8

8. The cut-off knife

The knife of the cookie machine is special coated to prevent sticking of the gures,

especially when the dough is sticky. Please avoid using sharp or hard objects to

clean the knife. A woolen cloth, soaked in comestible oil should be taken for that.

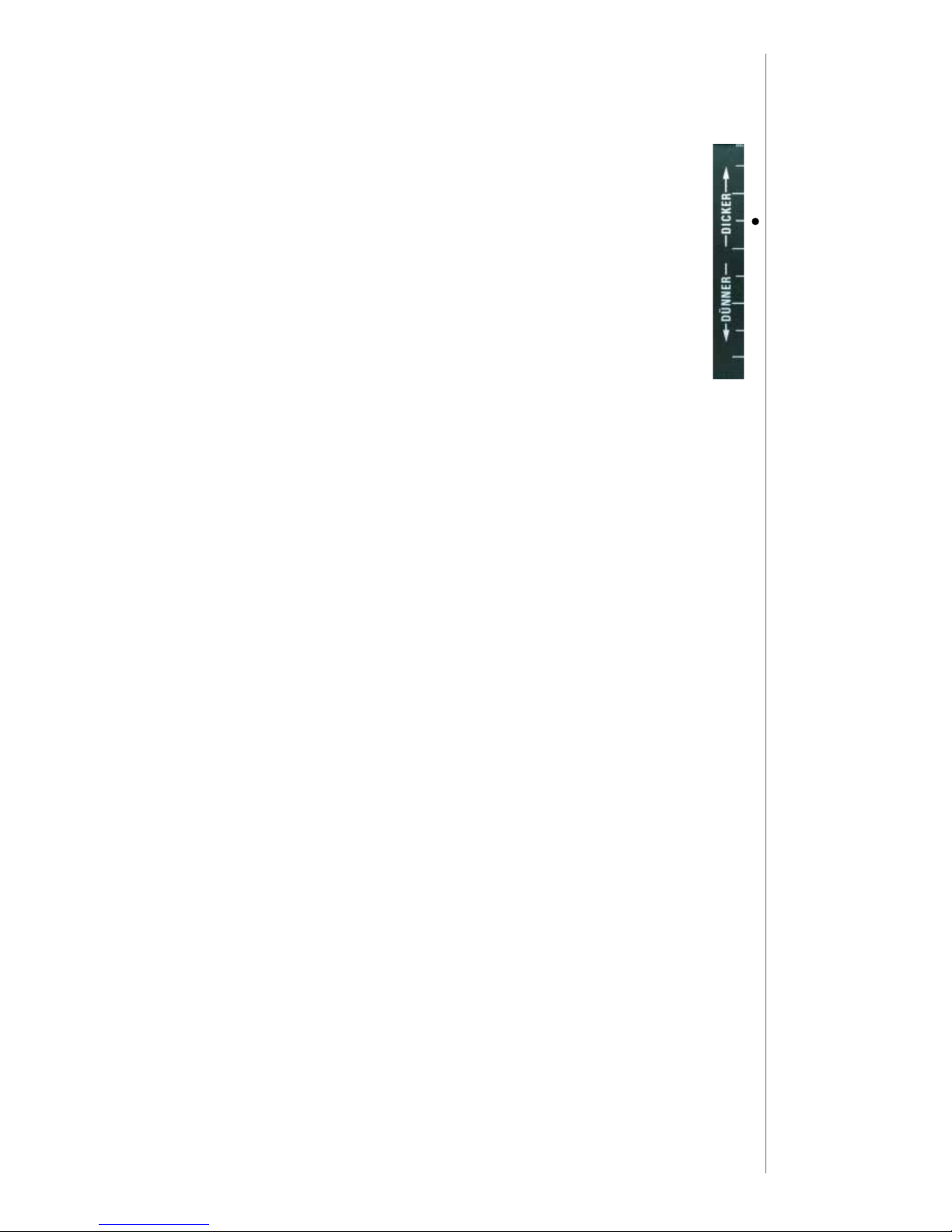

The position of the knife should be in the middle position at the start.

Thicker: The cookies will be thicker, when the distance between the knife

and the belt of dough on the kneading roller is lower.

Thinner: The cookies will be thinner, when the distance between the knife

and the belt of dough on the kneading roller is larger.

The basic setting is: 3. line from above.

The knife can be terminated with levers placed on the left side of the Plexiglas plate

- Thick - Thin - on the optimal character strength.

The knife is very thin and very narrow, in order to provide optimal results.

Therefore the thickness adjustment must be undertaken with caution to not jeopardi-

ze the knife. The standard setting is about the 6th Line from below.

When dough with swelling factor, like already risen dough with a leavening agent, it

may be that the optimal setting of the knife position is below.

The optimum thickness of gures is chosen when the gures are formed without any

irregulatities at the edges.

Is the lever switched upwards, (thick) thus forming one additional doughlm next to

the gure, which is undesirable.

By abrasion of the cutter drive, the lever require slight adjustment after some time,

because on the eccentric the slide pin and the slide ring are going to wear out.

You can see that from the gures, wich get thinner.

By rotating the two parts, the original condition can be restored.

If you have your dough kneading roller, including a coat of dough, and passed a long

time has left, it is required to switch the knife adjustment on thin and reset very slow-

ly and carefully on the right position while the machine is running.

Never set the lever in the lowest position while the machine is lled with dough.

Don‘t use the lever in any case to peel the dough. The knife could be drawn

into the feeding roller and break!

Never set the lever with a jerk at the upper position, because it is forced, in

this case, the knife in a position that can cause a breakage of the blade, or the

knife can draw into the feeding roller.

9. Warming up the machine (pre-heating of the rollers)

If you are unsure whether you need the heater to warm up the roller, you should

always take the pattern roller and warm up a bit.

For this just turn the main switch on (ON), the mode switch on (PERMANENT) and

the heater switch on (I). In this position, let the machine run about 5 minutes, with

high-fat dough with heater switch on (II) some minutes longer.

When the roller is warm enough, you can start with the lling of the dough.

Teon rollers are usually not heated!

For Sticky dough with honey or syrup the heater may be turned off!

In honey / syrupdoughs with fat, it may be necessary to turn the hea-

ter on!