INSTALLATION MANUAL

ZPS- K5.3, K10.3, K20.3 CLAMPING

MODULE WITH SENSOR MONITORING,

MOUNTING FLANGE

workholding@jergensinc.com

877.426.2504

SUBJECT TO TECHNICAL CHANGES.

JERGENS INC. · PHONE: 216.486.5540 · FAX: 216.481.6193 /553720 / 553721/

GENERALINSTRUCTIONS

TABLE OF CONTENTS

3

0.0

INTRODUCTION 4

0.1

Operating personnel ...................................................................................4

0.2

Trained personnel.......................................................................................5

0.3

Individual protective equipment ..................................................................5

0.4

General safety instructions ......................................................................... 6

0.5

Behavior in emergencies............................................................................. 6

0.6

Restrictions on use .....................................................................................7

0.7

Type plates .................................................................................................7

1.

TRANSPORT 8

2.

DESCRIPTION OF THE SYSTEM 8

2.1

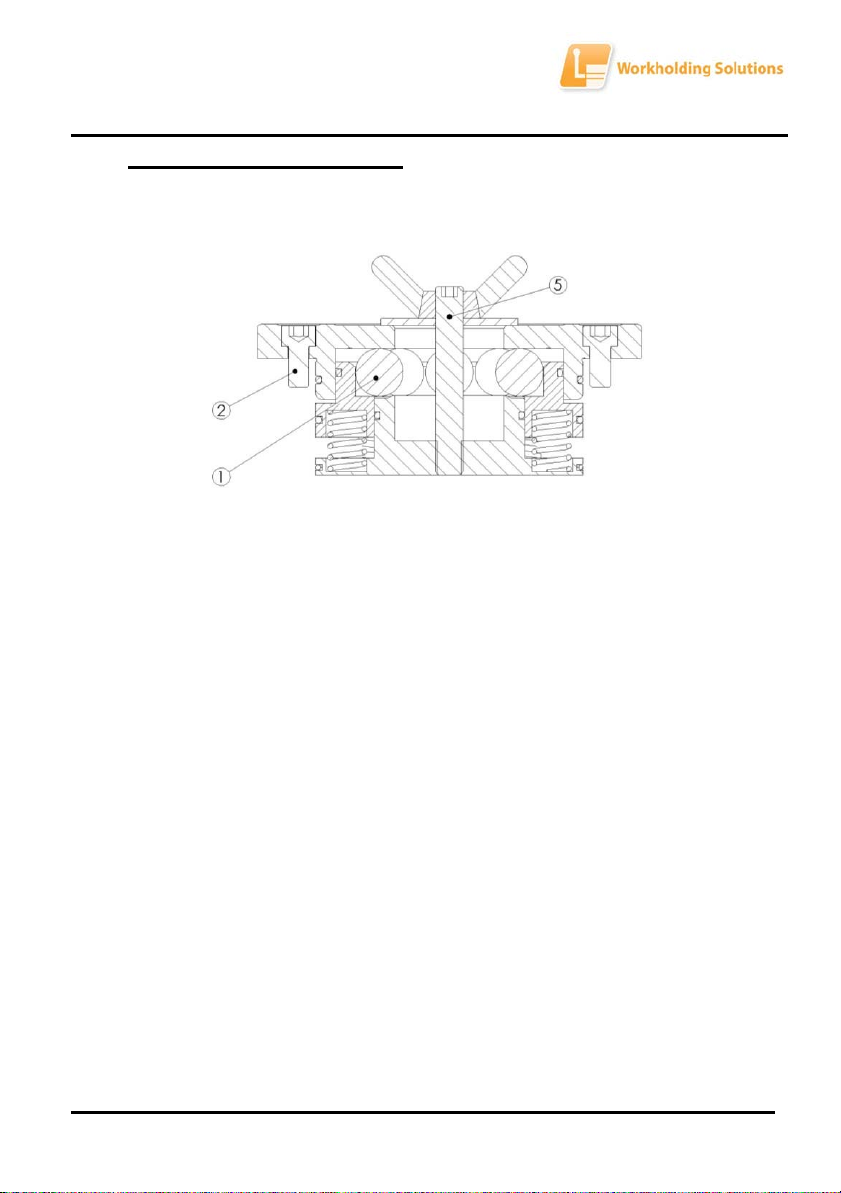

Structure of the Zero Point System (ZPS) ..................................................9

2.2

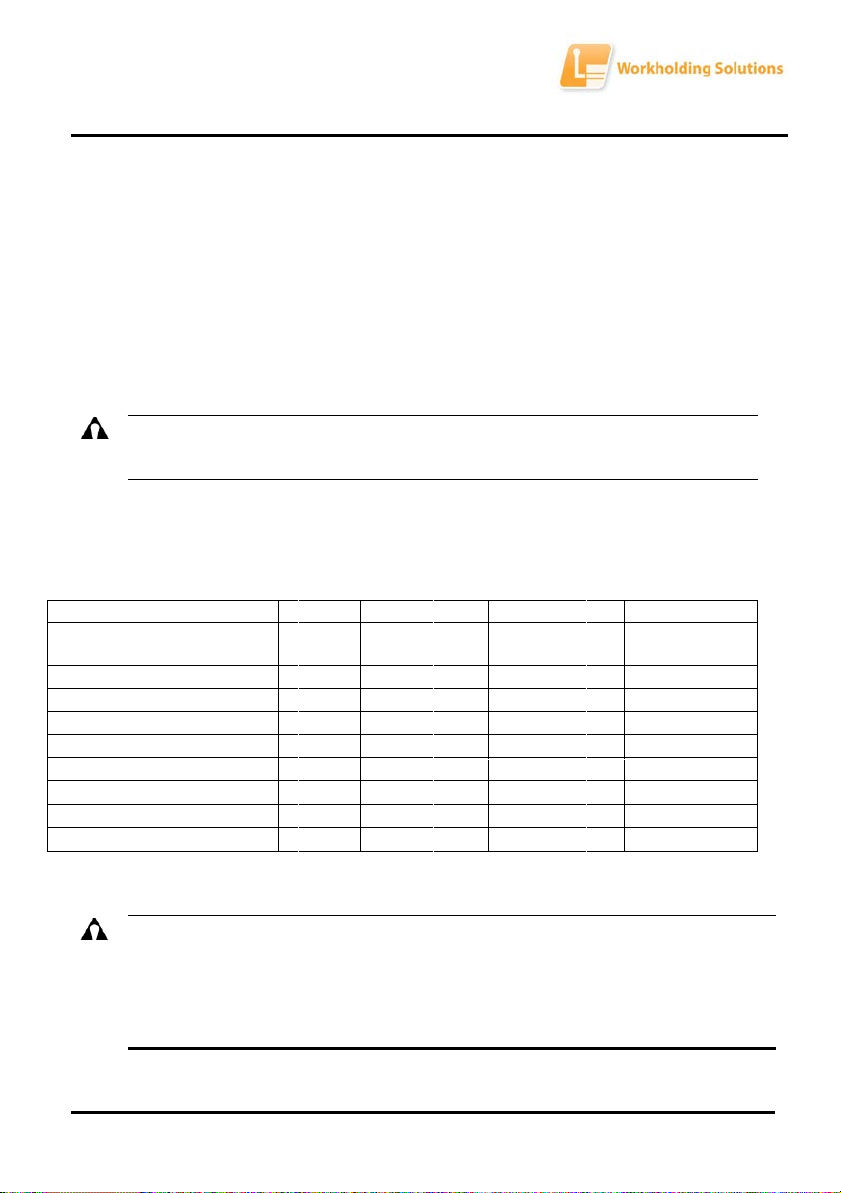

Technical data for inductive sensor ..........................................................11

2.3

Circuit diagram of the Zero PointSystem (ZPS).......................................11

2.4

Operation of the Zero Point System (ZPS) ...............................................11

3.

INSTALLATION 13

3.1

General.....................................................................................................13

3.2

Installation of the mounting flange............................................................14

3.3

Removal of the installation clamping module from the mounting flange... 14

3.4

4.

Installation of the clamping module in themounting flange ......................16

PULL STUD 17

4.1

Design.......................................................................................................17

4.2

Installation Instructions .............................................................................18

4.3

Tolerances and clamping nipple arrangement..........................................18

5.

PERFORMANCE AND RESTRICTIONS ON USE 20

5.1

Pull-in and locking force............................................................................20

5.2

Holding force.............................................................................................20

5.3

Safety precautions....................................................................................20

6.

MAINTENANCE 21

6.1

Introduction...............................................................................................21

6.2

Safety during maintenance.......................................................................21

6.3

Daily maintenance ....................................................................................21

6.4

Monthly maintenance................................................................................22

6.5

Maintenance.............................................................................................22

7.

POSSIBLE PROBLEMS AND HOW TO REMEDY THEM 23

8.

DECOMMISSIONING AND DISPOSAL 23

8.1

Decommissioning .....................................................................................23

8.2

Placing into storage ..................................................................................23

8.3

Disposal....................................................................................................23