Section 1 - General Information

1-1 1-1

9813/4700-1

Introduction

About this Manual

Machine Model and Serial Number

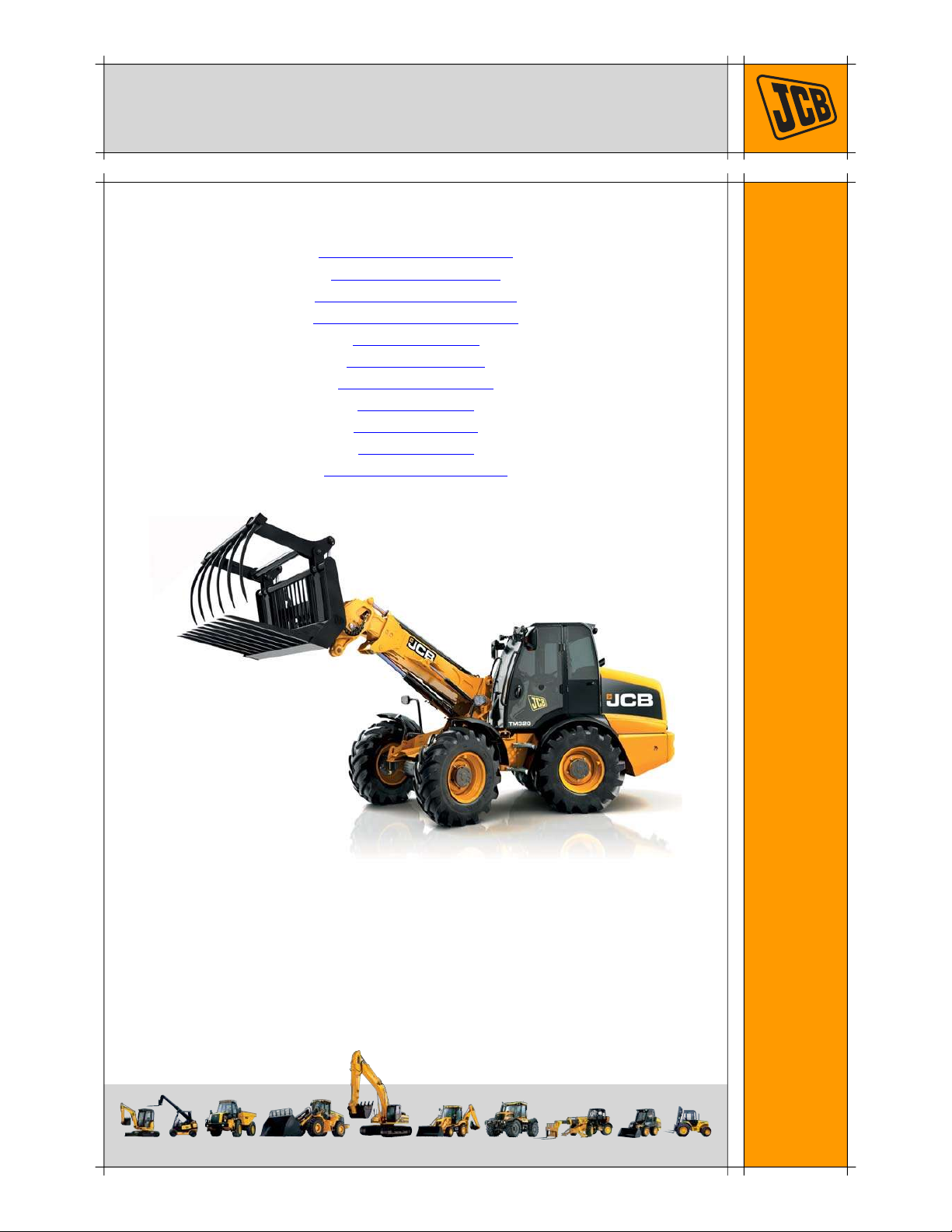

This manual provides information for the following

model(s) in the JCB machine range:

TM320 from machine serial number 2420601 to 2420800.

General

Before you start using the product, you must know how the

product operates. Use this part of the manual to identify

each control lever, switch, gauge, button and pedal. Do not

guess, if there is anything you do not understand, ask your

JCB dealer.

Name and Address of the Manufacturer

JCB Excavators Limited, Lakeside Works, Rocester,

Uttoxeter, United Kingdom, ST145JP.

Using this Manual

T1-044

This manual is arranged to give you a good understanding

of the machine and its safe operation. It also contains

maintenance information and specification data. Read this

manual from front to back before using the machine for the

first time. Particular attention must be given to all the safety

aspects of operating and maintaining the machine.

If there is anything you are not sure about, ask your JCB

distributor or employer. Do not guess, you or others could

be killed or seriously injured.

General warnings in this chapter are repeated throughout

the book, as well as specific warnings. Read all the safety

statements regularly, so you do not forget them.

Remember that the best operators are the safest

operators.

The illustrations in this manual are for guidance only.

Where the machines differ, the text and or the illustration

will specify.

This manual contains original instructions, verified by the

manufacturer (or their authorised representative).

The manufacturer's policy is one of continuous

improvement. The right to change the specification of the

machine without notice is reserved. No responsibility will

be accepted for discrepancies which may occur between

specifications of the machine and the descriptions

contained in this publication.

All optional equipment included in this manual may not be

available in all territories.

Left Side, Right Side

In this manual, 'left' A and 'right' B mean your left and right

when you are seated correctly in the machine.

C087420

Fig 1.

Cross References

T1-004_2

In this publication, page cross references are made by

presenting the subject title printed in bold, italic and

underlined. It is preceeded by the 'go to' symbol. The

number of the page upon which the subject begins, is

indicated within the brackets. For example: Cross

References ( 1-1).

Product Compliance

T1-055

Your JCB machine was designed to comply with the laws

and regulations applicable at the time of its manufacture

for the market in which it was first sold. In many markets,

laws and regulations exist that require the owner to

maintain the machine at a level of compliance relevant to

the machine when first produced. Even in the absence of

defined requirements for the machine owner, JCB