Control 29AV-1Premium Indoor/Outdoor

Monitor Speaker

®

Key Features:

䉴Extremely smooth, flat frequency

response with extended bandwidth.

䉴110° x 85° HF coverage, rotatable horn.

䉴110 Watt transformer for 70V or 100V

lines, with 8Ωthru.

䉴SonicGuard

™

overload protection.

䉴200 mm (8⬙) Kevlar cone woofer,

25 mm (1⬙) titanium diaphragm

compression driver.

䉴Includes InvisiBall

™

mounting hardware,

plus ten 6 mm attachment points for

suspension and optional U-bracket.

䉴Sealed input panel cover and screw-

down input terminals.

The Control

®

29AV-1 provides improved

voicing for extremely flat, high fidelity

performance, extended bandwidth and

well-controlled defined coverage from a

compact loudspeaker.

The rotatable high-frequency horn

allows use of the speaker in either vertical

or horizontal orientation. Consistent

coverage ensures excellent sound

character throughout the listening area.

Moderate magnetic shielding allows use

of the speaker as close as 230 mm (9⬙) to

video monitors.

The top-quality line distribution

transformer, designed for minimal insertion

loss and reduced saturation, allows

use of either 70V or 100V distributed

speaker lines. In bypass position, the 8Ω

impedance allows use of multiple speakers

on a loudspeaker line.

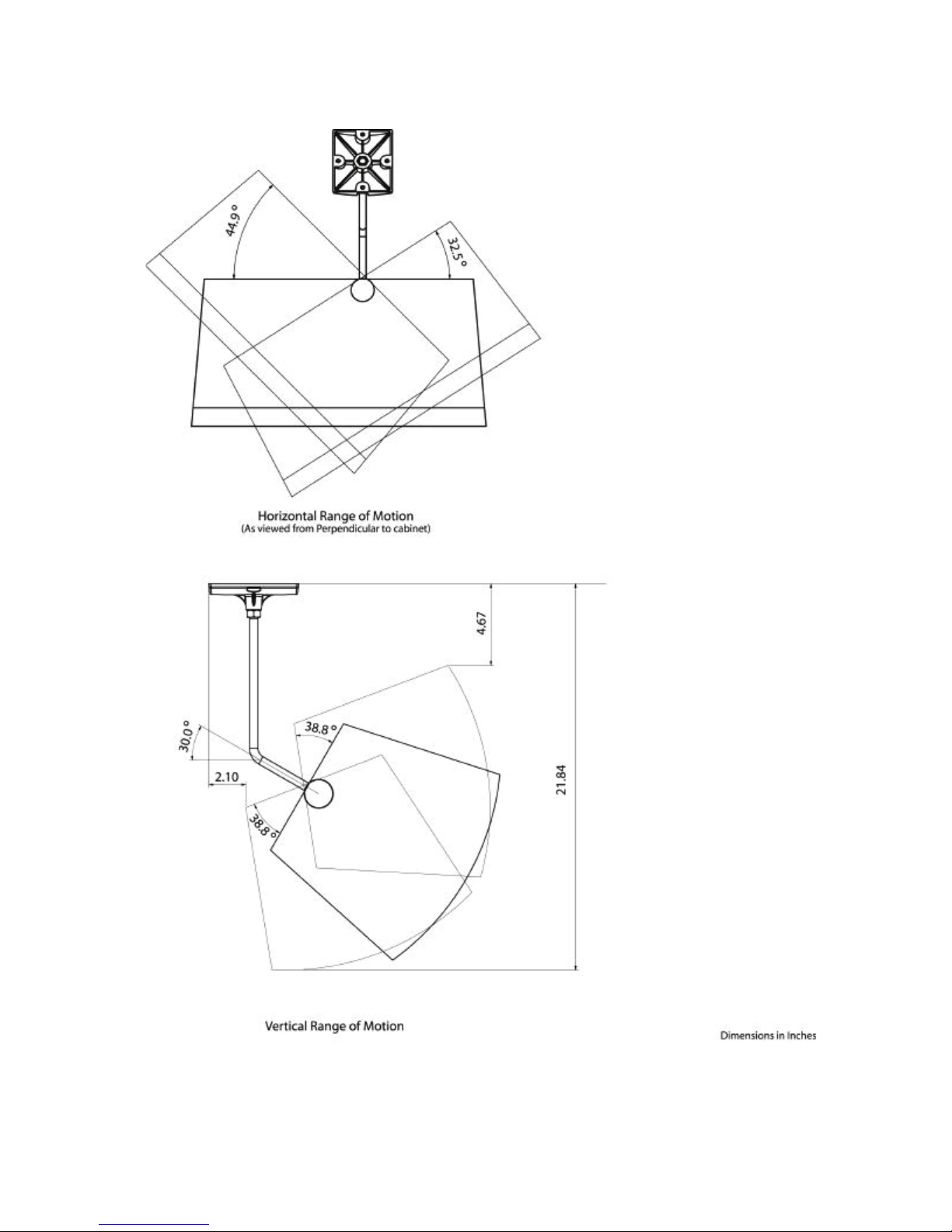

The included InvisiBall mounting

method is simple to install, aims easily and

provides a high degree of theft deterrence.

InvisiBall allows horizontal rotation of up

to 41° off-axis and vertical rotation of up

to 36° (horn end inward) or 23° (woofer

end inward). Attachment points for the

optional MTC-29UB U-bracket allows for

compact installation.

Weather resistance has been maximized.

The woofer’s cone is made of kevlar,

surround is pure butyl rubber, and the

driver basket is rear loaded to minimize

direct exposure. The compression driver’s

diaphragm is pure titanium. The grille is

thermoset composite coated and comes

with foam to minimize incursion of water.

Nickel/zinc rust-resistant terminals ensure

a secure input connection. An MTC-PC2

sealed-entrance cover is included to

further protect the speaker’s terminals.

JBL’s exclusive SonicGuard overload

protection is virtually inaudible to the

listener, ensuring reliability while

providing full fidelity sound.

Available in black or white (-WH). The

cabinet will accept a variety of paints to

match any décor.

Professional Series

Specifications:

Frequency Range (-10 dB)1: 37 Hz –18 kHz

Frequency Response (± 3 dB)1: 43 Hz – 15 kHz

100 Hr Power Capacity 2: 300 Watts Continuous Program Power

150 Watts Continuous Pink Noise

Maximum SPL @ 1m3: Short-Term: 118 dB; Long-Term: 112 dB

Nominal Sensitivity4: 90 dB, 1W @ 1 m (3.3 ft)

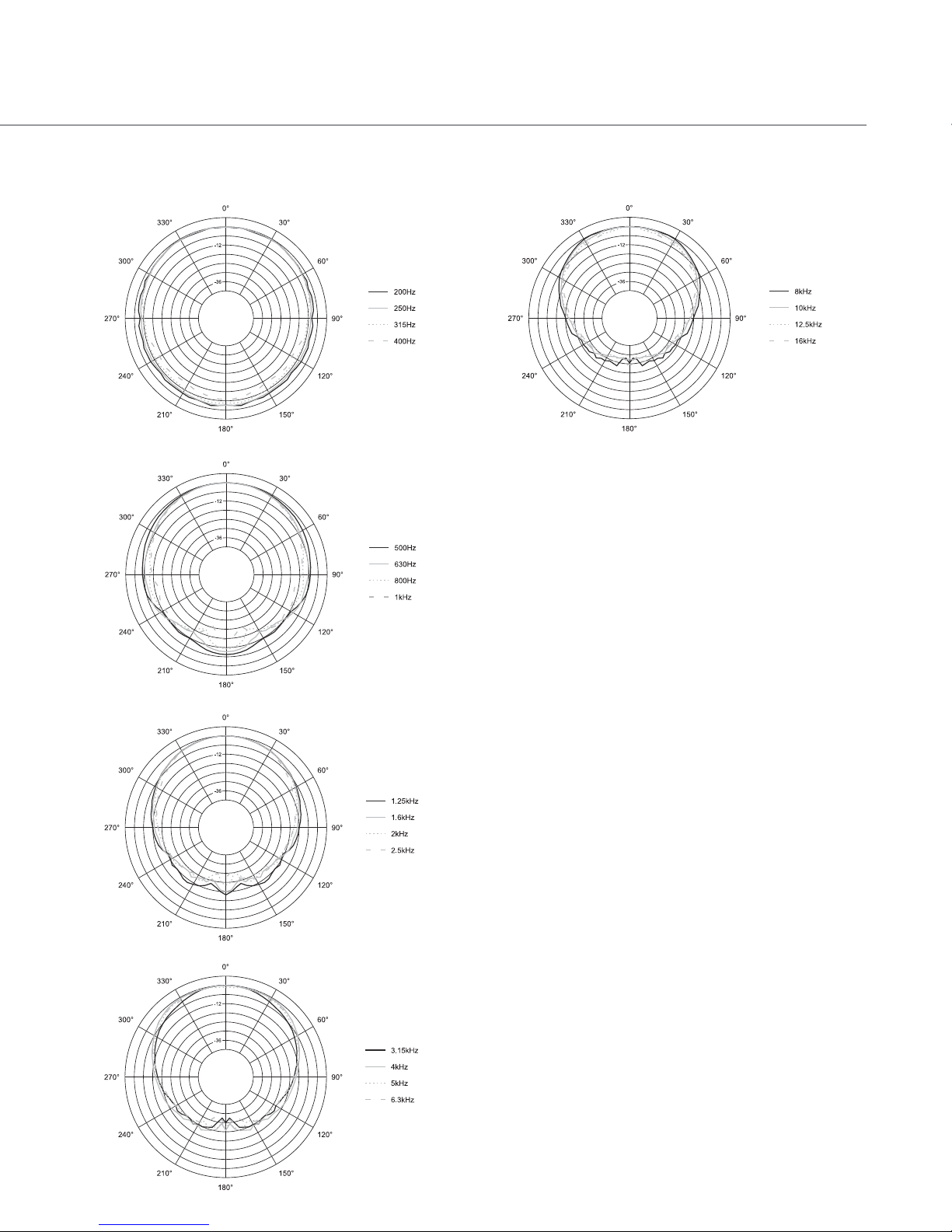

Nominal Coverage Angle5: 110° H x 85° V, rotatable

Directivity Factor (Q): 6.7, averaged 500 Hz to 16 kHz

Directivity Index (DI): 8.3 dB, averaged 500 Hz to 16 kHz

Nominal Impedance: 8 ohms

Minimum Impedance: 6.3 ohms @ 230 Hz 3.3 ohms @ 4.1 kHz

Crossover Type: 3rd order High Pass, 2nd order Low Pass with

impedance compensation, 2.5 kHz crossover

frequency

Transformer Taps: 70V: 110W, 55W, 28W & 14W

100V: 110W, 55W, & 28W

Thru Position: 8Ωnominal

Recommended High-Pass: See chart

Transducers:

Low Frequency: 200 mm (8 in) kevlar cone with pure butyl rubber

surround, 50 mm (2 in) voicecoil on fiberglass

former

High Frequency: 25 mm (1 in) compression driver, pure titanium

diaphragm with patented JBL diamond surround

Physical:

Enclosure Material: High impact polystyrene

Grille: Thermoset composite coated steel

Overload Protection: Full-range power limiting to protect network and

transducers. Serviceable internal fuse to protect

during extreme overload conditions.

Environmental: IEC 529 IP-X4 splashproof rating. Exceeds MilSpec

810 for humidity, salt spray, temperature & UV.

Passes Mil-Std-202F for salt spray.

Termination: Screw-down terminal strip, zinc plated copper

base, nickel plated metal screws/washers. Accepts

up to 9 mm outside 4 mm inside open lug (#6, #8

or #10 lug), plus bare wire (up to 12 AWG/2.5 mm

2

).

Safety Agency Rating: Transformer is listed per UL1876.

Colors: Black or white (-WH)

Dimensions (H x W x D): 520 x 306 x 277 mm (20.5 x 12.0 x 10.9 in)

Net Weight (ea): 12.2 kg (26.8 lbs)

Shipping Weight (ea): 14.0 kg (30.8 lbs)

Included Accessories: 1 pc MTC-PC2 input panel cover, InvisiBall

mounting base, 6 mm x 260 mm InvisiBall Hex

wrench.

Optional Accessories: MTC-29CM to install speaker down from the ceiling

MTC-29UB U-bracket

1In Half-space.

2 Continuous Pink Noise rating is IEC-shaped pink noise with a 6 dB crest factor for 100 hours continuously. Continuous

program power is defined as 3 dB above the Continuous Pink Noise Rating and is a conservative expression of the system’s

ability to handle normal speech and music program material.

3 Calculated from sensitivity and power handling. Power compression not considered.

4Half-space, averaged 100 Hz to 10 kHz 5 2 kHz to 14 kHz

JBL continually engages in research related to product improvements. Changes introduced into existing products without

notice are an expression of that philosophy.

72682_JBL.Ctrl29AV-1.indd 1 5/17/05 9:36:24 AM