Trailer is LEVEL in both horizontal axis – sideways and lengthways.

Other manuals for JackaJay

2

Table of contents