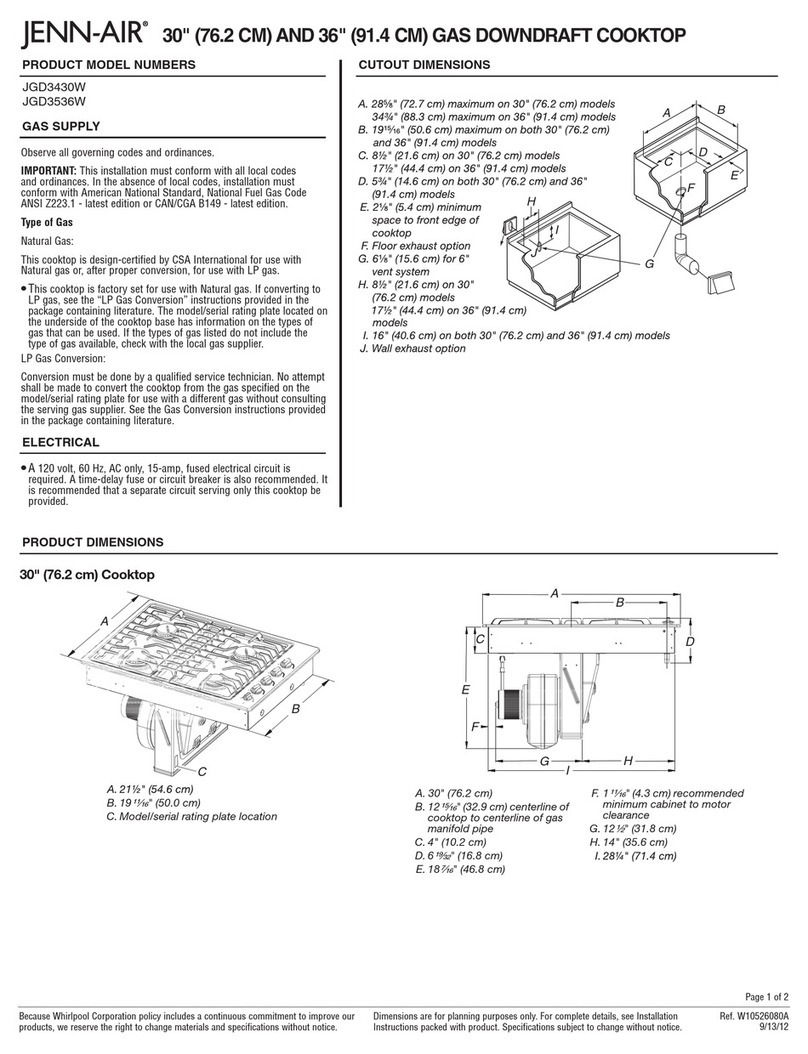

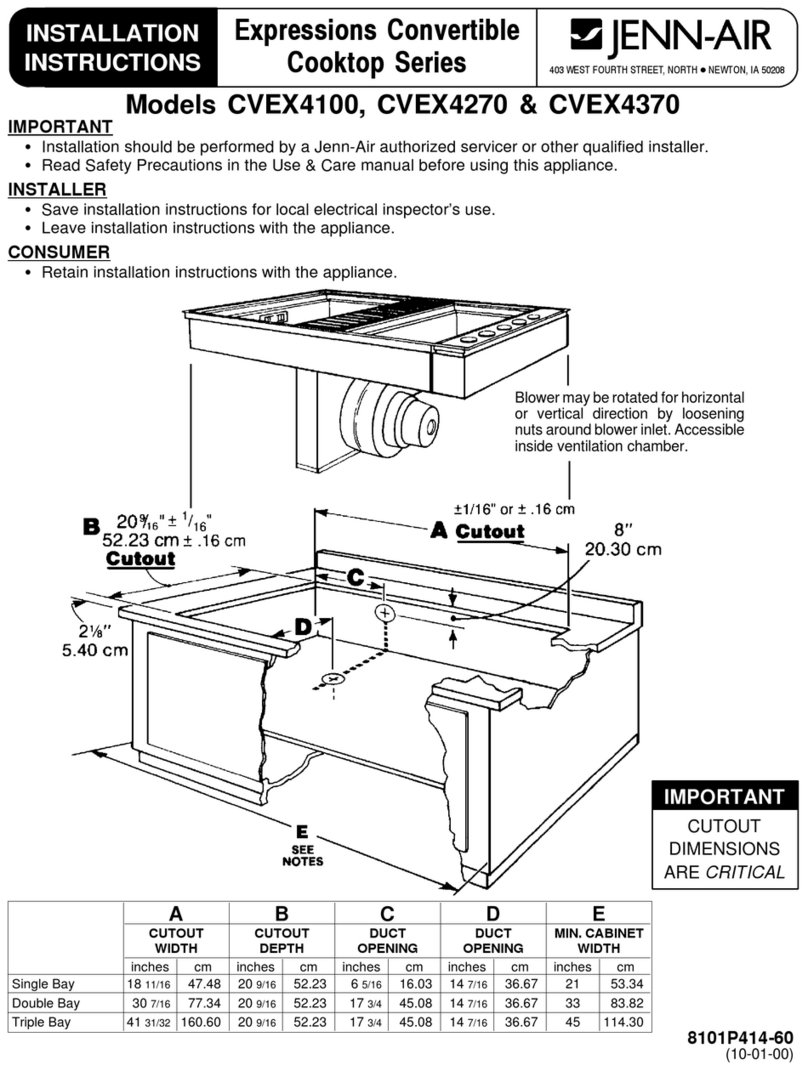

Location of Your Jenn-Air Appliance Preparation of Countertop

Locate this appliance away from combustiblematerials such The cutout in the countertop intowhich the appliance istobe

as window curtains and combustible wall decorations. The installed should be prepared according to the cutout dimen-

minimum horizontal clearance between the edge ofthe appli- sions given on page 1 of these instructions.

ance and adjacent combustible construction is:

• 0.75 inches (1.90 cm) at rear; CAUTION: Cutout dimensions are critical.Dimensions must

•2 inches (5.08 cm) at sides be measured and cut accurately to within + 1/16 to ensure

These minimum clearances pertain to vertical surfaces be-proper fit.

tween the countertop level and a level 18"above the coun-

tertop, Important Installation Suggestions:

1.Chamfer allexposed edges of decorative countertop lami-

ff*1nate to prevent damage from chipping.

2. Slightly radius corners ofcutout and file to insure smooth

18"edges and preventcorner cracking.

(45.7cm) 3. Rough edges, inside corners which have not been

rounded and forced fits can contribute to cracking of the

countertop laminate.

_]_J 2./_i_ 4.Unit must be supported onallfour sides by thecountertop

and countertop must besupported within 3"ofedgeof

(s.o8crn) cutout.

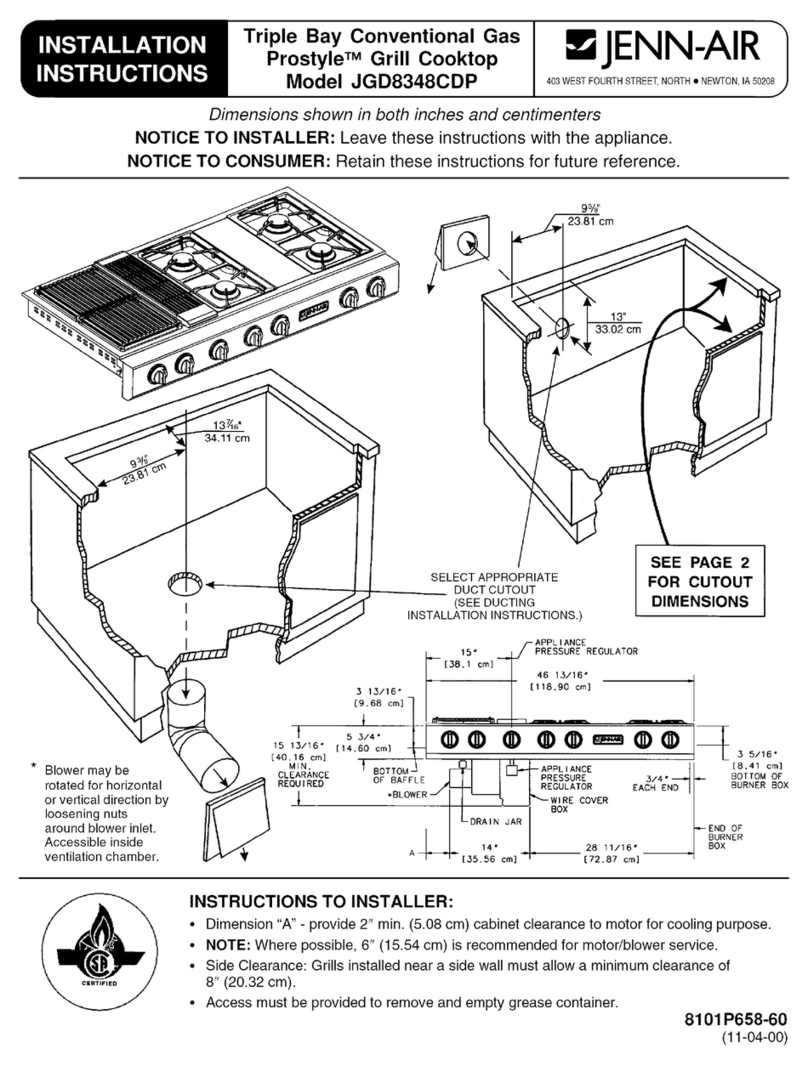

Fig. 1: MinimumHorizontalClearance Installation of Appliance

NOTE: These are not recommended clearances, but rather Follow accompanying ducting instructions carefully.

the minimum allowable clearances. Overall performance of

your cooktop will be enhanced by providinga6"or greater This appliance is designed to always be vented outdoors.

clearance on either side ofthe unit.Thisappliance should beducted separately fromothervented

appliances.

Installing Cabinetry Over Your Cooktop

Observe the following clearances to overhead cabinetry. This appliance is designed for usewith the gas appliance

pressureregulator provided.

The installationofthisappliance mustconform with localcodes

or, in the absenceoflocal codes,with the latest edition ofthe

National Fuel Gas Code, ANSI 7_223.1USAor current CAN/--

CGA-B149 INSTALLATION CODE.

'"-f ¢-_B_This applianceisdesigned tooperate at a pressure of5 inches

Aofwatercolumnon naturalgas or, ifconverted for use with

_, LPgas(propane or butane), 10 inches ofwater column. Make

I_ _:=E:__;=_ sure this appliance issuppliedwiththe type ofgas forwhich

_itis designed.

Fig. 2: MinimumClearancesto OverheadCabinetry This appliance was adjusted at the factory for use with natu-

ral gas. If, in the future, this appliance is to be used on a

A = 30 inches (76.2 cm) minimum vertical clearance be- different type ofgas, all of the conversion adjustments de-

tween cooking surfaceand combustibleconstruction scribed on pages 4 and 5 must be made by aservicetechni-

or metal cabinets above theappliance. This clearance clan or other qualified person beforeattempting to operate

may be reduced to not less than 24 inches by protect- the cooktop on that gas. Natural gas should be supplied to

ing theundersideofthe combustible materialor metal the appliance at a line pressure between 6 and 14 inches of

cabinet abovethe cooking surfacewith not less than water column or, if converted for LP gas, between 11 and 14

1/4-inchinsulating millboardcovered withsheet metal inches.

not less than 0.0122-inch thick.*

B=13 inches (33.0 cm) maximumdepth ofcabinets in- WARNING - Ifthe pressure ofthe gas system supplying

stalled abovecooking surface,this applianceexceeds 14'W.C., an external regulator (not

I provided) must be installed in thegas line to reduce the

CAUTION: Avoid use of cabinets above cooktop for storage system pressure to no more than 14" W.C.Failure to do

to eliminate potential hazard of reaching over open flames, this can result in excessive gas flow and exp os on.

*Jenn-AirOver-the-Range microwaveovens (model #M418andM438) have Make sure your appliance issupplied withthe type ofgas for

beenlistedby ULfor useoverGasandElectricRanges.Whenproperly which it is adjusted and that the gas isbeing supplied within

installedata minimumheightof66 inchesfromthefloortothetopofthe

microwave,theclearancetothecookingsurfaceatthecenterwillbe133.4 the appropriate pressure range.

inches. 2