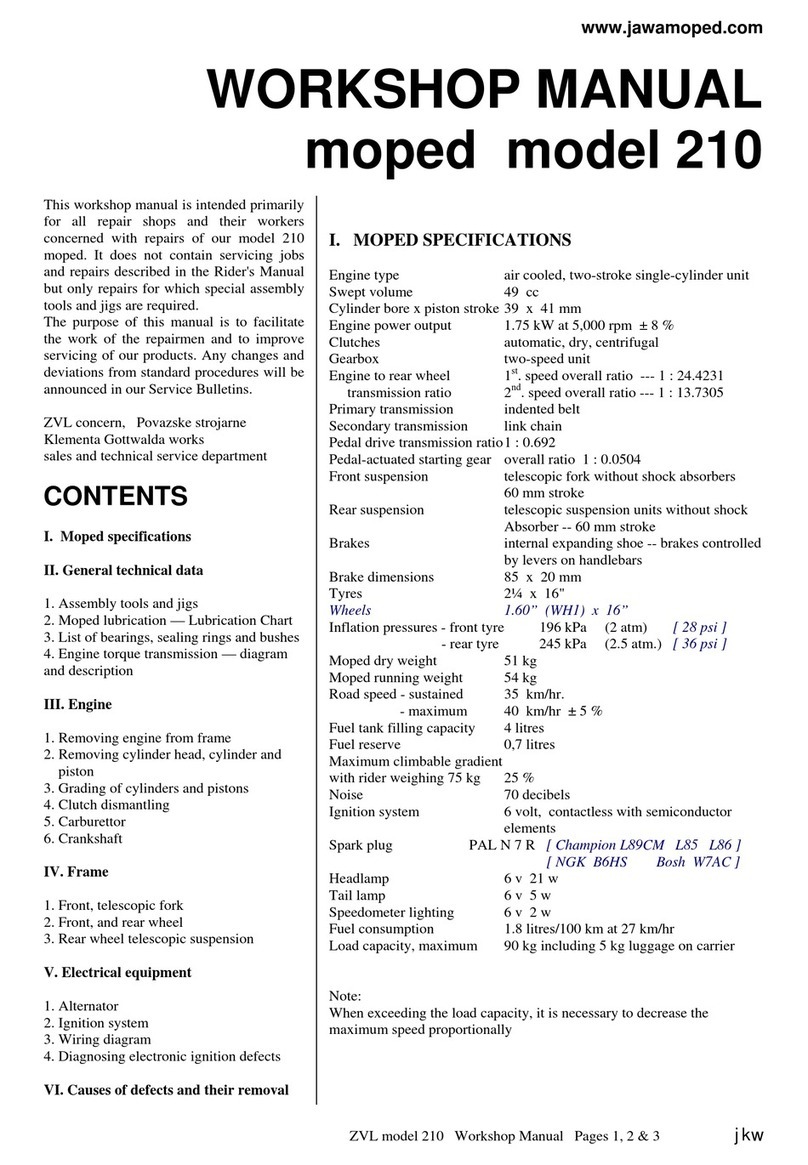

WORKSHOPMANUAL

___________________________________________________________________________

LISTOFREPAIRTOOLSFORTYPE638, 639,640

ITE

M

NR.

TYPE

DESIG.

SERIALNR. QUAN

TITY

DESCRIPTION

1S-46 9.71.51559.4 1 Feelergaugeforignitionadvance adjustment

2S-97 9.71.880097 1 Drag(forrotor)

3S-63 9.71.51589.4 1 Pawlretsiner

4S-64 9.71.515590.4 1 Drift, centeringbushes

5S-71 9.71.51577.4 1 Driftfordriving outbearings

6S-72 9.71.51576.4 1 Driftfordriving homesealing rings

7S-81 16-19758-4 1 TubularspaNner–steeringhead

8S-85 9.71.52248.4 1 Drag, removing primarysprocket

9S-86 9.71.52253.4 1 Driftdia

10 S-87 9.71.52252.4 1 MandrelforgudgeonpinpreSsing dia. 16 inandout

11 S-88 9.71.52251.4 1 AuxilIarybush, connectingrodsmallend

12 S-90 28-86-763 1 Jigwithboltsforseparatingcrankcasehalves

13 S-66 9.71.51603.3 1 AuxilIaryclutchplate

14 S-92 28-86-765 1 Drift

15 S-93 28-86-766 1 Forklegextractor

16 S-94 28-86-814 1 Primarchainadapter

17 S-201 9.96.55407.3 1 Lever

18 S-203 28-86-767 1 Pliers

19 S-205 28-86-725-2 1 Pressingjigwithaccessories

ListoflubricantsrecommendedformotorcycleJAWA350

Useofoil typeofoilintheCzechrep. ViscosityClass notes

A gearbox MogulTrans90 APIGL4

temperatureover0°C

brakeleverpins Gyrol90 SAE 90

clutchleverpins

brakecams MogulTrans80W/90APIGL4 wholeyear

standpins

bowdencables Byrol80W/90 SAE 80W/90

B enginelubrication

B1 lubricatedpetrol Mixtureratio1:60 –afterrunning in, 1:50 duringrunningin

Forwholeyearriding useoilofviscosityclass SAE 30-40 fortwostrokeenginesand

withclassificationaccordingtoAPITS.

B2 LubricationwithOil–mastersystemForwholeyearriding usepredilutedorsyntetic

oilfortwostrokeenginesaccordingtorecommendationofindividualoilproducers.

Forridingintemperaturesover0°Ccanbeusedoilfortwostrokesenginesof

viscosityclass SAE 30-40 andwithclassificationaccordingtoAPI-TC.