www.jawamoped.com

WORKSHOP MANUAL

moped model 210

This workshop manual is intended primarily

for all repair shops and their workers

concerned with repairs of our model 210

moped. It does not contain servicing jobs

and repairs described in the Rider's Manual

but only repairs for which special assembly

tools and jigs are required.

The purpose of this manual is to facilitate

the work of the repairmen and to improve

servicing of our products. Any changes and

deviations from standard procedures will be

announced in our Service Bulletins.

ZVL concern, Povazske strojarne

Klementa Gottwalda works

sales and technical service department

CONTENTS

I. Moped specifications

II. General technical data

1. Assembly tools and jigs

2. Moped lubrication — Lubrication Chart

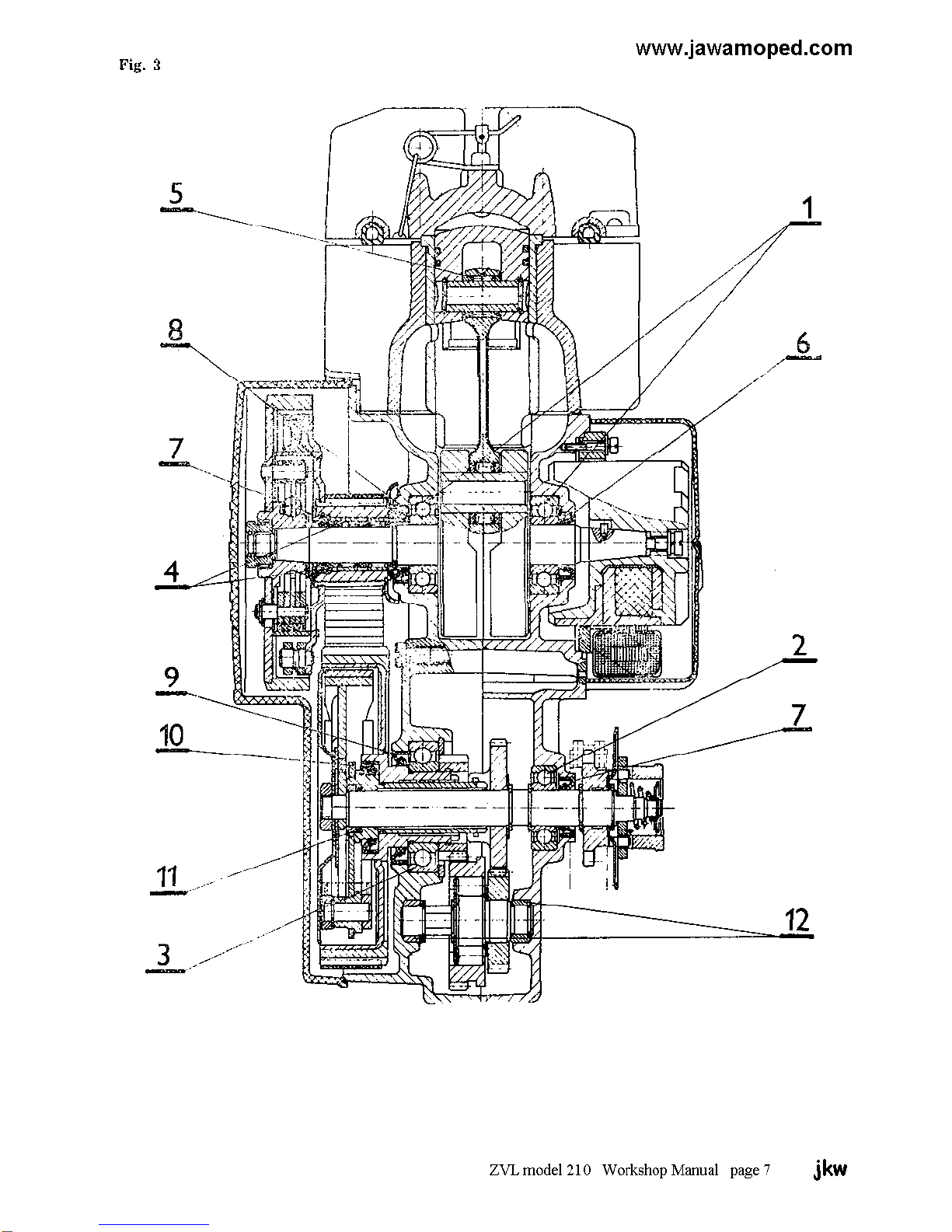

3. List of bearings, sealing rings and bushes

4. Engine torque transmission — diagram

and description

III. Engine

1. Removing engine from frame

2. Removing cylinder head, cylinder and

piston

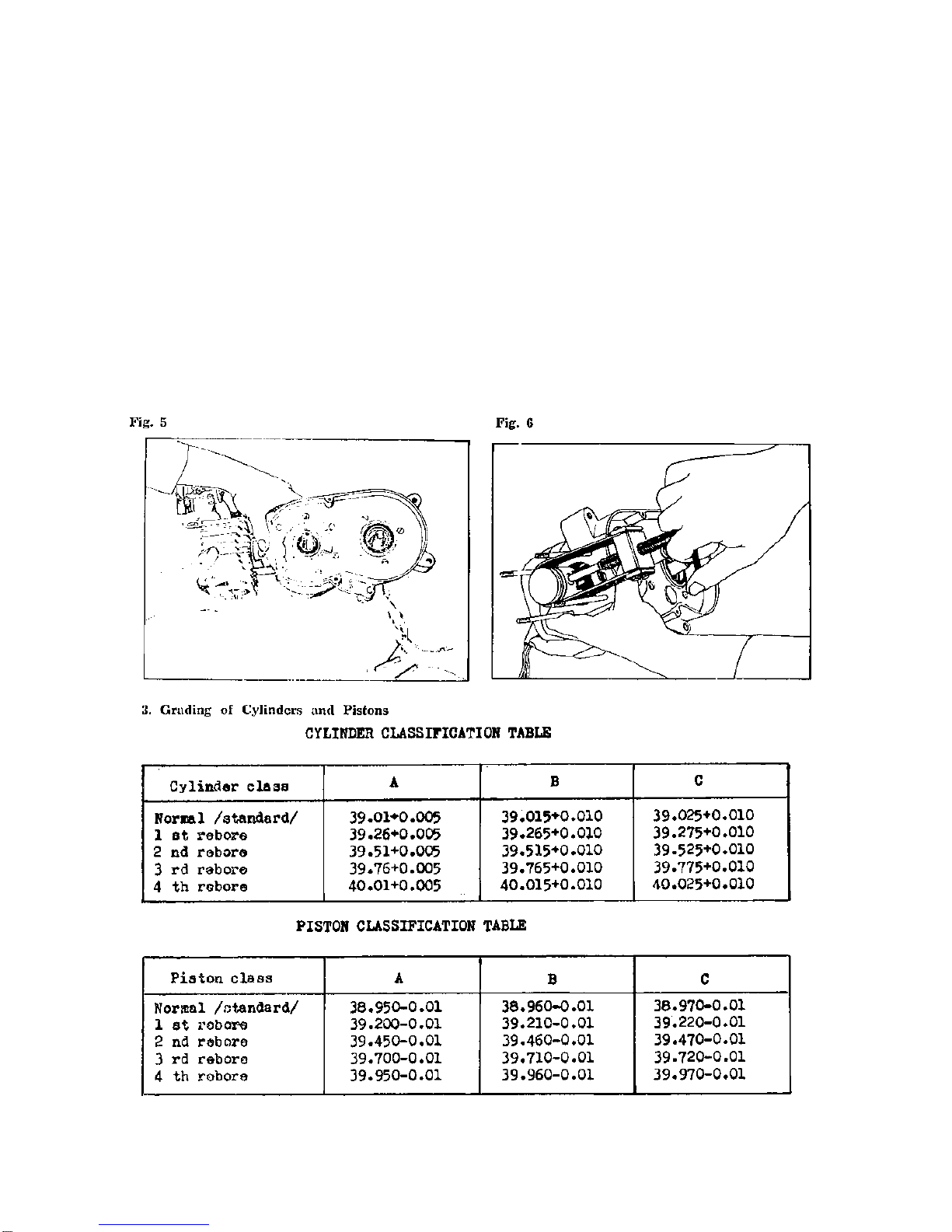

3. Grading of cylinders and pistons

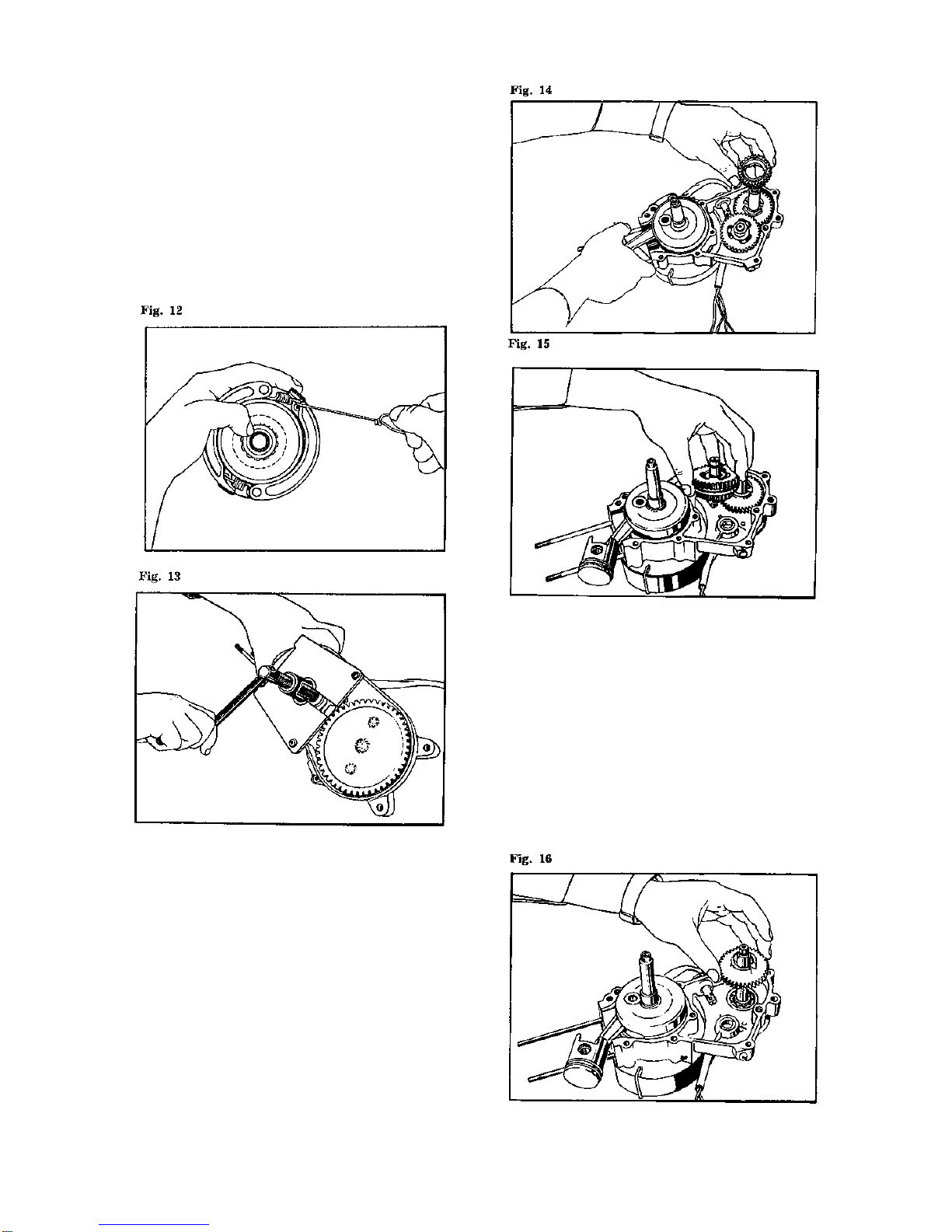

4. Clutch dismantling

5. Carburettor

6. Crankshaft

IV. Frame

1. Front, telescopic fork

2. Front, and rear wheel

3. Rear wheel telescopic suspension

V. Electrical equipment

1. Alternator

2. Ignition system

3. Wiring diagram

4. Diagnosing electronic ignition defects

VI. Causes of defects and their removal

I. MOPED SPECIFICATIONS

Engine type air cooled, two-stroke single-cylinder unit

Swept volume 49 cc

Cylinder bore x piston stroke 39 x 41 mm

Engine power output 1.75 kW at 5,000 rpm ± 8 %

Clutches automatic, dry, centrifugal

Gearbox two-speed unit

Engine to rear wheel 1st. speed overall ratio --- 1 : 24.4231

transmission ratio 2nd. speed overall ratio --- 1 : 13.7305

Primary transmission indented belt

Secondary transmission link chain

Pedal drive transmission ratio1 : 0.692

Pedal-actuated starting gear overall ratio 1 : 0.0504

Front suspension telescopic fork without shock absorbers

60 mm stroke

Rear suspension telescopic suspension units without shock

Absorber -- 60 mm stroke

Brakes internal expanding shoe -- brakes controlled

by levers on handlebars

Brake dimensions 85 x 20 mm

Tyres 2¼ x 16"

Wheels 1.60” (WH1) x 16”

Inflation pressures - front tyre 196 kPa (2 atm) [ 28 psi ]

- rear tyre 245 kPa (2.5 atm.) [ 36 psi ]

Moped dry weight 51 kg

Moped running weight 54 kg

Road speed - sustained 35 km/hr.

- maximum 40 km/hr ± 5 %

Fuel tank filling capacity 4 litres

Fuel reserve 0,7 litres

Maximum climbable gradient

with rider weighing 75 kg 25 %

Noise 70 decibels

Ignition system 6 volt, contactless with semiconductor

elements

Spark plug PAL N 7 R [ Champion L89CM L85 L86 ]

[ NGK B6HS Bosh W7AC ]

Headlamp 6 v 21 w

Tail lamp 6 v 5 w

Speedometer lighting 6 v 2 w

Fuel consumption 1.8 litres/100 km at 27 km/hr

Load capacity, maximum 90 kg including 5 kg luggage on carrier

Note:

When exceeding the load capacity, it is necessary to decrease the

maximum speed proportionally

ZVL model 210 Workshop Manual Pages 1, 2 & 3 jkw