ACTIVITY DESCRIPTION

The Jäspi GTV Hybrid 500 energy heater is suitable alongside all forms of energy, both heat pumps and traditional heating modes. Product

design has been based on versatility, space friendliness and advanced energy economy.

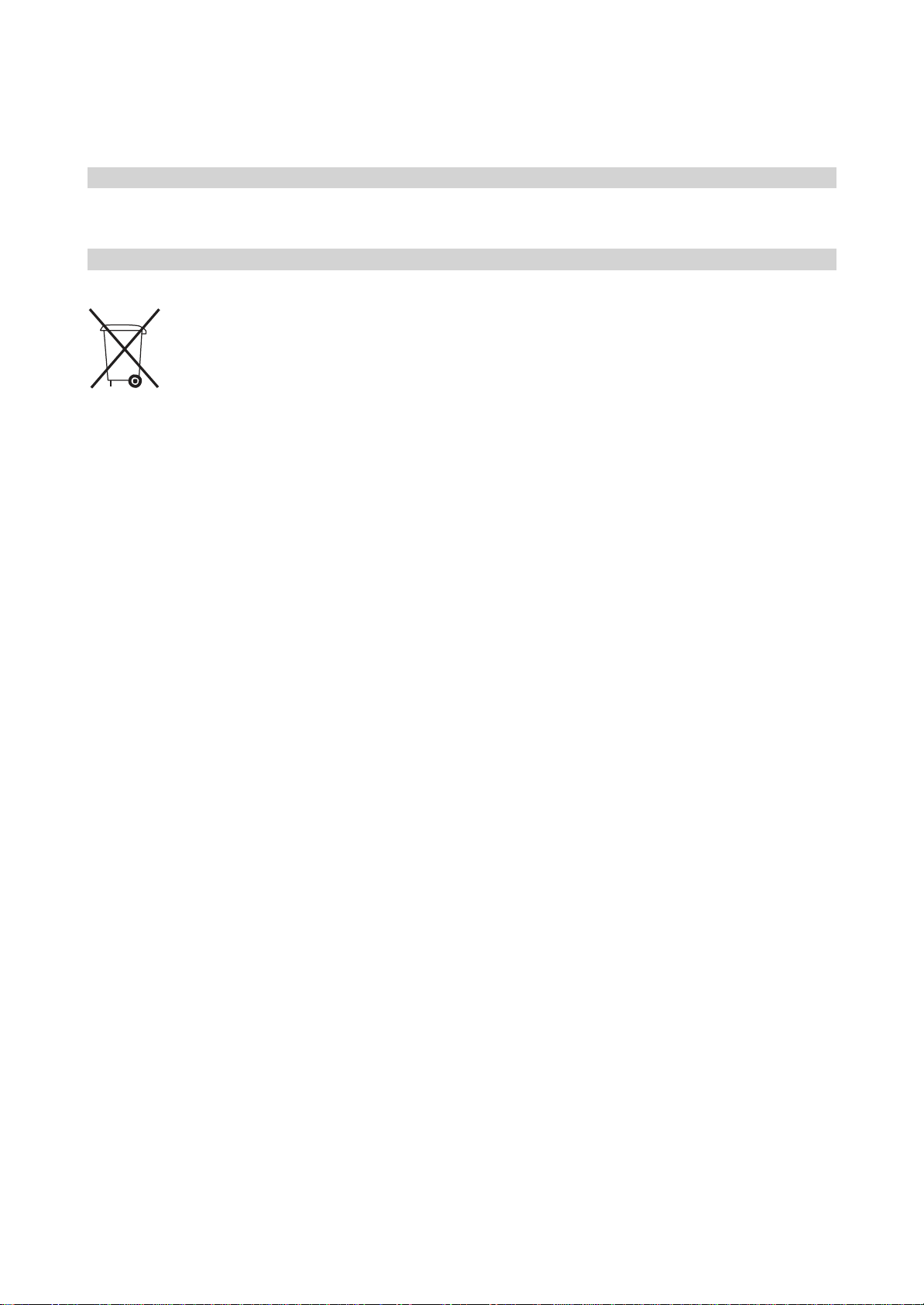

Hybrid accumulators are energy accumulators developed alongside low-temperature systems (e.g. heat pumps and solar energy) that provide heating

of a waterborne floor and/or radiator system and hot water. Hybrid bookers are suitable for both new and renovation sites. The water space of the

500-liter Hybrid Accumulator is divided into two parts; a top of 300 liters and a lower part of 200 liters separated by an intermediate bulkhead with

a flow channel. At the bottom of the 200 litres, which serves as the buffer tank for the heating circuit, a solar charging spiral and a preheating spiral

of domestic water are located. The top 300 liters store energy for the needs of the domestic water cycle.

Jäspi Hybrid heaters are ideally

suited to all heat pumps on the

market, e.g. alongside rapidly

increasing air-to-water heat

pumps. If the consumption of

domestic water is consistently

particularly high,

or if the property has a po-

reamme, we recommend

connecting the Jäspi water heater

to the Hybrid Heater.

To ensure the yield of heating and

hot domestic water, the hybrid

heater heat pump combination is

always equipped with spare heat

sources, e.g. electricity. Jäspi

Elbox (6kW + 6 kW) is available

as an accessory for hybrid

accumulators

+ Power watch automation). Jäspi

Elbox's power guard car

automation enables efficient use

of the main fixed fuse by taking

into account the rest of the

property's electrical load.

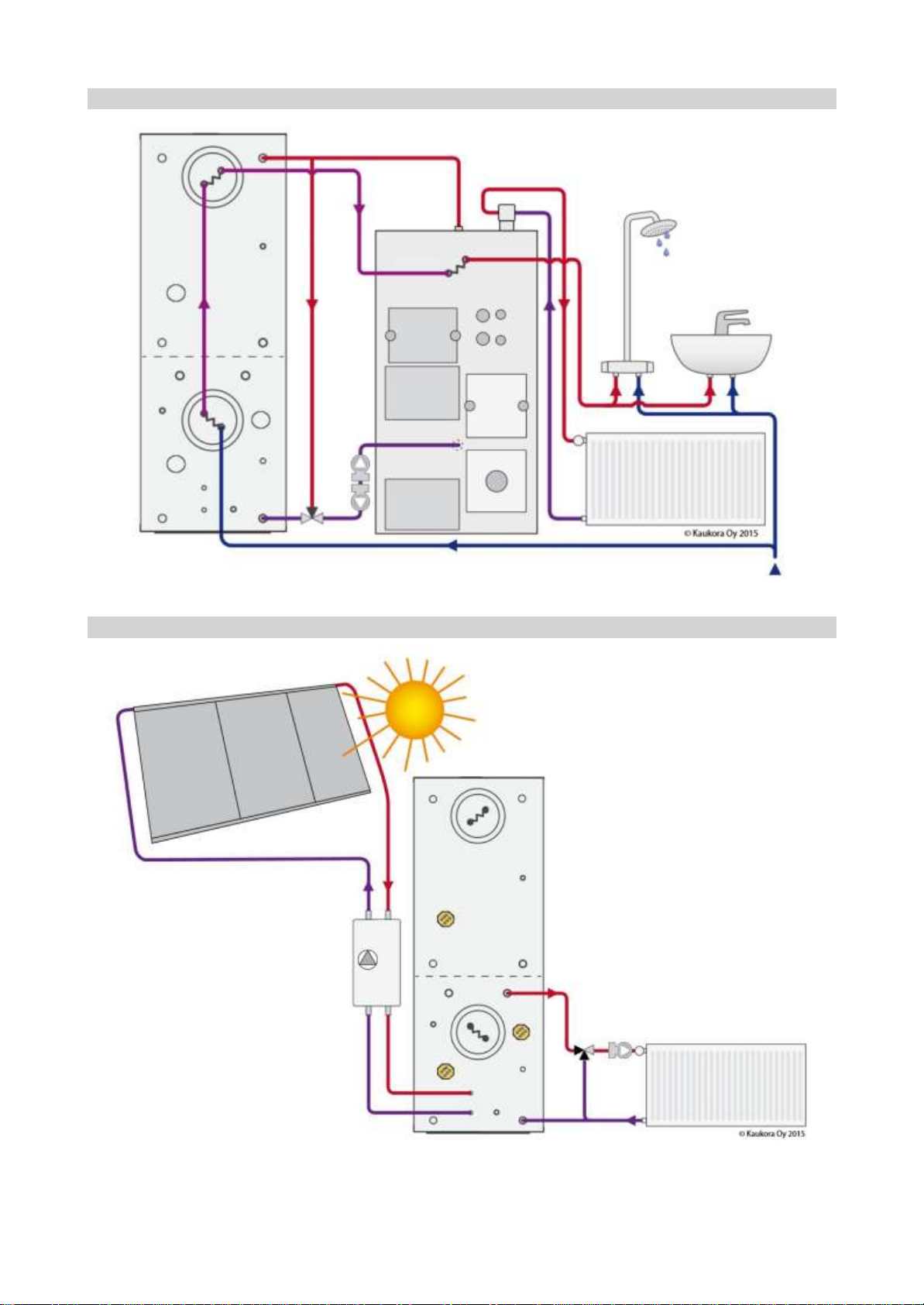

1 Temperature distribution and combinations in hybrid use

Figure 1 shows the temperature distribution of the boiler water in hybrid use, where the upper part of the accumulator is heated hotter than the lower

part of the accumulator. The intermediate bulkhead below the halfway point of the boiler prevents the hot water at the top of the tank and the hot

water at the bottom of the tank from being mixed without need.

Entities:

A: Domestic water charging, inlet to tank / Heating circuit, output from tank

B: Domestic water charging, output from tank / Heating circuit, inlet to tank

C: Charging low temperature heating, inlet to tank / Low temperature heating circuit, output from tank

D: Low temperature heating charge, output from tank / Low temperature heating circuit, input into tank

S1: One S2 of the domestic water firing

resistance: One S3 of the auxiliary heating

element: One of the emergency heating

resistance

More detailed coupling images can be found at the end of the operating instructions.