2-2

Before Entering the Cab

The following checks should be made each time you return

to the machine after leaving it for any period of time. We

advise you also to stop the machine occasionally during

long work sessions and do the checks again. All these

checks concern the serviceability of the machine. Some

concern your safety. Get your service engineer to check and

correct any defects.

!WARNING

Walking or working under a raised boom and dipper is

hazardous. You could be crushed by the boom and

dipper or get caught in the linkages. Lower the boom

and dipper before doing these checks. If you are new to

this machine, get an experienced operator to lower the

boom and dipper for you.

If there is nobody to help you, study this handbook until

you have learned how to lower the boom and dipper.

8-2-1-1

!CAUTION

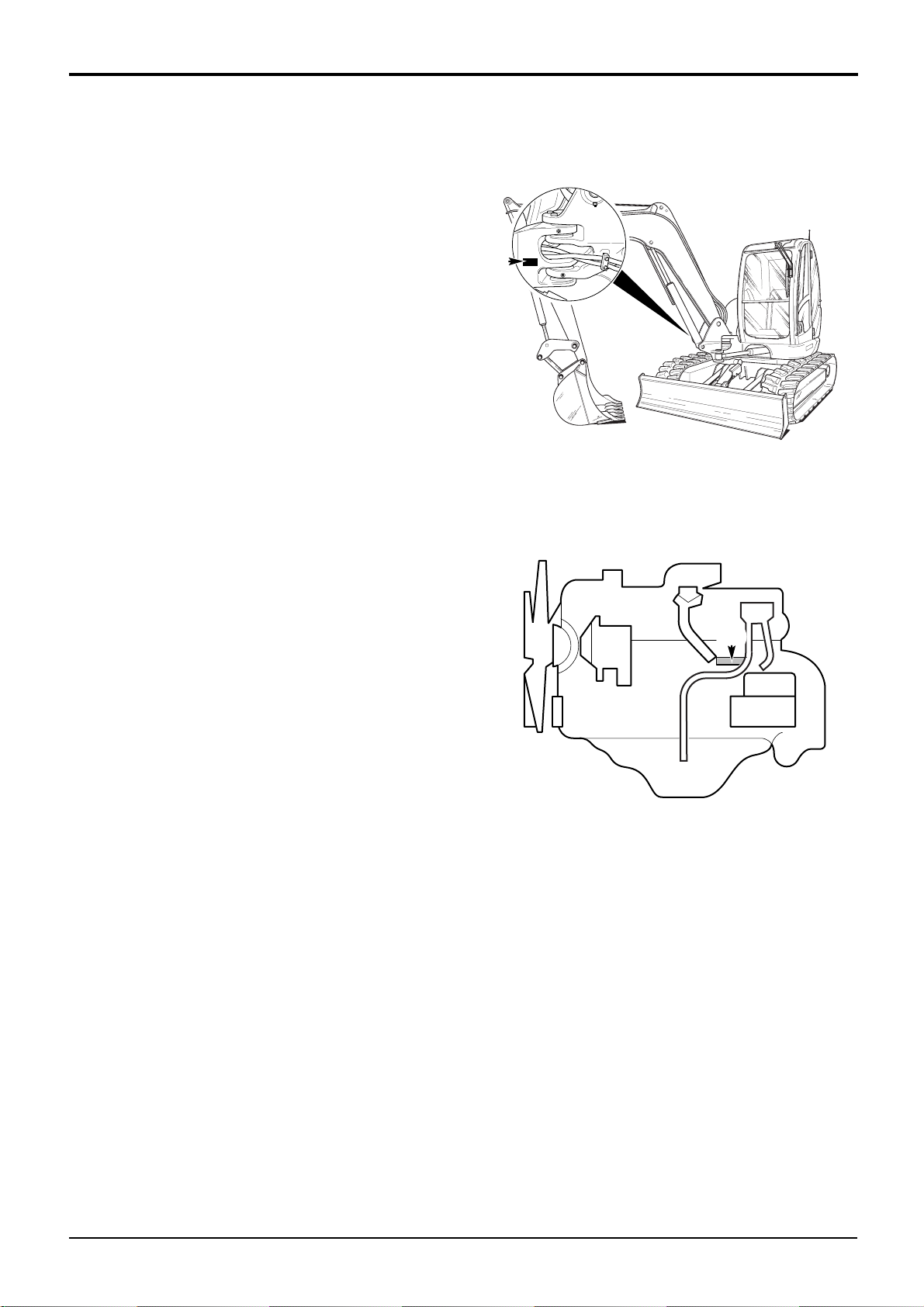

On machines fitted with hose burst protection valves, the

attachments cannot be lowered with the engine stopped.

On these machines start the engine and lower the

attachments before doing the walk round inspection.

2-2-3-5

!CAUTION

The hydraulic oil filler cap may be hot if the machine has

recently been used. If this is the case, wear suitable

gloves when tightening or loosening this cap.

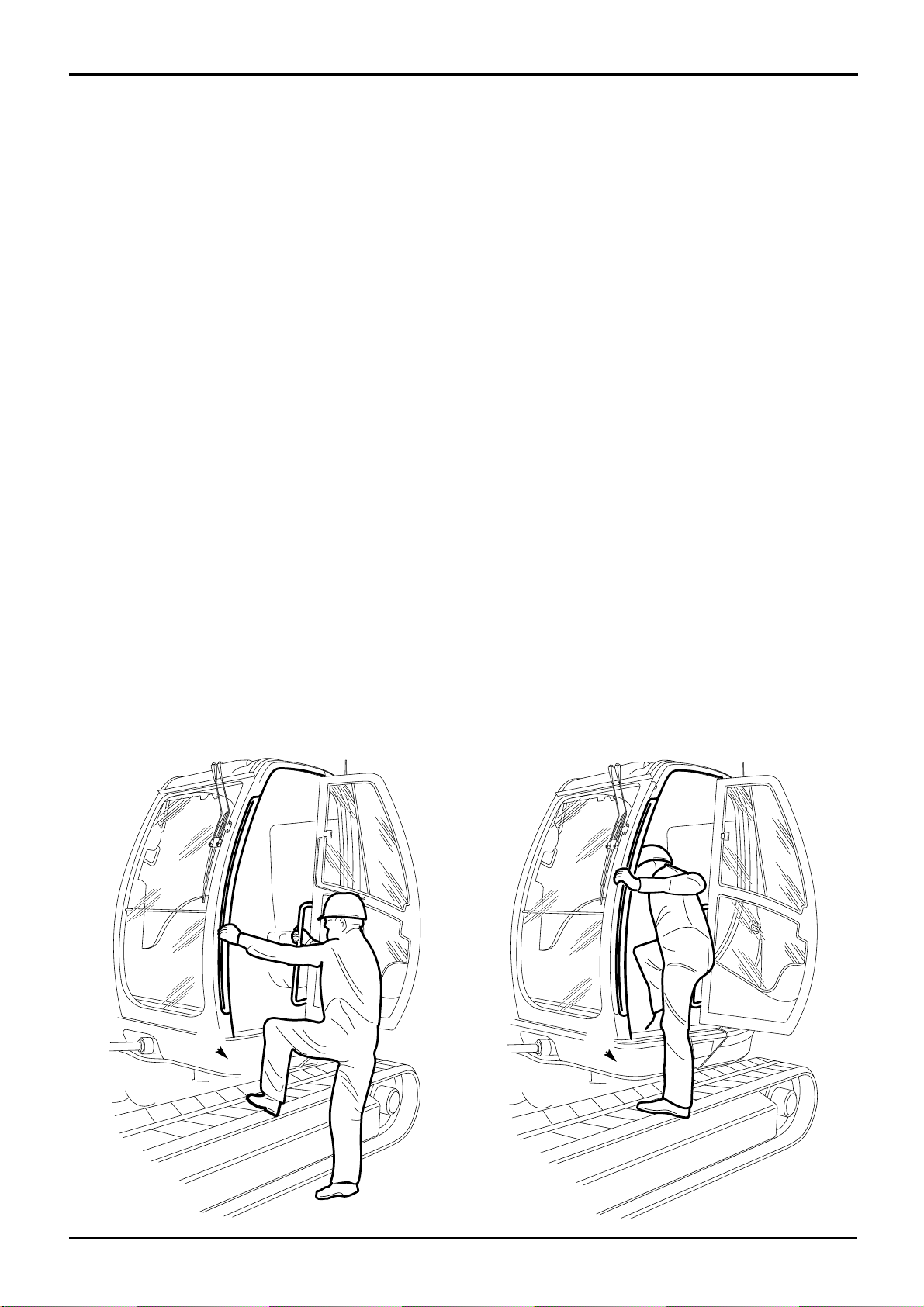

1 Check for Cleanliness

aClean the windows, light lenses and rear view

mirrors.

bRemove dirt and debris, especially from around the

linkages, rams, pivot pins and radiator grille.

cMake sure the cab step and handholds are clean

and dry.

dClean all safety decals. Replace any that are missing

or cannot be read.

2 Check for Damage

aInspect the machine generally for damaged and

missing parts.

bMake sure that all pivot pins are secured in place.

cInspect the windows for cracks and other damage.

dCheck for oil, fuel and coolant leakages beneath the

machine.

eCheck the tracks (rubber). Check for cut rubber and

penetration by sharp objects. Do not use a machine

with damaged tracks.

3 Check for Security

aCheck the security of the hinged covers on the

engine compartment and hydraulic compartment.

bMake sure that the hydraulic oil and diesel fuel filler

caps are both tightly closed. REMEMBER THAT THE

HYDRAULIC FILLER CAP MAY BE HOT IF THE

MACHINE HAS RECENTLY BEEN USED. (We also

recommend that you lock the fuel filler cap.)

Section 1 General Information

9803/9330

Section 1

2-2

Issue 1

Operation