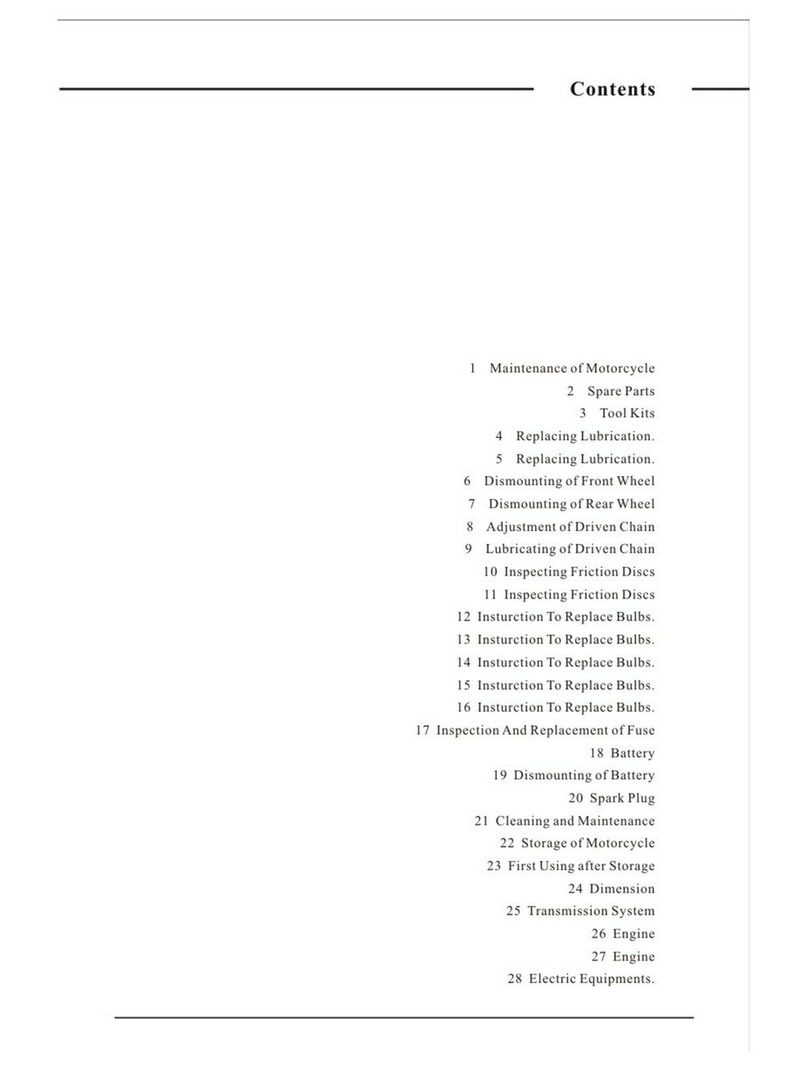

2. Table of Contents 8.13. Rear Wheel Brake Check and Adjustment

23

1) Introduction 1

2) Table of Contents 2

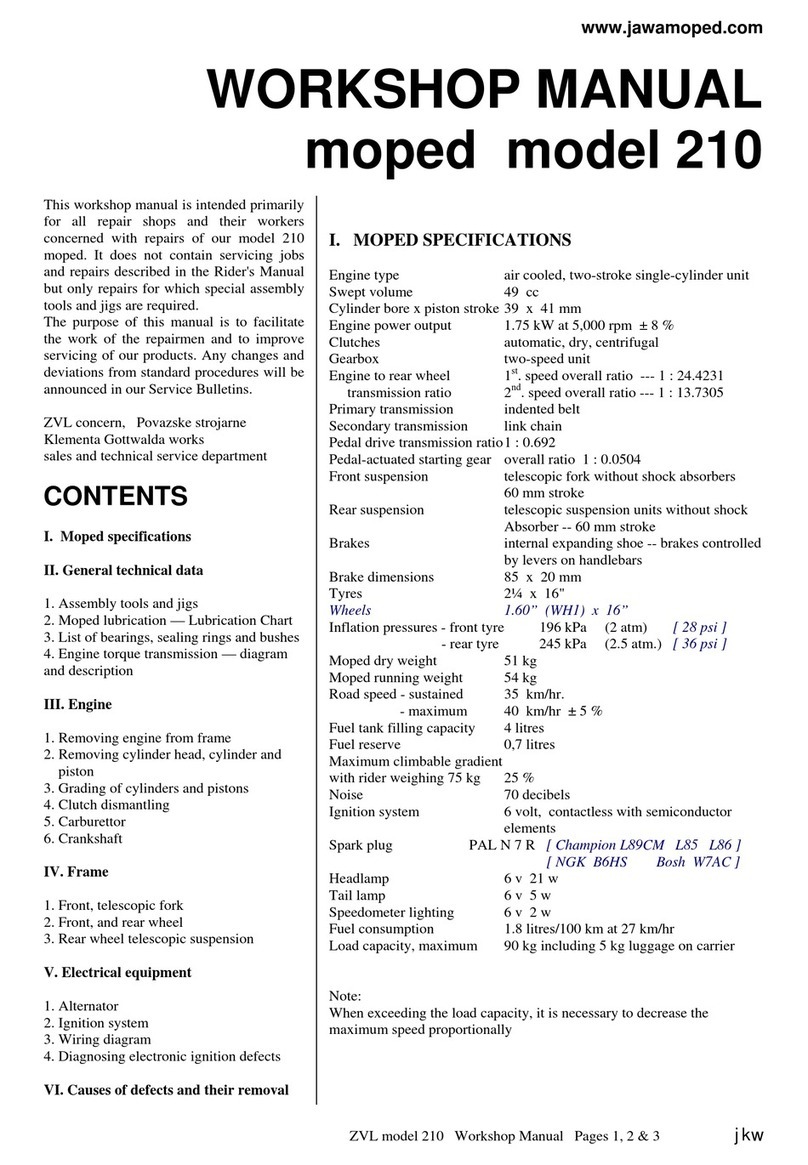

3) Technical Data 3-6

3.1. Engine 3

3.2. Undercarriage 3-4

3.3. Electric Equipment 4

3.4. Working Liquids 4-5

3.5. Other Data 5-6

4) Technical Description 7

4.1. Identification Marking 7

5) Familiarization with Motorcycle before Drive

8-12

5.1. Control Elements 8

5.2. Brake Control 9

5.3. Clutch Control 9

5.4. Gear Shifting 9

5.5. Fuel Cock Control 10

5.6. Choke Lever Control 10

5.7. Side Stand 10

5.8. Tool Box 10

5.9. Machine Locking 11

5.10. Working Liquid Refilling 11-12

6) Motorcycle Check before Drive 13

6.1. Brake Check 13

6.2. Clutch Check 13

6.3. Gas Grip Check 13

6.4. Chain Check 13

6.5. Tyre Check 13

6.6. Wheel Check 13

6.7. Electric Installation Check 13

7) Driving the Motorcycle 14-15

7.1. Motorcycle Starting 14

7.2. Motorcycle Setting in Motion 14-15

7.3. Motorcycle Stopping 15

7.4. Engine Running-In 15

8) Adjustment and Maintenance 15-29

8.1. Lubrication and Maintenance Schedule

16-17

8.2. Torques 17

8.3. Table of Lubricants 18

8.4. Gear Oil Level Check 18

8.5. Gear Oil Replacement 18

8.6. Fuel Cock Cleaning 19

8.7. Air Filter Cleaning 19

8.8. Carburetter Check 20

8.9. Sparking Plug Check 20

8.10. Ignition 20

8.11. Clutch Check and Adjustment 21

8.12. Front Wheel Brake Check and Adjustment

22

8.14. Excessive Effect of Brakes 23

8.15. Rear Stop Light Switch 24

8.16. Front Stop Light Switch 24

8.17. Chain Tightening 24

8.18. Chain Cleaning 25

8.19. Front Wheel Mounting and Dismantling

25

8.20. Rear Wheel Mounting and Dismantling

25

8.21. Telescopic Fork 25

8.22. Steering Bearing Clearance Check 26

8.23. Wheel Bearing Check 26

8.24. Side Stand Check 26

8.25. Exhaust Equipment Decarbonization 26

8.26. Headlight Adjustment 26

8.27. Lamp Replacement 27

8.28. Fuse Replacement 27

8.29. Battery Check 28

8.30. Electric Installation Diagram 29

8.31. Table of Failures 28

9) Care of the Motorcycle 30-31

9.1. Motorcycle Cleaning 30

9.2. Motorcycle Storage 30

9.3. Winter Operation and Protection against

Corrosion 30-31

9.4. Fuel Saving 31

9.5. Ecologic information 31

2