Xuzhou Jiayu Solar Energy Technology Co.,Ltd.

North of Peigong Road, East of Hankang Road, Peixian Economic,Development Zone, Xuzhou City, Jiangsu Province, 221000, P.R. China

Website: www.jayusolar.com Email: ranfeng@jayusolar.com Tel: +86 13151232006

Installation Manual

GENERAL INFORMATION

Installing solar photovoltaic systems requires specialized skills and knowledge. The installer assumes all risk

of injury, including risk of electric shock. Module installation should be performed only by a qualified installer.

All modules come with a permanently attached junction box and 4mm²wire. Jayu Solar can provide

customers with fitted cables for ease of installation, if desired.

When disconnecting wires connected to a photovoltaic module that is exposed to sunlight, an electric arc

may occur. Arcs can cause burns, start fires or otherwise create safety problems. Exercise caution when

disconnecting wiring on modules exposed to sunlight.

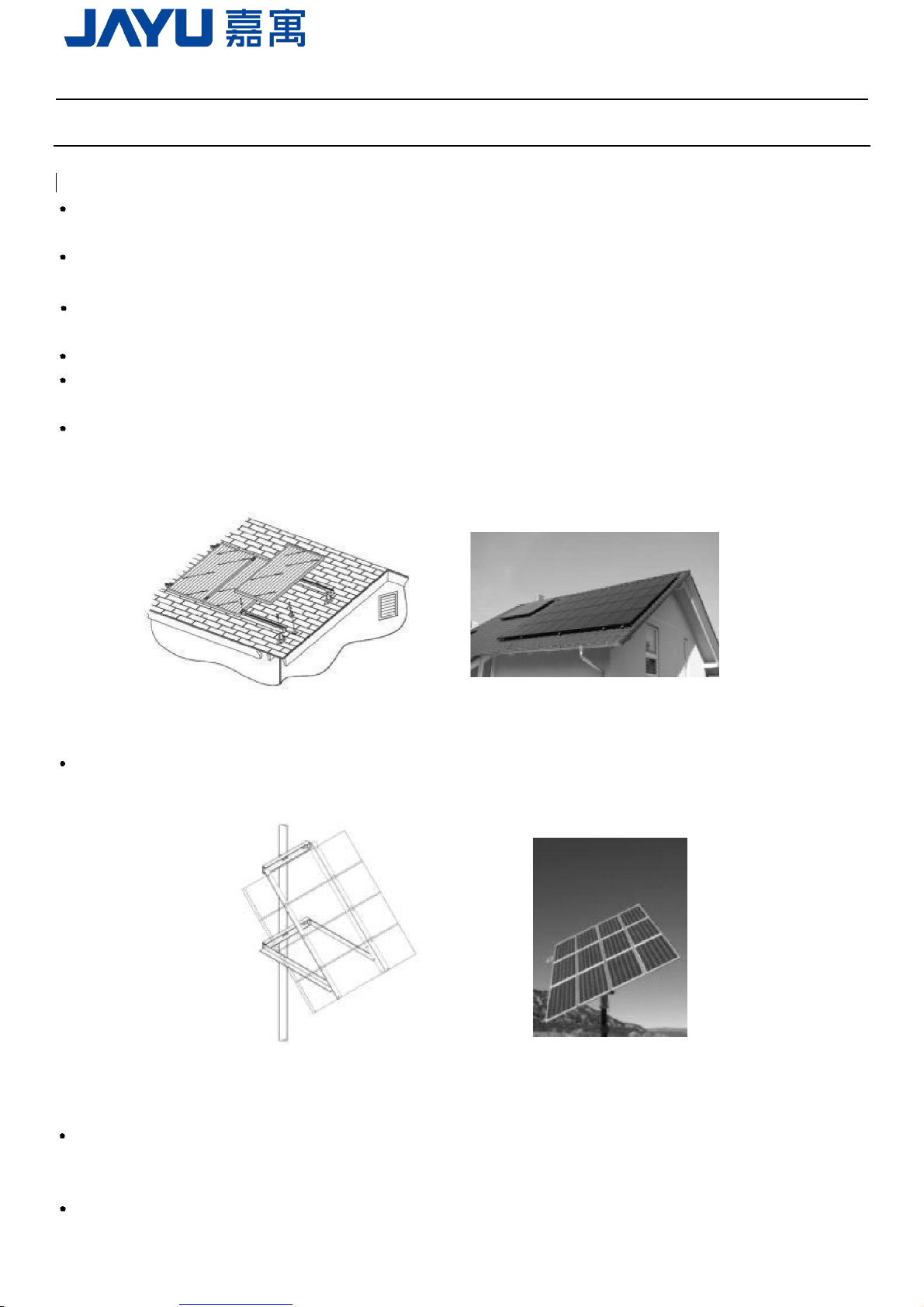

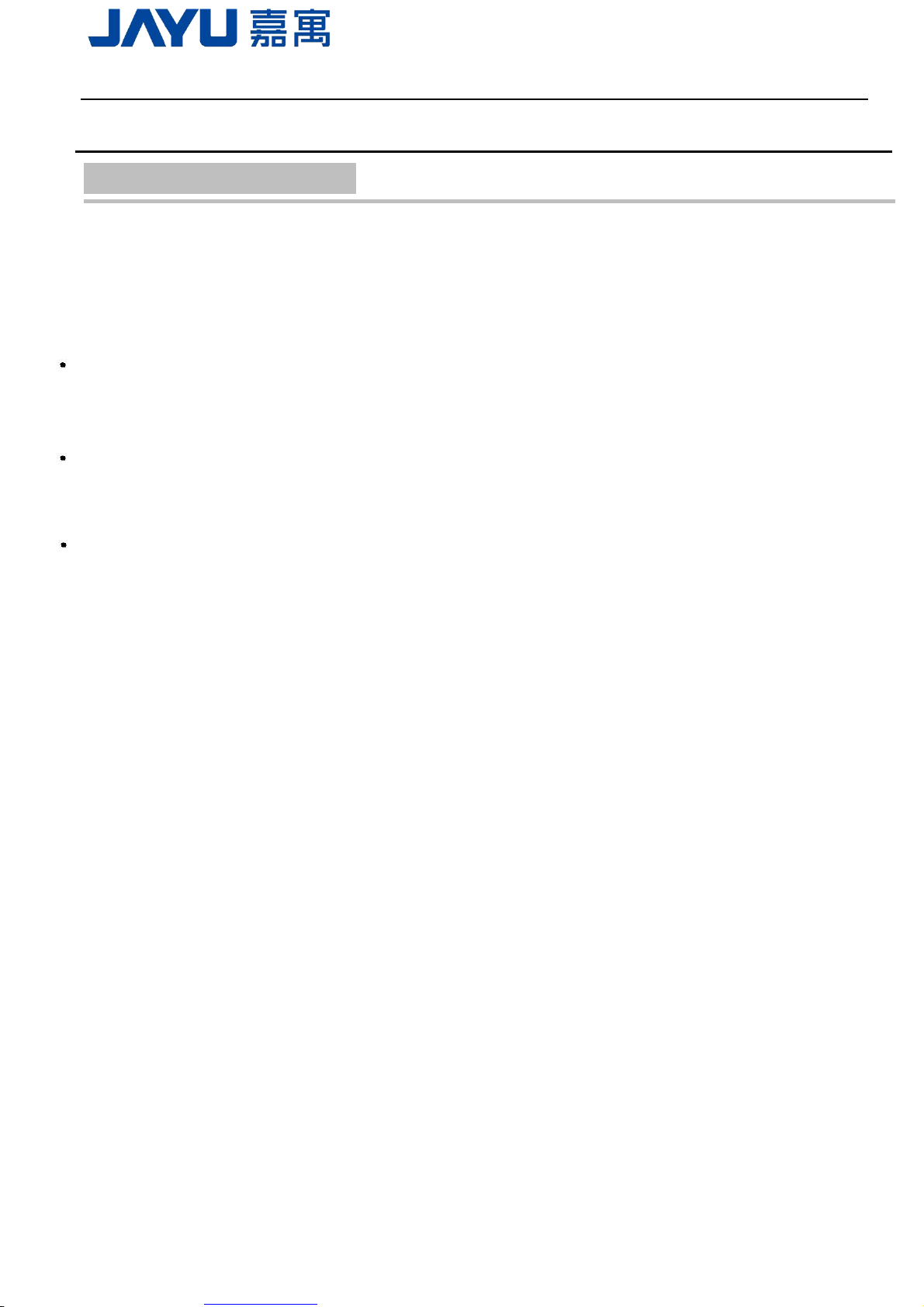

Photovoltaic solar modules convert light energy to direct-current electrical energy, and are designed for

outdoor use. Proper design of support structures is the responsibility of the system designer and installer.

Do not attempt to disassemble the module, and do not remove any attached nameplate

or components. Doing so will void the warranty.

Do not use mirrors or other hardware to artificially concentrate sunlight on the module.

Safety precautions for installing a solar photovoltaic system

Solar modules produce electrical energy when light shines on the front surface. The DC voltage may exceed 30V.

If modules are connected in series, the total voltage is equal to the sum of the individual module voltages. If

modules are connected in parallel, the total current is equal to the sum of individual module current

Keep children well away from the system while transporting and installing mechanical and electrical

components.

Completely cover the module with an opaque material during installation to keep electricity from being

generated.

Abide with the safety regulations for all other components used in the system, including wiring and cables,

connectors, charging regulators, inverters, storage batteries and rechargeable batteries, etc.

Use only equipment, connectors, wiring and support frames suitable for use in a solar electric systems.

Always use the same type of module within a particular photovoltaic system.

Modules rated for use in this application class may be used in systems operating at greater than 50V DC or

240W, where general contact access is anticipated. Modules qualified for safety through this part of

IEC61730 and IEC61730-2 and within this application class are considered to meet the requirements for

safety classⅡ. Under normal conditions, a photovoltaic module is likely to experience conditions that

produce more current and/or voltage than reported at standard test conditions. Accordingly, the value of Isc

and Voc marked on this module should be multiplied by of 1.25 when determining component voltage ratings,

conductor current ratings, fuse sizes, and size of controls connected to the PV output.

The recommend maximum series fuse is 15A(156 module).

The modules have been evaluated for a maximum positive loading of 5400pa.

Do not wear metallic rings, watchbands, ear, nose, or lip rings, or other metallic devices

while installing or troubleshooting a photovoltaic systems.

Be sure to use appropriate safety equipment (insulated tools, insulated gloves, etc) approved

for use in electrical installations.

Application class A: meet the requirements for safety class II.

1/13