Table of Contents

INTRODUCTION ............................................... 2

Foreword ........................................................ 2

Contact Info ................................................... 2

Functional Overview ...................................... 2

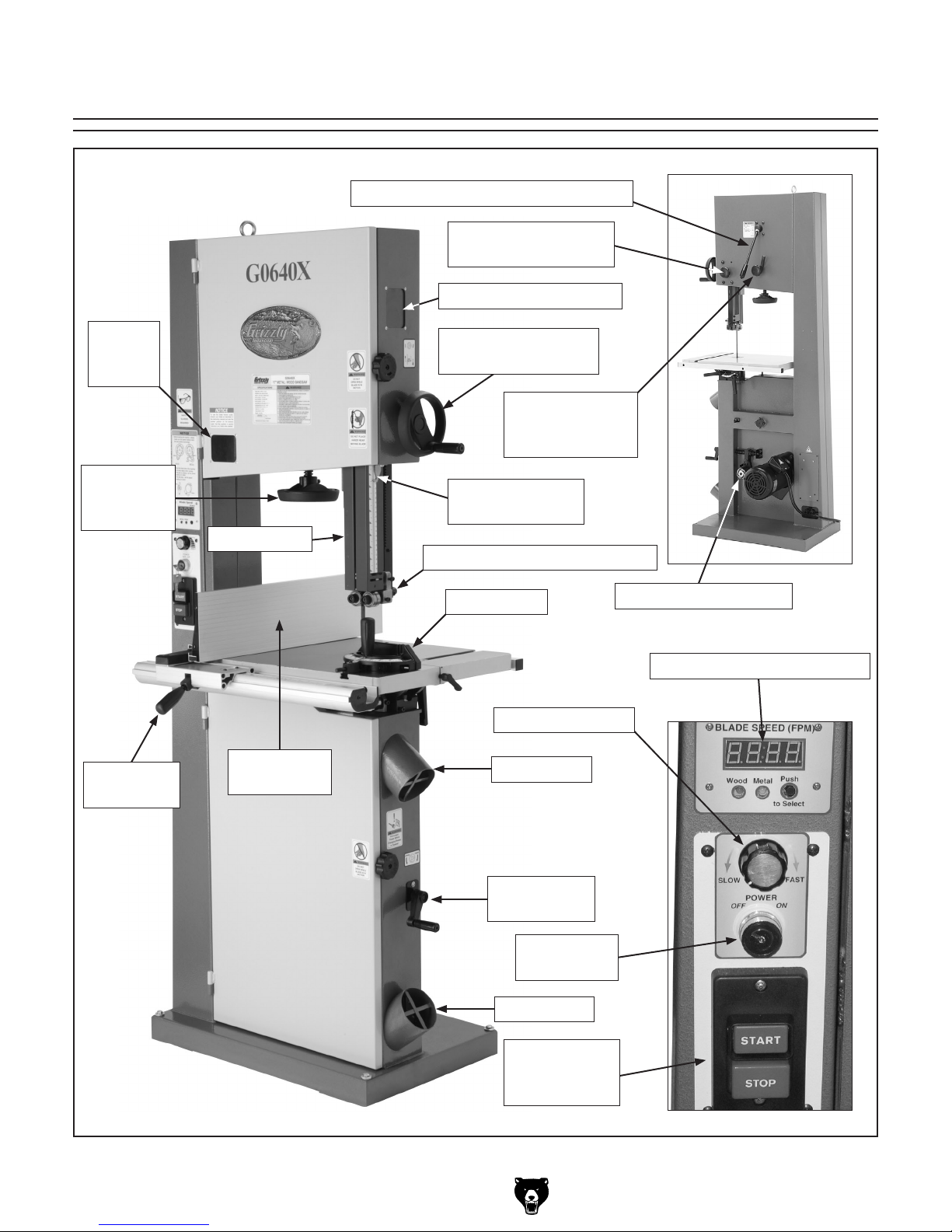

Identification ................................................... 3

Machine Data Sheet ...................................... 4

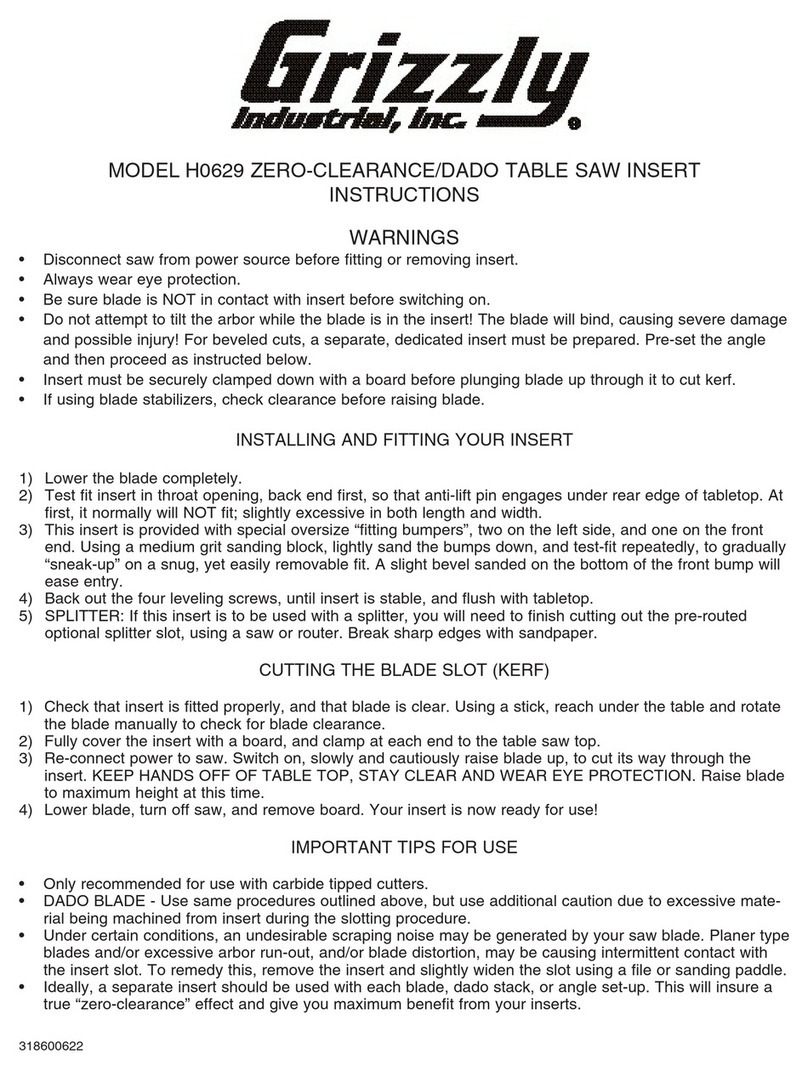

SECTION 1: SAFETY ....................................... 6

Safety Instructions for Machinery .................. 6

Additional Safety Instructions for Bandsaws . 8

SECTION 2: CIRCUIT REQUIREMENTS ........ 9

220V Operation .............................................. 9

SECTION 3: SETUP ....................................... 10

Setup Safety ................................................ 10

Items Needed for Setup ............................... 10

Unpacking .................................................... 10

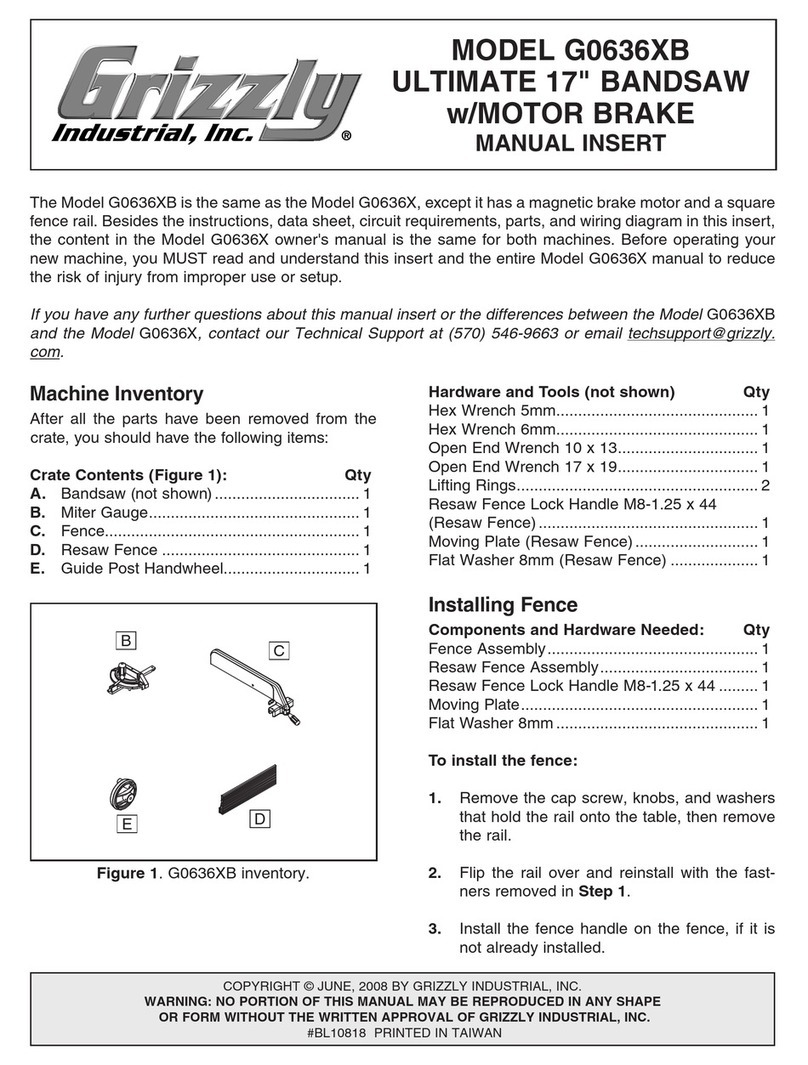

Inventory ...................................................... 11

Clean Up ...................................................... 12

Site Considerations ...................................... 12

Moving & Placing Bandsaw ......................... 13

Mounting ...................................................... 13

Assembly ..................................................... 14

Blade Tracking ............................................. 17

Test Run ...................................................... 18

Blade Tensioning ......................................... 19

Adjusting Blade Guides ............................... 20

Adjusting Support Bearings ......................... 21

Adjusting Positive Stop ................................ 22

Aligning Table .............................................. 23

Aligning Fence ............................................. 24

Miter Gauge ................................................. 24

SECTION 4: OPERATIONS ........................... 25

Operation Safety .......................................... 25

Guide Post ................................................... 25

Quick Release Blade Tension ..................... 26

Table Tilt ...................................................... 26

Blade Terminology ....................................... 27

Blade Selection ............................................ 27

Blade Breakage ........................................... 29

Blade Care & Break-In ................................. 29

Blade Changes ............................................ 30

Blade Speed ................................................ 31

SECTION 5: WOOD CUTTING ...................... 32

Workpiece Inspection .................................. 32

Cutting Tips .................................................. 32

Ripping ......................................................... 33

Crosscutting ................................................. 33

Resawing ..................................................... 34

Stacked Cuts ............................................... 35

Cutting Curves ............................................. 35

Cutting Circles ............................................. 35

SECTION 6: METAL CUTTING ...................... 36

Workpiece Inspection .................................. 36

Cutting Tips .................................................. 36

Choosing Blades and Speeds ..................... 37

Metal Chip Inspection Chart ........................ 38

SECTION 7: ACCESSORIES ......................... 39

SECTION 8: MAINTENANCE ......................... 41

Schedule ...................................................... 41

Cleaning ....................................................... 41

Wheel Brush ................................................ 41

Lubrication ................................................... 41

Redressing Rubber Tires ............................. 43

SECTION 9: SERVICE ................................... 44

Troubleshooting ........................................... 44

Replacing V-Belts ........................................ 46

Adjusting Wheel Brush ................................ 46

Wheel Alignment .......................................... 47

Shimming Table ........................................... 49

Blade Lead ................................................... 49

Adjusting Tension Lever .............................. 50

Electrical Component Wiring ....................... 51

Wiring Diagram ............................................ 52

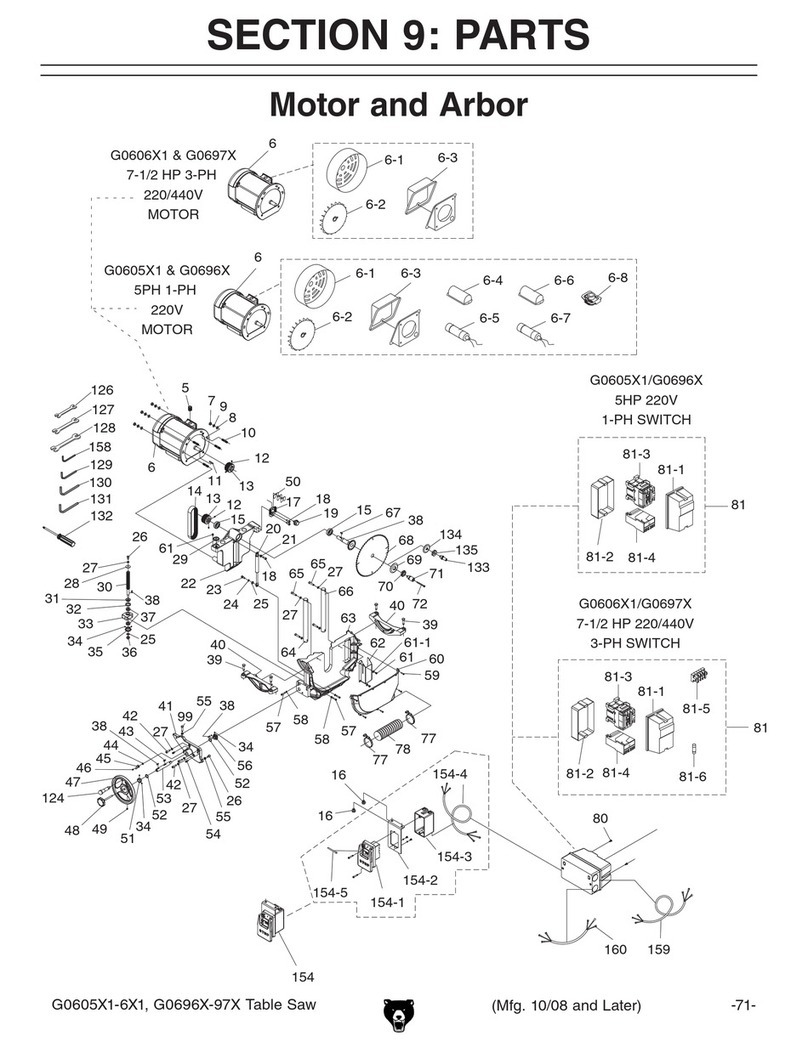

Main Parts .................................................... 53

Fence & Blade Guides ................................. 54

Parts List ...................................................... 55

Labels .......................................................... 58

WARRANTY AND RETURNS ........................ 61