Jancy JB2400 Bender

Congratulations on your purchase of a Jancy Slugger pipe/tube bending machine. Slugger machines are

designed to deliver years of dependable service. Please take a moment to complete and mail your warranty reg-

istration card. Doing so will validate your machine’s warranty period and ensure prompt service if needed. Thank

you for selecting a Slugger product from Jancy Engineering.

table of contents

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GROUNDINGINSTRUCTIONS...................................5

POWERSUPPLY..............................................5

EXTENSIONCORDS...........................................5

GETTINGSTARTED ...........................................6

OPERATINGINSTRUCTIONS....................................7

TURNINGONTHEPOWER.....................................7

FORM DIE ASSEMBLY INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PRESSURE DIE ASSEMBLY INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . 7

MAKINGABEND..............................................8

MAINTENANCE & TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

APPENDIX A: BEND QUALITY AND TROUBLESHOOTING . . . . . . . . . . . 10

APPENDIX B: COMMON PIPE AND TUBE BENDING TERMS . . . . . . . . . 11

PARTSBREAKDOWN.........................................12

PARTSLIST.................................................14

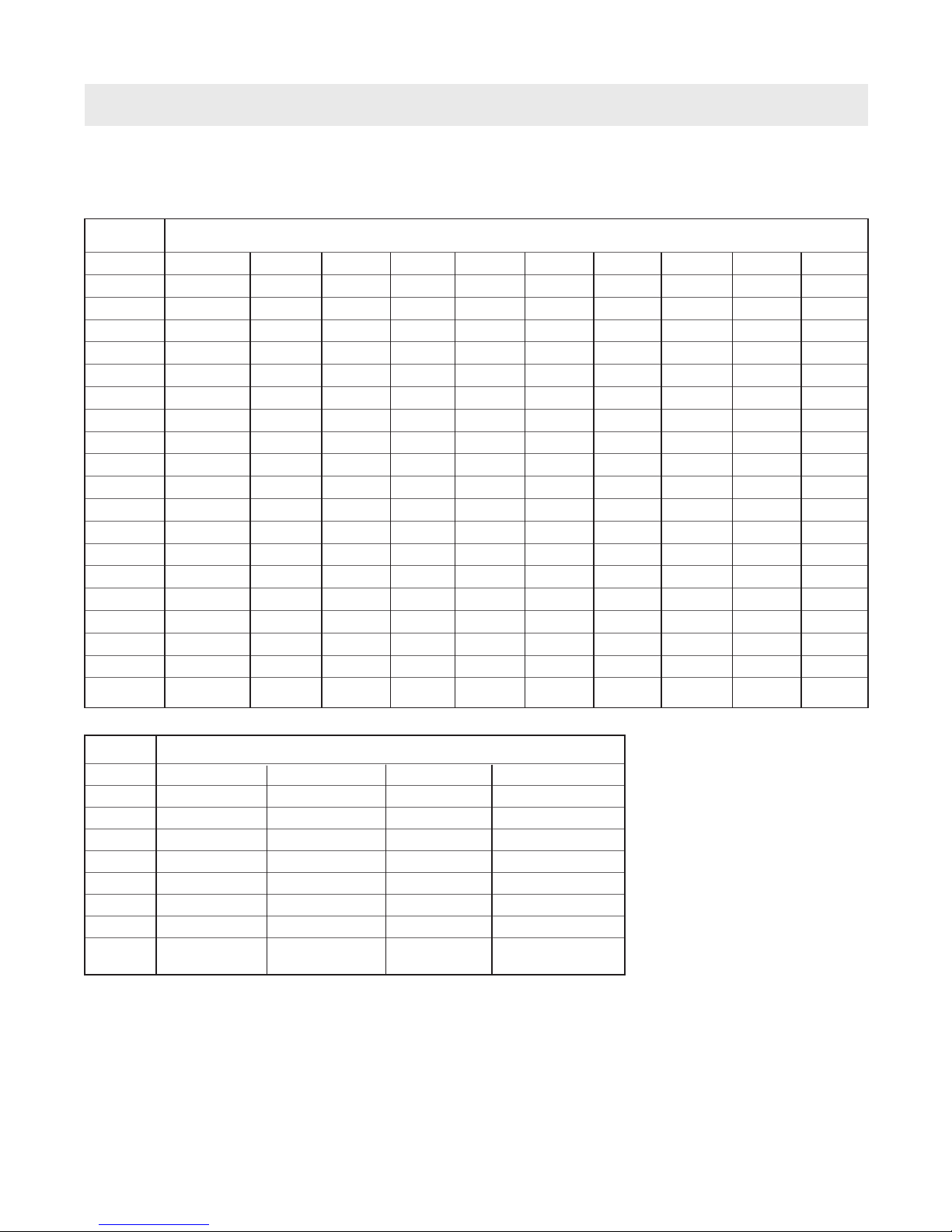

MAINTENANCERECORDS ....................................15

JANCY ENGINEERING RESERVES THE RIGHT TO MAKE

IMPROVEMENTS AND MODIFICATIONS TO DESIGN WITHOUT PRIOR NOTICE.

limited warranty

Jancy Engineering Inc. will, within eighteen (18) months from the date of purchase, repair or replace any goods

found to be defective in material or workmanship, provided the product warranty registration card has been returned

to Jancy Engineering Inc. within thirty (30) days of purchase date. This warranty is void if the item has been dam-

aged by accident, neglect, improper service, or other causes not arising out of defects in materials or workmanship.

This warranty does not apply to machines and/or components which have been altered, changed, or modified in

any way, or subjected to use beyond recommended capacities and specifications. Electrical components are sub-

ject to respective manufacturers’ warranties. All goods returned defective shall be returned prepaid freight to Jancy,

which shall be the buyer’s sole and exclusive remedy for defective goods. In no event shall Jancy Engineering be

liable for loss or damage resulting directly or indirectly from the use of merchandise or from any other cause. Jancy

Engineering is not liable for any costs incurred on such goods or consequential damages. No officer, employee, or

agent of Jancy is authorized to make oral representations of fitness or to waive any of the forgoing terms of sale

and none shall be binding on Jancy.

2