JBF Environmental Technology

1

1 CHAPTER I - INTRODUCTION..........................................................................................3

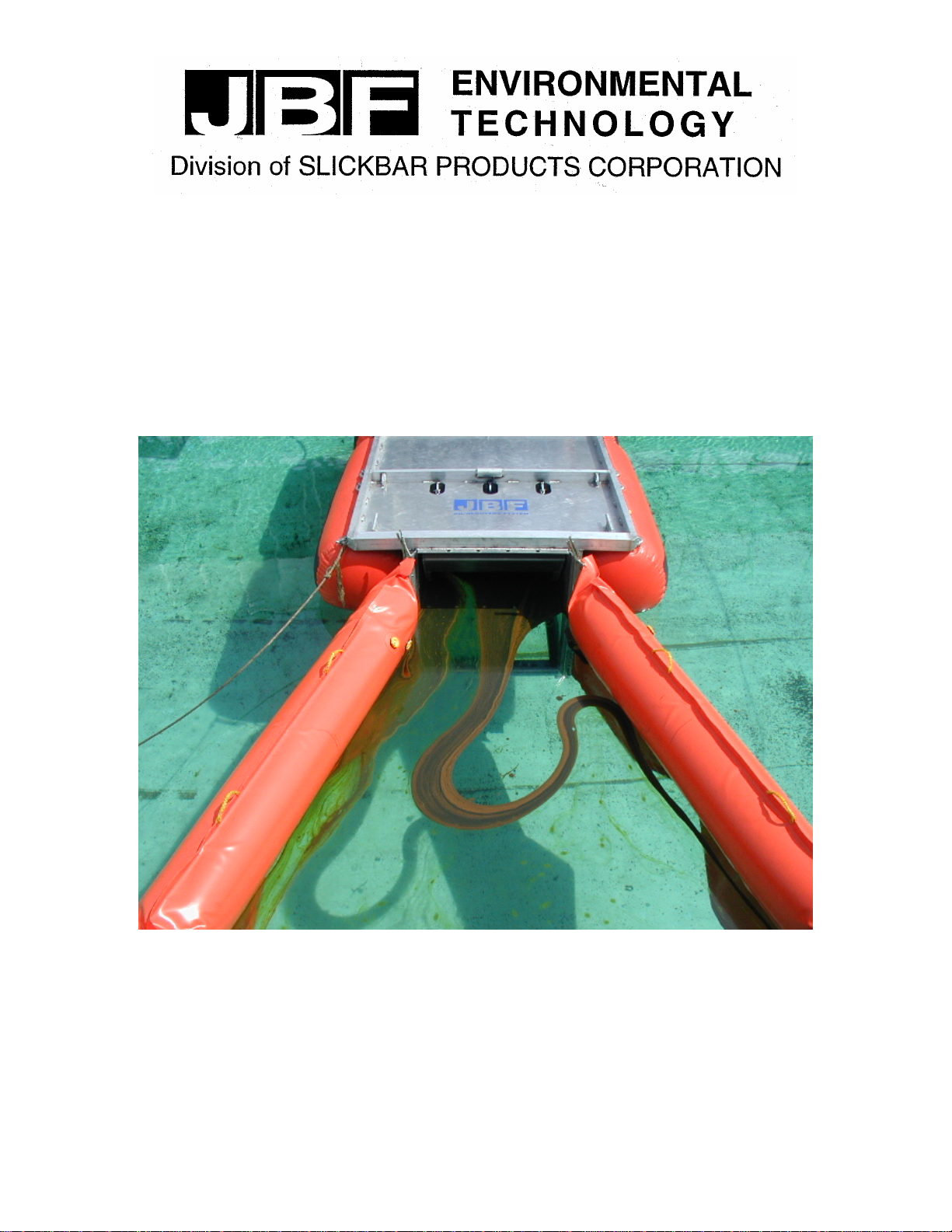

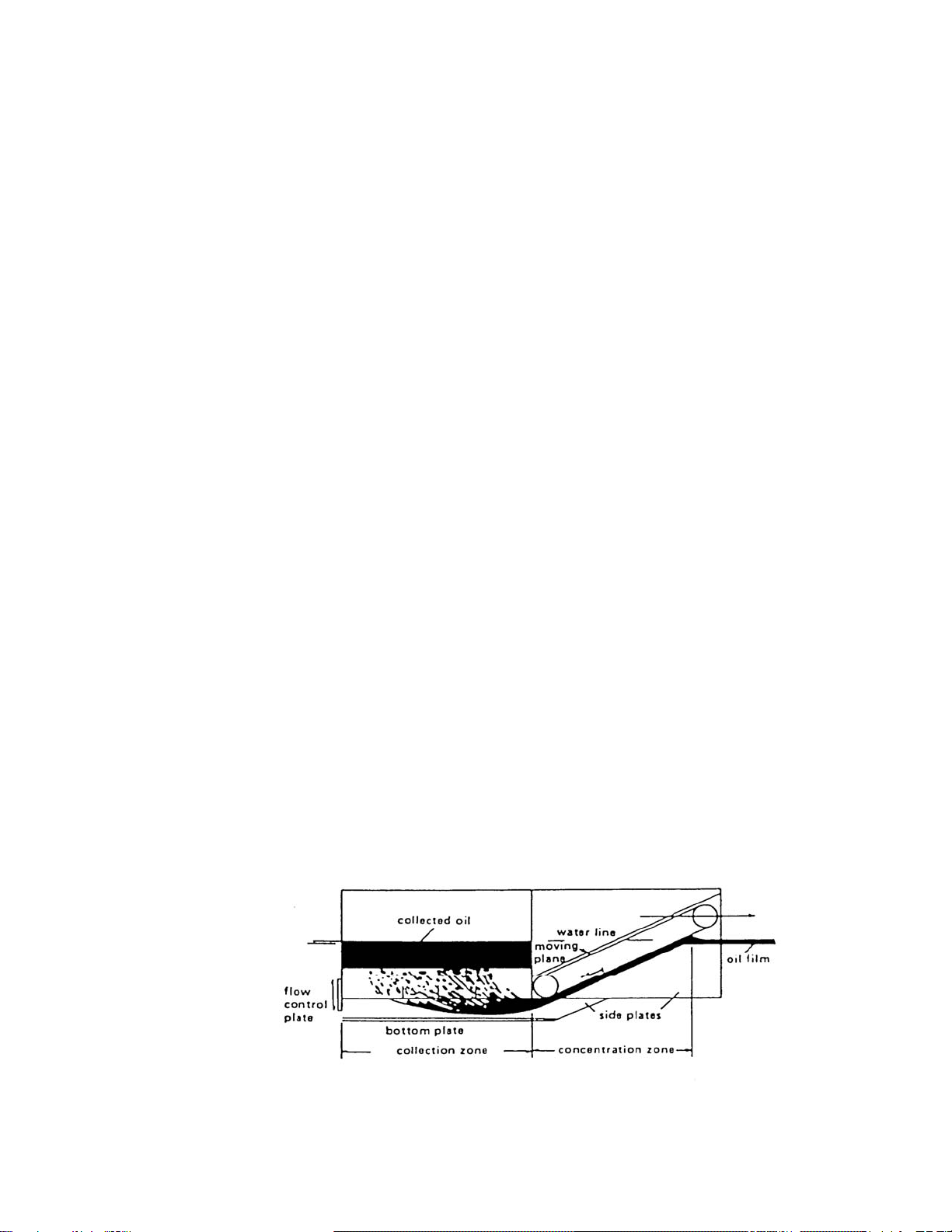

A JBF DIP 500 SKIMMING SYSTEM .................................................................................3

i) Explanation of the skimmer / DIP principle...................................................................3

ii) JBF DIP concept..........................................................................................................3

iii) IN-LINE ADVANCING SKIMMER-SWEEPING-FSB....................................................4

iv) SELECTION OF THE DIP 500.....................................................................................6

v) INTERFACE WITH PUMPS AND HYDRAULIC POWER UNITS.................................6

vi) OIL RECOVERY PERFORMANCE .............................................................................6

2 SYSTEM DESCRIPTION AND CHARACTERISTICS........................................................7

A GENERAL DESCRIPTION..............................................................................................7

B OPERATING CONCEPT AND LIMITS............................................................................9

i) Transportation & Storage:............................................................................................9

ii) Deployment time & Configurations:..............................................................................9

iii) Oil Recovery: ...............................................................................................................9

iv) Speed limitations:.........................................................................................................9

v) Sea state limitations...................................................................................................10

vi) Debris handling..........................................................................................................10

C MAJOR COMPONENTS ...............................................................................................10

i) Moving plane assembly..............................................................................................10

ii) Belt Motor...................................................................................................................11

iii) Collection Well...........................................................................................................11

iv) Oil Transfer Pumps....................................................................................................11

v) Pontoons....................................................................................................................11

vi) Control Stand.............................................................................................................11

vii) Transition booms .......................................................................................................12

viii) Debris Rakes .............................................................................................................12

ix) Belt Wiper ..................................................................................................................12

D COMPONENT DESCRIPTION AND CHARACTERISTICS...........................................12

i) The Hand winch.........................................................................................................12

ii) DOP 250 pump..........................................................................................................13

3 STORAGE AND TRANSPORT ........................................................................................13

A Storage..........................................................................................................................13

B Transportation ...............................................................................................................13

4 ASSEMBLY AND DEPLOYMENT....................................................................................13

A DIP 500 ASSEMBLY .....................................................................................................13

i) Assemble DIP 500 Unit..............................................................................................13

ii) Assemble Outrigger Arm............................................................................................15

iii) Deployment of DIP 500 .............................................................................................15

5 SKIMMING OPERATIONS...............................................................................................16

A PREPARATIONS FOR SKIMMING...............................................................................16

i) Operation...................................................................................................................16

ii) Connect applicable boom system and rigging............................................................17

iii) Hydraulic control stand ..............................................................................................17

B OPERATION OF MOVING PLAN ASSEMBLY ............................................................18

i) Running the belt.........................................................................................................18

ii) If the DIP belt becomes jammed or stops running. ....................................................18