1 CONTENTS

SECTION ................................................ PAGE SECTION................................................. PAGE SECTION.................................................PAGE

© 2018, Ransomes Jacobsen Limited. All Rights Reserved

INTRODUCTION

IMPORTANT 3

PRODUCT IDENTIFICATION 4

GUIDELINES FOR THE DISPOSAL OFSCRAP PRODUCTS 6

DURING SERVICE LIFE 6

END OFSERVICE LIFE 6

PARTS MANUAL 7

KEY NUMBERS 7

SAFETY

HOW TOOPERATE SAFELY........................................... 9

SAFE OPERATION 9

PREPARATION 9

OPERATION 10

ROPS 11

SAFE HANDLING OFFUELS 11

MAINTENANCE AND STORAGE 11

WHEN YOU PUT THE MOWER ONA TRAILER 12

IMPORTANT SAFETY NOTES 13

DECALS

SAFETY DECALS 16

INSTRUCTION DECALS 18

CONTROLS

OPERATOR WORKSTATION 20

CONTROL PANEL 21

STARTER KEY SWITCH 22

THROTTLE CONTROL 22

PARKING BRAKES 22

TRANSPORT LOCK SWITCH 22

CUTTER SWITCH 23

4 WHEEL DRIVE INREVERSE DIRECTION SWITCH 23

CRUISE CONTROL SWITCH 23

DPF SWITCH 24

AUXILARY HYDRAULIC SERVICES KIT SWITCH (OPTIONAL) 24

LIGHT SWITCH (OPTIONAL) 24

HAZARD WARNING SWITCH (OPTIONAL) 24

ROTATING BEACON (OPTIONAL) 25

LIFT/LOWER SWITCH’S25

INDICATOR LAMPS 25

WEIGHT TRANSFER BUTTON 25

VISUAL DISPLAY 26

STARTUP SCREEN 26

WARNING / SERVICE SCREEN 26

FIRST SCREEN 27

ENGINE START 27

THE ENGINE WILL NOT START 27

BRIGHTNESS SELECT 28

BRIGHTNESS ADJUST 28

TIME DISPLAY OPTION 28

MAIN MENU SELECT 28

CLOCK SELECT 29

DATE SELECT 29

TIME SELECT 29

DATE FORMAT 29

SERVICE MENU 30

FAULT LOG 30

FAULT LOG 30

FAULT LOG DETAIL 31

SERVICE MENU - TIME UNTIL SERVICE 31

TIME UNTIL SERVICE 31

DIAGNOSTICS 32

I/ODIAGNOSTICS 32

CONNECTOR J1 32

CONNECTOR J2 32

CONNECTOR J3 33

CONNECTOR J4 33

CONNECTOR J5 33

CONNECTOR J6 33

ECU (ENGINE CONTROL UNIT) MONITOR (J1939) 34

SERVICE MANAGER PIN INPUT 34

ECU MONITOR INFORMATION (J1939) 34

INFORMATION SCREEN ONE 34

INFORMATION SCREEN TWO 35

MODE MENU 36

AUTOMATIC / MANUAL / CREEP MODE SELECTION 36

MEASURE UNITS MENU 36

MEASURE UNITS 37

PIN MENU 38

INPUT PIN 38

CRUISE CONTROL 38

CRUISE SELECT 38

CROSS CUT 39

CROSS CUT ACTIVE / INACTIVE 39

VEHICLE SPEED 39

MAXIMUM SPEED SETTINGS MENU 39

PIN CHANGE 40

NEW PIN 40

INCLINOMETER 40

DRIVE MODES40

BRIGHTNESS ADJUST 40

LANGUAGE MENU 41

LANGUAGE OPTION 41

WARNING SLOPE ANGLE SLOPE ANGLE ALERT42

WARNING SLOPE ANGLE INHIBIT LIFT42

WARNING SLOPE ANGLE INHIBIT CUT42

WARNING OIL-PRESSURE FAULT 43

WARNING CLEAR RADIATOR SCREENS 43

WARNING ENGINE FAULT 43

WARNING FOOT PEDAL FAULT 44

WARNING BATTERY FAULT 44

WARNING CHARGE FILTER BLOCKED 44

WARNING HYDRAULIC OIL-LEVEL LOW 44

WARNING SERVICE NEEDED 45

WARNING SOLENOID FAULT 45

WARNING (TST) TILT SENSOR TECHNOLOGY FAULT 45

WARNING MAXIMUM SLOPE ANGLE EXCEEDED 45

TRACTION PEDAL 46

STEERING TILT CONTROL 46

HORN 46

POWER OUTLET 46

SEAT RIGHT-SIDE ARMREST AND POD 47

PARKING BRAKE RELEASE VALVE 48

TOW VALVE 48

LIGHTING KIT (OPTIONAL) 48

CAB CONTROLS 49

OPERATION

DAILY INSPECTION 50

OPERATOR PRESENCE AND SAFETY INTERLOCK SYSTEM 51

PROCEDURE FOR OPERATION 52

TOFIT THE CUTTER DECKS TOTHE MACHINE 53

OPERATION OFTHE MACHINE 56

HOW TOSTART THE ENGINE 56

HOW TODRIVE 57

HOW TOMOW 57

TOSTOP THE ENGINE 57

TOREMOVE A BLOCKAGE FROM CUTTING UNITS 58

TRANSPORTING ONA TRAILER 59

SLINGING AND JACKING THE MACHINE 59

MOWING ONSLOPES 60

ADJUSTMENTS

GENERAL PRECAUTIONS 63

ENGINE FAN BELT 64

WEIGHT TRANSFER ADJUSTMENT 64

STEERING SHAFT ADJUSTMENT 64

AXLE STOP ADJUSTMENT 65

HEIGHT OFCUT ADJUSTMENT 66

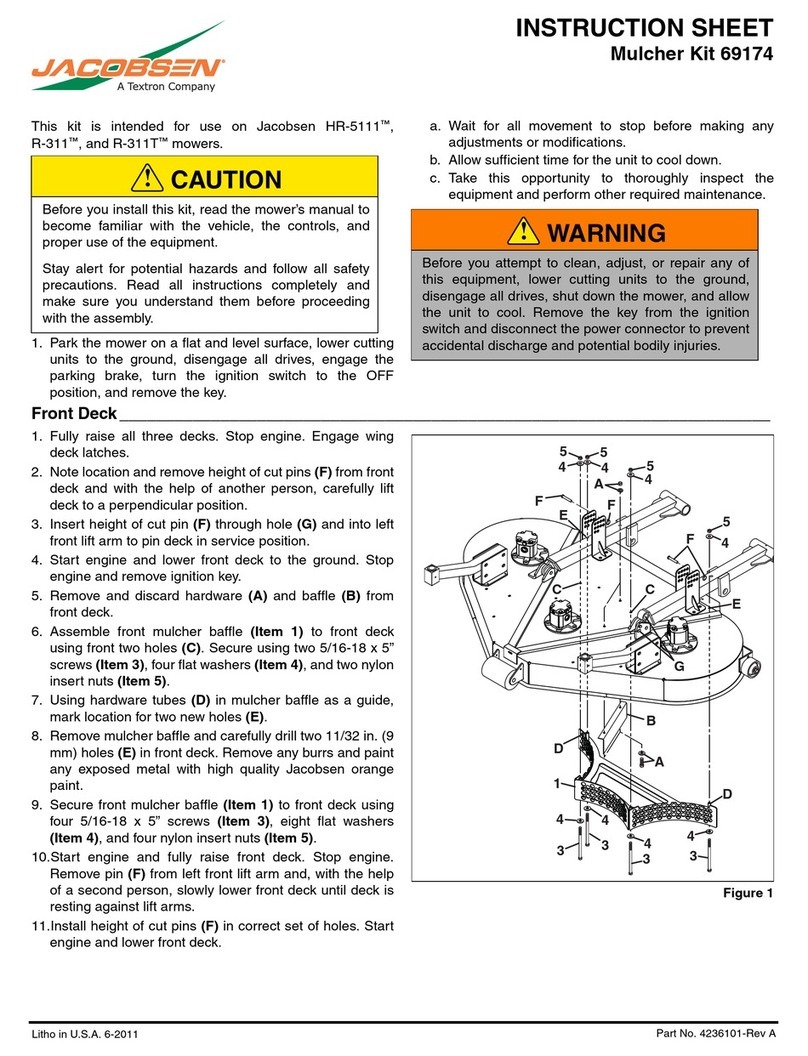

HEIGHT OFCUT ADJUSTMENT (FRONT DECK) 66

HEIGHT OFCUT ADJUSTMENT (WING CUTTER DECKS) 67

GENERAL INSTRUCTIONS FOR GRAMMER SEATS 68

SEAT (GRAMMER MSG85) 69

AIR SUSPENSION SEAT (GRAMMER MSG75 -521) 70

WEIGHT ADJUSTMENT 70

FRONT AND BACK ADJUSTMENT 70

BACKREST EXTENSION 70

LUMBAR SUPPORT (OPTIONAL)71

LEFT HAND ARMRESTS 71

ARMREST ADJUSTMENT 71

BACKREST ADJUSTMENT 71

MAINTENANCE 72

AIR SUSPENSION SEAT (GRAMMER MSG95 -721) 73

WEIGHT ADJUSTMENT 73

HEIGHT ADJUSTMENT 73

ARMRESTS ADJUSTMENT (OPTION) 74

ARMREST (OPTION) 74

BACKREST ADJUSTMENT (OPTION) 74

LUMBER SUPPORT (OPTION) 74

BACKREST ADJUSTMENT (OPTION) 74

FORE / AFT ADJUSTMENT (OPTION) 75

MULTIFUNCTION ARMREST (OPTION) 75

LUBRICATION AND MAINTENANCE

MAINTENANCE 76

MAINTENANCE AND LUBRICATION CHARTS 78

GENERAL PRECAUTIONS82

ENGINE 82

ENGINE LUBRICATION 83

ENGINE COOLANT 84

HYDRAULIC SYSTEM 86

HYDRAULIC FILTER 87

HYDRAULIC TEST PORTS 88

FUEL 89

FUEL SYSTEM 90

AIR CLEANER 91

BATTERY 92

CHARGE THE BATTERY93

ENGINE EXHAUST93

DIESEL PARTICULATE FILTER 94

HYDRAULIC HOSES95

TYRES 96

WHEEL MOUNTING PROCEDURE 96

BLADE CHANGE 97

INSPECTING BLADES 98

SHARPENING BLADES 98

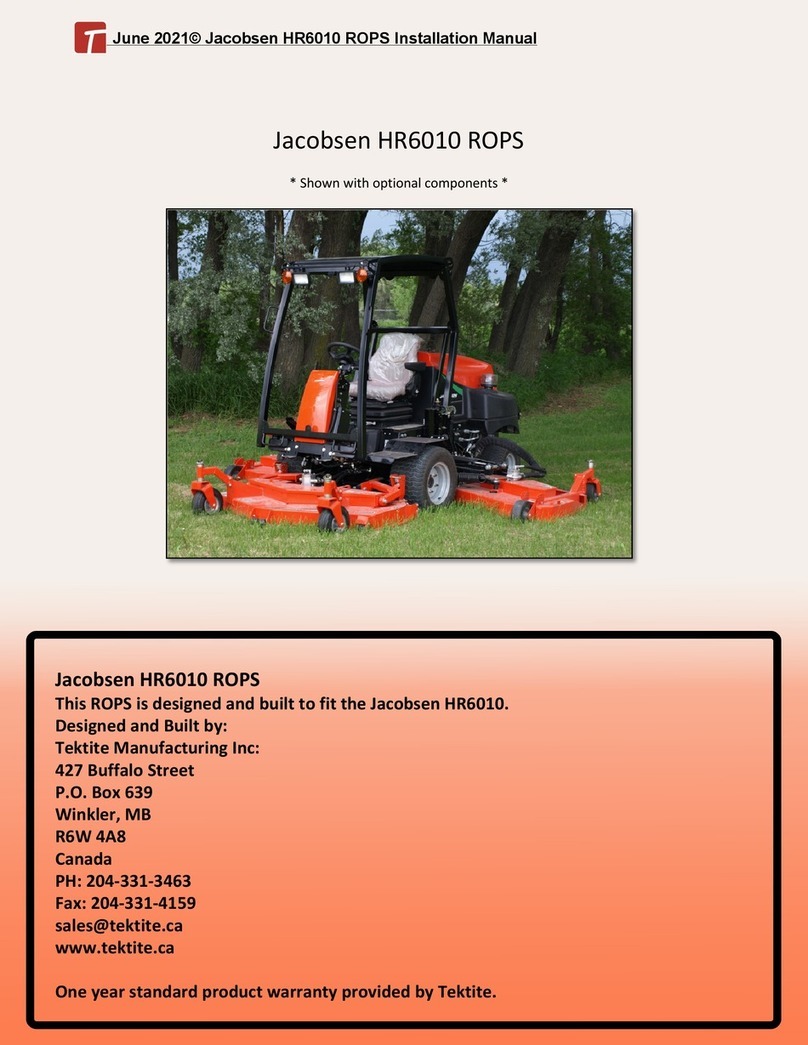

FOLDING ROPS 99

CARE AND CLEANING 100

MOWER STORAGE 101

LUBRICATION OFCUTTING UNIT................................. 102

PROBLEM SOLVING

ENGINE PROBLEM DIAGNOSTICS 104

QUALITY OFCUT PROBLEM SOLVING 106

THE STEP CUT 107

SCALPING 108

STRAGGLERS 109

STREAKS 110

WINDROWING 111

MISMATCHED CUTTER DECKS 112

FUSES AND RELAYS

FUSE AND RELAY/COMPONENT IDENTIFICATION 114

SPECIFICATIONS

ENGINE SPECIFICATION 117

DIMENSIONS & WEIGHTS (ROPS MACHINE) 118

DIMENSIONS & WEIGHTS (CAB MACHINE)120

MACHINE SPECIFICATION 122

VIBRATION 123

NOISE 124

SLOPES 124

CUTTING PERFORMANCE 124

CUTTER DECK SPECIFICATION125

RECOMMENDED LUBRICANTS 126

ACCESSORIES 126

CERTIFICATES OFCONFORMITY 127

GUARANTEE

WARRANTY 132

SERVICE132