Table of Contents

1 Summary .............................................................................................. 3

1.1 Name plate ........................................................................................................ 3

1.2 Product series .................................................................................................... 4

1.3 Technical standards............................................................................................6

1.4 Peripheral Electrical Devices and System Configuration......................................8

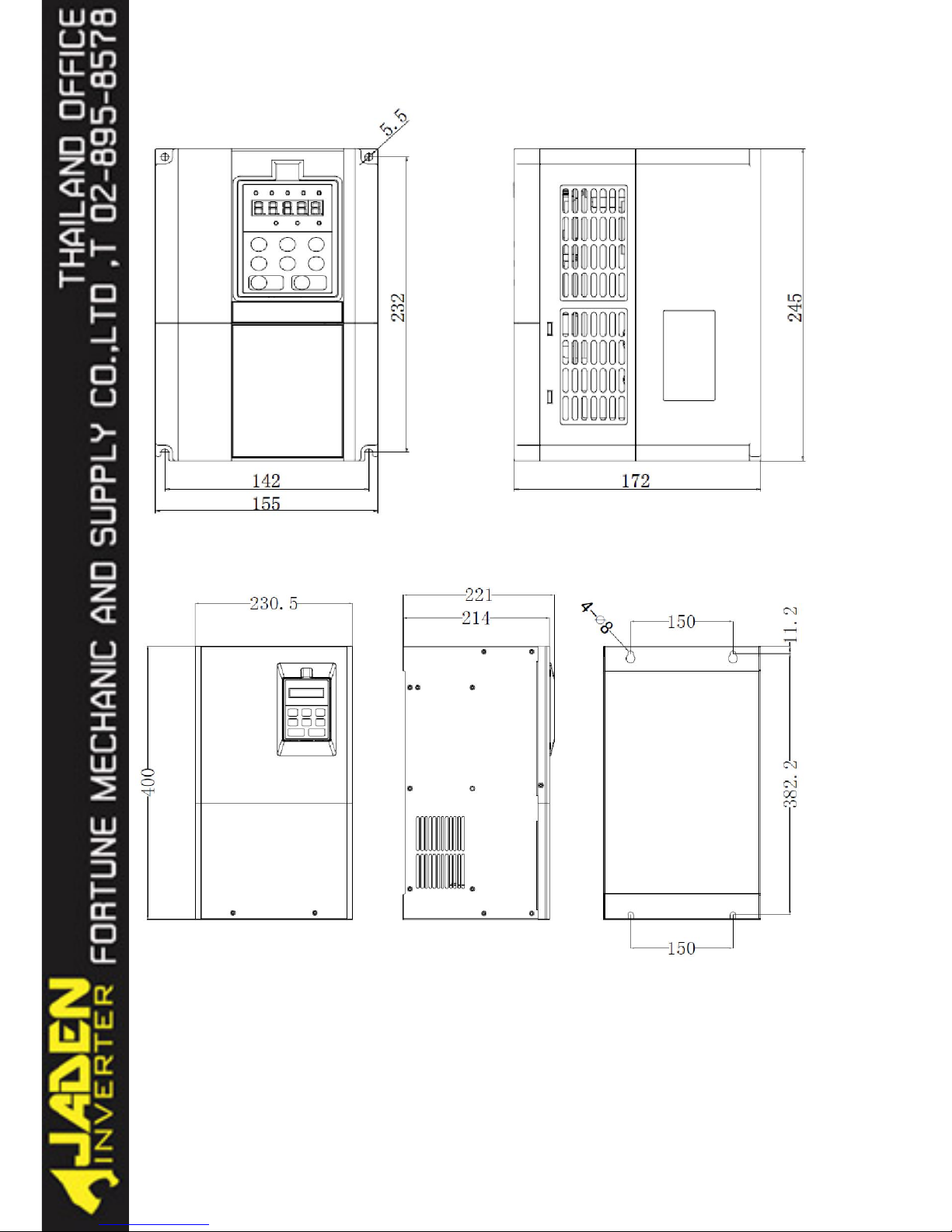

1.5 Product outline and installation dimensions.........................................................9

2 Wirings ............................................................................................... 14

2.1 Standard wiring diagrams................................................................................. 14

2.2 Main circuit wiring terminals ........................................................................... 16

2.3 Control circuit wiring terminals........................................................................ 17

3 Panel operations ................................................................................ 23

3.1 Keyboard interface........................................................................................... 23

3.2 Parameter setting example & motor auto-tuning................................................ 25

3.3 JOG................................................................................................................. 26

4 Function codes (Parameters) ............................................................ 27

4.1 Basic monitoring parameters: d0.00-d0.41........................................................ 27

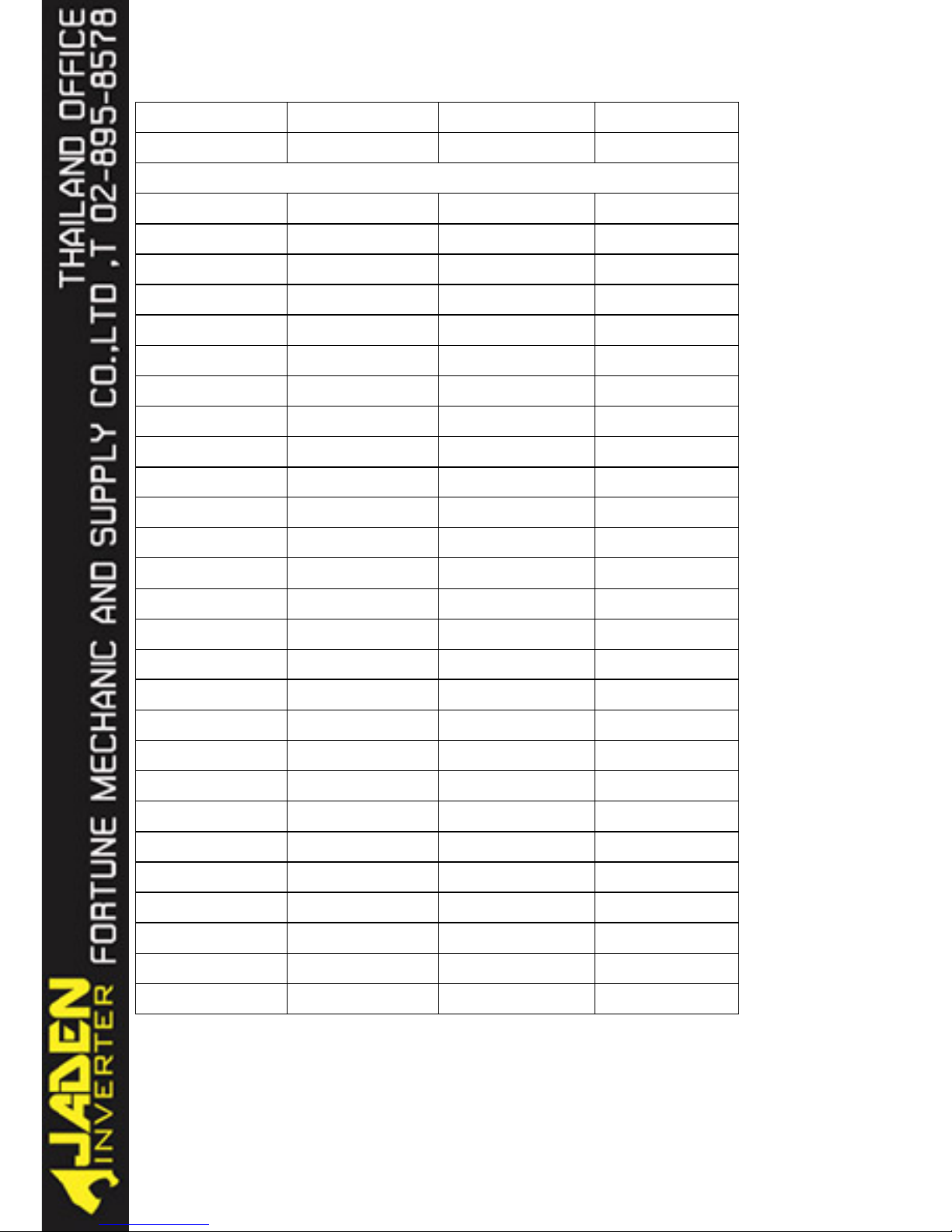

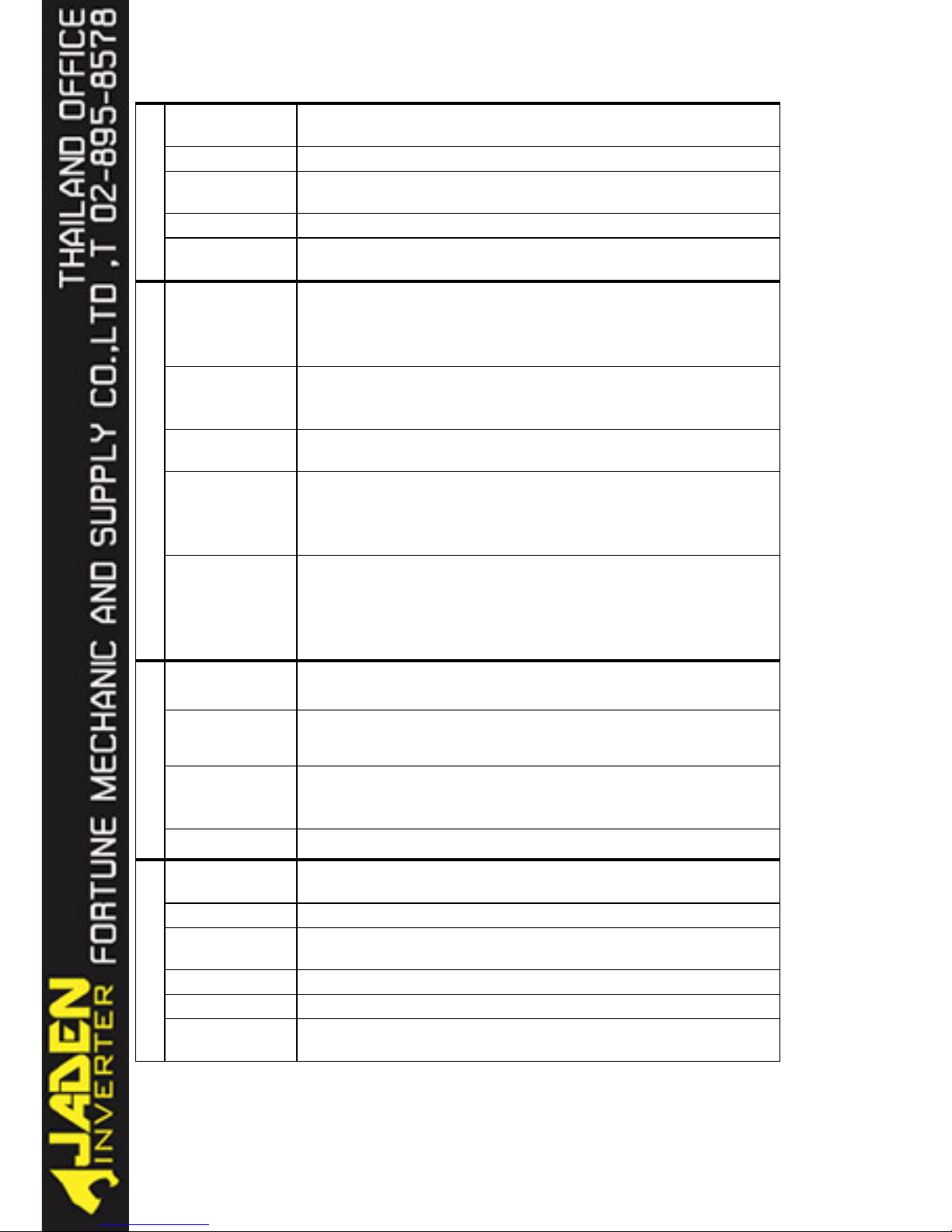

4.2 Basic functions group: P0.00-P0.28.................................................................. 31

4.3 First motor parameters: P1.00-P1.37................................................................. 41

4.4 V/F control parameters: P2.00-P2.15................................................................ 46

4.5 Vector control parameters: P3.00-P3.22............................................................ 51

4.6 Input terminals: P4.00-P4.39............................................................................ 55

4.7 Output terminals: P5.00-P5.22.......................................................................... 68

4.8 Start/stop control: P6.00-P6.15......................................................................... 74

4.9 Operation panel and display: P7.00-P7.14......................................................... 79

4.10 Auxiliary functions: P8.00-P8.53.................................................................... 82

4.11 Fault and protection: P9.00-P9.70................................................................... 92

4.12 PID functions: PA.00-PA.28......................................................................... 103

4.13 Swing Frequency, Fixed Length and Count: PB.00-PB.09............................. 108

4.14 Multi-reference and simple PLC: PC.00-PC.51............................................. 111

4.15 Communication parameters: PD.00-PD.06.................................................... 116

4.16 PE group: reserved....................................................................................... 117

4.17 Function code management: PP.00-PP.04..................................................... 117

4.18 Torque control parameters: B0.00-B0.08....................................................... 119

4.19 Control optimization parameters: B5.00-B5.09.............................................. 121

4.20 Extended function parameters: B9.00-B9.09 ................................................. 123