ASG, Division of Jergens, Inc.

15700 S. Waterloo Road | Cleveland, OH 44110-3898 | Phone: (888) 486-6163 | Fax: (216) 481-4519 | Email: asginfo@asg-jergens.com | Web: www.asg-jergens.com | Revision: 07/21/2020 | Page 1 of 15

ASG ST Series Smart Transducer Digital Torque Tester

Operation Manual

Basic Description and Guidelines ..............................................................................2

Recommended Use ...................................................................................................2

General Characteristics ....................................................................................2

Installing the Batteries.....................................................................................2

Transducer Guidelines ......................................................................................2

Interchanging a Transducer ..............................................................................3

Safety Instructions............................................................................................3

Basic Operation................................................................................................3

Modes of Operation..................................................................................................4

Language Mode ...............................................................................................4

Units Mode ......................................................................................................4

Date Mode .......................................................................................................4

Track Mode ......................................................................................................5

Peak Mode .......................................................................................................5

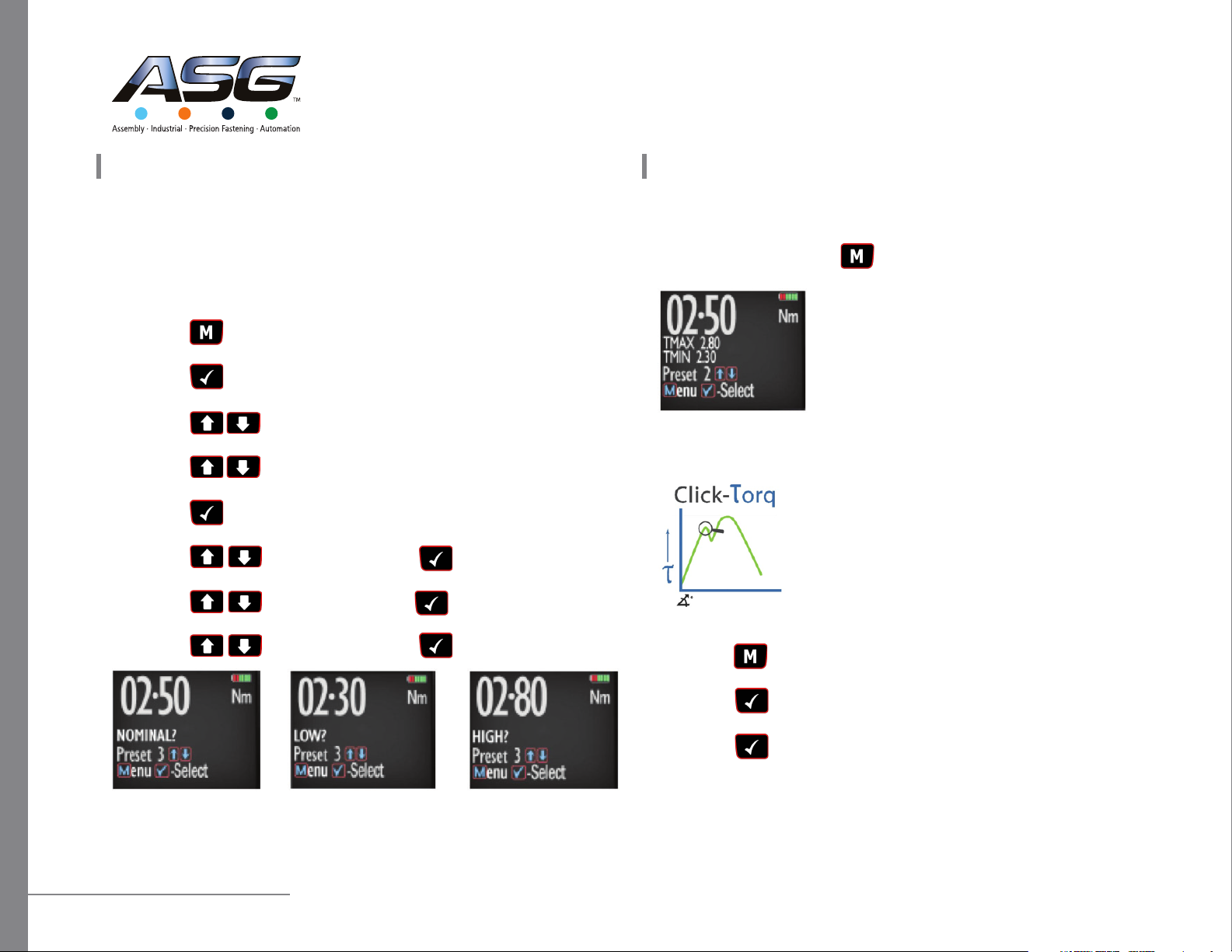

Preset Mode.....................................................................................................5

Set Mode..........................................................................................................6

Click-Torque Mode ...........................................................................................6

Dynamic Peak Mode ........................................................................................7

Recall Mode .....................................................................................................7

Upload Mode ...................................................................................................7

Comms Mode...................................................................................................7

Clear Mode ......................................................................................................8

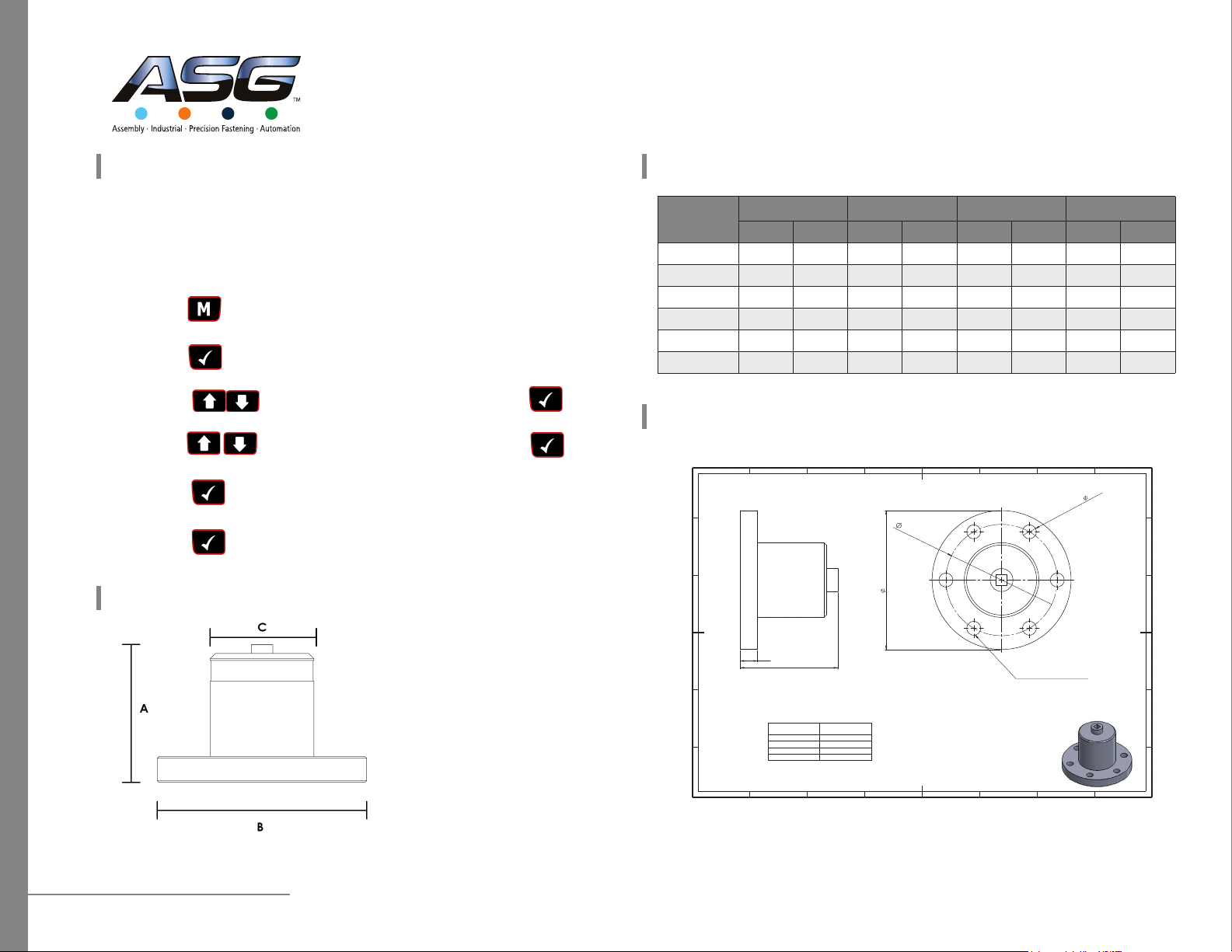

Product Dimensions .................................................................................................8

Transducer Flange .....................................................................................................8

Table of Contents Table of Contents (Cont.)

PCFE - PC Software...................................................................................................9

Installing the PCFE ...........................................................................................9

Communication with PCFE...............................................................................9

PCFE User Instructions ...........................................................................................10

Password........................................................................................................10

Menu Bar .......................................................................................................10

Calibration Settings........................................................................................11

Current Settings .............................................................................................11

Preset Conguration ......................................................................................11

Status Bar ......................................................................................................12

Results Table Controls ....................................................................................12

Results Table ..................................................................................................12

SPC Graph......................................................................................................13

Congure Torque Device Presets Using PCFE .................................................14

Add Data Field ...............................................................................................14

Wireless Communications ......................................................................................15

Connecting to a Wireless Receiver .................................................................15

Receiving Torque Results to the PCFE.............................................................15