Jefferson Solenoid Valves U.S.A. Inc. Z1314BV**AT Z1314BLV24AT Instruction Manual

Popular Control Unit manuals by other brands

Pfeiffer

Pfeiffer TC 110 operating instructions

Ebyte

Ebyte E104-BT51 user manual

HAUTAU

HAUTAU LSF 24 operating instructions

Georg Fischer Piping Systems

Georg Fischer Piping Systems CONTAIN-IT Plus instruction manual

SSS Siedle

SSS Siedle Vario Product information

Honeywell

Honeywell NOTIFIER M701E installation instructions

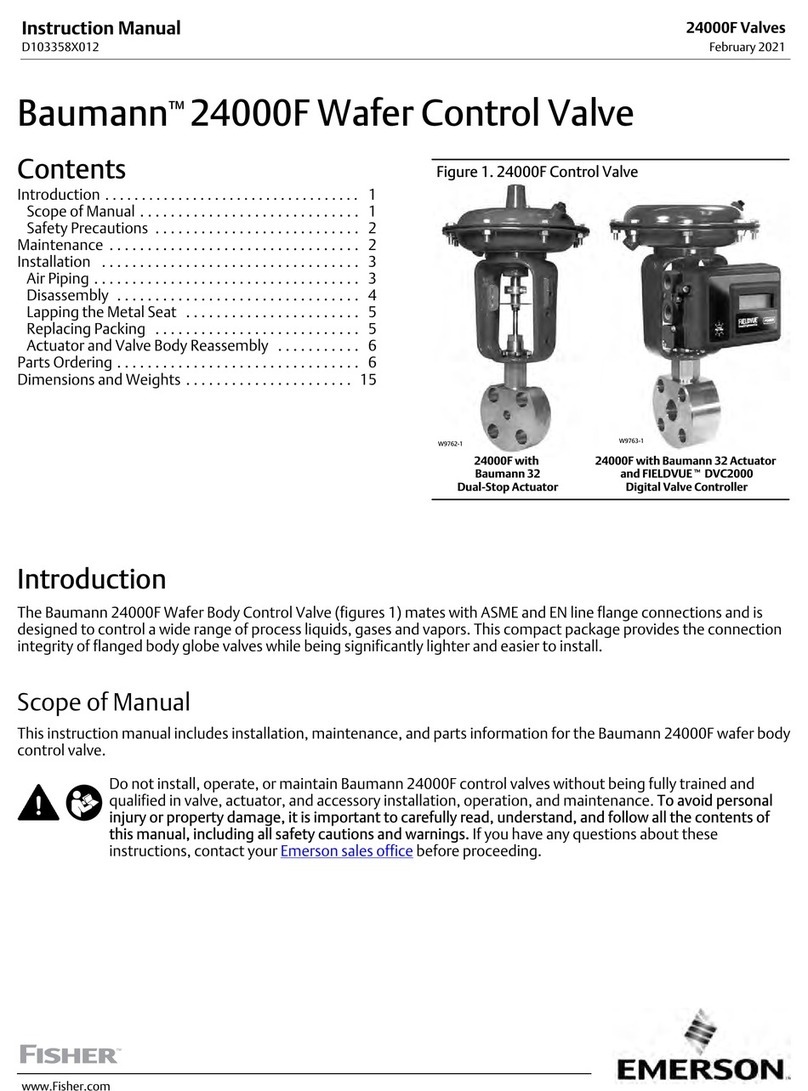

Emerson

Emerson Fisher Baumann 24000F instruction manual

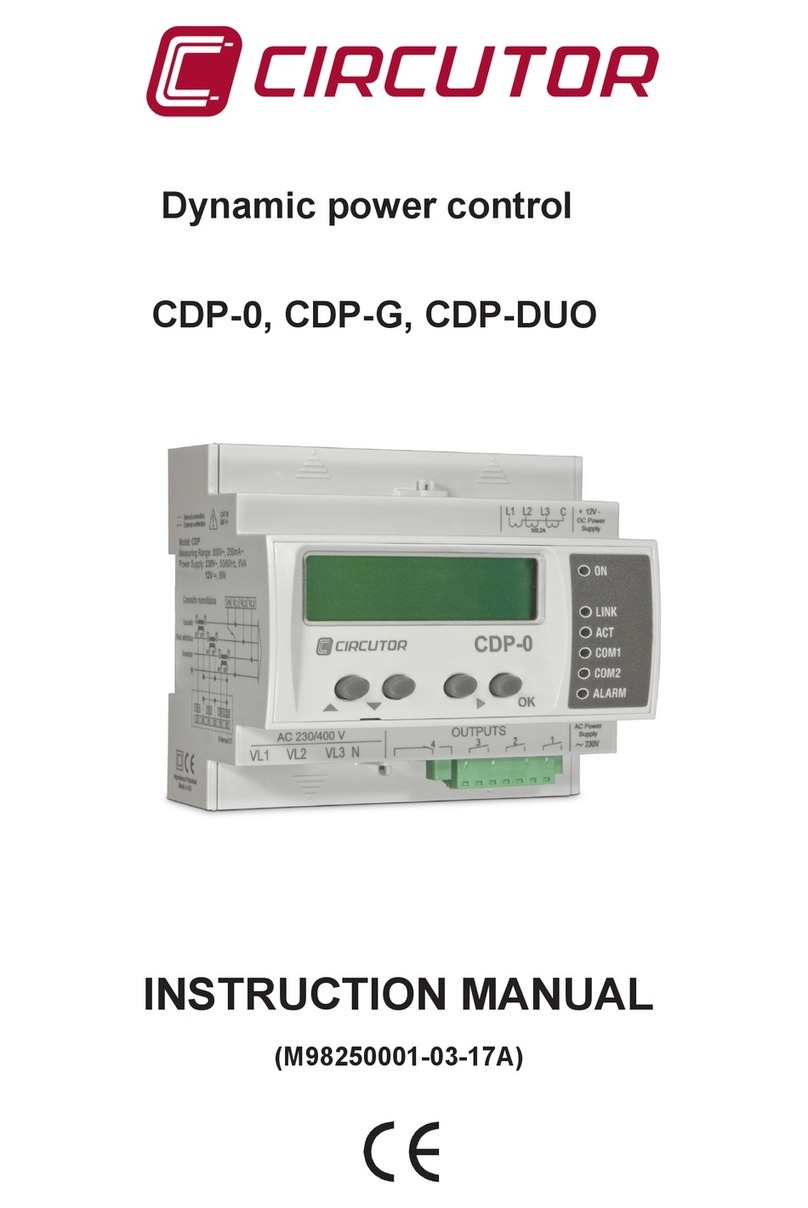

Circutor

Circutor CDP-0 instruction manual

Hydropa

Hydropa DS-11 Series operating manual

Texas Instruments

Texas Instruments TLVM13660 user guide

Greenheck

Greenheck KFCC Installation, operation and maintenance manual

Grundfos

Grundfos CU 321 Installation and operating instructions