Safet Instructions

WARNING

To guard against injury, basic safety precautions s ould be observed, including t e following:

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

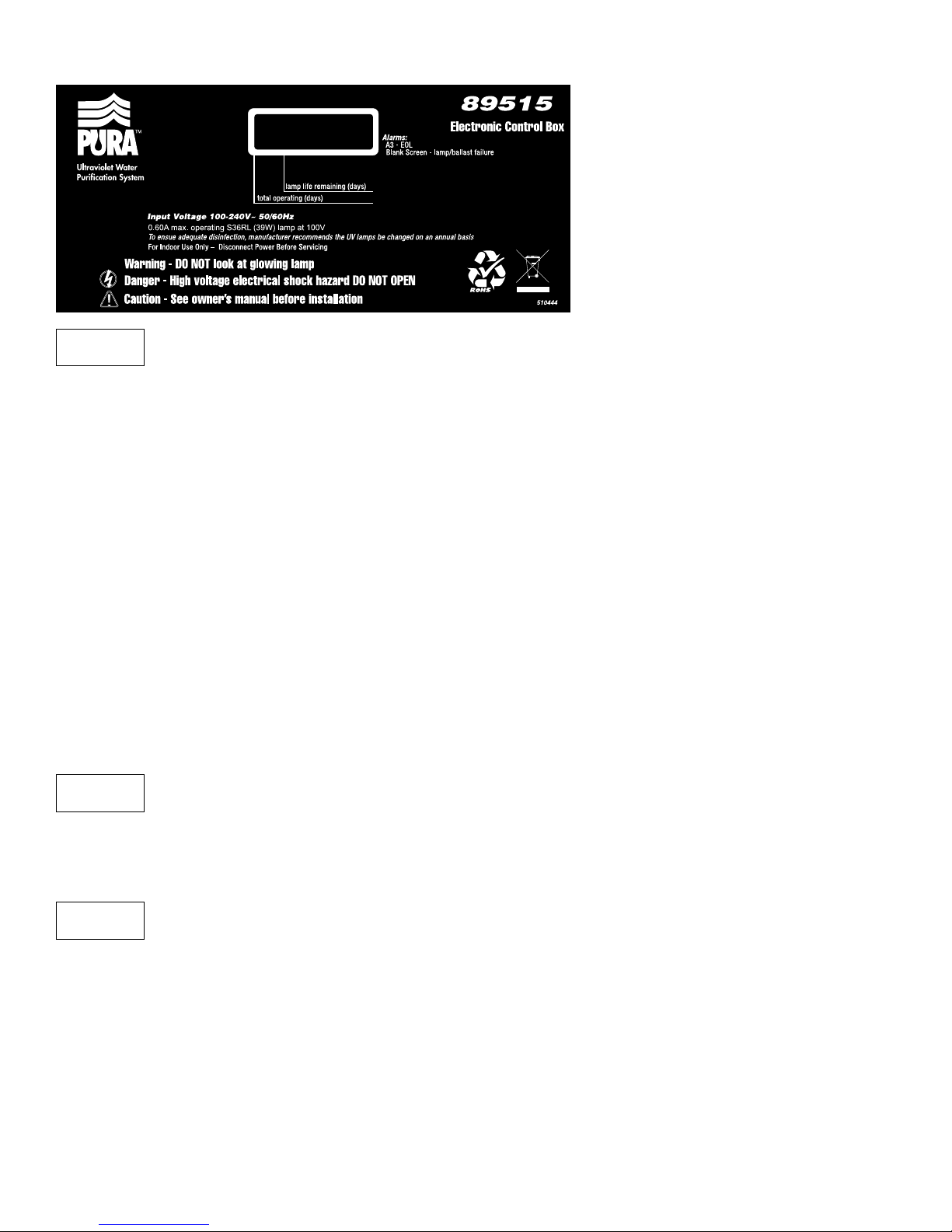

2. CAUTION - Always disconnect power before servicing.

3. DANGER - To avoid possible electric s ock, special care s ould be taken since water is present near electrical equip-

ment. Unless a situation is encountered t at is explicitly addressed by t e provided maintenance and troubles ooting

sections, do not attempt repairs by yourself, refer to an aut orized service facility.

4. Carefully examine t e disinfection system after installation. It s ould not be plugged in if t ere is water on parts not

intended to be wet suc as, t e ballast or lamp connector.

5. Do not operate t e disinfection system if it as a damaged cord or plug, if it is malfunctioning or if it as been dropped

or damaged in any manner.

6. Always disconnect water flow and unplug t e disinfection system before performing any cleaning or maintenance activ-

ities. Never yank t e cord to remove from an outlet; grasp t e wall plug and pull to disconnect.

7. Do not use t is disinfection system for ot er t an intended use (potable water applications). T e use of attac ments

not recommended or sold by t e manufacturer/distributor may cause an unsafe condition.

8. Intended for indoor use only. Do not install t is disinfection system w ere it will be exposed to t e weat er or to tem-

peratures below freezing. Do not store t is disinfection system w ere it will be exposed to t e weat er or to tempera-

tures below freezing unless all water as been drained from it and t e water supply as been disconnected.

9. Read and observe all t e important notices and warnings on t e water disinfection system.

10. If an extension cord is necessary, a cord wit a proper rating s ould be used. A cord rated for less Amperes or Watts

t an t e disinfection system rating may over eat. Care s ould be taken to arrange t e cord so t at it will not be tripped

over or pulled. Circuit breaker must not exceed power cord current rating (ie - 15A for Nort American NEMA 5-15P).

11. SAVE THESE INSTRUCTIONS

WARNING: T e UV lig t given off by t is unit can cause serious burns to unprotected eyes and skin. Never look directly

at an illuminated UV lamp. W en performing any work on t e UV disinfection system always unplug t e unit first. Never

operate t e UV system w ile t e UV lamp is outside of t e UV c amber.

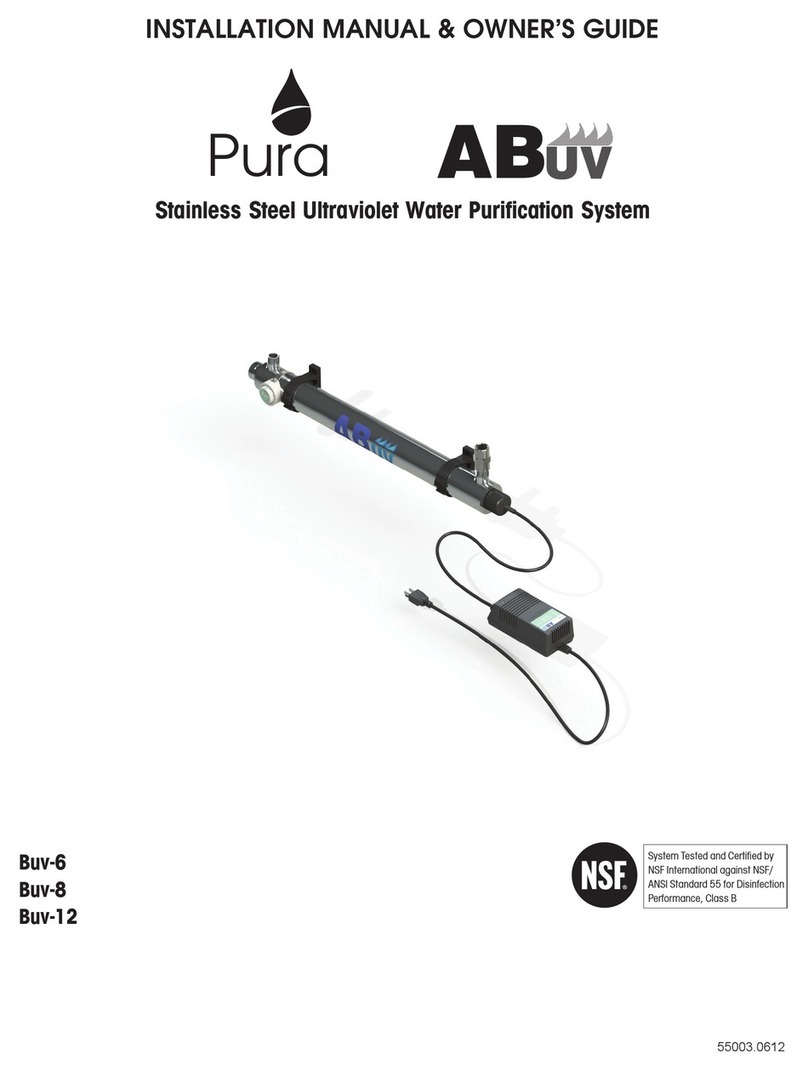

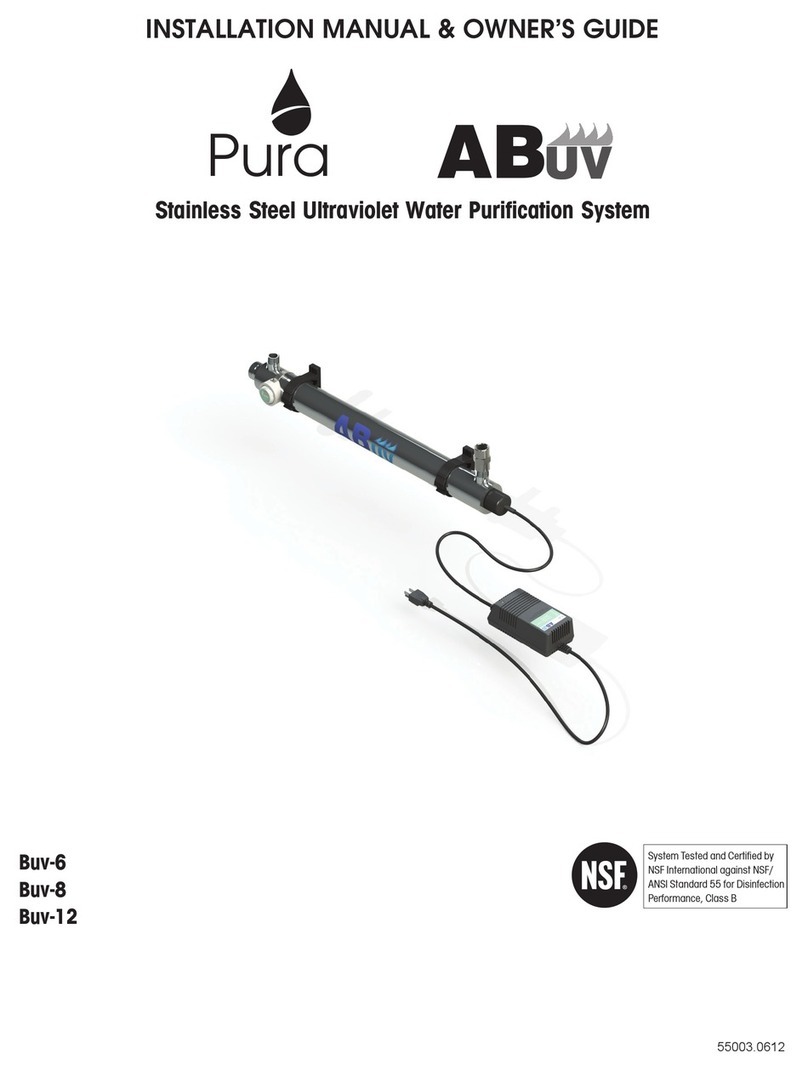

You ave purc ased one of t e most tec nologically

advanced Ultraviolet Water Treatment System available

anyw ere in t e world. It as been designed wit you, t e

consumer, in mind. PURA®products are lig tweig t, easy

to use, and simple to maintain. PURA products will pro-

vide you wit ealt y, clean drinking water for years to

come.

What is Ultraviolet?

Ultraviolet (UV) lig t from t e sun as long been known

for its ability to destroy microorganisms. However, it as

only been in recent years t at equipment producing UV

lig t as been manufactured for residential use.

UV energy is produced by low-pressure mercury vapor

enclosed in a tubular lamp. W ile a UV lamp resembles a

standard fluorescent lamp, it is similar in appearance only.

Energy produced by t e UV lamp as t e ability to

destroy microorganisms t at can live in water. T ere are

five major groups of microorganisms t at are altered by a

specific spectrum of ultraviolet lig t: viruses, bacteria,

fungi, algae, and protozoa.

W en t ese microbes are exposed to t e proper amount

of UV energy, t eir DNA structure is scrambled, and t ey

are unable to reproduce. Since t e cell is now sterile or

dead, it is no longer a t reat.

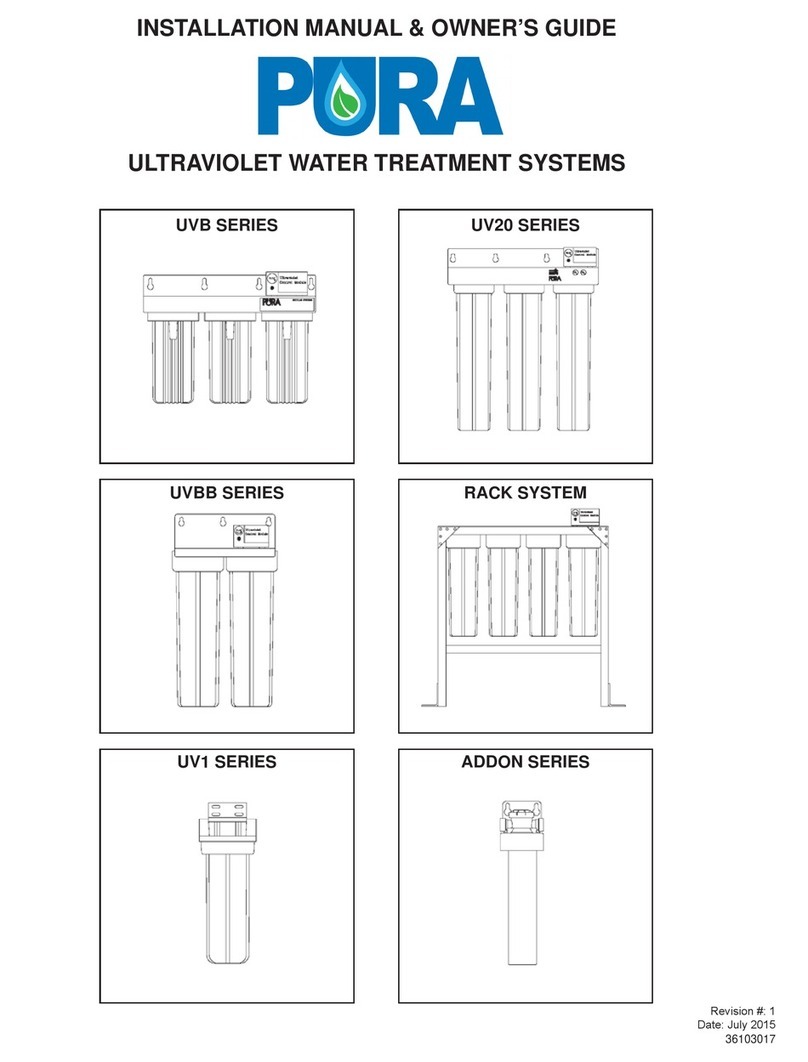

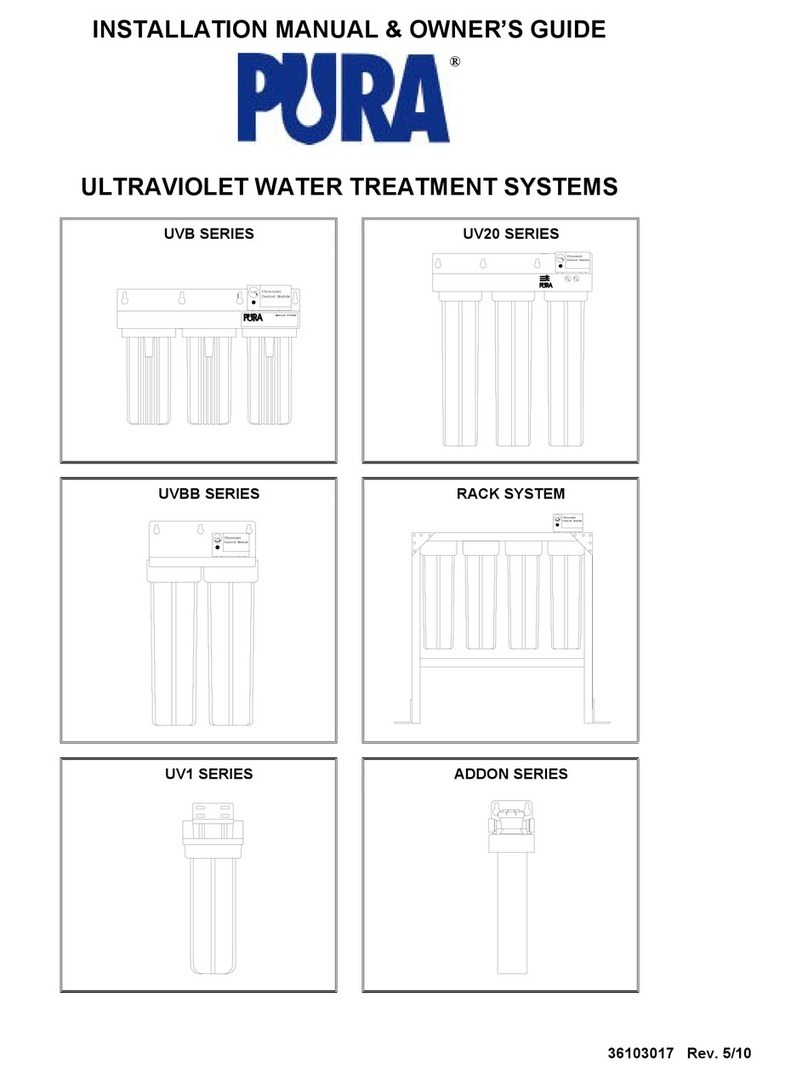

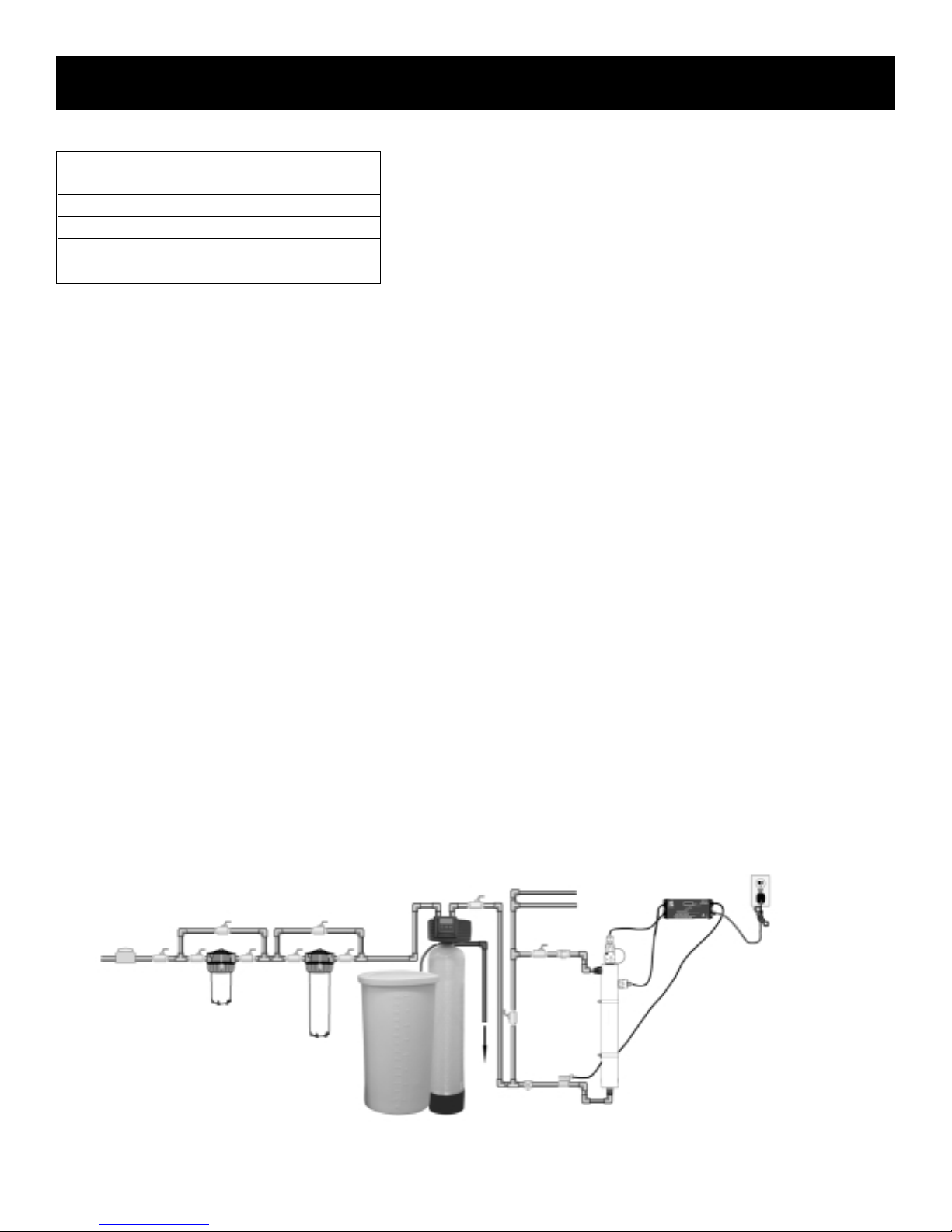

PURA S stems

PURA recommends t at all UV systems include pre-fil-

ters to process t e water before it reac es t e UV lamp.

T is will ensure t at maximum UV exposure is ac ieved.

PURA Ultraviolet Water Treatment Systems are designed

for indoor use only.

PURA Systems are designed to provide complete water

treatment in a compact, easy-to-use package. Please fol-

low t e directions in t is Guide exactly w en installing

your PURA System to ensure t at it operates correctly.

Specifications

Item # Model# Flow Rate** Flow Rate** Flow Rate** Power Lamp Inlet/ UV Chamber Size Control Box Size eight

@ 16 mJ/cm2@ 30 mJ/cm2@ 40 mJ/cm2Consumption atts Outlet (D x L) (L x x H) lbs (kg)

usgpm (L/min) usgpm (L/min) usgpm (L/min) atts Size inches (cm) inches (cm)

8750 UVSS-6 11 (41.63) 6 (22.71) 4.5 (17) 30 25 3/4" NPT 2.5"(6.35) x 22.07"(57.6) 7.3"(18.54) x 3.15"(8) x 2.52"(6.4) 7 (3.18)

8751 UVSS-10 20 (75.7) 10 (37.85) 7.7 (29.14) 46 37 3/4" NPT 2.5"(6.35) x 35.7"(90.6) 7.3"(18.54) x 3.15"(8) x 2.52"(6.4) 11 (5)

8752 UVSS-15 29 (109.76) 15 (56.77) 11 (41.63) 48 39 1" NPT 3.5"(8.9) x 38.1"(96.7) 7.3"(18.54) x 3.15"(8) x 2.52"(6.4) 14 (6.36)

8753 UVSS-6M 11 (41.63) 6 (22.71) 4.5 (17) 30 25 3/4" NPT 2.5"(6.35) x 22.07"(57.6) 8.3"(21) x 3.15"(8) x 2.52"(6.4) 8 (3.63)

8754 UVSS-10M 20 (75.7) 10 (37.85) 7.7 (29.14) 46 37 3/4" NPT 2.5"(6.35) x 35.7"(90.6) 8.3"(21) x 3.15"(8) x 2.52"(6.4) 12 (5.45)

8755 UVSS-15M 29 (109.76) 15 (56.77) 11 (41.63) 48 39 1" NPT 3.5"(8.9) x 38.1"(96.7) 8.3"(21) x 3.15"(8) x 2.52"(6.4) 15 (6.81)

1

*Flow r tes st ted t 96% UVDEOL. The m nuf cturer reserves the right to m ke product improvements which m y devi te from the specific tions nd

descriptions st ted herein, without oblig tion to ch nge previously m nuf ctured products or to note the ch nge.