LIMITED WARRANTY

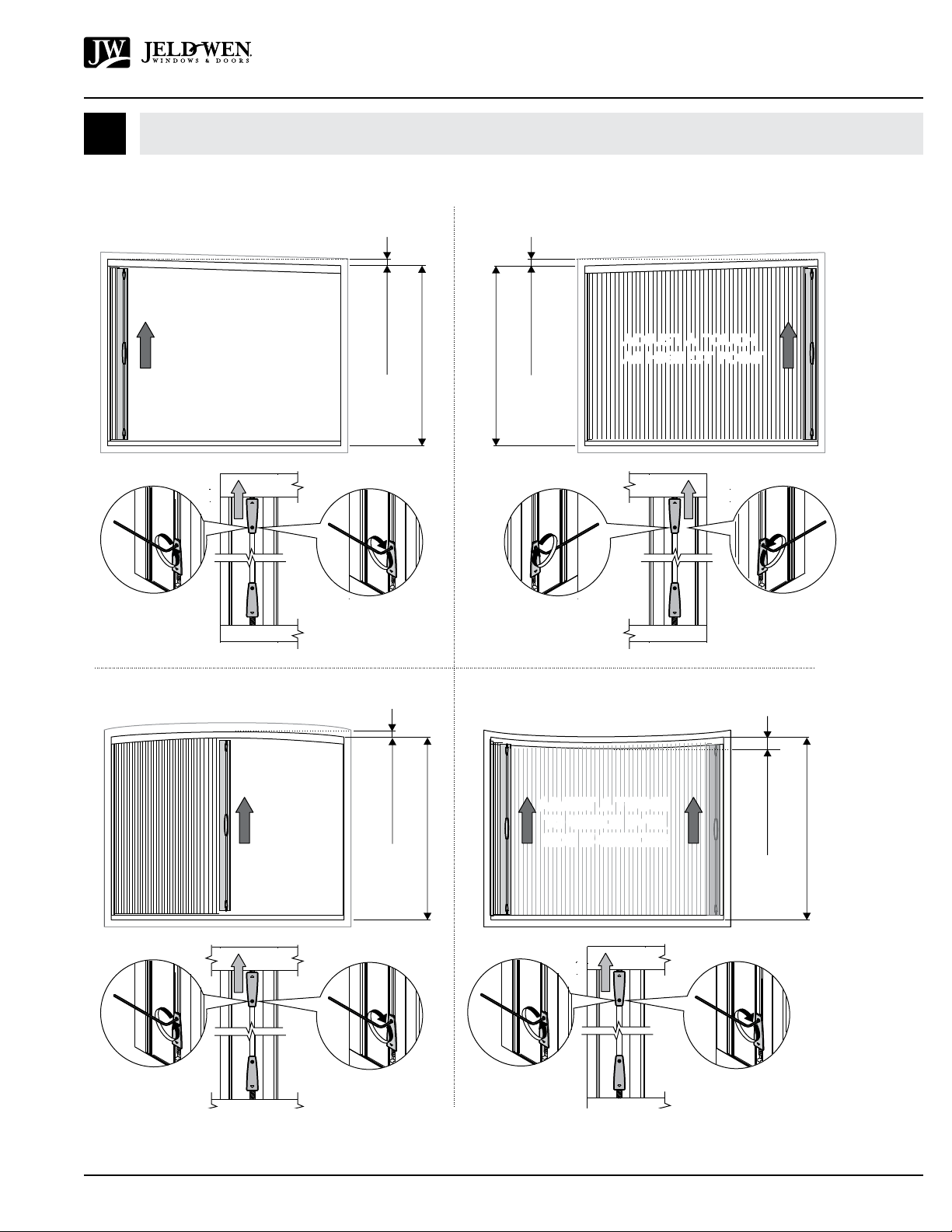

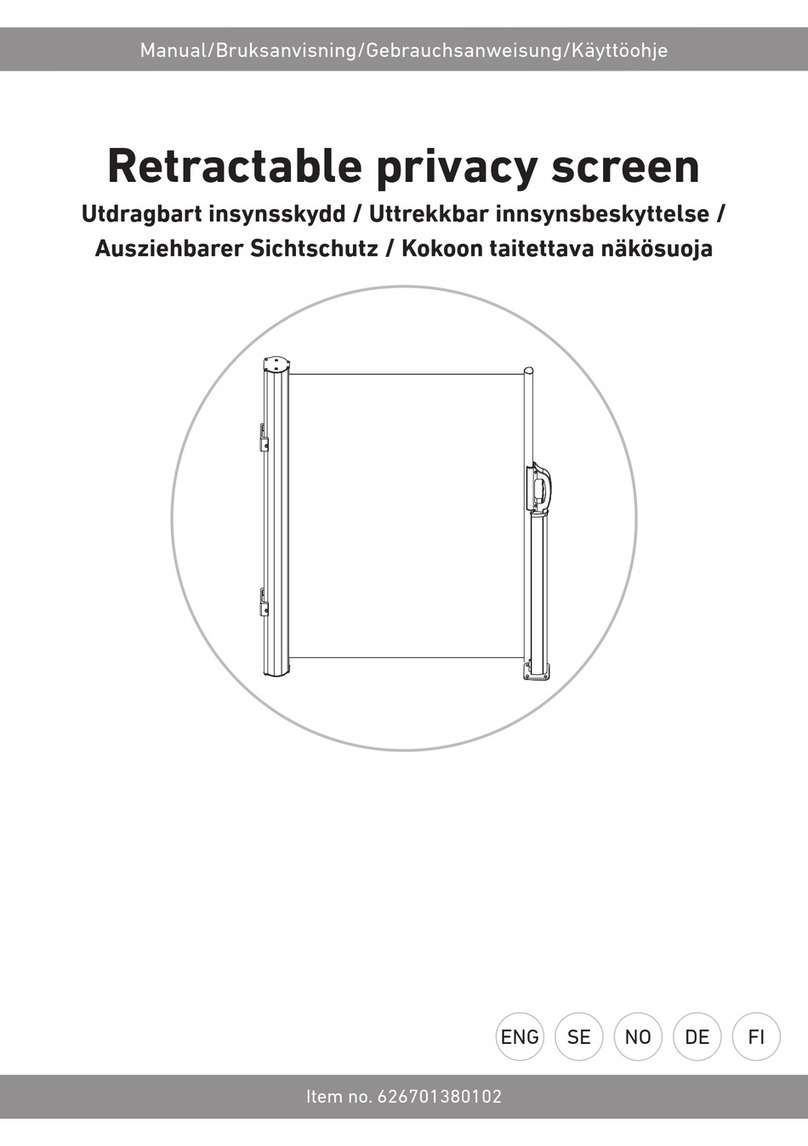

Installation Instructions

for Siteline®Low-Friction Glider™Wall System Brio®Pleated Screens

Distributed by JELD-WEN®(JII-90048)

11

Brio USA (the supplier) warrants that the Brio 612 Retractable Pleated

Insect Screen is supplied free of manufacturing defects and material aws.

Should any defect in materials and/or workmanship become apparent

within 5 years from the date of purchase, the supplier will, at its option,

repair or replace the product free of charge.

The Warranty Does Not Cover:

• Improper screen assembly, installation and /or adjustment provided by

others

• Damage as a result of environmental conditions, strong winds, natural

disasters or other events beyond the control or the Supplier

• Damage to the screen mesh, tensioning cords and / or channels caused

by deliberate or accidental misuse, abuse or neglect

• Damage caused by humans or pets accidentally running or walking into

the screen when in use

• Damage caused to the screen components by inadequate maintenance,

i.e. failure to routinely remove dirt, dust and debris from the channel

and mesh

• General deterioration in appearance or performance that occurs as a

result of normal operation and normal wear and tear

• Progressive deterioration of nishes and materials due to exposure to

sun, rain, abrasion, heat and /or cold

• Damage caused by the contamination of the screen mesh due to

excessive moisture, construction dust or debris, and aggressive cleaning

agents

• Damage to the mesh caused by contact with excessive heat surfaces

including, but not limited to construction equipment, cigarette ash,

matches, cigarette lighters, sparks or hot cooking utensils

• Damage caused by any third party

The supplier’s liability shall be limited to the repair or replacement (at the

Suppliers option) of the defective product. The Supplier will not be liable

for any other direct or indirect costs, loss or damage to person or property,

except as required by law, or any consequential losses or loss of prot.

The Supplier excludes, to the extent permitted by law, all other warranties,

whether expressed, implied or statutory.

Care & Maintenance

Cleaning The Top And Bottom Channels

Dust and debris can collect in the guide channels overtime. Removal of

such build up is easy and important to the screen’s smooth movement.

While the screen is retracted, remove any debris with a soft cloth or a

vacuum cleaner with a soft brush nozzle. Dusty or coastal environments

will require regular cleaning.

Cleaning The Screen Mesh

The Screen Mesh should be lightly dusted to maintain an unobstructed

view and air ow. While the screen is extended, remove any build up with

a vacuum cleaner with a soft brush nozzle, care should be taken not to

tear or rip the mesh.

Wind & Operation Tips

The screen is tted with ‘tensioning’ cords located within the guide

channel & track that not only provide stability to the screen, but control

the vertical orientation of the handlebar and help prevent the mesh from

blowing out of the in windy conditions. Should the blow out gently retract

the screen and the mesh should self-feed back into the, if not simply pop

the mesh back by hand.

On large openings the screen mesh acts like a sail. In gusty or windy

conditions it is recommended to keep the screen retracted to reduce

possibility of damage occurring. If the mesh is damaged or a tension cord

breaks, the screen will need to be replaced. The screen has been designed

to be interchangeable with a replacement. It is recommended you contact

the original installer.

Servicing

If the mesh is damage or a tension cord breaks, the screen will need to

be replaced. The screen has been designed to be interchangeable with

a replacement screen assembly which is reinstalled into the existing

channels. We recommend contacting the original installer to have the

screen cut to size and retted.