9803/6020 Issue 1

Introduction

This publication is designed for the benefit of JCB Distributor Service Engineers who are receiving, or have received, training

by JCB Technical Training Department.

These personnel should have a sound knowledge of workshop practice, safety procedures, and general techniques associated

with the maintenance and repair of hydraulic earthmoving equipment.

Renewal of oil seals, gaskets, etc., and any component showing obvious signs of wear or damage is expected as a matter of

course. It is expected that components will be cleaned and lubricated where appropriate, and that any opened hose or pipe

connections will be blanked to prevent excessive loss of hydraulic fluid and ingress of dirt. Finally, please remember above all

else SAFETY MUST COME FIRST!

The manual is compiled in sections, the first three are numbered and contain information as follows:

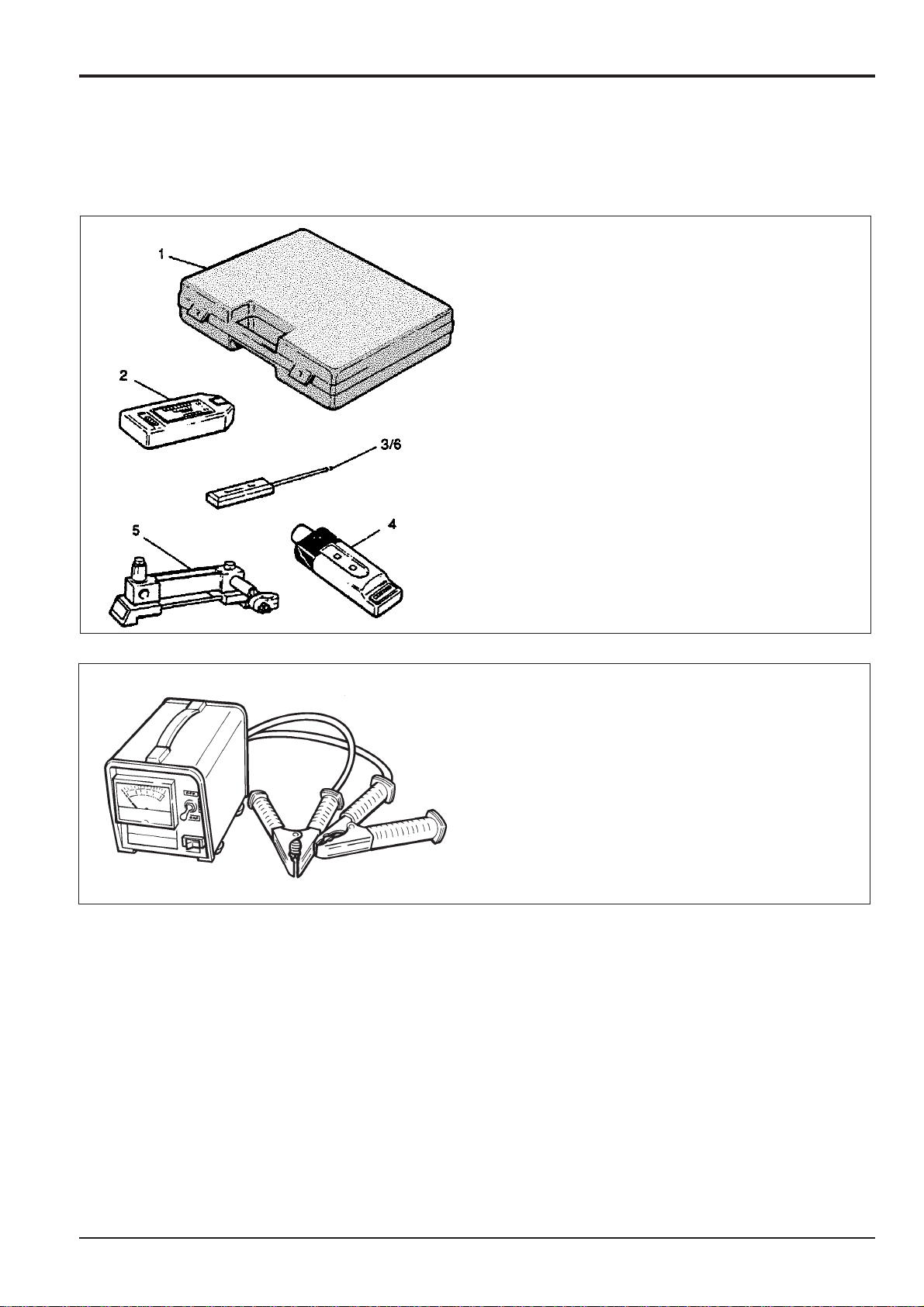

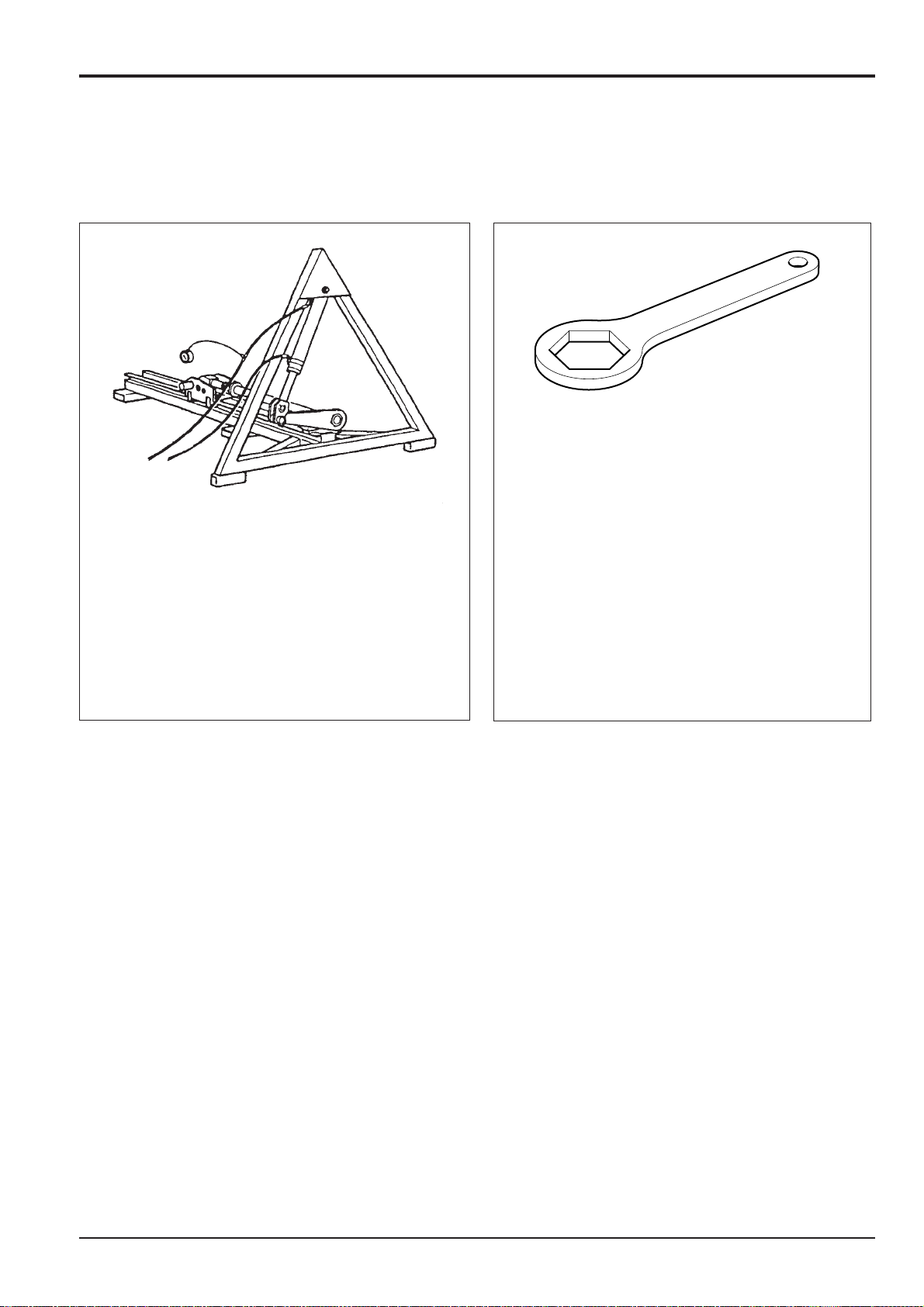

1 = General Information - includes torque settings and service tools.

2 = Care & Safety - includes warnings and cautions pertinent to aspects of workshop procedures etc.

3 = Routine Maintenance - includes service schedules and recommended lubricants for the whole machine.

The remaining sections are alphabetically coded and deal with Dismantling, Overhaul etc. of specific components, for

example:

A = Attachments

B = Body & Framework ...etc

The page numbering in each alphabetically coded section is not continuous. This allows for the insertion of new items in later

issues of the manual.

Section contents, technical data, circuit descriptions, operation descriptions etc. are inserted at the beginning of each

alphabetically coded section.

All sections are listed on the front cover; tabbed divider cards align directly with individual sections on the front cover for rapid

reference.

Where a torque setting is given as a single figure it may be varied by plus or minus 3%. Torque figures indicated are for dry

threads, hence for lubricated threads may be reduced by one third.

‘Left Hand’ and ‘Right Hand’ are as viewed from the rear of the machine facing forwards.

Note: In this manual the term ‘swing’ may sometimes be used in place of ‘slew’ and the term ‘arm’ may sometimes be used in

place of ‘dipper’.