J&D MAnufacturing JD-N2 User manual

MANUAL

JD-N2

Installation / User’s Guide

ATTENTION ELECTRICIAN

SEE WIRING DETAILS ON PAGES A-3 TO A-5 AND

ADDITIONAL INFORMATION IN SECTION B

USER’S GUIDE

INSTALLATION GUIDE

INDEX / WARRANTY

WIRING DIAGRAM

73.3

JD-N2

JD-N2

Section A-2

WARNINGS AND PRECAUTIONS

Although the manufacturer has made every effort to ensure the accuracy of the

information contained herein, this document is subject to change without notice due to

ongoing product development.

WARNINGS AND PRECAUTIONS

Equipment, probe failure, blown fuses and/or tripped breakers may prove harmful to the

contents of the building. Therefore it is strongly recommended to install backup devices

and alarm or warning devices. Spare equipment should also be available at the owner’s

site. Equipment manufactured by the manufacturer is protected against normal line

surges. High surges caused by thunder storms or power supply equipment may damage

this equipment. For added security against line voltage surges it is recommended that

surge and noise suppression devices be installed at the electrical distribution panel. Use

of shielded cable for probes is recommended for protection against lightning. These

devices are available from most electrical supply distributors.

RECOMMENDATIONS

The manufacturer recommends that all installation procedures described herein be

performed by a qualified electrician or installation technician. Furthermore the

manufacturer recommends to test all the functions and equipment connected to the JD-

N2, including the alarm system and backup devices, after installation, after changes to

the installation and every month after that.

Fuse verification and replacement, as well as the proper setting of control values shall

be the responsibility of the owner of this equipment.

JD-N2 WIRING DIAGRAM

JD-N2 Section A-3

WIRING DIAGRAM

JD-N2

SECTION A

JD-N2

JD-N2

Section A-4

Wiring Diagram

WIRING DIAGRAM JD-N2

WIRING DIAGRAM

JD-N2

23/02/10

CONFIGURATION

WIR

REV

0

SEE NOTES ON NEXT PAGE

REL 1 REL 2

1314 A

54

ON-OFF BOARD

L2/N

L1

GNA

PRB 1

ALARM

5

N0

C

NC

5

L1

L2/N

TEMP. PROBE

6

7

THE JD-N2 MUST BE ON

AN INDEPENDENT CIRCUIT

WARNING!!!

SET LINE VOLTAGE

TO CORRECT VALUE BEFORE

ATTEMPTING TO OPERATE

THE COMPUTER.

LINE VOLTAGE

SELECTOR

230V

JD-N2

1319 A

CLOSE

OPEN

COM

WINCH

L2/N L1

JD-N2 WIRING DIAGRAM

JD-N2 Section A-5

JD-N2

Electrician’s notes

wiring tips and hints (see guide for details)

(PROBE WIRING) SHIELDED WIRE AWG #22, 500ft (150m) MAXIMUM

LENGTH.

HIGH VOLTAGE WIRE INSTALLED ACCORDING TO LOCAL WIRING CODE.

INSTALL LOW VOLTAGE WIRES (PROBES, COMPUTER LINK OR

POTENTIOMETER WIRES) AT LEAST 12in. (30cm) AWAY FROM HIGH

VOLTAGE WIRES (120/230VAC, 24VDC). ALWAYS CROSS HIGH AND LOW

VOLTAGE WIRES AT A 90-DEGREE ANGLE.

RELAYS: 12A @ 240VAC RESISTIVE, MOTOR 1HP @ 240VAC, 1/2HP @

120VAC AT EACH OUTPUT.

1 WIRE ONLY PER GREEN TERMINAL. USE WIRE CONNECTOR IF YOU

WANT TO CONNECT MORE THAN 1 WIRE, NO BIGGER THAN AWG #12,

NO SMALLER THAN AWG #28.

CHECK INSTALLATION GUIDE FOR ALARM WIRING.

USE SHIELD FOR SHIELDING PURPOSE ONLY. CONNECT THE SHIELD TO

GROUND PLATE . NEVER LEAVE THE SHIELD UNCONNECTED AT BOTH

ENDS. NEVER CONNECT BOTH ENDS OF THE SHIELD TO GROUND

PLATE . THE USE OF A SHIELD FOR ALL PROBES IS MANDATORY.

1

2

5

6

7

3

4

JD-N2 INSTALLATION

JD-N2

Section B-6

INSTALLATION

JD-N2

SECTION B

JD-N2 INSTALLATION

JD-N2 Section B-7

This section will inform the electrician on proper wiring and installation

procedures for the JD-N2.

The manufacturer recommends that the following installation instructions be

followed as closely as possible, and that all work be performed by a certified

electrician. Failure to do so may void the warranty.

Unpacking

Unpack the JD-N2 and inspect contents for damage. Should the contents appear

to be damaged, contact your local distributor to return the material.

The package should contain the following standard items:

1 JD-N2 control

4 Brackets / 4 screws

1 2004-10K inside temperature probe (30 feet cable)

1 Installation / User’s Guide

Mounting Hardware Required

This is the list of the mounting hardware needed, which is not included with the

product:

Shielded two-wire cable, AWG #22 (to extend probes).

4 screws (to hang the unit onto the wall).

Screwdrivers.

Soldering iron kit or approved sealed connectors.

Drill and hole saw kit

JD-N2 INSTALLATION

JD-N2

Section B-8

General installation guidelines

JD-N2 Control

-It is recommended to install the unit in a hallway to limit the JD-N2 exposure

to noxious gases.

-In order to avoid condensation problems inside the controller, it is

recommended to install the JD-N2 on an inside wall. If it is not possible, use

spacers to have an air gap between the wall and the JD-N2.

-It is required to install the JD-N2 right side up with the cable entry holes facing

down.

-The enclosure is watertight, but do not spray water or immerse the JD-N2 in

water. Cover it carefully with plastic when cleaning the room.

-The JD-N2 should be installed in easily accessible location but away from

damaging elements (heat, cold, water, direct sunlight, …).

-Do not drill the face, the side, the top or the rear of the control.

-Do not install the JD-N2 control near high voltage equipment, power supply or

transformer.

Electrical Cables

-All electrical cables must be installed according to local wiring codes.

-All cable shields must be connected to the JD-N2 power ground only. The

shield is needed to protect the JD-N2 against any electromagnetic

interference generated by lightning or nearby operating machinery.

-Never use the shield as a conductor.

-Connect only one end of the shield to the ground of the JD-N2.

-Use separate conduit for the low voltage cables (communication,

potentiometer and probes) and the high voltage cables. There must be at

least 1 foot (30 cm) between low voltage and high voltage conduits.

-If a low-voltage cable has to cross over a high voltage cable, make this

crossing at 90°.

-All cable connections must be soldered or done with approved sealed

connectors.

-Probe cables must be 500’ (150m) or less.

-It is prohibited to use overhead cables outside the building.

JD-N2 INSTALLATION

JD-N2 Section B-9

Electrical Power

-Protection from electrical surge should be included in the planning of each

installation.

-It is strongly recommended to have a backup power source to ensure life-

sustaining conditions in case of power failure (see figure 3).

-The backup system and alarm must be thoroughly tested and verified as

working properly before using the ventilation system.

Mounting

-The enclosure must be mounted in a location that will allow the cover to be

completely opened right up against the wall.

-Fasten the four brackets to the four mounting holes on the back of the

enclosure, using the four screws provided with the brackets.

-Then mount the enclosure on the wall by inserting screws through the

brackets’ adjustment slots, into the wall. Make sure to position the enclosure

so that all wires extend out of the bottom section of the enclosure.

-The bracket slots also serve to adjust the position of the controller.

-Once you have adjusted the controller position, tighten the four mounting

screws.

FIGURE NO. 1 Mounting Position and Devices

JD-N2 INSTALLATION

JD-N2

Section B-10

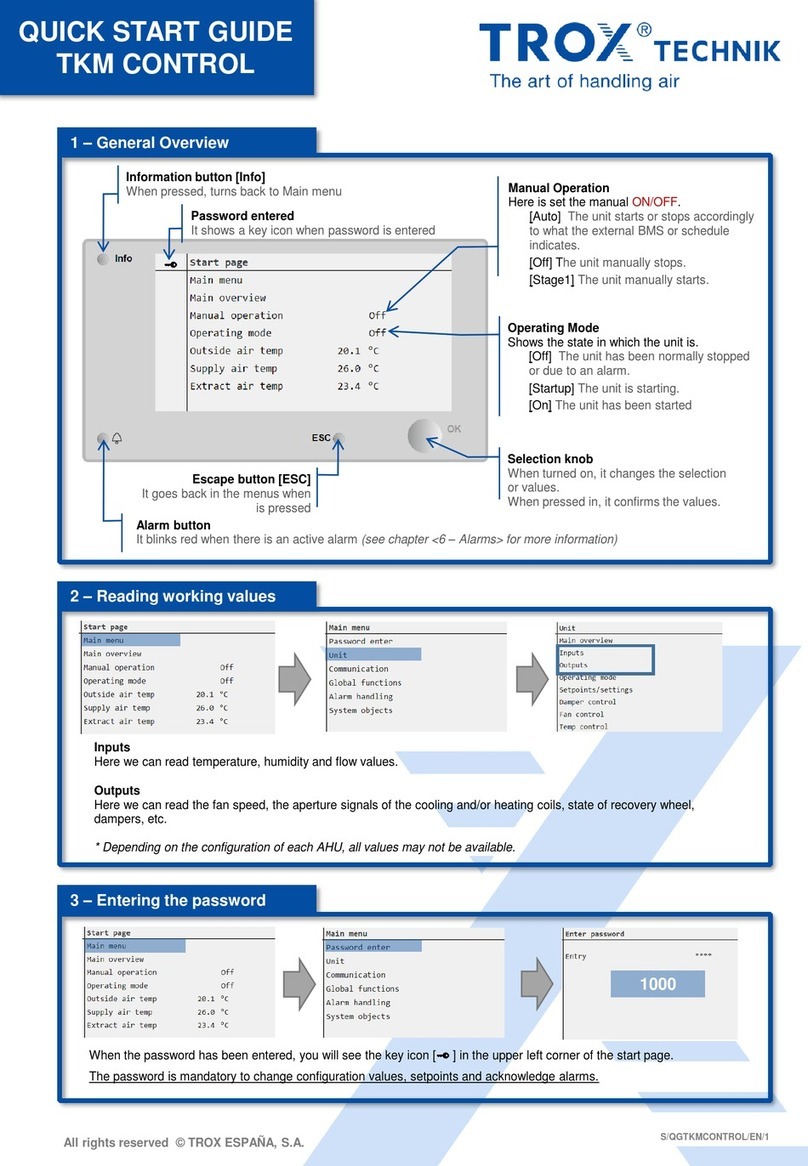

Connection Procedure

Detailed Wiring Diagrams

Typical Sensor Wiring for Probes

The inside temperature sensor should be located in the area which gives the

most accurate temperature reading to achieve optimum ventilation. The sensor

should also be connected to the JD-N2 with a shielded two-wire cable. It should

be located in an area protected from operating machinery, animal bites,

personnel or anything that could damage the sensor. See also “General

installation guidelines”.

FIGURE NO. 2 Typical Temperature Probe Wiring

SHIELD

TEMP. PROBE

JD-N2 INSTALLATION

JD-N2 Section B-11

Typical Power Backup Wiring

A backup relay (DPDT) connects to the power source 1 in normal operation but

will switch to the power source 2 if source 1 is disabled. The backup relay should

be selected to ensure it is able to support the required power load.

FIGURE NO. 3 Typical Power Backup Wiring

8 PIN RELAY DPDT

(OMRON model MK2EP-UA-AC120)

3

4

5

6

2

1

8

7

NO2

NO1

NC 1

NC 2

COM 2

COM 1

L2/N GND

L1

3

4

5

6

2

1

8

7

L2 L1 GND

source 1

DISTRIBUTION

PANEL

L2 L1

N

LINE

115/230 VAC

source 2

DISTRIBUTION

PANEL

LINE

115/230 VAC

JD-N2 INSTALLATION

JD-N2

Section B-12

Typical Alarm Connection Wiring

The JD-N2 provides a normally open and normally closed dry contact to set off

an alarm in case low or high temperature condition occurs. Moreover, this same

contact can be used to signal a power failure or other malfunctions. It may be

connected to an alarm system or directly to a siren and /or auto-dialer.

Make the normally closed (NC) or normally open (NO) connections as indicated

in figures 4 and 5.

FIGURE NO. 4 Typical Alarm Connection Wiring

ALARM SYSTEM /

AUTO DIALER

ALARM

N0

C

NC

L1

L2

/

N

JD-N2

1319 A

FIGURE NO. 5 Typical Siren Connection Wiring

Normally closed

manual OFF switch

ALARM

N0

C

NC

L1

L2/N

JD-N2

1319 A

JD-N2 INSTALLATION

JD-N2 Section B-13

Powering Up Procedure

Once the JD-N2 is properly mounted on the wall and all modules and sensors

connected to the terminal block, perform the following step:

Verify all Connections

Seal all cable entry holes.

Hermetically Close the JD-N2

Close the front panel and the lower access cover.

Put the power on

Secure the front panel with a lock

JD-N2 INSTALLATION

JD-N2

Section B-14

Downloading the Configuration

When upgrading your system with a new configuration, you will have to download

the configuration.

There are two ways to download a configuration in the JD-N2 controller.

1) Downloading by powering down.

A. Ensure the power source of the JD-N2 is OFF (flip the circuit breaker on

the distribution panel).

B. Remove the faceplate screws and lift up the cover.

C. Insert the configuration chip (MMX) into the socket of the main board.

D. Switch on the power source. The display on the front panel should indicate

dnld for approximately 15 seconds. If dnld is not displayed, try one

more time. If dnld is still not displayed, remove and replace the

configuration chip (MMX).

E. When the downloading procedure is complete, remove the configuration

chip (MMX) and place it in the bottom part of the enclosure or in another

safe location. Once the MMX Chip is removed, the JD-N2 starts up and

executes the configuration.

2) Downloading while the JD-N2 is powered up.

A. Remove the faceplate screws and lift up the cover.

B. Place the MMX chip into the socket of the main board. At this moment, the

MMX Detected parameter will appear.

C. Adjust the MMX Detected parameter to dnld and press the the + and

– buttons for two seconds. The display on the front panel should indicate

dnld for approximately 15 seconds. If dnld is not displayed, try one

more time. If dnld is still not displayed, remove and replace the

configuration chip (MMX).

D. When the downloading procedure is complete, remove the configuration

chip (MMX) and place it in the bottom part of the enclosure or in another

safe location. Once the MMX Chip is removed, the JD-N2 starts up and

executes the configuration.

WARNING: During this procedure, some components are live and can

be dangerous if touched.

JD-N2 INSTALLATION

JD-N2 Section B-15

Uploading the Configuration

It is possible to upload a configuration into a configuration chip (MMX) in order to

save parameters and setup or to backup the configuration.

Here’s the procedure to upload a configuration.

A. Make sure that the JD-N2 is powered up.

B. Remove the faceplate screws and lift up the cover.

C. Place the MMX chip into the socket of the main board. At this moment, the

MMX Detected parameter will appear.

D. Adjust the MMX Detected parameter to upLD and press the + and –

buttons for two seconds. The display on the front panel should indicate

upLD for approximately 15 seconds. If upLD is not displayed, try one

more time. If upLD is still not displayed, remove and replace the

configuration chip (MMX).

E. When the uploading procedure is complete, remove the configuration chip

(MMX) and place it in the bottom part of the enclosure or in another safe

location. Once the MMX Chip is removed, the JD-N2 will continue to

execute the configuration.

WARNING: During this procedure, some components are live and can

be dangerous if touched.

JD-N2 INSTALLATION

JD-N2

Section B-16

JD-N2Compatible Probes

This is the list of all compatible probes that can be connected with JD-N2 control

with a short description of their function.

Temperature probe 2004-10K (black cap)

Temperature probe with a temperature range of -58 to 140°F (-50 to 60°C).

JD-N2 INSTALLATION

JD-N2 Section B-17

Specifications

Storage temperature -4°F to 131°F (-20°C to 55°C)

Operating temperature 32°F to 113°F (0°C to 45°C)

Humidity 90% maximum Non-condensing

Weight 2.6 lb (1.2 kg)

Size 9” x 7” x 4 3/4” (22.8 cm x 17.7 cm x 11.5 cm)

Protection index IP 66

Warranty 2 years

POWER SUPPLY

Operational voltage range (SW1 @ 115V) 92 to 125VAC

Operational voltage range (SW1 @ 230V) 184 to 250VAC

Operational frequency range 45 to 65 Hz

Power supply circuit consumption (CPU

Board) 20 W maximum

Fuse 250mA, 250VAC

PROBE INPUT

Temperature probe 2004-10K

Maximum wire length 500 feet (150 m)

Recommended wires 2 conductors, stranded, shielded, AWG #22

ALARM RELAY

Maximum current 1 A at 30VDC

OUTPUT RELAYS

Maximum Current 1HP @ 240VAC, 1/2HP @ 120VAC,

12A@240VAC

Caution Notice These relays are rated by UL and CSA at 1HP

@ 240VAC, 1/2HP @ 120VAC. However, for

outputs requiring frequent activation it is

recommended not to use more than 1/2HP @

240VAC, 1/4HP @ 120VAC per relay.

Important Notice.

-It is important to have a backup system in case of a system failure.

-Low-voltage and high-voltage wire must be passed through different

conducts at least 1 foot (30 cm) apart. If low-voltage and high-voltage

conduits must be crossed, the crossing must be at a 90-degree angle.

-All wiring must be made by a certified electrician and conform to local

electrical regulations.

JD-N2 INSTALLATION

JD-N2

Section B-18

Troubleshooting

SYMPTOM CAUSE REMEDY

Temperature probe

reads LO Temperature is below -58°F

(-50°C).

Probe is disconnected or

defective.

Check all connections. If

the problem persists, and

the temperature is within

normal range, replace the

probe.

Temperature probe

reads HI Temperature is above

140°F (60°C).

Probe is short circuited or

defective.

Check all connections. If

the problem persists, and

the temperature is within

normal range, replace the

probe.

Displays are blank JD-N2 is not powered.

Flat cable between the

main and top boards of the

JD-N2is disconnected.

Make sure the control is

powered.

Make sure the fuse is

correct.

Make sure the flat cable is

connected.

JD-N2 USER’S GUIDE

JD-N2 Section C-19

USER’S GUIDE

JD-N2

SECTION C

JD-N2 USER’S GUIDE

JD-N2

Section C-20

Control Description

73.3

[5]

[1]

[2]

[3]

[4]

[6]

Table of contents

Other J&D MAnufacturing Control System manuals

Popular Control System manuals by other brands

eqss

eqss Overwatch JLG ES Series installation manual

Agrilight

Agrilight AGRIBOX pro Installation and user manual

Swagelok

Swagelok Changeover SCO user manual

Leviton

Leviton Lumina LU20S-DNW installation instructions

Siemens

Siemens SIMATIC IPC547J manual

Dickey-John

Dickey-John IntelliAg MVT Operator's manual