JENCO 3331 User manual

Op

erat

i

on

M

anua

l

MODEL 3331

Microcomputer Based Conductivity/Resistivity Transmitter

JENCOELECTRONICS, LTD.

MANUFACTURER OF PRECISION INSTRUMENTS

1

CONTENTS

GENERAL INTRODUCTION………………………………………..………....................2

INITIAL INSPECTION……...………………..................................................................2

USING THE JENCO MODEL 3331……......................................................................3

A. Mounting procedure.....................................................................................3

B. Front panel....................................................................................................5

C. LCD screen....................................................................................................7

D. Rear connectors...........................................................................................8

E. Measure mode.............................................................................................10

F. Setting mode................................................................................................11

G. Conductivity/Resistivity calibration mode..............................................18

H. 4~20mA output..........................................................................................18

ERROR DISPLAY AND TROUBLESHOOTING……………..……….........................21

SPECIFICATIONS……………..………………………………………........................23

WARRANTY……………..………...............................................................................25

2

GENERAL INTRODUCTION

Thank you for selecting the JENCO Model 3331. The 3331 Conductivity/Resistivity

transmitter is a rugged microprocessor based instrument assembled in a watertight 1/8

DIN case, designed for use in laboratories and process control applications.

The system displays Conductivity / Resistivity or Temperature status in one large LCD

screen.

The model 3331 microprocessor performs a self-diagnostic routine every time you turn

on the unit, it will provide you with basic information on the stability of the instrument.

The model 3331 has an isolated 4-20mA analog output, offset and span configurable

for the Conductivity or Resistivity display.

INITIAL INSPECTION

Carefully unpack the unit and accessories. Inspect for damages made in shipment. If

any damage is found, notify your Jenco representative immediately. All packing

materials should be saved until satisfactory operation is confirmed.

3

USING THE JENCO MODEL 3331 ERVIEW

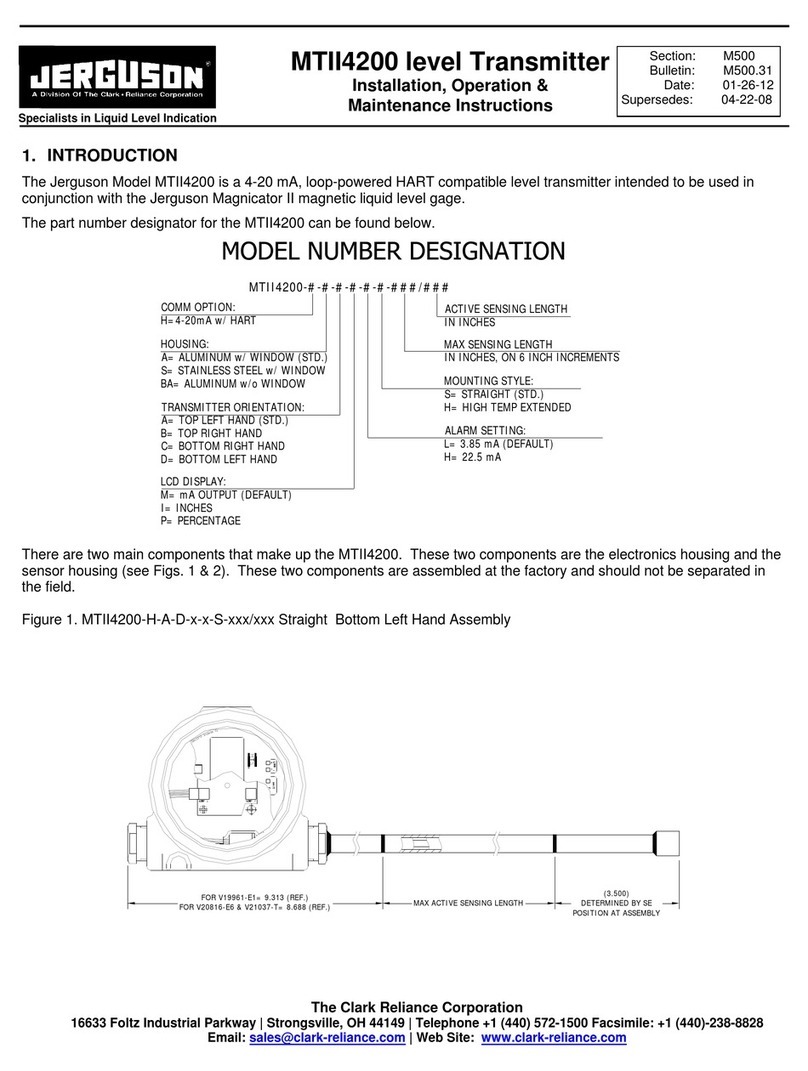

A. Mounting Procedure

PANEL CUTOUT DIMENSIONS

45.0

1.772"

92.0 3.622"

0.813 0.032

0.61

0.024

0.00

0.000

0.000 0.000

±±

±

±

DRAWING 1

1. Make a cutout on any panel, with a

thicknessof1/16inch(1.5mm)to

3/8 inch (9.5mm). Refer to

DRAWING 1.

Mounting Brackets

DRAWING 2

2. Remove the mounting assembly

from the controller and insert the

4

controller into the cutout. Refer to

DRAWING 2.

Panel Mounting brackets

DRAWING 3

3. Replace the mounting bracket

assembly onto the controller and

secure the controller to the

mounting panel. Refer to

DRAWING 3.

【

Note

】

:

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

5

B. Front Panel

The front panel consists of a 4-digit LCD display and 4 keys.

mS

ATC

COND TRANSMITTER 3331

1. [MODE]key:

1a. In the Measure mode, this key will switch the display in sequence from

Conductivity, Temperature and back to Conductivity again or from Resistivity,

Temperature and back to Resistivity again.

1b. In the Calibration/Setting mode, pressing this key for five seconds will move

you back to the previous parameter in the case when recalibration / resetting is

required.

6

2. [UP]key:

2a. In the Calibration mode, pressing this key will increase the numeral increment.

In the Setting mode, pressing this key will show the next possible option and

increase the numeral increment.

2b. In the Measure mode, pressing this key and [ENTER] key at the same time,

the unit will enter the Calibration mode.

3. [DOWN]key:

3a. In the Calibration mode, pressing this key will decrease the numeral

increment. In the Setting mode, pressing this key will show the next possible

option and decrease the numeral increment.

3b. In the Measure mode, pressing this key and [ENTER] key at the same time,

the unit will enter the Setting mode.

4. [ENTER]key:

In any mode where the user can change the settings, pressing this key will save

the new settings. If no change has been made then pressing this key will just lead

7

the user to the next setting.

C. LCD screen

uS

CAL mA

MAN

M

mS

ATC

12 3456

987

1. Major LCD display.

2. CAL – This icon will be displayed if the meter is in the Calibration/Setting mode.

3. mA – This icon, when displayed, indicates the meter is in the 4mA or 20mA

Setting mode.

8

4. MΩ–Unit indicator.

5. ℃–Temperature and unit display.

6. uS – Unit indicator.

7. ATC –This icon will be displayed when a temperature probe is connected.

8. MAN –This icon will be displayed if no temperature probe is not connected.

9. mS – Unit indicator.

D. Rear connectors

100~230VAC

LNE

mA

+-

CELL 10K TH

GNDGND

9

*Specify “L’ = “Live Lead” 100 to 230 VAC Volts and “N” = “Neutral Lead”

1. Connect the AC line to the rear of the instrument. The model 3331 can be used

with 100~240V AC at 50/60 HZ. Make sure the EARTH connector is connected to

the earth lead of the AC power line.

2. Set the proper load to the 4-20mA-output connector. Make sure that the load

impedance is less than 500 Ohms.

【

Note

】

:

(1) Make sure that the power is unplugged before wiring your probes etc.

(2) Make sure you connect the AC power cord to the correct AC terminals. Incorrect

connection may damage the unit permanently.

10

E. Measure mode

Turning on the unit will always display the Measure mode. This instrument is designed

to provide 2 distinct measurements: Conductivity, Temperature or Resistivity,

Temperature.

MODE

mS

ATC ATC

M

ATC ATC

MODE MODE

MODE

or

1. Conductivity – Current conductivity of the solution.

2. Resistivity –Current resistivity of the solution.

3. Temperature – Current temperature of the solution.

【

Note

】

:

Pressing [MODE] key in the Measure mode will cycle the display between the two

modes above.

11

F. Setting mode

Pressing [DOWN] key and [ENTER] key at the same time, the meter will enter into the

Setting mode.

1. Temperature compensation select:

+ENTER

Temperature coefficient select

MAN

CAL

ATC

CAL

ENTER ENTER

Pressing [UP] key or [DOWN] key in this screen will cycle the display between 01

(Thermistor: 10k ohm), 02 (Manual) modes above.

Select the preferred temperature compensation mode, press [ENTER] key to save,

and enter the next setting screen.

12

2. Temperature Coefficient select:

Temperature compensation select

probe Basic cell constant select

ENTER

ENTER ENTER

CAL CAL

Pressing [UP] key or [DOWN] key in this screen will cycle the display between

E2.00, E0.00 above.

Select the preferred coefficient, press [ENTER] key to save, and enter the next

setting screen.

13

3. Probe Basic cell constant select:

Temperature coefficient select

Range select

ENTER

ENTER ENTER ENTER

CAL CALCAL

Pressing [UP] key or [DOWN] key in this screen will cycle the display from C1.00,

C0.10 to C0.01 basic cell constant above.

Select the preferred basic cell constant, press [ENTER] key to save, and enter the

next setting screen.

14

4. Range select:

Pressing [UP] key or [DOWN] key in this screen will cycle the display from

CF01/0.000~1.999uS/cm, CF02/0.00~19.99uS/cm, CF03/0.000~1.999MΩ,

CF04/0.00~19.99MΩ(Basic cell K is C0.01) or CF01/0.00~19.99uS/cm,

CF02/0.0~199.9uS/cm(Basic cell K is C0.10) or CF01/0.0~199.9uS/cm,

CF02/0~1999uS/cm, CF03/0.00~19.99mS/cm (Basic cell K is C1.00) above.

Select the preferred basic cell constant , press [ENTER] key to save, and enter the

next setting screen.

4mA output setting

ENTER

ENTER ENTER ENTER ENTER

CAL

4mA output setting

CAL CAL CAL CAL

15

4mA output setting

ENTER

ENTER ENTER

CAL

CALCAL

4mA output setting

ENTER

ENTER ENTER ENTER

CAL

CAL CAL CAL

16

5. 4 mA output setting:

mA output parameters select

20mA output setting

ENTER

ENTER

CAL CAL

mA

pH

Pressing [UP] key or [DOWN] key in this screen to adjust the 4 mA value, this

value is used for scaling the 4-20mA analog output.

Pressing [ENTER] key to save, and enter the next setting screen.

17

6. 20mA output setting:

4mA output setting

Measure mode

ENTER

ENTER

CAL CAL

mA

pH

Pressing [UP] key or [DOWN] key in this screen to adjust the 20 mA value, this

value is used for scaling the 4-20mA analog output.

Pressing [ENTER] key to save, and goes to the Measure mode.

18

G. Conductivity/Resistivity Calibration mode

The model 3331 uses 1-point calibration for conductivity or resistivity.

In the Measure mode, pressing [UP] key and [ENTER] key at the same time to allow

the meter to go to the Conductivity / Resistivity calibration mode.

At the Conductivity / Resistivity calibration mode,the“CAL”iconanda

conductivity/resistivity reading will display. Rinse the conductivity probe in distilled

water and immerse it into the standization solution. Allow temperature reading to

stabilize, press [UP] key or [DOWN] key to change this reading to that of the

standization solution value, then press [ENTER] key to save. Calibration is now

completed.

H. 4-20 mA output

1. Isolation voltage:

The maximum isolation voltage of the 4-20mA output contacts is 500 VDC. The

voltage differential between the 4-20mA output contacts and the load should not

exceed 500 VDC.

19

2. Output load:

The maximum load is 500 ohm. Output current inaccuracies may occur for load

impedance in excess 500 ohm.

3. The analog output will produce a linear analog output. The user can only bind the

ANALOG OUTPUT to one reading at a time. The user can change this anytime by

changing option at the Calibration/Setting mode screen.

The analog output will be restricted on the 4 mA setting, 20 mA setting and the

current bound display.

Adjustable

Bandwidth Bandwidth

Adjustable

Set

point point

Set

2

0mA

4mA 4mA

20mA

mA mA

Decreasing current for Increasing current for

increasing conductivity increasing conductivity

COND.

C

OND

.

Table of contents

Other JENCO Transmitter manuals

Popular Transmitter manuals by other brands

Emerson

Emerson Rosemount ET310 quick start guide

Long Range Systems

Long Range Systems T7460 user manual

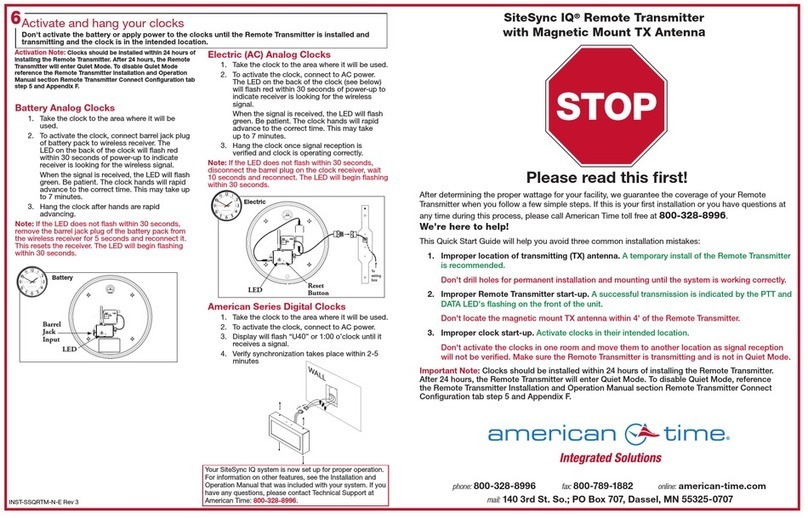

American Time

American Time SiteSync IQ Quick start installation guide

Honeywell

Honeywell SmartLine SLN 700 Series user manual

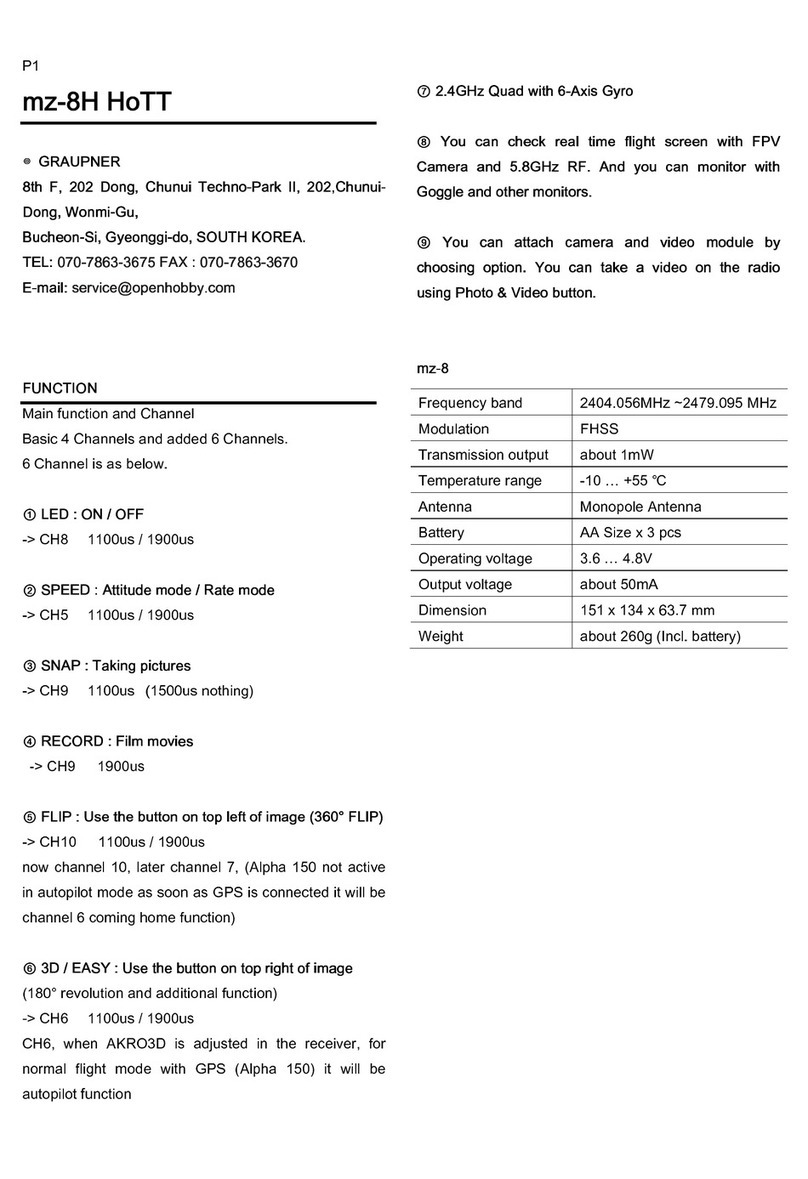

GRAUPNER

GRAUPNER mz-8 manual

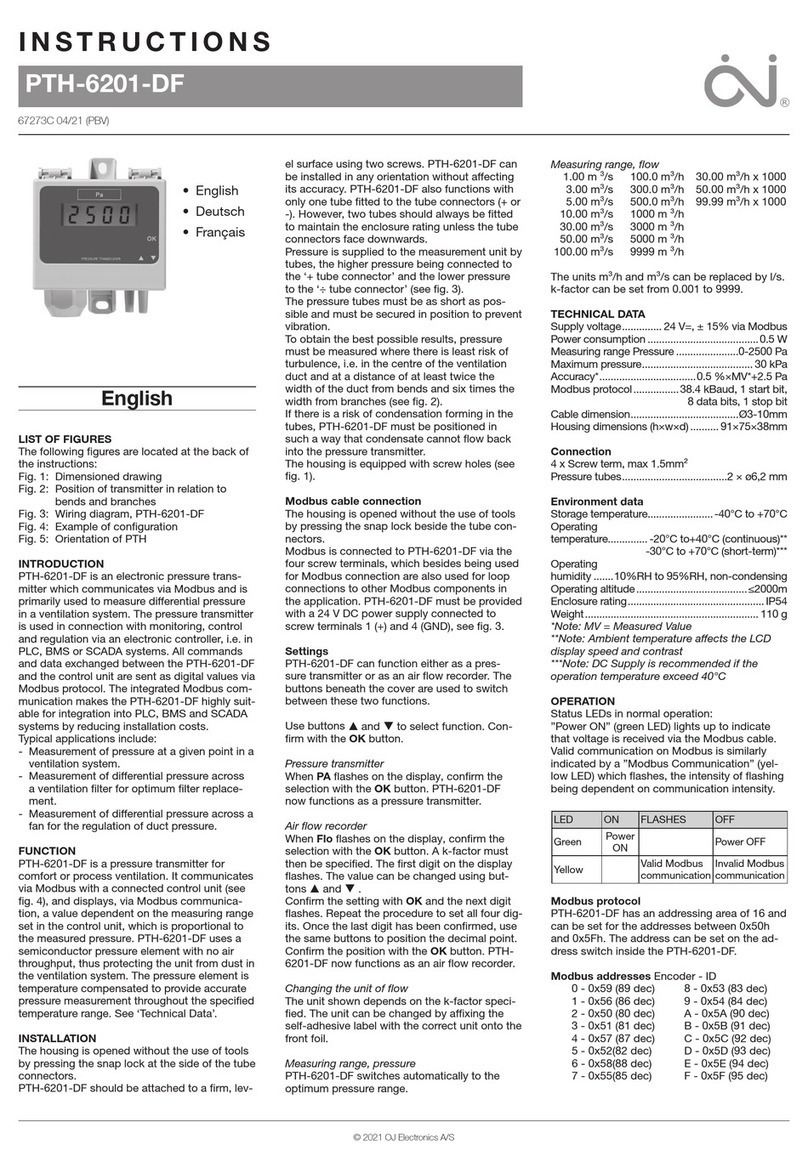

OJ Electronics

OJ Electronics PTH-6201-DF instructions

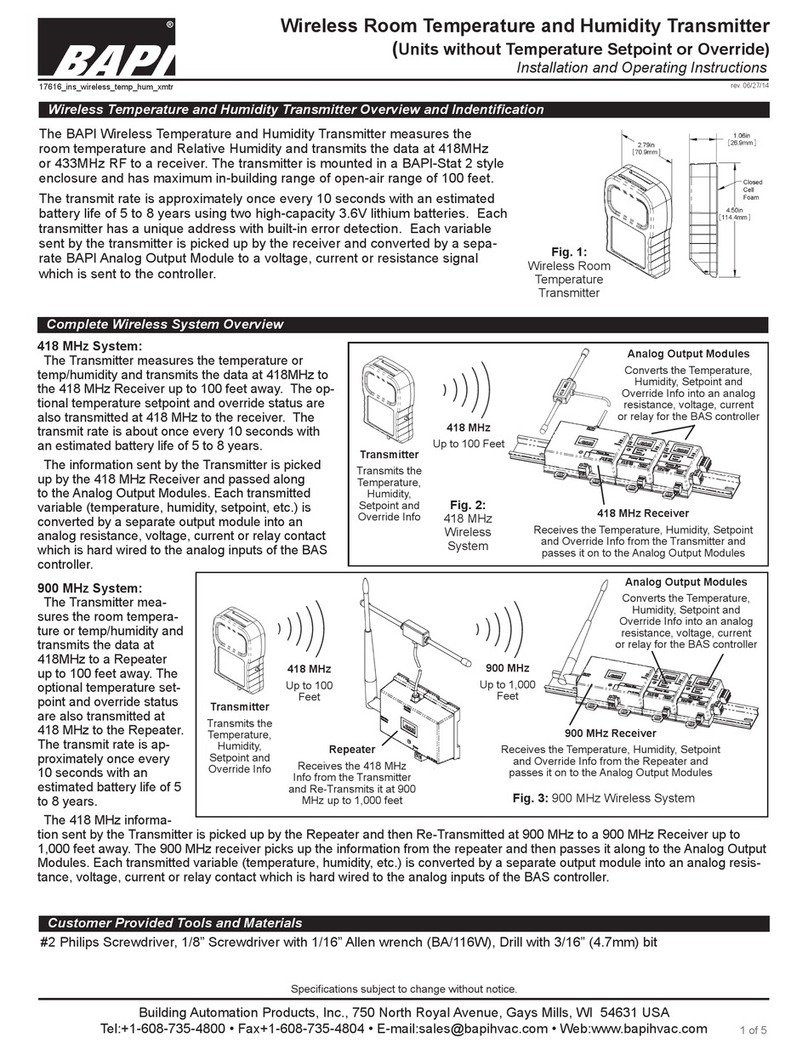

BAPI

BAPI Wireless Room Temperature and Humidity... Installation and operating instructions

Jerguson

Jerguson MTII4200 Series Installation, operation & maintenance instructions

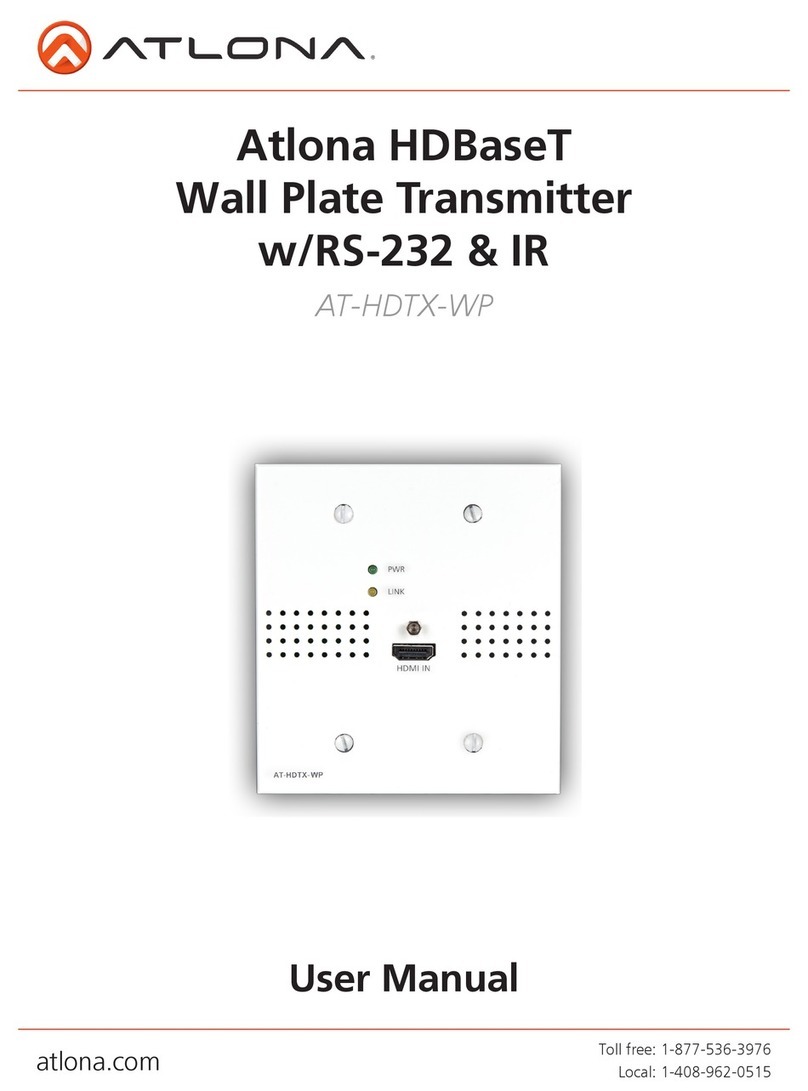

Atlona

Atlona AT-HDTX-WP user manual

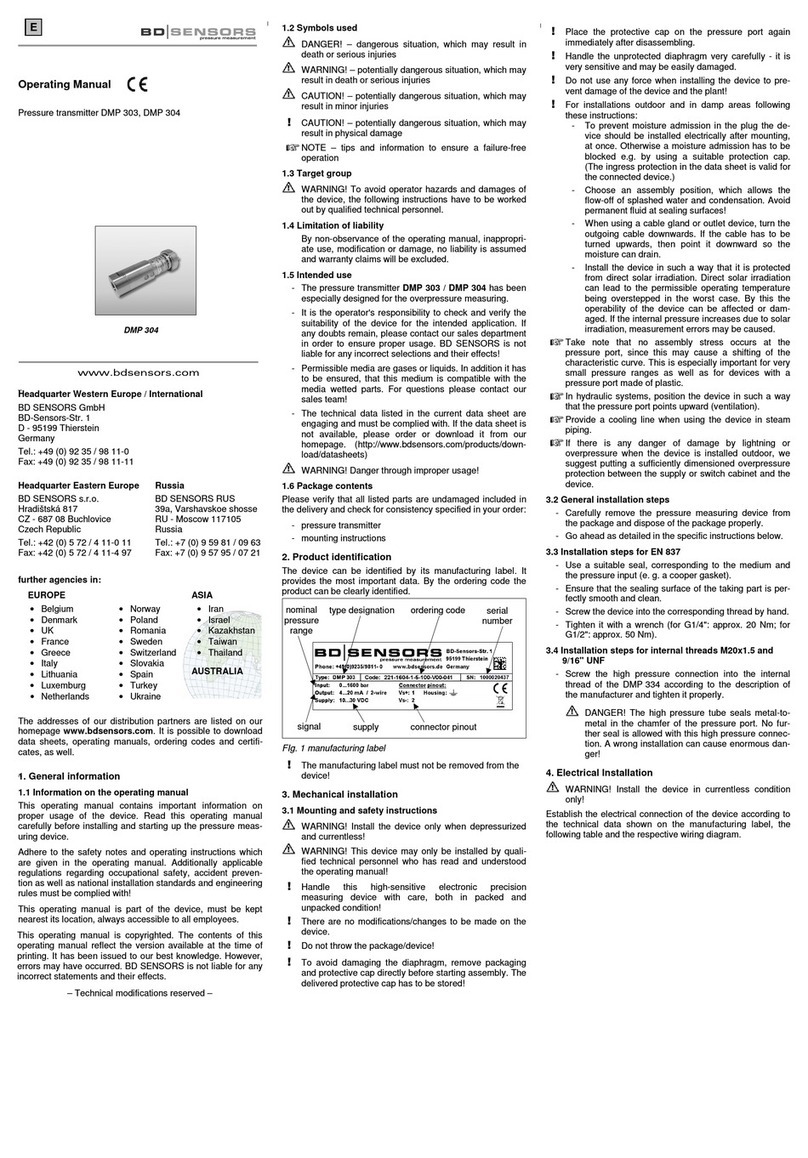

BD Sensors

BD Sensors DMP 303 operating manual

ASTRO

ASTRO 43 SAW quick start guide

Micatrone

Micatrone MF-PFT Installation & operation manual