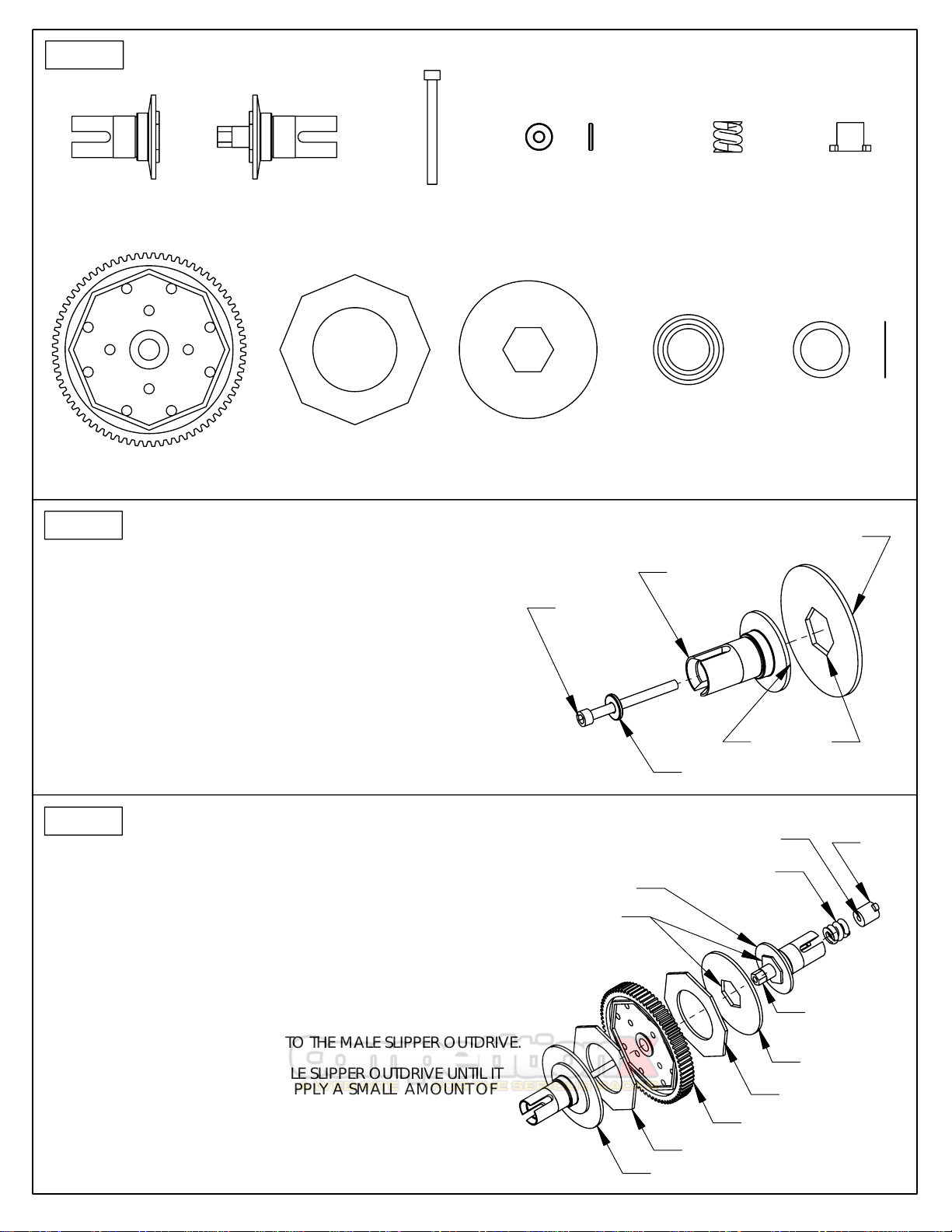

1. TRIM ANY BURRS FROM THE INSIDE OF THE GEAR WITH A HOBBY KNIFE.

2. ADD A GENEROUS AMOUNT OF STEATLH DIFF LUBE TO THE RING GEAR

BALL HOLES AND PUSH IN THE TWELVE 3/32 DIFF BALLS. THEN PUSH IN

THE LUBE THAT CAME OUT.

TRIM ANY BURRS FROM THE INSIDE

OF THE GEAR WITH A HOBBY KNIFE

STEALTH DIFF LUBE

AFTER APPLYING THE STEALTH DIFF LUBE,

SNAP THE 3/32 DIFF BALLS IN PLACE

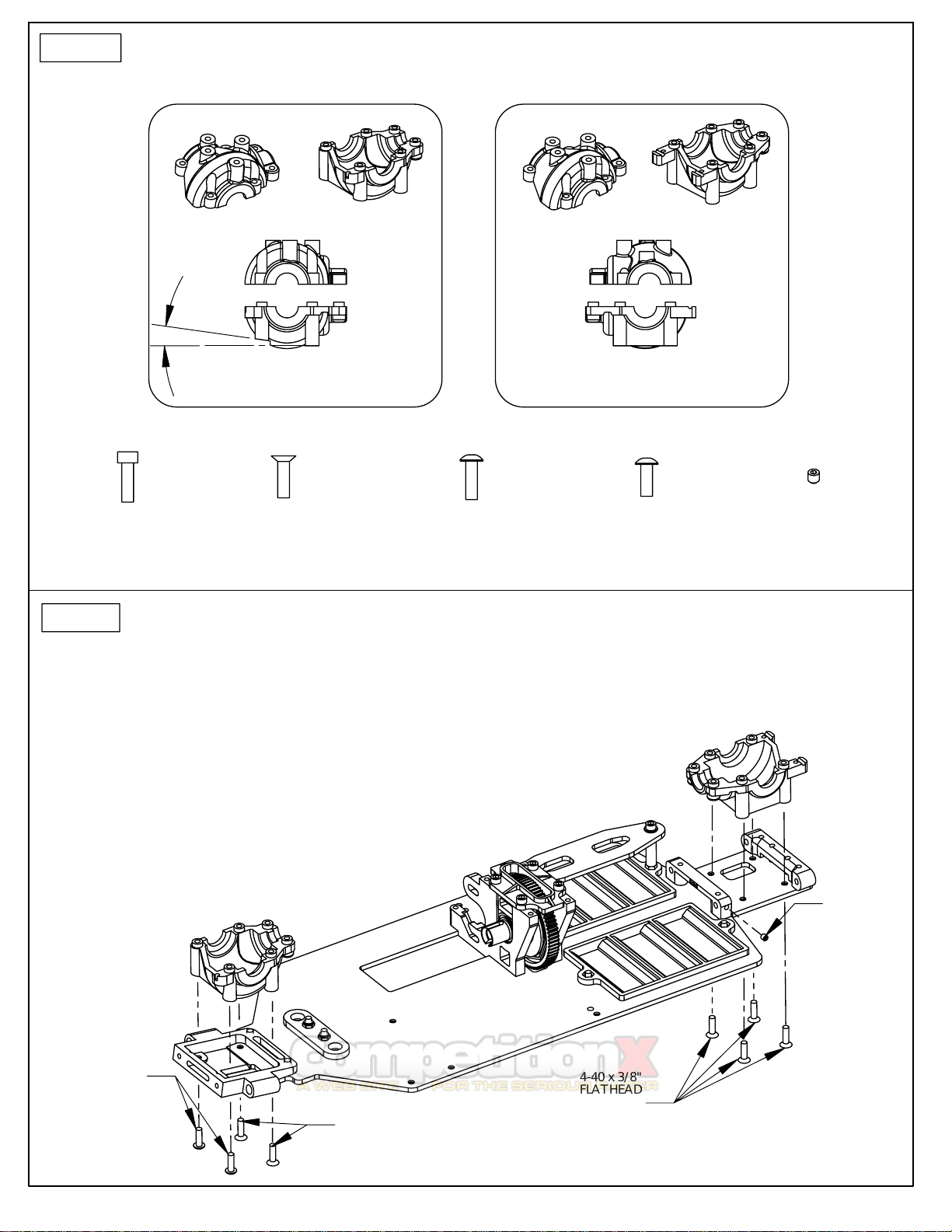

SHORT HUB ASSEMBLY

LONG HUB ASSEMBLY:

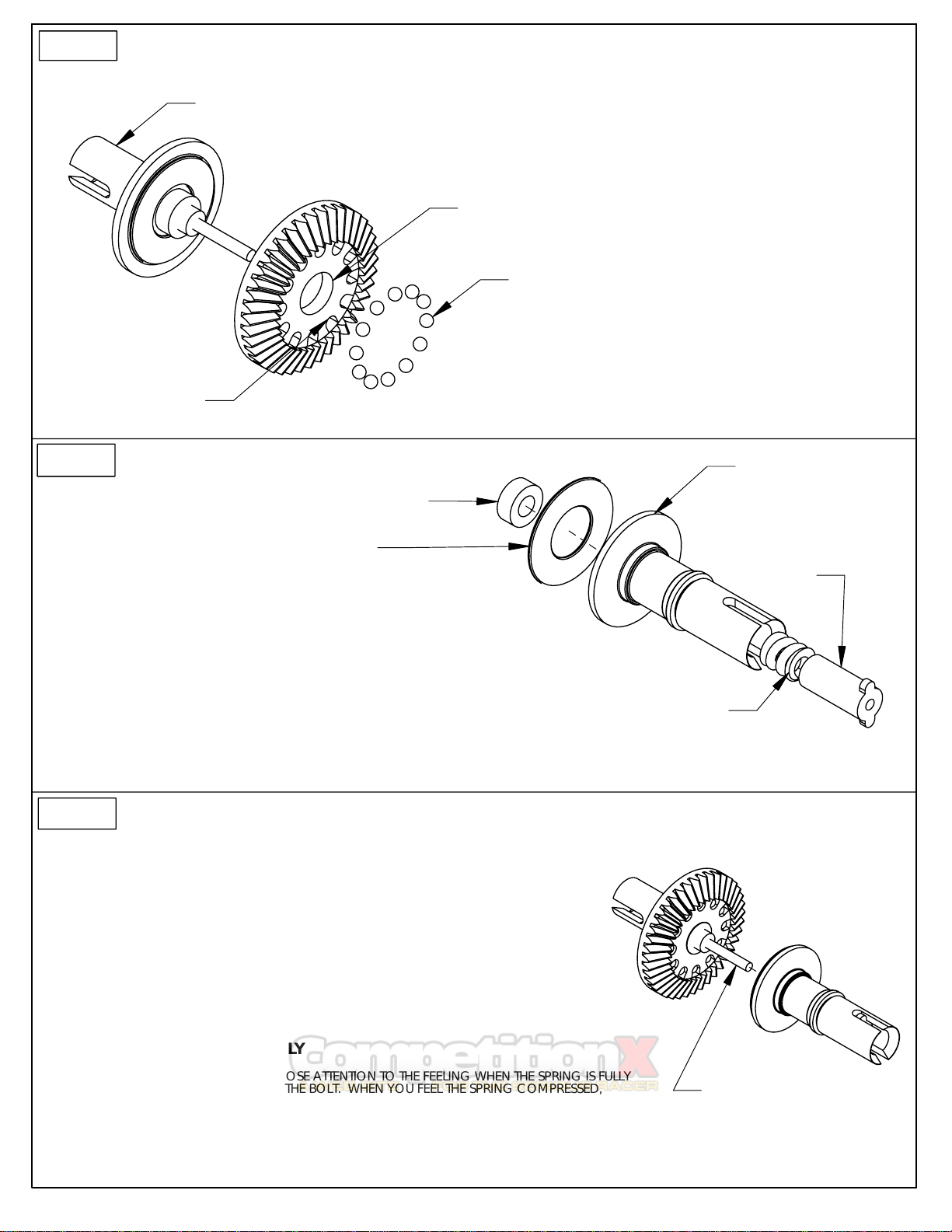

1. INSERT THE DIFF SPRING INTO THE LONG OUTDRIVE HUB.

2. INSERT THE T-NUT INTO THE LONG HUB UNTIL IT TOUCHES

THE DIFF SPRING.

3. ADD A LIGHT COAT OF STEALTH LUBE TO THE LONG HUB FACE.

4. PLACE A DIFF DRIVE RING ONTO THE FACE OF THE LONG HUB.

5. INSERT THE 3/16 x 5/16 DIFF BEARING INTO THE LONG HUB. NOTE: REMOVE ANY OIL RESIDUE FROM OUTDRIVE

HUB THOROUGHLY BEFORE APPLYING STEALTH LUBE.

3/16 x 5/16 DIFF BEARING

DIFF DRIVE RING

LONG OUTDRIVE HUB

DIFF SPRING

T-NUT

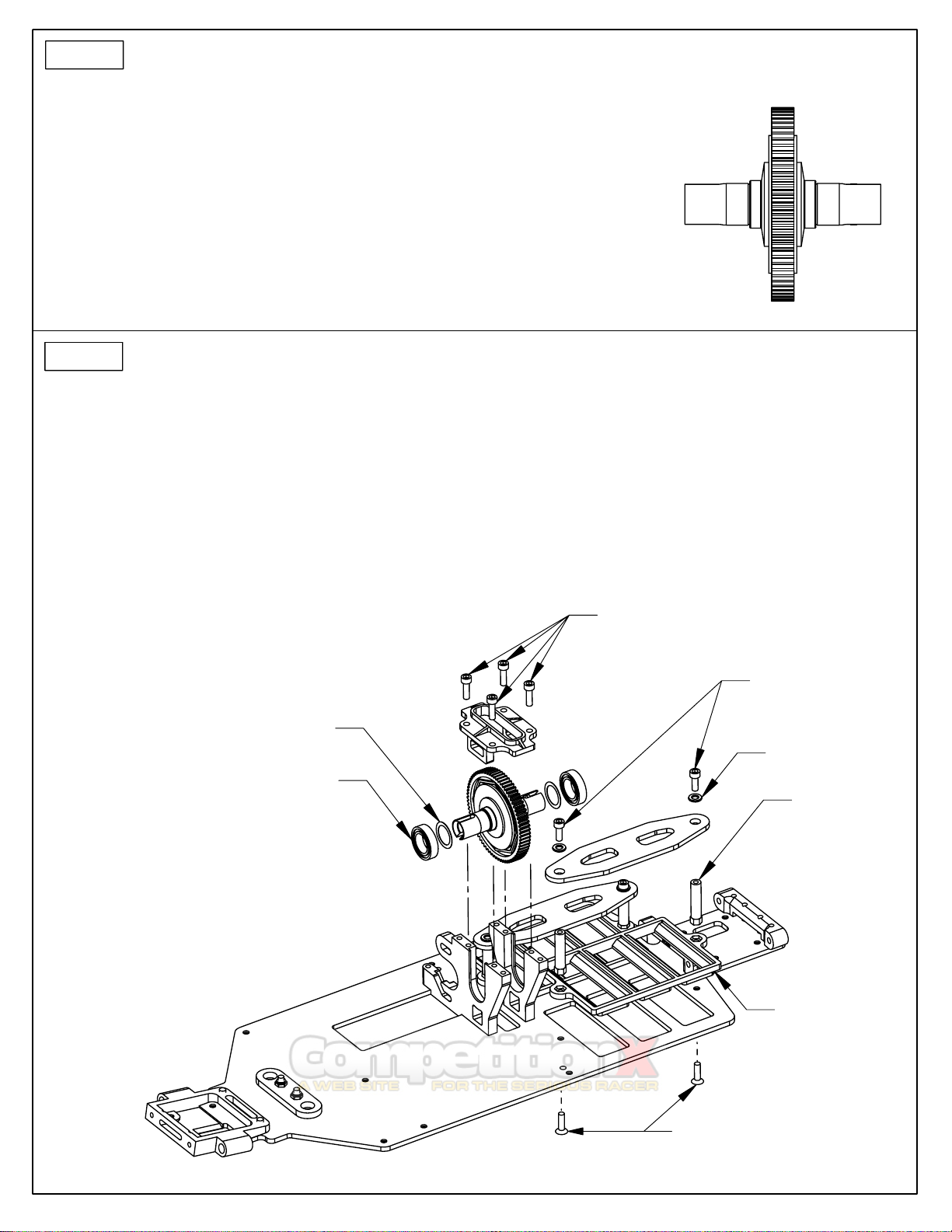

DIFF ASSEMBLY:

1. INSERT THE LONG HUB ASSEMBLY INTO THE SHORT HUB ASSEMBLY,

MAKING SURE YOU LINE UP THE BOLT IN THE HUB AND THE BOLT

THREADS INTO THE T-NUT.

CHECK ALIGNMENT OF THE HUBS

2. TIGHTEN THE DIFF WITH YOUR 5/64" ALLEN WRENCH, BUT NOT COMPLETELY.

3. SCREW IN THE DIFF BOLT A FEW TURNS THEN STOP TO ROTATE THE DIFF HUBS

IN OPPOSITE DIRECTIONS. THEN SCREW IN THE BOLT SOME MORE. FOLLOW

THIS PROCEDURE TO CHECK PROPER ALIGNMENT OF THE PARTS. THE

FOLLOWING NOTE CLARIFIES THIS.

READ THE FOLLOWING CAREFULLY

AS YOU TIGHTEN THE DIFF BOLT, PAY CLOSE ATTENTION TO THE FEELING WHEN THE SPRING IS FULLY

COMPRESSED. DO NOT OVERTIGHTEN THE BOLT. WHEN YOU FEEL THE SPRING COMPRESSED,

LOOSEN THE DIFF BOLT 1/4 TURN. NO MORE, NO LESS. AFTER YOU HAVE DRIVEN THE CAR FOR ONE

BATTERY PACK, RECHECK THE DIFF ADJUSTMENT AS ABOVE SO THAT WHEN YOU FEEL THE SPRING

FULLY COMPRESSED, LOOSEN THE DIFF BOLT 1/4 TURN. NEVER ADJUST THE DIFF ANY OTHER WAY.

NOW ASSEMBLE THE SECOND DIFF THE SAME WAY

TIGHTEN USING 5/64" ALLEN WRENCH

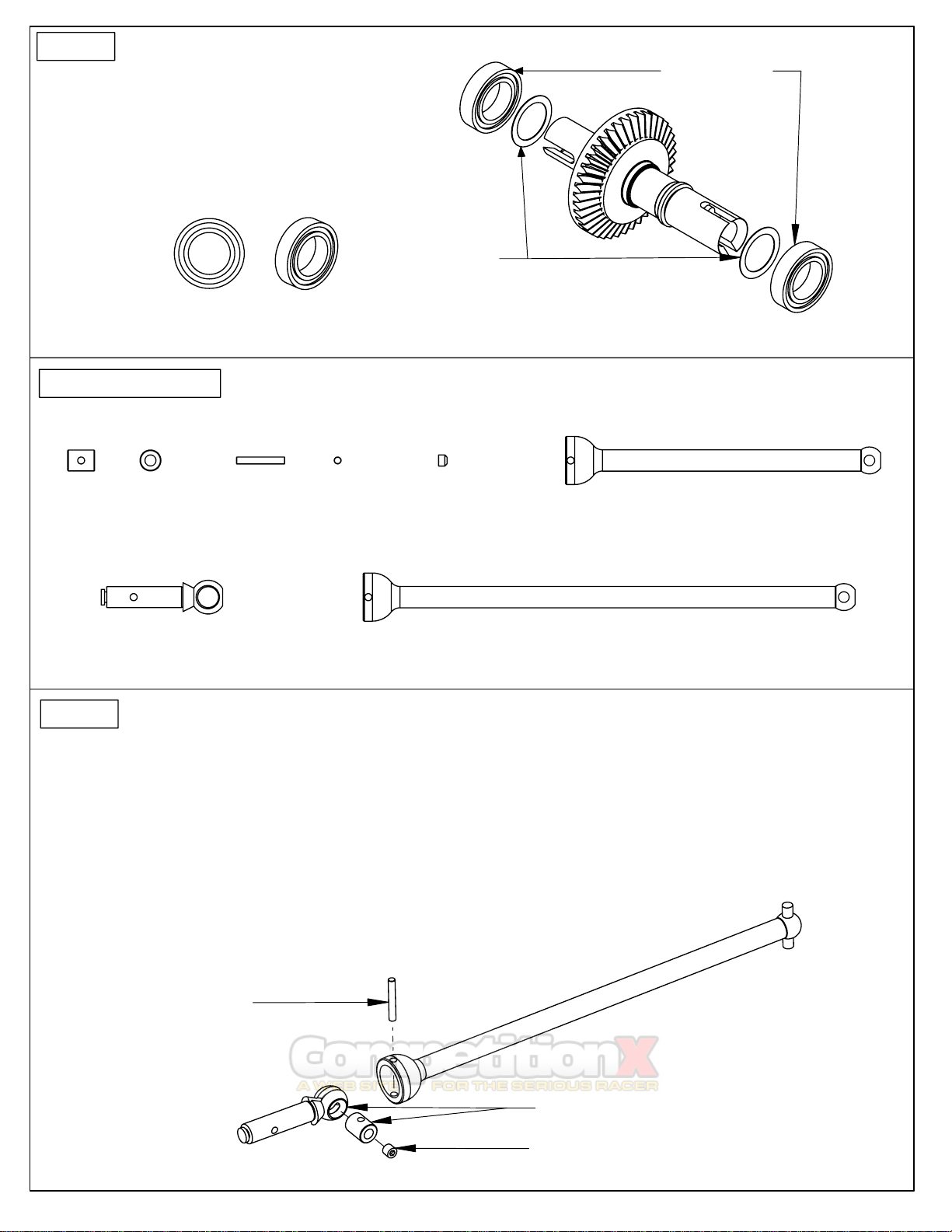

DIFFERENTIAL RING GEAR:

STEP 3

STEP 4

STEP 5

PAGE 6