3

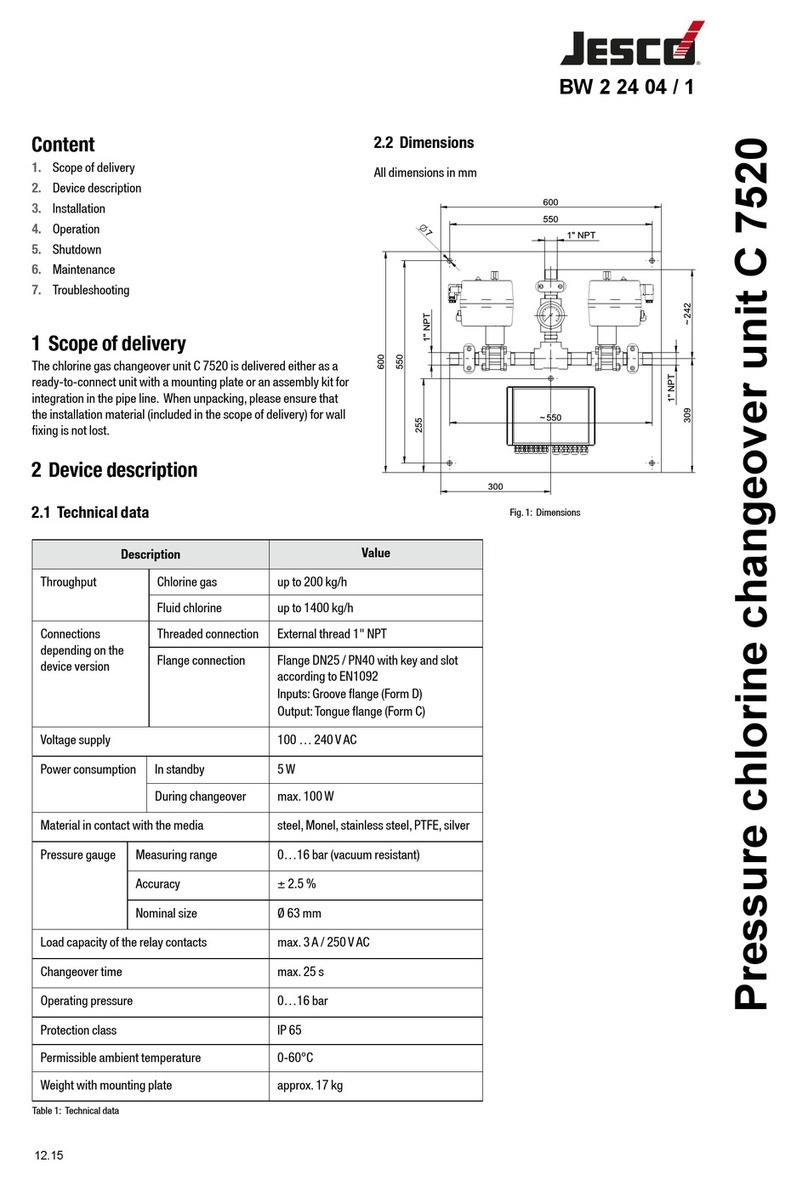

Content

1. Safety......................................................................................................................................................................................................4

1.1 General..................................................................................................................................................................................................4

1.2 Kennzeichnung von Hinweisen in der Betriebsanleitung.........................................................................................................................4

1.3 Qualification and training of personnel...................................................................................................................................................5

1.4 Important safety instructions..................................................................................................................................................................5

1.5 Hazards due to non-compliance with safety instructions........................................................................................................................5

1.6 Safe operation .......................................................................................................................................................................................6

1.7 Safety instructions for the owner/operator .............................................................................................................................................6

1.8 Safety instructions for inspection-, maintenance-, and installation work.................................................................................................6

1.9 Unauthorized modifications and production of spare parts .....................................................................................................................6

1.10 Impermissible modes of operation .......................................................................................................................................................6

1.11 Dosierung von Chemikalien..................................................................................................................................................................7

1.12 Scope of delivery .................................................................................................................................................................................8

2. General....................................................................................................................................................................................................9

3. Function...................................................................................................................................................................................................9

4. Technical data........................................................................................................................................................................................10

5. Mechanical handling capacity performance curves ................................................................................................................................10

6. Measurement drawing...........................................................................................................................................................................12

7. Installation.............................................................................................................................................................................................13

7.1 General information .............................................................................................................................................................................13

7.2 Installation location..............................................................................................................................................................................13

7.3 Drainage discharge..............................................................................................................................................................................14

7.4 Pressure sustaining and safety valves..................................................................................................................................................14

7.5 Injection nozzles ..................................................................................................................................................................................15

7.6 Electrical connection............................................................................................................................................................................15

7.7 Installation example............................................................................................................................................................................17

8. Stroke length setting..............................................................................................................................................................................17

9. Start up.................................................................................................................................................................................................18

10. Shutdown ............................................................................................................................................................................................19

11. Maintenance........................................................................................................................................................................................19

11.1 Lubricants .........................................................................................................................................................................................19

11.2 Maintenance of storage .....................................................................................................................................................................19

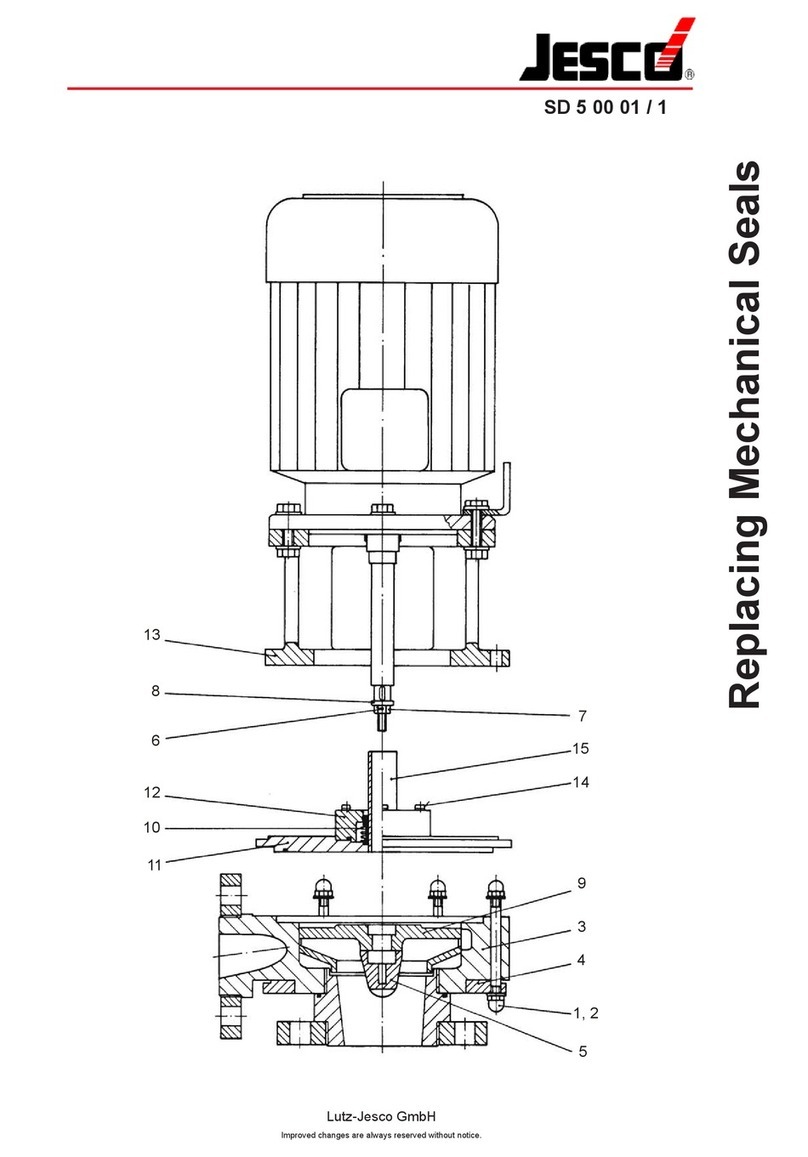

11.3 Replacing the diaphragm...................................................................................................................................................................20

11.4 Valves................................................................................................................................................................................................22

12. Spare parts list MIDIDOS E 24...72.......................................................................................................................................................26

12. Spare parts list MIDIDOS E 120............................................................................................................................................................28

13. Troubleshooting ...................................................................................................................................................................................30

14. Declaration of conformity.....................................................................................................................................................................32

15. Declaration of harmlessness................................................................................................................................................................33

16. Warranty..............................................................................................................................................................................................34