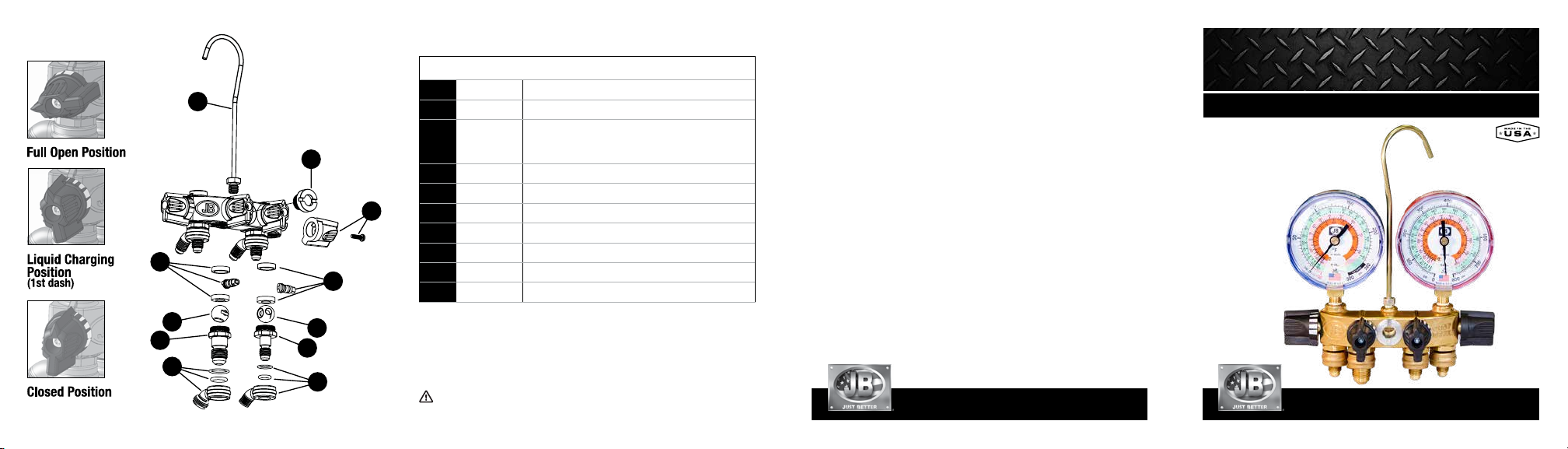

Liquid Charging Repair Parts

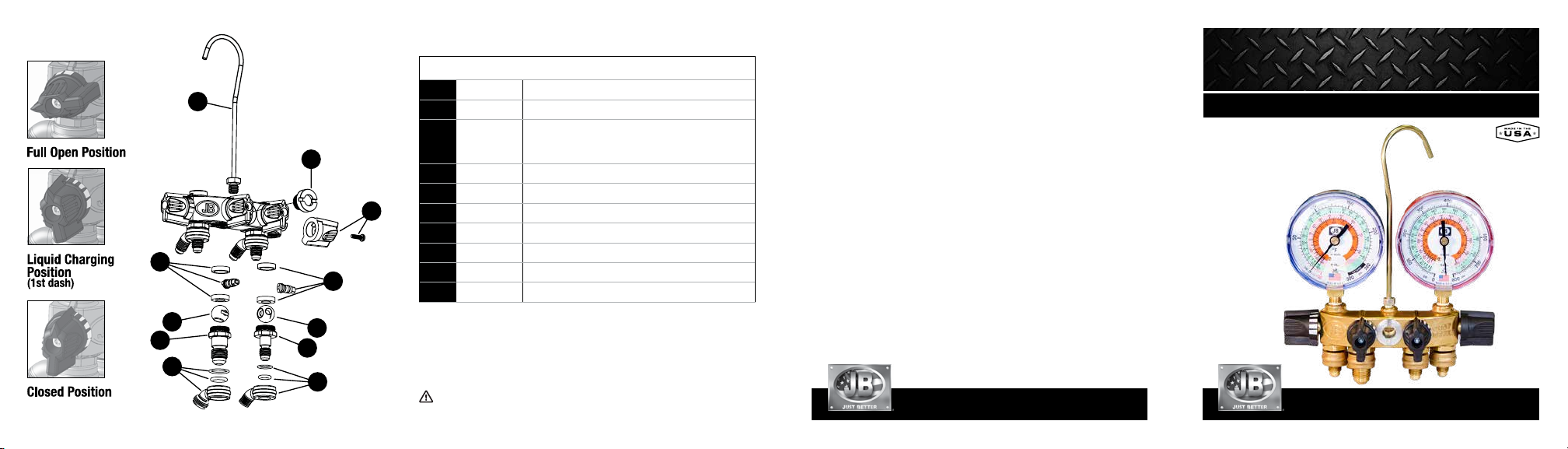

See your wholesaler for a complete line of gauges.

10

2

1

3

5

3

6

4

8

9

7

REVOLVER®

4-VALVE BALL MANIFOLD

Limited Warranty

Manifold bar has a lifetime warranty, while the components, (gauges,

hoses, handles, hose holders, etc.), are covered under the limited

warranty policy. Products are warrantied for a period of one year from

date of shipment by JB and limited to repair, replacement or credit,

if in our opinion are defective due to workmanship and/or materials.

Defective components should be returned to the wholesaler from which

the product was purchased for evaluation. Manifolds are designed for

use with all refrigerants except Ammonia (R717). Working pressures

are limited to gauge dial range. Use of this manifold under any other

conditions voids the warranty.

For Professional Use Only

JB manifolds are designed for use by technically trained HVAC/R

service engineers only. Due to the high pressures encountered in all

systems that this manifold will be used on, plus the dangers due to

the physical and chemical nature of refrigerants and oils present in all

systems, misapplication could result in injury or death.

REVOLVER®SERIES MANIFOLDS

1M2-102N Hanging hook

2MR-502 Handle and screw

3MR-BVK

Ball valve kit including:

(2) seals, (1) stem, (2) o-rings

and (1) washer

4MR-444 1/4" retainer tting

5MR-446 3/8" retainer tting

6MR-611 Throttle ball

7MR-610 Ball

8MR-504 1/4" hose holder sleeve and o-rings

9MR-506 3/8" hose holder sleeve and o-rings

10 MR-525 Sight glass with o-ring

JB INDUSTRIES

Limited Warranty

Manifold bar has a lifetime warranty, while the components, (gauges,

hoses, handles, hose holders, etc.), are covered under the limited

warranty policy. Products are warrantied for a period of one year from

date of shipment by JB and limited to repair, replacement or credit,

if in our opinion are defective due to workmanship and/or materials.

Defective components should be returned to the wholesaler from which

the product was purchased for evaluation. Manifolds are designed for

use with all refrigerants except Ammonia (R717). Working pressures

are limited to gauge dial range. Use of this manifold under any other

conditions voids the warranty.

For Professional Use Only

JB manifolds are designed for use by technically trained HVAC/R

service engineers only. Due to the high pressures encountered in all

systems that this manifold will be used on, plus the dangers due to

the physical and chemical nature of refrigerants and oils present in all

systems, misapplication could result in injury or death.

JB INDUSTRIES

Part No. 26000-308 0818

WARNING: This product can expose you to chemicals including lead which are

known to the State of California to cause cancer and birth defects or other reproductive harm.

For more information go to www.P65Warnings.ca.gov