Jefferson JEFBG6 User manual

User Manual

v.1.1

JEFBG6 • JEFBG8

BENCH GRINDER

INDUSTRIAL

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com

2

CONTENTS

Specications 2

Safety Guidelines 3

Operation Guide 4

Maintenance 5

Troubleshooting 5

Environmental Protection 6

WEEE Waste Electrical and Electronic Equipment Statement 6

EC Declaration of Conformity 7

Parts List & Diagram - Main Assembly 8

Limited Warranty Statement 10

SPECIFICATIONS

JEFBG6 JEFBG8

Size 6" 8"

Input Voltage ~ Frequency: 230V ~ 50Hz 230V ~ 50Hz

Motor Output: 600W 800W

Grinding Wheel: 150 x 25 x 32mm 200 x 32 x 32mm

Speed: 2950rpm 2950rpm

Rated Working Time: 30mins 30mins

Weight: 16.5kg 26.5kg

Important: Please read all these instructions before operating this product and save these instructions. This manual has been compiled by

Jefferson Tools and is an integrated part of the product with which it's enclosed and should be kept with it for the future reference.

This manual describes the purpose for which the product has been designed and contains all the necessary information to ensure its correct and

safe use. We recommend that this manual is read before any operation or, before performing any kind of adjustment to the product and prior to any

maintenance tasks. By following all the general safety instructions contained in this manual you will help to ensure operator safety and extend the

potential lifespan of the equipment.

All photographs and drawings in this manual are supplied by Jefferson Tools to help illustrate the operation of the product. Whilst every effort

has been made to ensure accuracy of information contained in this manual our policy of continuous improvement determines the right to make

modifications without prior warning.

Note: The information contained in this Instruction Manual is designed to assist you in the safe operation and maintenance of the equipment.

Some illustrations in this Instruction Manual may show details or attachments that differ from those on your own equipment. Contact your nearest

Jefferson Dealer if you are unsure about any information included in this manual or require any additional information about the safe use, operation

maintenance, or repair of this equipment.

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com 3

Read and ensure that you understand all of the operating instructions, safety precautions and warnings in this Instruction Manual before

operating or maintaining this equipment. An accident can often be avoided by recognizing a potentially hazardous situation before it

occurs, and by observing appropriate safety procedures. Hazards that must be avoided to prevent bodily injury or machine damage are

identied by warnings on the equipment and in this Instruction Manual. Never use this equipment or modify it in any way that has not been

specically recommended by the manufacturer. Contact a qualied electrician for advice on any issues relating to electrical safety in your

working environment.

ELECTRICAL SAFETY

Ensure that you check the equipment thoroughly to ensure it is safe and t for purpose before each use. It is important that

you inspect all plugs, sockets, power cables and electrical ttings for wear and damage and repair or replace any defective

components. The risk of electric shock can be minimised by the correct use of the appropriate electrical safety devices.

• We recommend that you use an RCD (Residual Current Device) when connecting this equipment.

• This equipment must be stored and maintained as instructed and kept in safe working condition and routinely PAT (Portable Appliance Test)

tested to ensure safe electrical connection.

• Ensure that the insulation on all cables and on the appliance is safe before connecting it to

the power supply.

• Ensure that the voltage rating on the appliance suits the power supply to be used and that

the plug is wired correctly and tted with a 13A fuse as shown in Fig.1.

• Never pull or carry the appliance by the power cable.

• Never pull the plug from the socket by the cable.

• Never use worn or damaged cables, plugs or connectors. Ensure that any faulty, worn, or damaged

components are repaired or replaced immediately by a qualied electrician.

• Replace a damaged plug with a BS1363/A 13 Amp 3-pin plug and wired as shown in Fig.1.

a) Connect the Green & yellow earth wire to the earth terminal ‘E’.

b) Connect the Brown live wire to the live terminal ‘L’.

c) Connect the Blue neutral wire to the neutral terminal ‘N’.

• Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

EQUIPMENT SAFETY

Warning: Ensure that the grinder is disconnected from the mains power, and ensure the grinding wheels are at a standstill before attempting to

change accessories, service or carry out any maintenance on this equipment.

• Ensure that the equipment is kept in good condition and check moving parts alignment regularly.

• Replace or repair damaged parts before use. Contact your Jefferson dealer for advice on repair or replacement parts. Use recommended

parts only. Non-approved parts may be dangerous and will invalidate the warranty.

• Never use a damaged grinding stone as it is dangerous and may cause damage or serious personal injury.

• Only persons qualied under the “Abrasive Wheels Regulations” and holding a current grinding wheel certicate are to change or dress

grinding stones.

• Keep all guards and holding screws in place, tight and in good working order. Check regularly for damaged parts.

• A guard or any other part that is damaged should be repaired or replaced before tool is used.

• Important: The safety guard supplied with this equipment is a mandatory tting where the grinder is used in premises covered by the Health

& Safety at Work Act.

• Only use this equipment in a suitable working environment that is clean, tidy and free from clutter. Ensure adequate lighting is available for

safe use.

• Before each use check grinding wheel for condition. If worn or damaged replace immediately.

• Always wear approved eye or face protection when operating the grinder and ear defenders as required.

• Use breathing protection in accordance with COSHH regulations if fumes or dust pose a hazard.

• Keep hands and body clear of the work piece when operating the grinder.

• Maintain correct balance and footing. Ensure the oor is not slippery and wear non-slip shoes.

• Remove ill tting clothing. Remove ties, watches, rings, and other loose jewellery, and contain and/ or tie back long hair.

• Keep children and unauthorised persons away from the working area.

• Never use the grinder to achieve a task it was not designed to perform or modify or adapt it for any other use.

SAFETY GUIDELINES

Fig.1

Cable Grip

Neutral

Wire

(Blue)

Earth

Wire

(Brown)

Earth Wire

(Yellow

& Green) 13 Amp

Fuse

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com

4

• Never place your hands, ngers or other body parts near the moving parts during operation. Ensure that the equipment is isolated from the

power supply and all switches in the OFF position before carrying out maintenance, repairs or adjustments.

• Never operate this equipment without all guards or safety features in place and in proper working order. If maintenance or servicing requires

the removal of a guard or safety features, be sure to replace the guards or safety features before resuming operation.

• When not in use, the grinder should be stored in dry place. Keep out of reach of children. Keep children and animals away from the work

area.

• Clear all work areas of unnecessary tools, debris, furniture etc. prior to use. Cluttered work areas can lead to injuries.

• Do not wear loose clothing or jewellery when operating this equipment. They can be caught in moving parts. Wear protective hair covering to

contain long hair.

• Do not operate this equipment when you are tired or if you are under the inuence of alcohol, drugs or medication that makes you drowsy.

• Keep all screws, bolts, and plates tightly mounted. Check regularly.

• Always contact an authorized service centre for advice on any repairs. Unauthorized modication may not only impair the equipment

performance but may also result in accident or injury to repair personnel who do not have the required knowledge and technical expertise to

perform the repair operations correctly.

• Do not operate in the vicinity of ammable liquids, gases or solids.

• Some dusts created by the grinding process are harmful or toxic. To risk exposure always work in a well-ventilated area wearing suitable

respiratory protection.

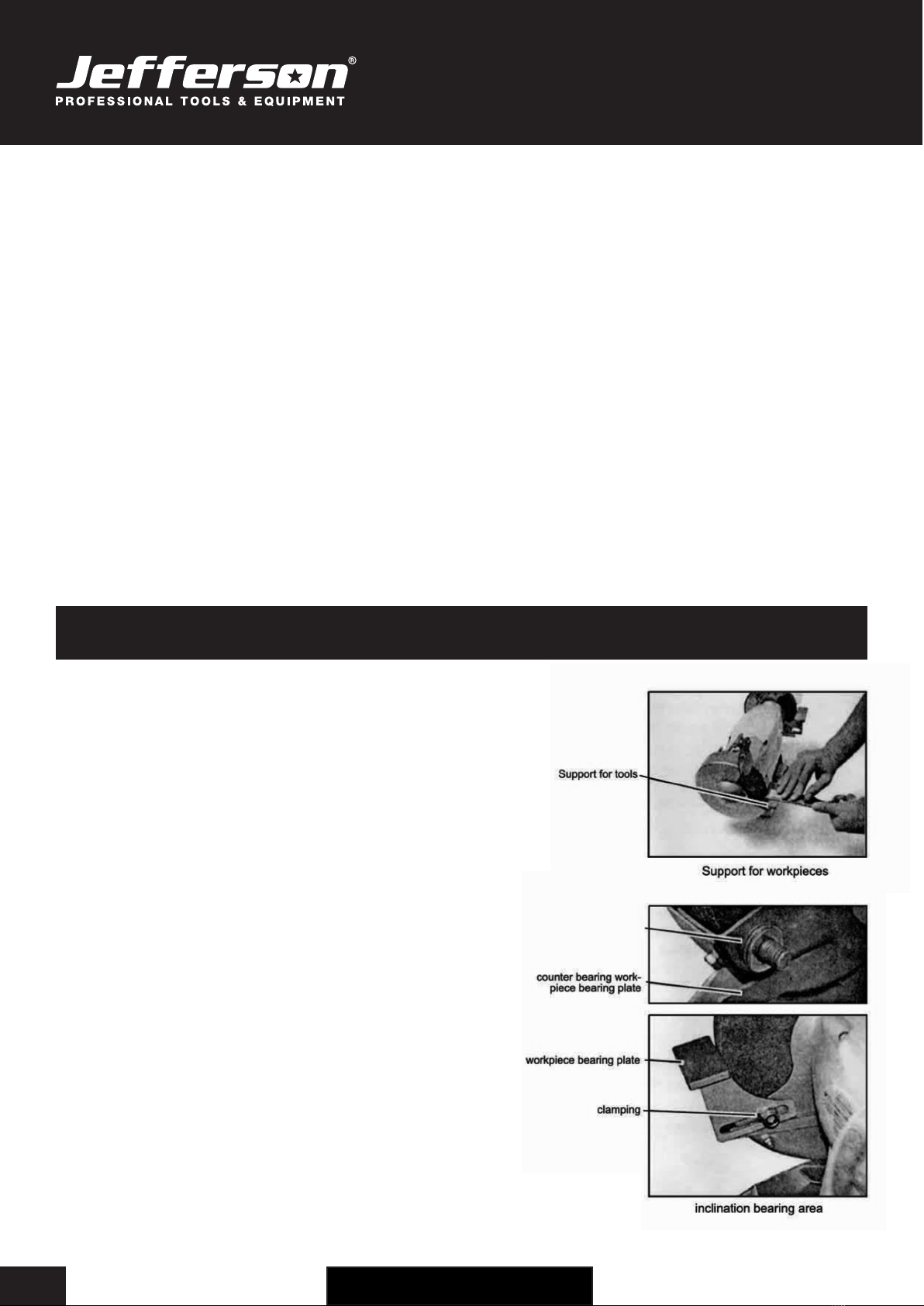

OPERATION GUIDE

Before Use:

Check inspect the equipment for damage and that it is safe to use before

connecting it to the power supply:

• Ensure that the workpiece is free from oil, grease, paint and other substances

that might clog the grinding wheels

• Ensure that the grinding wheels are kept clean to ensure safe and optimal

use.

• Check that the tool rests are securely xed and set at a maximum of 2mm

from the grinding stone.

• Check that eye shields are in good condition, are secure and that you can see

through them clearly.

• Turn the grinding stones by hand and check for any damage. Check they do

not touch the tool rests and are correctly aligned.

• If any of the above checks fail, replace, repair, or adjust as necessary before

starting the grinder.

Using The Grinder:

• Plug grinder into the mains power supply. Place the eye shield in its

appropriate safety location.

• Switch the grinder on, and bring the work piece slowly into contact with the

spinning stone, or wire wheel.

• When you have completed your task, unplug the grinder from the mains

power supply, and clean the machine ready for next use

Grinding Stones:

Grinding stones should only be assembled by a person holding a grinding wheel

certicate. There are generally two grades of grinding stone: ne stones are

preferred for hard materials and coarse stones for soft materials.

When grinding, should surface of the stone become “loaded” (coated with

particles of the material being ground) it is probably the wrong grade of stone for

the job. Contact your Jefferson Dealer for advice if required.

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com 5

MAINTENANCE

Important: Ensure the grinder is unplugged from the mains power supply before performing any maintenance or service:

• As the grinding stone wears, adjust the position of the tool rests accordingly. The rest must be at a maximum of 2mm from the stone surface.

• Regularly remove the grinding stone covers and clean out any dust and dirt.

• The grinding stone should be replaced when the distance between the external diameter of the grinding wheel and the edge of the grinding

wheel cover is greater than 6mm.

• The machine motor and bearing are sealed units and require no regular maintenance.

• If you require any advice on the servicing or maintenance of this equipment contact your nearest Jefferson Dealer.

TROUBLESHOOTING

FAULT CAUSE REMEDY

The motor will not start.

- Problem with electrical connection. - Check correct electrical connection is available and that

the equipment is connected to the supply.

- Check plug, fuse, replace or repair if necessary.

- Check if RCD has been tripped, reset if necessary.

- Check for damage to the cable, replace or repair if

necessary.

- The power witch has not been tuned on. - Turn the power switch on the grinder to the "ON"

position.

- Faulty motor - Contact your nearest Jefferson Dealer for advice.

Motor will not start.

Fuse blows.

Circuit breaker is tripped.

- Too many devices running off the power outlet. - Reduce number of connections on the power circuit.

- Incorrect fuse or damaged fuse. - Check fuse rating is 13A - replace if necessary.

- Wheels cannot rotate due to obstruction. - Turn off the power switch and unplug the equipment

from the supply.

- Check and remove the obstruction from the wheel.

- Check that the wheel is not obstructed by the tool rest.

- Turn the wheel by hand to check it is moving freely

before reconnecting to the power supply.

- Problem with extension cable (if in use) - Repair or replace the extension cable.

- Short circuit - Contact your nearest Jefferson Dealer for advice.

Motor fails to develop full power. Motor overload Reduce load to the motor. Do not force the workpiece on

the grinding wheel.

Low line voltage Check that the electrical supply rating matches the

equipment specications.

Use a shorter extension cable (if applicable).

Loose cable connections - Contact your nearest Jefferson Dealer for advice.

Faulty motor - Contact your nearest Jefferson Dealer for advice.

Frequent fuse or RCD breaker failure. Motor overload Reduce load to the motor. Do not force the workpiece on

the grinding wheel.

Overload on the electrical circuit. - Reduce number of connections on the power circuit.

Incorrect fuse or faulty RCD. - Check and replace if necessary (always use a qualied

electrician).

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com

6

WEEE Waste Electrical and Electronic Equipment Statement

Information on Disposal for Users of Waste Electrical & Electronic Equipment

This symbol on the product(s) and / or accompanying documents means that used electrical and electronic products should

not be mixed with general household waste. For proper treatment, recovery and recycling, please take this product(s) to

designated collection points where it will be accepted free of charge.

For private households:

Dispose of this product at the end of its working life and in compliance with the EU Directive on Waste Electrical and Electronic

Equipment (WEEE). Contact your local solid waste authority for recycling information for this equipment.

Disposing of this product correctly will help save valuable resources and prevent any potential negative effects on human health and the

environment, which could otherwise arise from inappropriate waste handling.

Please contact your local authority for further details of your nearest designated collection point.

Penalties may be applicable for incorrect disposal of this waste, in accordance with you national legislation.

For business users in the European Union:

If you wish to discard electrical and electronic equipment, please contact your dealer or supplier for further information.

Information on Disposal in other Countries outside the European Union:

This symbol is only valid in the European Union. If you wish to discard this product please contact your local authorities or dealer and ask for the

correct method of disposal.

ENVIRONMENTAL PROTECTION

Recycle any packaging and unwanted materials instead of disposing of them as waste. All tools, accessories and packaging

should be sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable, reaches the end of its working life and requires disposal, drain off any

uids (if applicable) into approved containers and dispose of the product and the uids according to local regulations.

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com 7

EC Declaration of Conformity

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following equipment

conforms to the requirements of the following Directives:

Directive: Description:

EN 61000-6-1:2001 (as amended)

Electromagnetic Compatibility

EN 61000-6-1:2001+A11(as amended)

Equipment Category: Bench Grinder

Product Name/Model: JEFBG6 • JEFBG8 - Industrial Bench Grinder

Notified Body: TÜV Rheinland Product Safety GmbH

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 14 December 2014

Name and address of manufacturer

or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park, Chester, United

Kingdom, CH4 9QR

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com

8

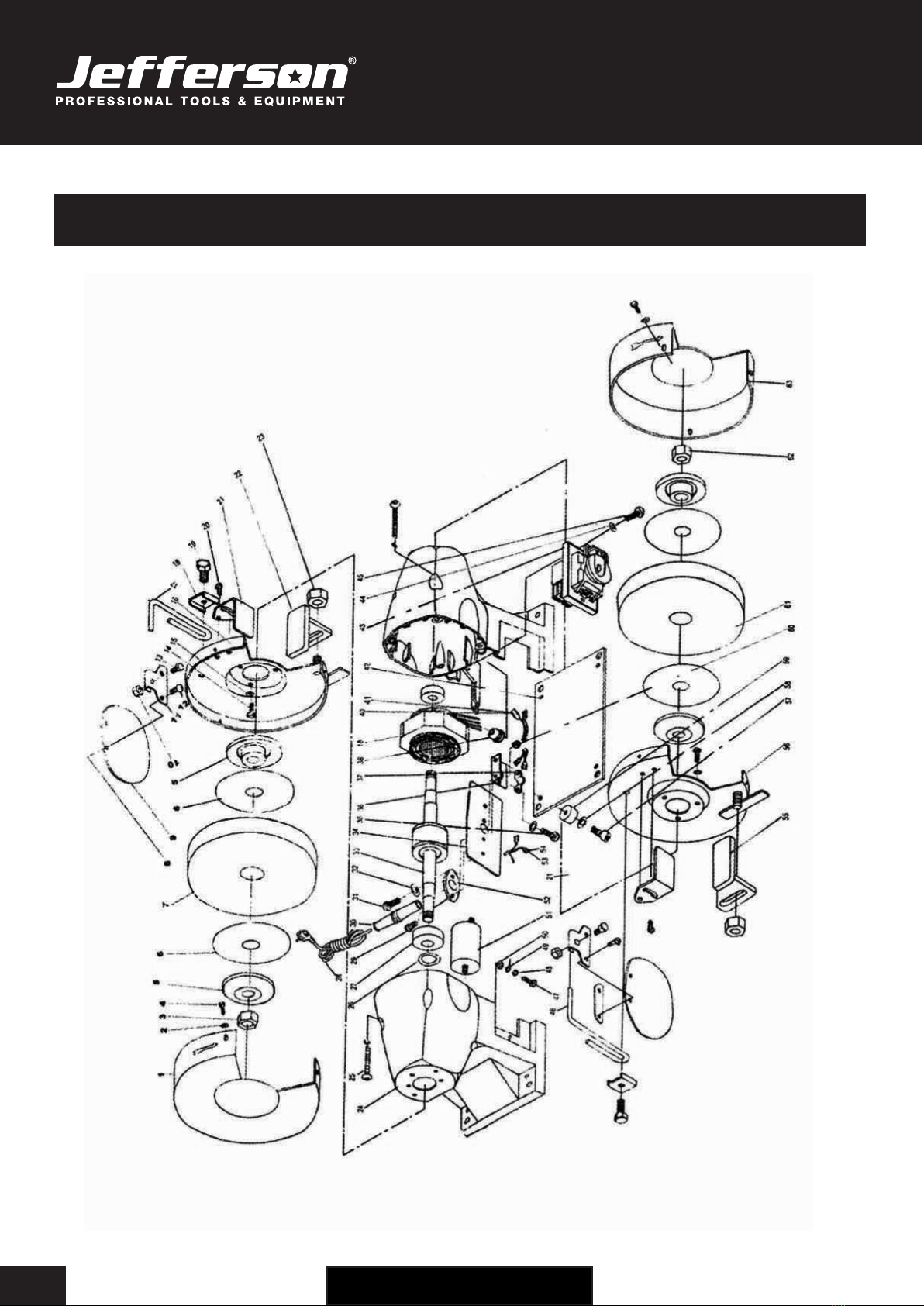

PARTS LIST & DIAGRAM - MAIN ASSEMBLY

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com 9

PARTS LIST & DIAGRAM - PUMP ASSEMBLY

# Description # Description

1Left protective cover 33 Motor Shaft

2Snap ring 34 Machine frame (right side)

3Left shaft nut 35 Screw

4Recessed head screw 36 Cable support

5Securing Disc / Counter-disc 37 Cable clamp

6Ring 38 Cable covering

7Grinding Wheel 39 Stator

8Mounting for spark guard (left side) 40 Cable lug

9Spark guard 41 Rubber cover for cable lug

10 Nut 42 Mounting plate

11 Plate 43 Power Switch

12 Locking Screw 44 Washer

13 Fastening screw 45 Screw

14 Locking Screw 46 Mounting for spark guard (right side)

15 Snap rng 47 Locking screw

16 Inner Cover for grinding wheel 48 Snap dng

17 Glass guard support (left side) 49 Earthing point

18 Plate 50 Star ring

19 Hex bolt 51 Capicitor

20 Screw 52 Clamping

21 Adjustable prptective cover 53 Cable lug

22 Workpiece support (left side) 54 Rubber cover

23 Fastening nut 55 Wokpiece support (right side)

24 Machine frame 56 Inner cover for grinding wheel (right side)

25 Screw 57 Screw

26 Snap dng 58 Washer

27 Shaft bearing 59 Bottom Cartridge

28 Power Cable with plug 60 Paper Ring

29 Screw 61 Grinding wheel

30 Main lead cleat 62 Right shaft nut

31 Locking screw 63 Right protective cover

32 Washer

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com

10

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects in workmanship

or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or components of this product

that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal operations, improper care, service

or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from the end user, then

the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

• JEFBG6 • JEFBG8 - Industrial Bench Grinder

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of 90 days cover or the

remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form. Online warranty registration is recommended as it eliminates the need to

provide proof of purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or replacement at an

authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange collection and

transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not

covered under the terms of the Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred.

These costs will be agreed with the customer before the machine is returned.

*Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability under this

warranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc.) caused by

the defect or the time involved to correct the defect. This written warranty is the only express warranty provided by Jefferson with respect to its

products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine inspection of cables for possible

wear and to correct any issues prior to cable failure.

LIMITED WARRANTY STATEMENT

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com 11

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where

final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form online and submit it

to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest authorised Jefferson

repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together with a copy of

the original proof of purchase. Please note that Jefferson cannot assume any responsibility for any damage incurred to equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions of their road haulage association directives.

Please note: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is defective and in need

of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all equipment presented must have been

used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer (normally within 7

working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour time at £30 per hour plus return

carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identified as the cause of the problem, a

minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working days upon receipt

of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not immediately available Jefferson will

contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry via email to warranty@

jeffersontools.com

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without

guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of

this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification. All images are for

illustration purposes only.

USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL BENCH GRINDER

www.jeffersontools.com

12

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

www.jeffersontools.com

www.jeffersontools.com

This manual suits for next models

1

Other Jefferson Grinder manuals