Pay attention to the following when discarding the machine:

Burning the plastic parts such as the front panel may produce poisonous gas.

Dispose it as industrial waste.

cutting

Burning the electrolytic capacitors in the main circuit or on the PCBs may cause an explosion.

Smoke-may be harmful to your health!

Keep your head away from the smoke to avoid inhalation of waste gas

in cutting.

Keep the working environment well ventilated with exhaust or ventilation

equipment when .cutting

Arc radiation-may hurt your eyes and burn your skin!

Use proper mask and wear protective clothing to protect your eyes and

body.

Use proper mask or curtain to protect onlooker from being injured.

Magnetic field can make cardiac pacemaker a bit wonky!

Stay away from the power source to reduce the affect of magnetic filed.

Improper use and operation may result in a fire or an explosion!

Cutting spark may result in a fire, so please make ensure there are no

inflammables near the position, and pay attention to fire safety.cutting

Ensure there is fire extinguisher nearby, and make sure someone has

been trained to operate the fire extinguisher.

Do not weld closed container.

Do not use this machine for pipe thawing.

Hot workpiece can cause severe scald!

Do not touch hot workpiece with bare hands.

Cool the torch for a while after continuously working.cutting

Excessive noise does great harm to people’s hearing!

Wear ear covers or other hearing protectors when .cutting

Give warning to onlooker that noise may be potentially hazardous to

hearing.

Moving parts may injure your body!

Please keep away from moving parts (like fan).

Each door, panel, cover, baffle plate, and protective device the like

should be closed and located correctly.

Seek professional support when trouble strikes!

When trouble strikes in installation and operation, please inspect

according to related contents in this manual.

If you still cannot understand fully, or you still cannot solve the problem,

People with cardiac pacemaker should consult the doctor before carrying

out .cutting

please contact the dealer or the service center of JASIC to obtain

professional support.

Precautions for discard

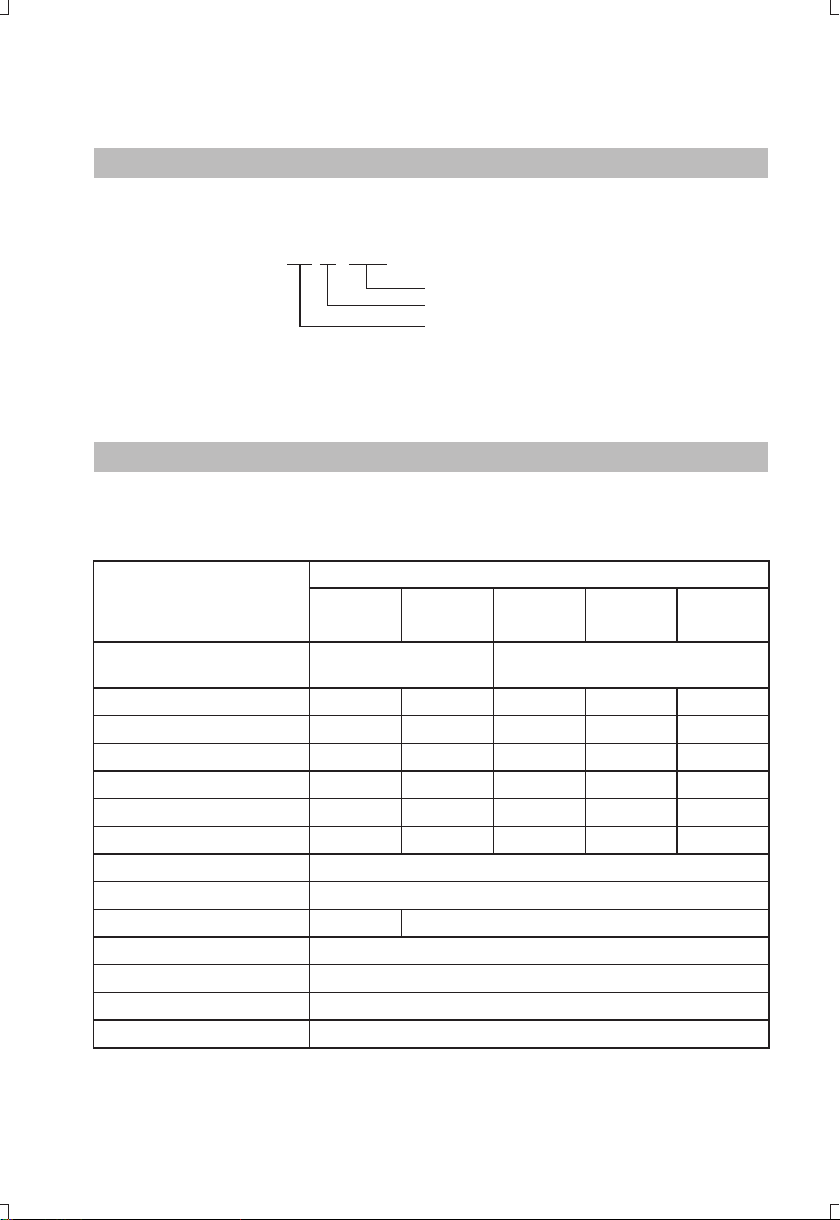

Precautions for operation