5

INDEX

I SPECIFICATION AND OPERATOR'S MANUAL Page

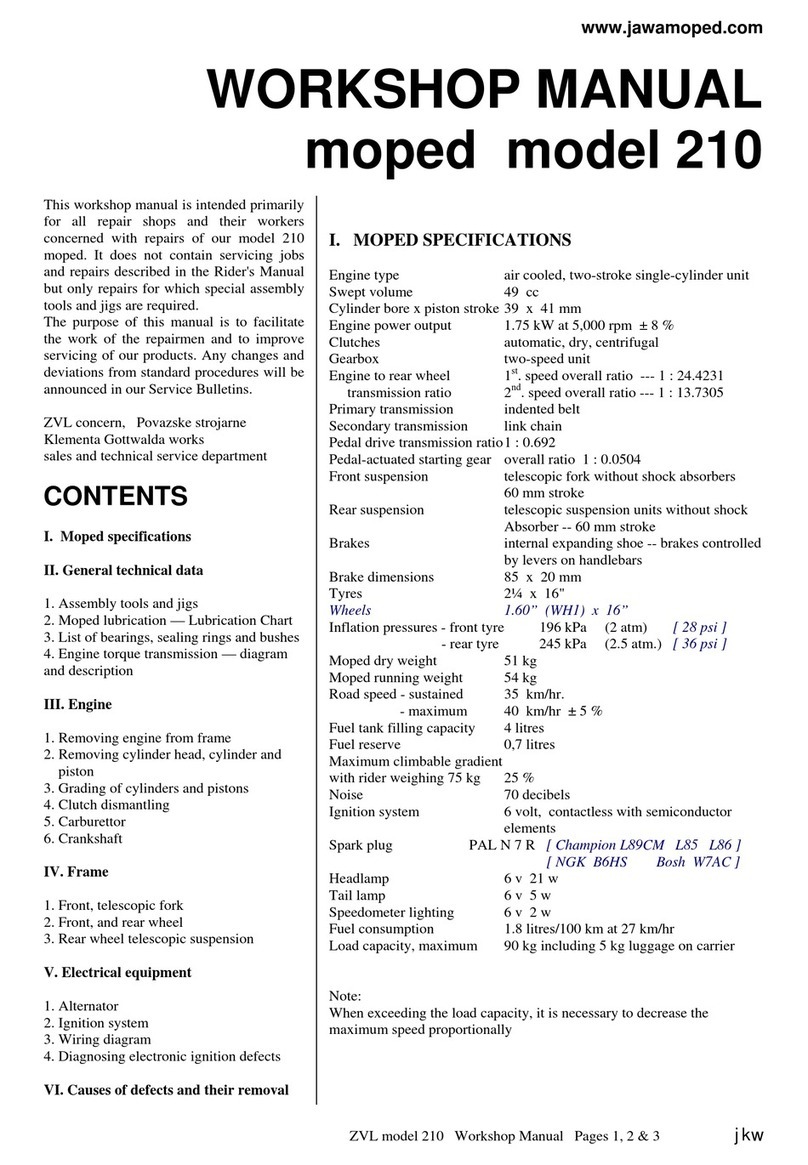

1. Technical data 7

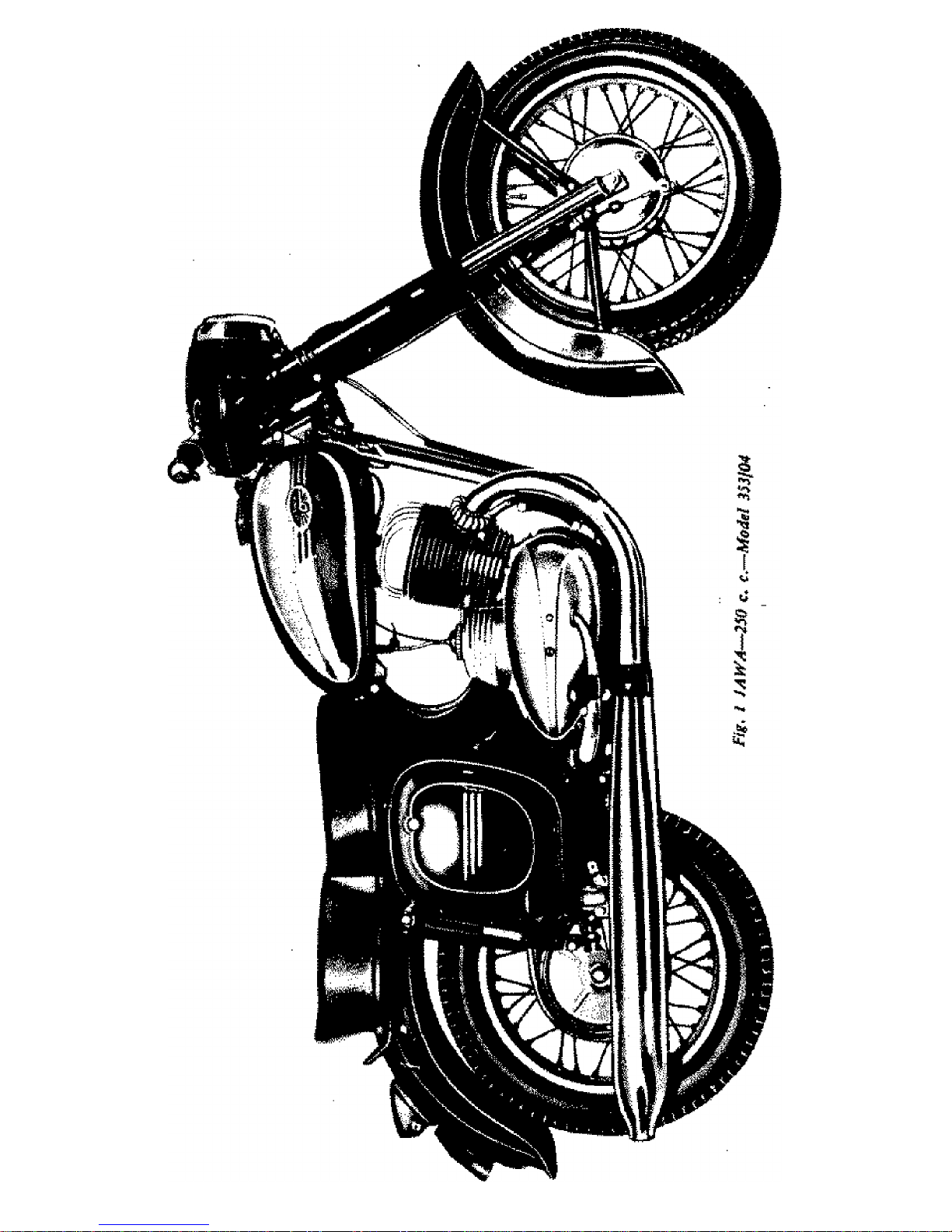

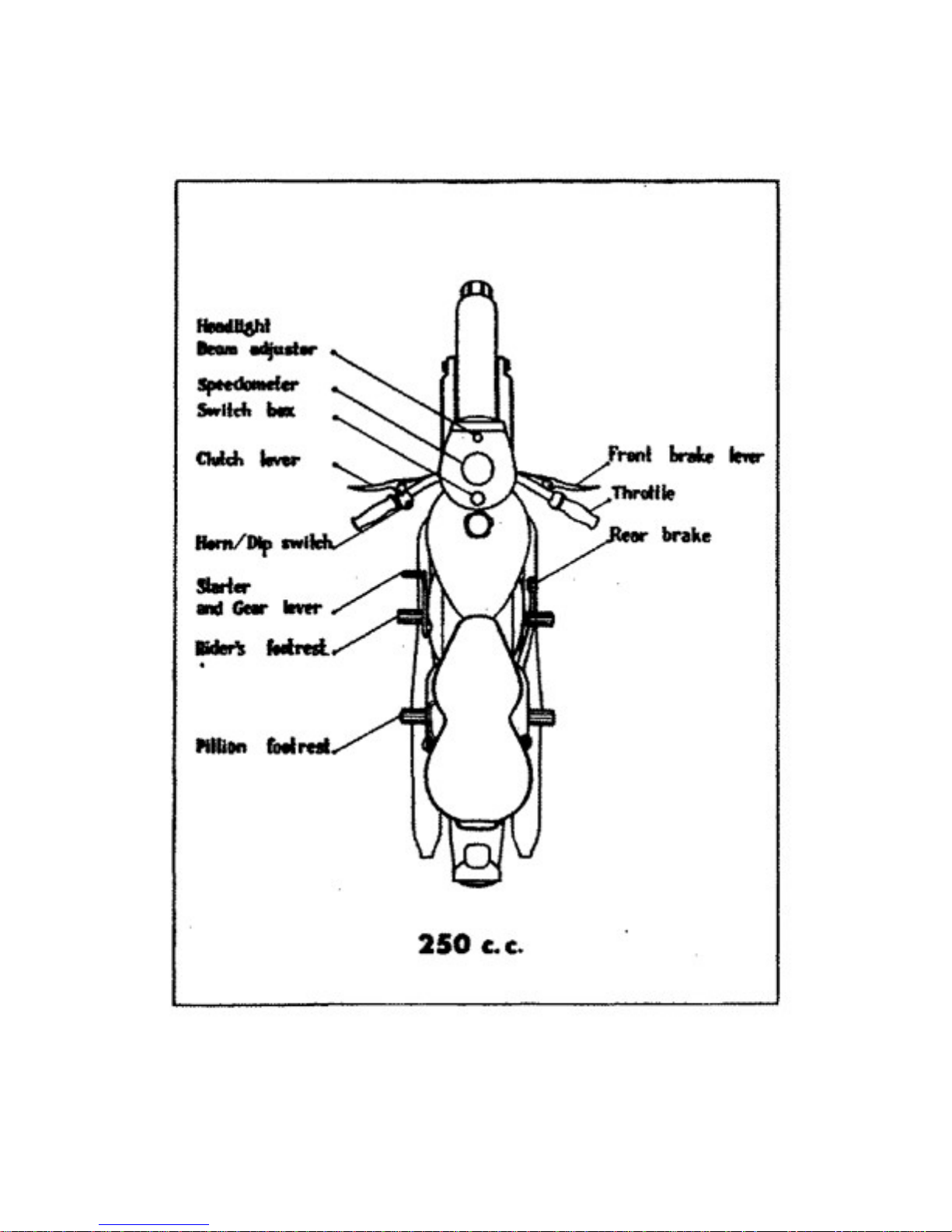

2. Description of motorcycle 10

3. Electrical equipment description 13

4. Running a new motorcycle 18

5. Servicing instructions 20

6. What should be avoided 23

II MAINTENANCE

1. Cleaning the motorcycle 24

2. Lubricating the motorcycle 25

3. Adjusting the brakes 30

4. Tyres 30

5. Adjusting the chain 33

6. Adjusting the clutch 34

7. Carburettor 35

8. Electrical equipment maintenance 38

9. Decarbonisation 41

III DISMANTLING AND ASSEMBLING WITHOUT THE AID OF SPECIAL TOOLS

1. Removing the front wheel 43

2. Removing the rear wheel 44

3. Removing the chaincase and the chain 45

4. Removing the rear chainwheel 45

5. Replacing the wheel ball bearings 45

6. Removing the cylinder head and barrel 49

7. Replacing the piston rings 50

8. Removing the carburettor 50

9. Dismantling the clutch 51

10. Dismantling the headlamp 51

11. Dismantling the steering head and fork legs 53

12. Handlebars --- twist grip 55

13. Removing the dual seat 55

14. Removing the fuel tank 55

15. Removing the cowls 55

16. Dismantling the rear suspension 56

17. Pivoted Fork 57

18. Removing the battery 58

19. Dismantling the switch box 58

20. Removing the engine from frame 59

21. Removing the R.H. and L.H. engine covers 59

IV DEFECTS, CAUSES AND REMEDIES 60

Two-stroke engine operation 63