4Please see operator manual for full details.

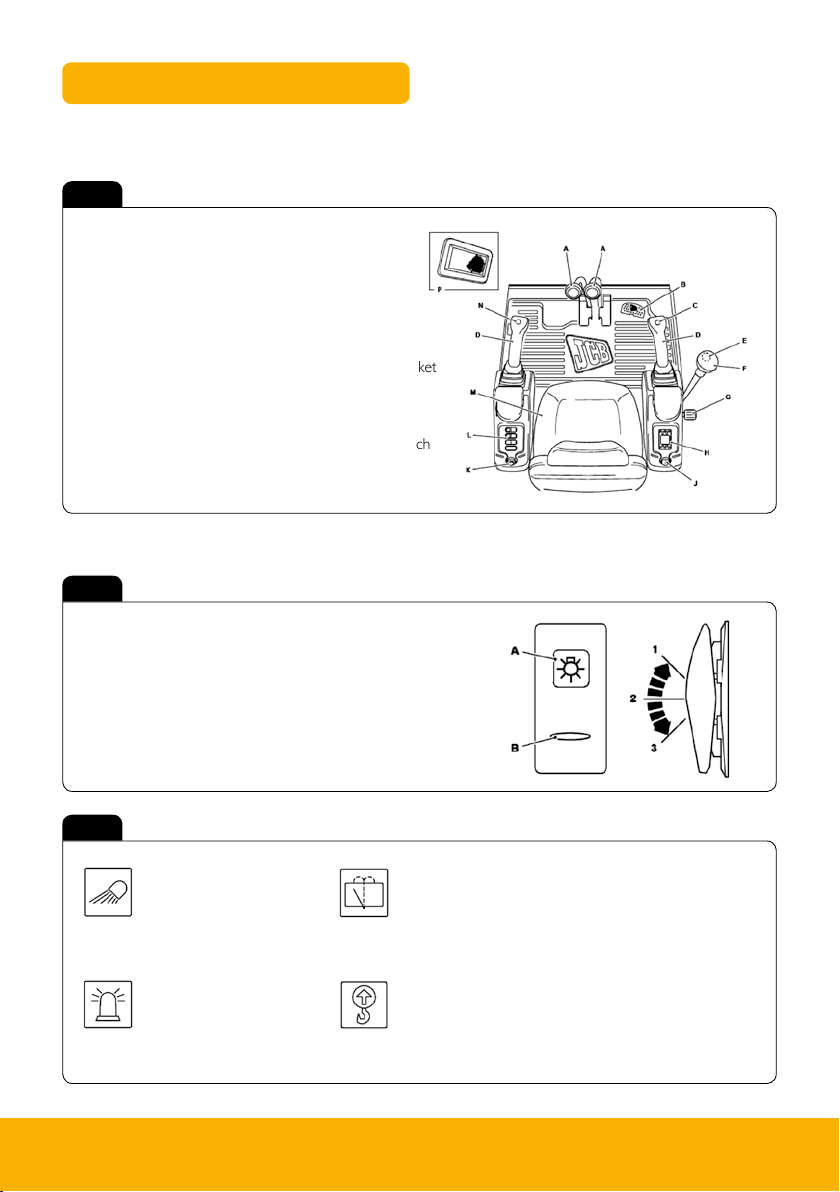

General

> Machine Type – Compact Excavator

> Self propelled machine with a tracked undercarriage

> 360° revolving upper structure with boom, dipper, bucket and slew mechanism

Intended Use

> Machine intended to be used in normal conditions as detailed in the operators manual

> With bucket fitted, machine work cycle consists of digging, elevating, slewing and discharging

of materials

> Applications include earthmoving, road construction, building and construction, landscaping etc.

> Can be used for object handling

> Not intended for use in mining and quarrying applications, demolition, forestry, any use

underground and any explosive atmospheres.

> Must not be used for forestry, used with attachments of unknown weight, used on surfaces with

unknown stability – list not exhaustive

>

PPE may be required in certain applications/environments e.g. high silica concentration or asbestos

> TThe machine should not be operated by any person without appropriate qualifications, training

or experience of using this type of machine

> Prior to use, the machines suitability should be considered with regards to the intended

applications and any hazards which may be present

Intended Use