Jegs 80040 User manual

Installation Instructions for 80040

Engine Stand

1000 lb. Capacity

Assembly

1. Install the 2 x 3-1/2" wheels (part 7) on the rear cross beam (part 4) and install 2 x 3" wheels (part 15) on the front

cross beam (part 16).

2. Attach the 4 mounting arms (part 19) to the turning plate (part 18) using the bolts and nuts provided (parts 6, 8, 20).

3. Assemble and fasten the front cross beam (part 16) and the middle beam (part 17) using the bolts and nuts provided

(parts 3, 13, 14).

4. Insert the middle beam (part 17) into the vertical column (part 1) using the bolt (part 10). Then attach the vertical

column (part 1) to the rear cross beam (part 4) using the bolts and nuts provided (part 3)

5. Put the turning plate (part 18) through the vertical column (part 1) and the handle (part 2) through the turning plate

hole and lock using the pin (part 9).

Product Specifications

Heavy duty steel channels

High strength steel construction

Engine stand capacity: 1000 lbs.

Rotation: 360°

Overall Size: 27.5” x 29.5” x 33”

Unpacking

When unpacking the tool:

Carefully remove the tool and accessories from the box.

Make sure that all items listed in the packing list are included.

Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

Do not discard the packing material until you have carefully inspected and successfully operated the tool.

WARNING: When using the tool basic safety precautions should always be followed to reduce the risk of personal

injury and damage to equipment.

Instruction

This product has many features which make using it more pleasant and enjoyable. Safety, performance, and

dependability have been given top priority in the design of this product making it easy to maintain and operate.

WARNING:

Do not attempt to use this product until you thoroughly read and completely understand the operator's manual. Pay

close attention to the safety rules, including Dangers, Warnings, and Cautions. If you use your product properly and

only as intended, you will enjoy years of safe, reliable service.

WARNING:

The operation of any tool can result in foreign objects being thrown into your eyes, which can result in severe eye

damage. Before beginning operation, always wear safety goggles or safety glasses with side shields and a full face

shield when needed. We recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses with

side shields. Always wear eye protection which is marked to comply with ANSI Z87.1.

General Safety Rules

WARNING: When using the tool basic safety precautions should always be followed to reduce the risk of personal

injury and damage to equipment!

Work area conditions. Cluttered areas invite Injuries.

Additional work area conditions. Do not use machines or power tools in damp or wet locations. Do not expose to

rain. Keep work area well lit.

Keep children away. Children must never be allowed the work area. Do not let them handle machines, tools or

extension cords.

Store idle equipment. When not in use tools must be stored in a dry location to inhibit rust. Always lock up tools

and keep them out of the reach of children.

1-800-345-4545 jegs.com

Use right tool for the job. Do not attempt to force a small tool or attachment to do the work of a larger industrial

tool. There are certain applications for which this tool was designed. It will do the job better and safer at the rate for

which it was intended. Do not modify this tool and do not use this tool for a purpose for which it was not intended.

Dress properly. Do not wear loose clothing or jewelry as they can get caught in moving parts. Protective,

electrically nonconductive clothing and nonskid footwear are recommended when working. Wear restrictive hair

covering to contain long hair.

Use eye protection. Always wear ANSI approved impact safety glasses underneath a full face shield during use.

Also wear heavy duty work gloves.

Do not over reach. Keep proper footing and balance at all times. Do not reach over or across running machines.

Maintain tools with care. Keep tools clean for better and safer performance. Follow instructions for lubricating and

changing accessories. The handles must be kept clean and dry from oil and grease at all times.

Remove adjusting keys and wrenches. Check that keys and adjusting wrenches are removed from the tool or

machine work surface before starting work.

Stay alert. Watch what you are doing. Use common sense. Do not operate any tool when you are tired.

Check for damaged parts. Before using any tool, any parts that appear damaged should be carefully checked to

determine that it will operate properly and perform its intended function. Any part that is damaged should be

replaced.

Replacement parts and accessories. When servicing use only identical replacement parts. Use of any other parts

will void the warranty. Only use accessories intended for use with this tool. Approved accessories are available

from our company.

Do not operate tools if under the influence of alcohol or drugs. Read warning labels on prescriptions to

determine if your judgment or reflexes are impaired while taking drugs

WARNNG: The warnings, cautions, and instructions discussed in this manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

Part

Description

QTY

1

Vertical Column

1

2

Handle (300mm)

1

3

Bolt M10 x 70

4

4

Rear Cross Beam

1

5

Bolt M8 x 65

2

6

M14 Washer

4

7

3-1/2” Wheel

2

8

M14 Nut

4

9

Pin

1

10

Bolt M12 x 25

1

11

M8 Nut

2

12

M8 Spring Washer

2

13

M10 Spring Washer

4

14

M10 Nut

4

15

3” Wheel

2

16

Front Cross Beam

1

17

Middle Beam

1

18

Turning Plate

1

19

Mounting Arms

4

20

Bolt M14 x 60

4

21

M8 Washer

2

22

Pipe

2

23

M10 Washer

8

1-800-345-4545 jegs.com

Table of contents

Popular Lifting System manuals by other brands

Conductix-Wampfler

Conductix-Wampfler BridgeGuard Plus ASSEMBLY, INSTALLATION, OPERATION & MAINTENANCE MANUAL

IDEAL

IDEAL TLX-7000-FLRAILKIT Assembly manual

The Handy

The Handy 21660 instructions

Guldmann

Guldmann Stepless Pro 30046-100 user manual

Sav

Sav NEO 2000 operating instructions

Duarib

Duarib Altitude 150 Assembly, Disassembly and Use Instructions

STARKE ARVID

STARKE ARVID MB-06 User and maintenance manual

Wayne-Dalton

Wayne-Dalton 8100 Installation instructions and owner's manual

BUCKINGHAM MFG

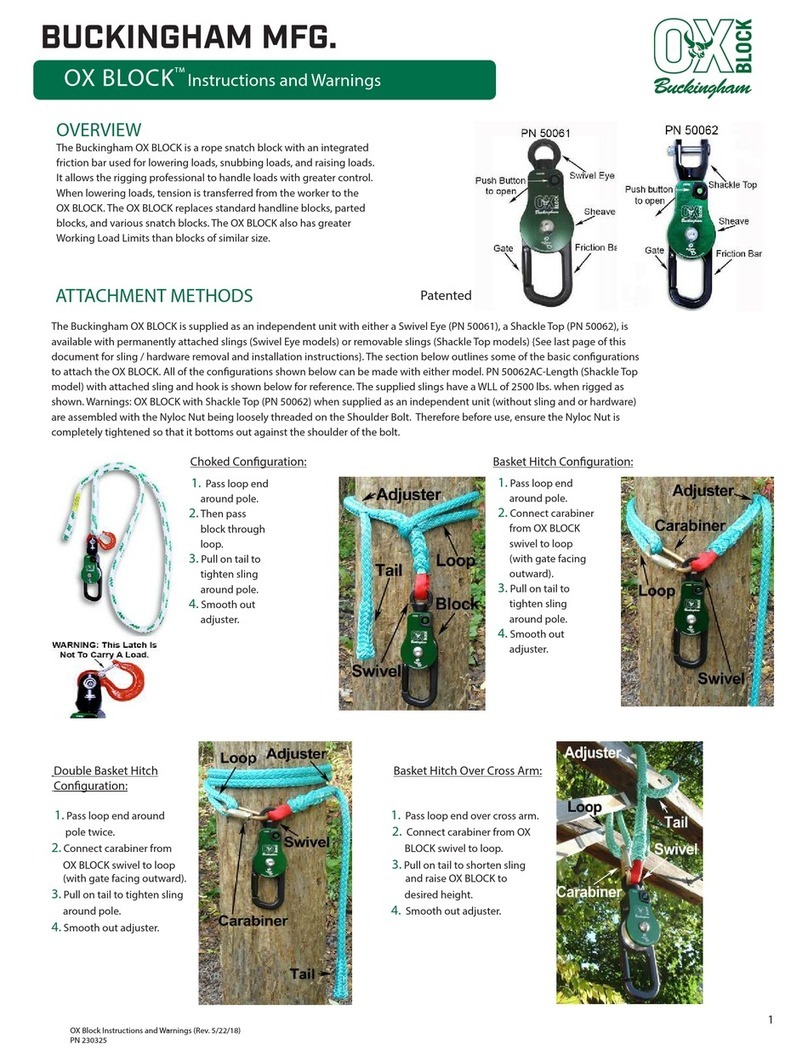

BUCKINGHAM MFG OX BLOCK Instructions and warnings

Sunshine

Sunshine QJ-Y-2-35 instruction manual

Thiele

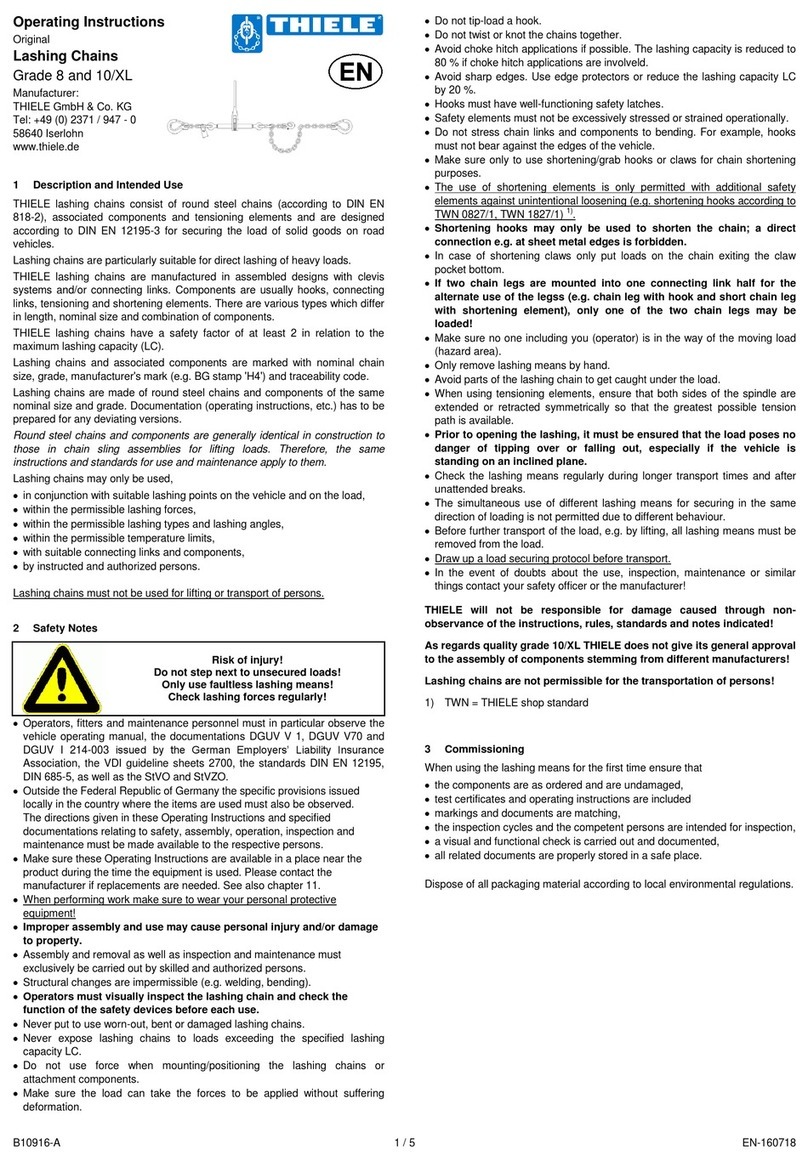

Thiele Grade 8 operating instructions

MITARI

MITARI MPMU-3 operating instructions