Jesco MAGDOS LK User manual

Dosing

Conveying

Control

Liquids

Gases

Systems

Original Operating Instructions

© Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump

MAGDOS LK

Operating Instructions

Read the Operating Instructions!

The user is responsible for installation and operation related mistakes!

Contents 3

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

Contents

1 Notes to the Reader............................................................4

1.1 General non-discrimination......................................................4

1.2 Explanation of signal words......................................................4

1.3 Explanation of warning signs....................................................4

1.4 Identification of warnings.........................................................4

1.5 Identification of instructions for action......................................5

2 Safety .................................................................................6

2.1 General warnings.....................................................................6

2.2 Hazards due to non-compliance with the safety instructions .....7

2.3 Safe operation .........................................................................7

2.4 Personal protective equipment.................................................7

2.5 Personnel qualification.............................................................7

3 Appropriate and intended use ...........................................8

3.1 Notes on product warranty.......................................................8

3.2 Intended purpose.....................................................................8

3.3 Device revision ........................................................................8

3.4 Principles ................................................................................8

3.5 Prohibited dosing media...........................................................8

3.6 Foreseeable misuse.................................................................8

4 Product Description .........................................................10

4.1 Properties..............................................................................10

4.2 Scope of delivery ...................................................................10

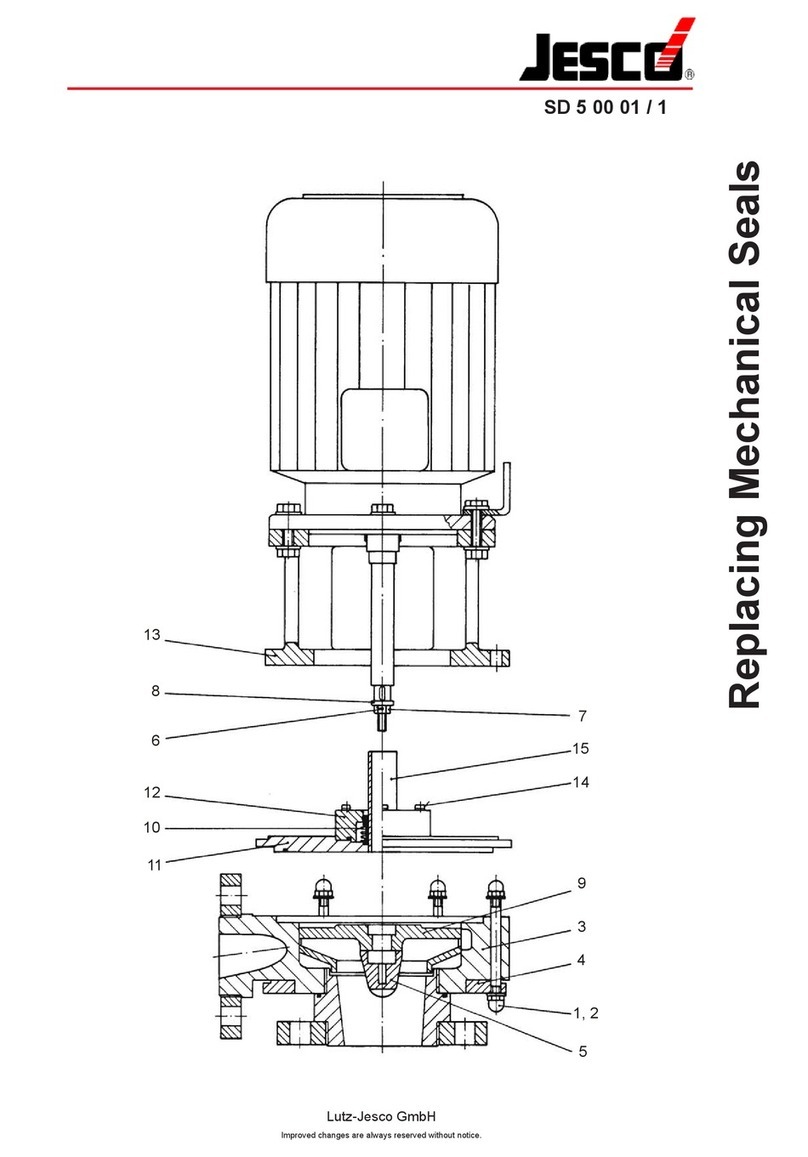

4.3 Structure of the dosing pump .................................................10

4.4 Function description ..............................................................11

4.5 Nameplate.............................................................................11

5 Technical Data..................................................................12

5.1 Delivery capacity data............................................................12

5.2 Operating conditions and limits ..............................................12

5.3 Electrical data........................................................................13

5.4 Other data .............................................................................13

6 Dimensions ......................................................................14

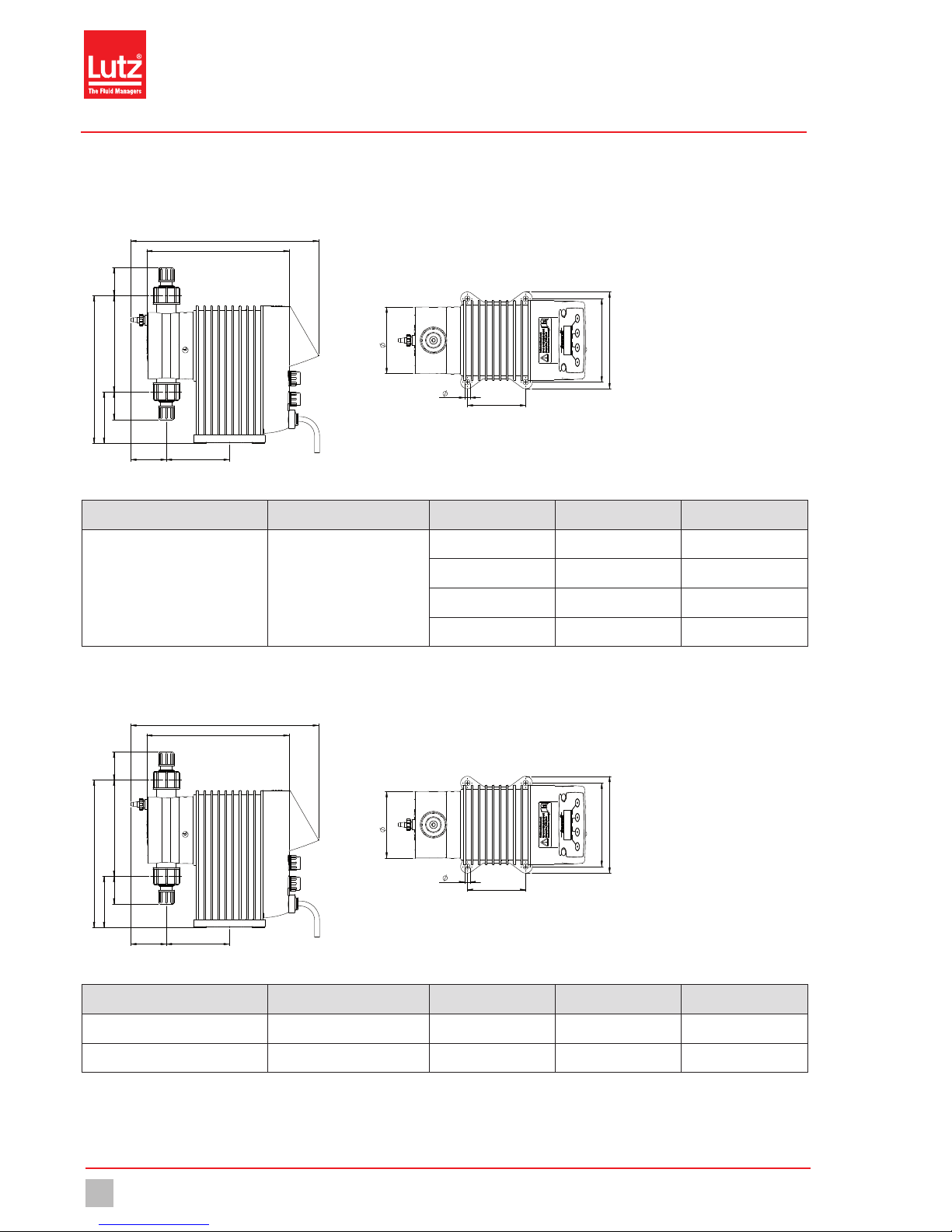

6.1 MAGDOS LK with dosing head made of PVC, PP or PVDF .........14

6.2 MAGDOS LK with dosing head made of stainless steel (1.4571)...

14

7 Installing the Dosing Pump..............................................15

7.1 Set up information .................................................................15

7.2 Installation examples .............................................................15

8 Hydraulic installation.......................................................16

8.1 Dimensioning of the system ...................................................16

8.2 System piping........................................................................17

8.3 Aligning the dosing head ........................................................17

8.4 Hydraulic connections............................................................17

8.5 Connecting a leakage drain....................................................19

8.6 Connecting the dosing head venting facility ............................19

8.7 Hydraulic accessories ............................................................20

9 Electrical installation.......................................................26

9.1 Principles ..............................................................................26

9.2 Description of connection sockets..........................................26

10 Control..............................................................................29

10.1 Operator controls of the control unit......................................29

10.2 Explanation of menu navigation............................................29

10.3 Explanation of the menu icons..............................................29

10.4 Menu settings at initial commissioning.................................30

10.5 Main menu ..........................................................................30

10.6 System setup.......................................................................30

10.7 Information about the dosing pump ......................................33

11 Operation..........................................................................34

11.1 Commissioning the dosing pump..........................................34

11.2 Operating modes .................................................................36

11.3 External On/Off via Release input..........................................39

11.4 Decommissioning the dosing pump......................................39

11.5 Shutting down in an emergency ...........................................40

11.6 Storage ...............................................................................40

11.7 Transportation......................................................................40

11.8 Disposal of old units.............................................................40

12 Maintenance ....................................................................41

12.1 Maintenance intervals..........................................................41

12.2 Tighten up dosing head bolts................................................42

12.3 Change the diaphragm.........................................................42

12.4 Clean suction and discharge valves......................................42

13 Troubleshooting ...............................................................43

13.1 Type of fault .........................................................................43

14 Spare parts.......................................................................46

14.1 Diaphragm spare parts kits ..................................................46

14.2 Dosing head spare parts kits including valves .......................46

15 Delivery characteristic curves.........................................47

16 Menu structure of the Control Unit ..................................48

16.1 Program start.......................................................................48

16.2 System setup.......................................................................48

16.3 Main menu ..........................................................................51

17 Appendix ..........................................................................53

17.1 Default settings....................................................................53

18 EC Declaration of Conformity...........................................54

19 Declaration of harmlessness...........................................55

20 Warranty application .......................................................56

Index ......................................................................................57

Notes to the Reader

General non-discrimination

4© Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

1 Notes to the Reader

These Operating instructions contain the information and rules of

behaviour necessary for safe and correct operation of the MAGDOS LK

dosing pump.

Follow these principles:

nRead the entire Operating instructions prior to commissioning the unit.

nEnsure that everyone who works with or on the dosing pump has read

the operating instructions and follows them.

nKeep the operating instructions for the entire service life of the dosing

pump.

nPass on the operating instructions to any subsequent owner of the

dosing pump.

1.1 General non-discrimination

In these operating instructions, only the male gender is used where

grammar allows gender allocation. The purpose of this is to make the text

easy to read. Men and women are always referred to equally. We would

like to ask female readers for understanding of this text simplification.

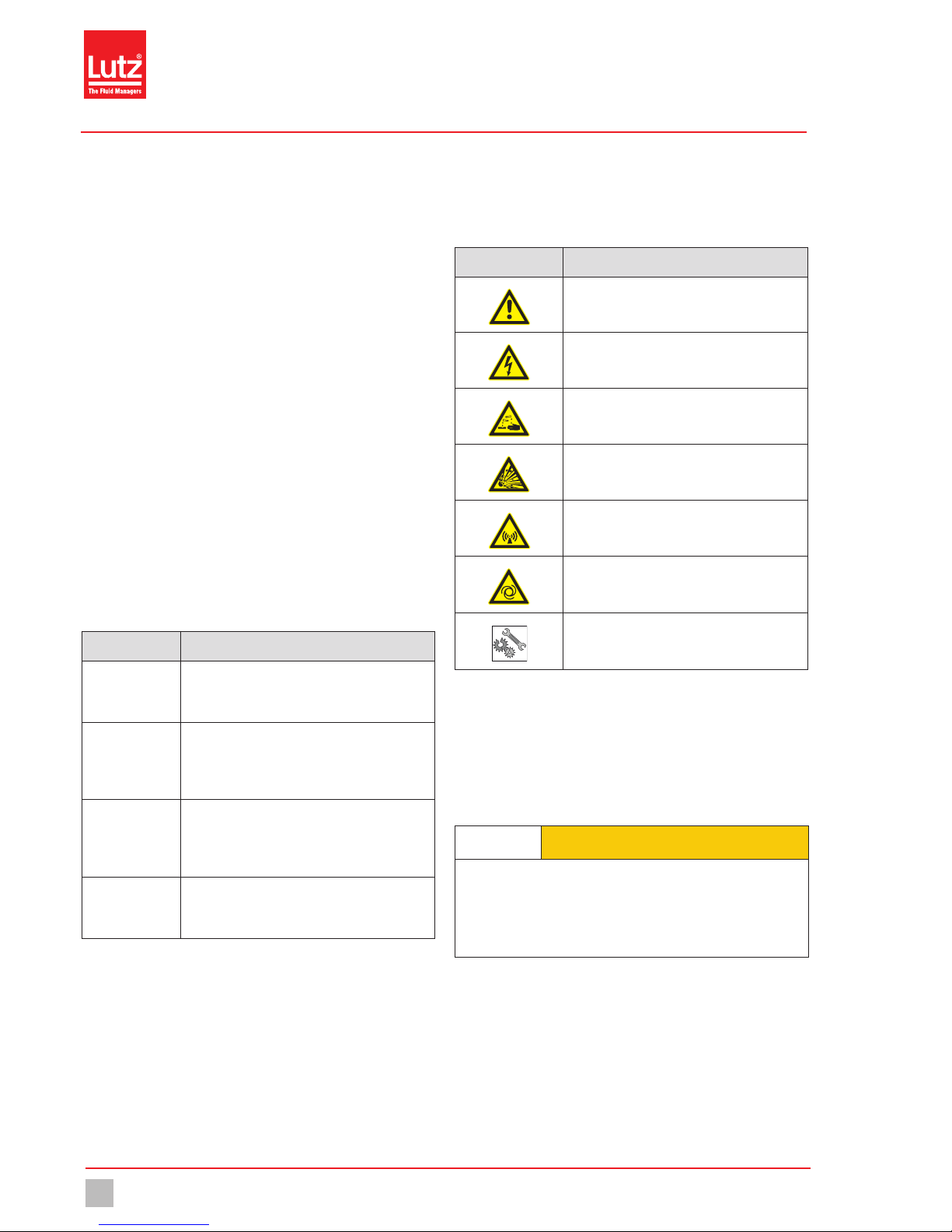

1.2 Explanation of signal words

Different signal words in combination with warning signs are used in

these Operating instructions. Signal words illustrate the gravity of

possible injuries if the risk is ignored:

Signal word Meaning

DANGER Refers to imminent danger. Ignoring this sign may

lead to death or the most serious injuries.

WARNING Refers to a potentially hazardous situation.

Ignoring this sign might lead to death or the most

serious injuries.

CAUTION Refers to a potentially hazardous situation.

Ignoring this sign may lead to light injuries or

damage to property.

NOTICE Refers to a danger which, if ignored, may

compromise the unit or its function.

Tab. 1: Explanations of signal words

1.3 Explanation of warning signs

Warning signs represent the type and source of a danger:

Warning sign Type of danger

General danger zone

Danger of electric shock

Danger of caustic or other burns.

Danger of explosions

Danger of magnetic radiation

Danger of automatic start up

Danger of damage to machine or compromised

function.

Tab. 2: Explanations of warning signs

1.4 Identification of warnings

Warnings are intended to help you recognise risks and avoid negative

consequences.

This is how warnings are identified:

Warning sign SIGNAL WORD

Description of danger.

Consequences if ignored.

ðThe arrow signals a precautionary measure to be taken to

eliminate the danger.

Notes to the Reader

Identification of instructions for action 5

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

1.5 Identification of instructions for action

This is how pre-conditions for action are identified:

üPre-condition for action which must be met before taking action.

This is how instructions for action are identified:

èSeparate step with no follow-up action.

1. First step in a series of steps.

2. Second step in a series of steps.

4Result of the above action.

üAction completed, aim achieved.

Safety

General warnings

6© Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

2 Safety

2.1 General warnings

The following warnings are intended to help you to eliminate the dangers

that can arise while handling the dosing pump. Risk prevention measures

always apply regardless of any specific action.

Safety instructions warning against risks arising from specific activities

or situations can be found in the respective sub-chapters.

DANGER

Danger to life due to electric shock!

Wrongly connected or located cables or damaged ones can injure you.

ðConnect the device only to a socket outlet with earthing contact

protected by a ground fault circuit interrupter (GFCI).

ðReplace damaged cables without delay.

ðDo not use extension cables.

ðDo not bury cables.

ðSecure cables to avoid being damaged by other equipment.

DANGER

Danger to life through explosions!

When using dosing pumps without ATEX certification in a potentially

explosive area, explosions can occur that result in fatal injuries.

ðNever use the MAGDOS LK dosing pump in potentially explosive

areas.

WARNING

Caustic burns or other burns through dosing media!

After connecting the mains supply, residual dosing media in the

dosing head can spray out.

ðBefore connecting the mains supply, connect the dosing lines.

ðCheck that all the screw connections have been tightened

correctly and are leak-proof.

WARNING

Caustic burns or other burns through dosing media!

While working on the dosing head, valves and connections, you may

come into contact with dosing media.

ðUse sufficient personal protective equipment.

ðRinse the dosing pump with a liquid (e.g. water) which does not

pose any risk. Ensure that the liquid is compatible with the dosing

medium.

ðRelease pressure in hydraulic parts.

ðNever look into open ends of plugged pipelines and valves.

WARNING

Caustic burns or other burns through dosing media!

The materials of the dosing pump and hydraulic parts of the system

must be suitable for the dosing medium that is used. Should this not

be the case, the dosing media may leak.

ðMake sure that the materials you are using are suitable for the

dosing medium.

ðMake sure that the lubricants, adhesives, sealants, etc. that you

use are suitable for the dosing medium.

WARNING

Danger due to magnetic radiation for people with

pacemakers!

During operation solenoid diaphragm dosing pumps emit a stray

magnetic field. If you do not keep far enough away, the function of a

pacemaker can be negatively affected.

ðPeople with pacemakers must always keep at least 50 cm away

from the dosing pump..

CAUTION

Increased risk of accidents due to insufficient qualifica-

tion of personnel!

Dosing pumps and their accessories may only be installed, operated

and maintained by personnel with sufficient qualifications. Insufficient

qualification will raise the risk of accidents.

ðEnsure that all action is taken only by personnel with sufficient and

corresponding qualifications.

ðPrevent access to the system for unauthorised persons.

Safety

Hazards due to non-compliance with the safety instructions 7

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

CAUTION

Danger of personal injury and material damage!

Changing dosing media can lead to unpredictable reactions.

ðThoroughly clean the dosing pump and appropriate sections of

the plant to avoid chemical reactions.

2.2 Hazards due to non-compliance with the safety

instructions

Failure to observe the safety instructions can pose a risk not only to the

personnel, but consequentially to the environment and the unit.

The specific consequences can be:

nFailure of vital functions of the dosing pump and the system,

nfailure of required maintenance and repair methods,

ndanger for individuals through dangerous dosing media,

ndanger to the environment through substances leaking from the

system.

2.3 Safe operation

Besides the safety instructions specified in these Operating instructions,

further safety rules apply and must be followed:

nAccident prevention regulations,

nsafety and operating provisions,

nsafety provisions for handling dangerous substances (mostly the

safety data sheets to dosing media),

nenvironmental protection provisions,

napplicable standards and legislation.

2.4 Personal protective equipment

Based on the degree of risk posed by the dosing medium and the type of

work you are carrying out, you must use corresponding protective

equipment. Read the Accident Prevention Regulations and the Safety

Data Sheets to the dosing media find out what protective equipment you

need.

As a minimum, the following protective equipment is recommended:

Protective clothing Protective gloves Goggles

Corresponding protective equipment must be used during these tasks:

nCommissioning,

nworking on the dosing pump while running,

ndecommissioning,

nmaintenance work,

ndisposal.

2.5 Personnel qualification

Any personnel who work on the dosing pump must have appropriate

special knowledge and skills.

Anybody who works with the dosing pump must meet the conditions

below:

nAttendance at all the training courses offered by the owner,

nPersonal suitability for the respective job,

nSufficient qualification for the respective job,

nTraining in handling of the dosing pump,

nKnowledge of safety equipment and the way this equipment

functions,

nKnowledge of these Operating instructions, particularly of safety

instructions and sections relevant for the job,

nKnowledge of fundamental regulations regarding health and safety

and accident prevention.

All persons must generally have the following minimum qualification:

nTraining as specialists to carry out work on the dosing pump

unsupervised,

nSufficient training that they can work on the dosing pump under the

supervision and guidance of a trained specialist.

These Operating instructions differentiate these user groups:

2.5.1 Expert staff

Expert staff are able, thanks to their professional training, knowledge and

experience as well as knowledge of the respective provisions, to do the

job allocated to them and recognise and/or eliminate any possible

dangers by themselves.

2.5.2 Trained persons

Trained persons have been trained by the operator into the tasks they are

supposed to perform and into the dangers stemming from improper

behaviour.

In the table below you can check what qualifications are the pre-condi-

tion for the respective tasks. Only people with appropriate qualifications

are allowed to perform these tasks!

Qualification Activities

Expert staff nAssembly

nHydraulic installations

nElectrical installations

nMaintenance

nRepairs

nCommissioning

nDecommissioning

nDisposal

nTroubleshooting

Trained persons nStorage

nTransportation

nControl

nTroubleshooting

Tab. 3: Personnel qualification

Appropriate and intended use

Notes on product warranty

8© Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

3 Appropriate and intended use

3.1 Notes on product warranty

Any non-designated use of the product can compromise its function or

intended protection. This leads to invalidation of any warranty claims!

Please note that liability is on the side of the user in the following cases:

nThe dosing pump is operated in a manner which is not consistent with

these Operating instructions, particularly the safety and handling

instructions and the chapter entitled „Appropriate and intended use“.

nIf people operate the product who are not adequately qualified to carry

out their respective activities,

nNo original spare parts or accessories of Lutz-Jesco GmbH are used,

nUnauthorised changes are made to the device by the user,

nThe user uses different dosing media than those indicated in the

order,

nThe user does not use dosing media under the conditions agreed with

the manufacturer such as modified concentration, density, tempera-

ture, contamination, etc.

3.2 Intended purpose

The MAGDOS LK dosing pump is intended for the following purpose: the

conveying and dosing of liquids.

3.3 Device revision

This operating manual applies to the following devices:

Device Month / year of

manufacture

Firmware

MAGDOS LK 03/2015 onwards 1.49 onwards

Tab. 4: Device revision

3.4 Principles

nBefore delivery, the manufacturer inspected the dosing pump and

operated it under specific conditions (with a specific dosing medium

with a specific density and temperature, with specific pipe dimen-

sions, etc.) Since these conditions vary at every installation location,

you must calibrate the dosing pump after delivery. For information on

the calibration procedure refer to “Calibrating the dosing pump“ (see

page35). For details on the approximate values and the capacity of

the dosing pump, refer to the chapter entitled “Delivery characteristic

curves“ (see page45).

nInformation on the usage and environment (see “Technical Data“ on

page12) applies.

nAny restrictions regarding the viscosity, temperature and density of

dosing media must be followed. You must only use dosing media at

temperatures above freezing point or below the boiling point of the

respective medium.

nThe materials of the dosing pump and hydraulic parts of the system

must be suitable for the dosing medium that is used. In this connec-

tion, note that the resistance of these components can change in

dependence on the temperature of the media and the operating

pressure.

i

Information on the suitability of materials combined with

different dosing media can be found in the Chemical

Resistance List of Lutz-Jesco GmbH.

The information in this resistance list is based on information

from the material manufacturers and on expertise obtained by

Lutz-Jesco from handling the materials.

As the durability of the materials depends on many factors,

this list only constitutes initial guidance on selecting material.

In all cases, test the equipment with the chemicals you use

under operating conditions.

nThe dosing pump is not intended for outdoor use unless appropriate

protective measures have been taken.

nAvoid leaks of liquids and dust into the casing and avoid direct

exposure to sunlight.

nYou must never operate dosing pumps in a potentially explosive

atmosphere if they do not have corresponding nameplates or an

appropriate EC Declaration of Conformity for potentially explosive

atmospheres.

3.5 Prohibited dosing media

The dosing pump must not be used for these media and substances:

nGaseous media,

nradioactive media,

nsolid substances,

ncombustible media,

nall other media that are not suitable for delivery using this dosing

pump.

3.6 Foreseeable misuse

Below, there is information about the applications of the dosing pump or

associated equipment that are not considered to be intended use. This

chapter is intended to allow you to detect possible misuse in advance and

to avoid it.

Foreseeable misuse is assigned to the individual stages of the product

lifetime:

3.6.1 Faulty assembly

nUnstable or unsuitable bracket

nDosing pump bolted wrongly or loosely

3.6.2 Faulty hydraulic installation

nSuction and pressure lines dimensioned incorrectly

nUnsuitable connection of the pipes due to wrong material or

unsuitable connections.

nSuction and pressure lines mixed-up

nDamage to threads due to them being tightened too much

nBending of pipelines

nNo free return flow of the pressure relief valve

nExcessive demand due to the pressure differences between the

suction and discharge valves

Appropriate and intended use

Foreseeable misuse 9

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

nThrough-suction at installation without back-pressure valves

nDamage due to undamped acceleration mass forces

nExceeding the admissible pressure on the suction and discharge sides

nUsing damaged parts

3.6.3 Faulty electrical installation

nConnecting the mains voltage without a protective earth

nUnsecured mains or one that does not conform to standards

nNot possible to immediately or easily disconnect the power supply

nWrong connecting cables for mains voltage

nDosing pump accessories connected to wrong sockets

nProtective earth removed

3.6.4 Faulty commissioning

nCommissioning with damaged plant

nShut-off valves closed at commissioning

nClosed suction or pressure line, e.g. due to blockages

nPersonnel was not informed before commissioning

nSystem was recommissioned after maintenance without all the

protective equipment and fixtures, etc. being reconnected.

nInadequate protective clothing or none at all

3.6.5 Faulty operation

nProtective equipment not functioning correctly or dismantled

nModification of the dosing pump without authority

nIgnoring operational disturbances

nElimination of operational disturbances by personnel without

adequate qualifications

nDeposits in the dosing head due to inadequate purging, particularly

with suspensions

nBridging the external fuse

nOperation made more difficult due to inadequate lighting or machines

that are difficult to access

nOperation not possible due to dirty or illegible display of the dosing

pump

nDelivery of dosing media for which the system is not designed

nDelivery of particulate or contaminated dosing media

nInadequate protective clothing or none at all

3.6.6 Faulty maintenance

nCarrying out maintenance during ongoing operation

nCarrying out work that is not described in the operating instructions

nNo adequate or regular inspection of correct functioning

nNo replacement of damaged parts or cables with inadequate

insulation

nNo securing against reactivation during maintenance work

nUsing cleaning materials that can cause reactions with the dosing

media

nInadequate cleaning of the system

nUnsuitable purging medium

nUnsuitable cleaning materials

nCleaning materials left in system sections

nUsing unsuitable cleaning equipment

nUsing the wrong spares or lubricants

nContaminating the dosing medium with lubricant

nInstalling spares without following the instructions in the operating

manual

nBlocking venting orifices

nPulling off sections of the plant

nContamination at installation without a dirt trap

nMixing up the valves

nMixing up the sensor lines

nNot reconnecting all the lines

nDamaging or not installing all the seals

nNot renewing seals

nNot paying attention to safety data sheets

nInadequate protective clothing or none at all

3.6.7 Faulty decommissioning

nNot completely removing the dosing medium

nDismantling lines while the dosing pump is running

nDevice not disconnected from the power supply

nUsing the wrong dismantling tools

nInadequate protective clothing or none at all

3.6.8 Faulty disposal

nIncorrect disposal of dosing media, operating resources and other

materials

nNo labelling of hazardous substances

Product Description

Properties

10 © Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

4 Product Description

4.1 Properties

The MAGDOS LK is a Solenoid-Diaphragm Dosing Pump that is used

when precise dosing results are required.

They are characterized by the following properties:

nOutput range from 0.5 to 15 l/h, up to 16 bar,

nReproducible dosing precision of w 2%,

nIntegrated automatic dosing head venting facility (except with

stainless steel (1.4571) dosing heads),

nSuitable for highly aggressive or poisonous dosing media,

nOperating modes: Manual mode and Pulse input,

nGraphic display: 128 x 64 px, 1.5“, monochrome, illuminated,

nMenu languages: English, German, French, Spanish, Portuguese,

Dutch,

nFour multifunction keys for operator inputs,

nFloor- and wall-mounting options,

nRelease code and security code,

nCalibration option,

nEco-Mode energy-saving mode,

nConnections: M12x1 connector, A-coded

4.2 Scope of delivery

Please compare the delivery note with the scope of delivery. The

following items are part of the scope of delivery:

nMAGDOS LK dosing pump,

nOne set each of hose clamping connections for the suction and

discharge sides for hoses with diameters of 4/6 mm, 6/9 mm and

6/12 mm (made of PVC, PP and PVDF),

n3 covering caps for electrical connections (mounted on the dosing

pump),

nMains cable,

nOperating Manual,

nInspection report and test certificate (optional),

nAccessory kit (optional).

4.3 Structure of the dosing pump

4.3.1 General Overview

a

b

c

Fig. 1: Overview of MAGDOS LK dosing pump

No. Description

aDosing head

bDrive unit

cControl unit

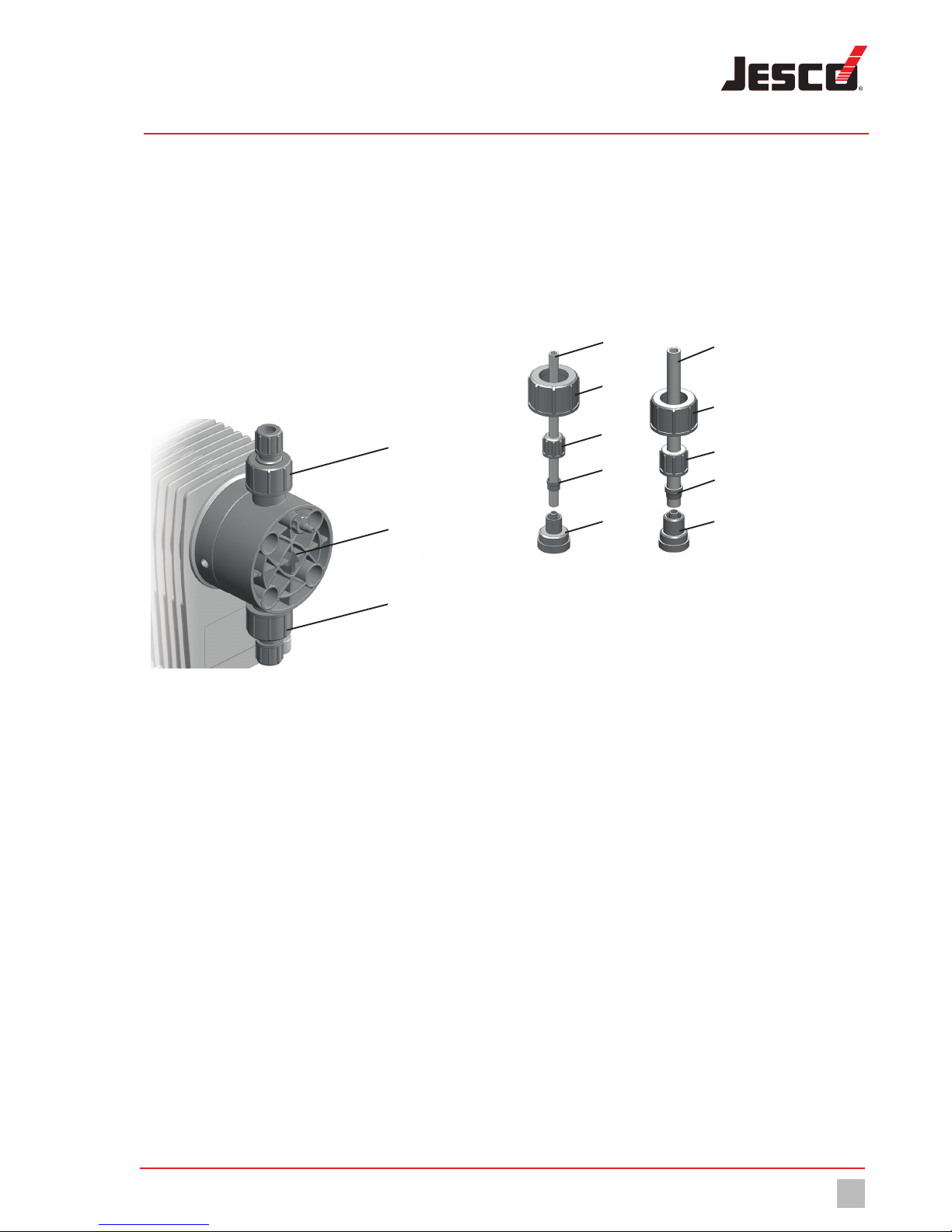

4.3.2 Dosing head

a

c

d

b

Fig. 2: Dosing head

No. Description

aValve and connection on the discharge side

bintegrated dosing head venting facility (plastic version only)

cArrow indicating the direction of throughflow of the dosing

medium (plastic version only)

dValve and connection on the suction side

Product Description

Function description 11

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

4.3.3 Control elements

a

b

d

c

Fig. 3: Controller of MAGDOS LK dosing pump

No. Description

aGraphic display

bMultifunction keys on the contol unit for operator inputs

cConnection sockets for external operation or connecting

accessories

dMains cable for power supply

Tab. 5: Designation of components

4.4 Function description

Dosing pumps are positive displacement pumps. They are used if

precisely defined delivery of a medium is necessary. A constant volume

per stroke or time is delivered.

The system delivers or meters the dosing medium by means of a

repeated sequence of suction strokes followed by pressure strokes. This

results in a pulsing flow.

If the dosing pump is in the suction stroke phase, the diaphragm is pulled

into the rear final position. Due to the resulting vacuum in the dosing

head, the discharge valve closes, the suction valve opens and dosing

medium flows from the suction line into the dosing head.

If the dosing pump is in the pressure stroke phase, the diaphragm is

moved into the front final position. Due to the pressure in the dosing head,

the suction valve closes and the dosing medium flows through the

discharge valve from the dosing head into the pressurised pipe.

4.5 Nameplate

There is information on the equipment about safety or the product‘s way

of functioning. The information must stay legible for the duration of the

service life of the product.

Fig. 4:

Material:

Max. XXX l/h at bar

Max. XXX l/h at bar

IP XX, XXX V, XXXX Hz, XX W

Lutz-Jesco GmbH

30900 Wedemark Germany

XX/XXXX

S/N: XXXXXXXXXXP/N:

Made in Germany

*102A12345678*

*12345678012345*

MAGDOS LK

a

b

c

d

e

MAGDOS LK nameplate

No. Description

aProduct, type, nominal size

bPart number

cType of material of dosing head/ type of material of seals

dMaximum delivery capacity at average pressure

eMaximum delivery capacity at maximum pressure

fProtection class

gVoltage supply

hFrequency

iPower consumption

jWEEE label

kLabel showing conformity with applicable European directives

lMonth / year of manufacture

mSerial number

Tab. 6: Nameplate

f g h i

j

k

l

m

Technical Data

Delivery capacity data

12 © Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

5 Technical Data

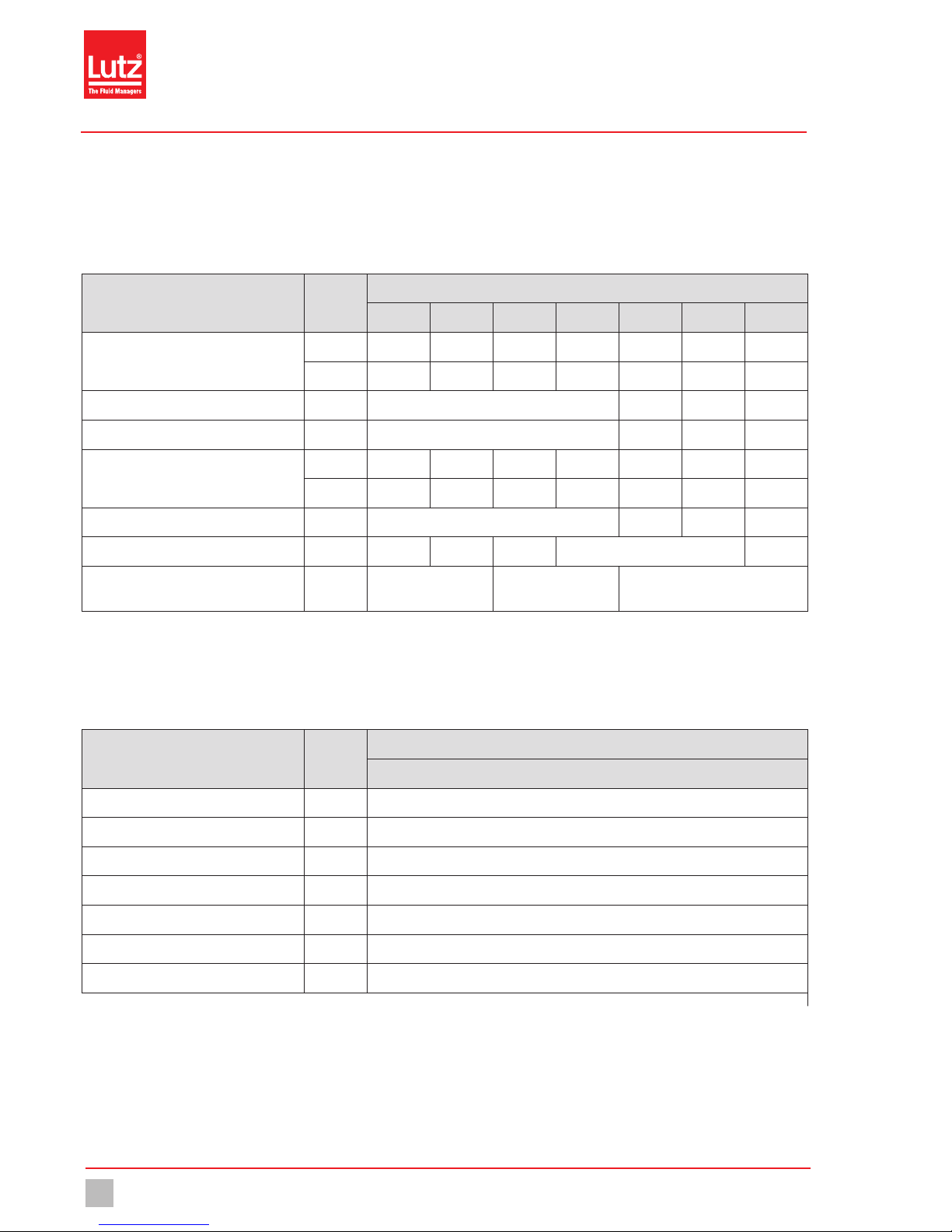

5.1 Delivery capacity data

Please note that some of this data only represents guide values. The actual capacity of a dosing pump depends on various factors. For approximate

values of the delivery capacity at different pressures, refer to “Delivery characteristic curves“ (see page45).

Information Value

MAGDOS LK size

05 1 2 4 6 10 15

Delivery capacity at max. back pressure

l/h 0.36 0.76 1.9 3.4 6.2 9.0 13

ml/stroke 0.05 0.05 0.2 0.32 0.57 0.83 0.87

Max. back pressure bar 16 8 6 3

Max. delivery pressure in Eco-Mode 1* bar 10 6 4 2

Delivery capacity at average back pressure

l/h 0.54 1.1 2.3 3.8 6.8 10 15

ml/stroke 0.08 0.08 0.24 0.35 0.63 0.92 1

Average back pressure bar 8 4 3 1

Max. stroke frequency RPM 120 250 160 180 250

Suction head for non-gassing media

(suction line filled) mWS 5 3 2

Tab. 7: Output data

* In the case of operation in Eco-Mode energy saving mode, the delivery capacity is 5-10 % less than in normal mode (with the same back pressure).

If necessary, recalibration may be necessary (see “Calibrating the dosing pump“ on page 35).

5.2 Operating conditions and limits

Information Value

MAGDOS LK size

05 – 15

Permitted ambient temperature °C 0 – 45 (0 – 40 with PVC parts)*

Relative humidity %Max. 90

Max. sound pressure level (depressurised) dB(A) 68 – 75

Max. sound pressure level (at test pressure) dB(A) 65 – 70

Max. supply pressure mbar 800

Viscosity limits mPas 300** / 1000***

Adjustable dosing range %0 – 100

Tab. 8: Operating conditions and limits

* Use of dosing pumps at ambient temperatures of under 5 °C has to be checked individually. In those cases please contact the manufacturer.

** With a viscosity of ~300 mPas and above, you must use spring-loaded valves.

*** If the viscosity is above 1000 mPas, this must be checked individually and the stroke frequency must be between 50 and 100 strokes/min.

Technical Data

Electrical data 13

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

5.2.1 Permitted temperature of the medium

Information Value MAGDOS LK (all sizes)

Dosing head made of PVC °C 0 – 35

Dosing head made of PP °C 0 – 60

Dosing head made of PVDF °C 0 – 80

Dosing head made of stainless steel (1.4571) °C 0 – 80

Tab. 9: Permitted temperature of the medium

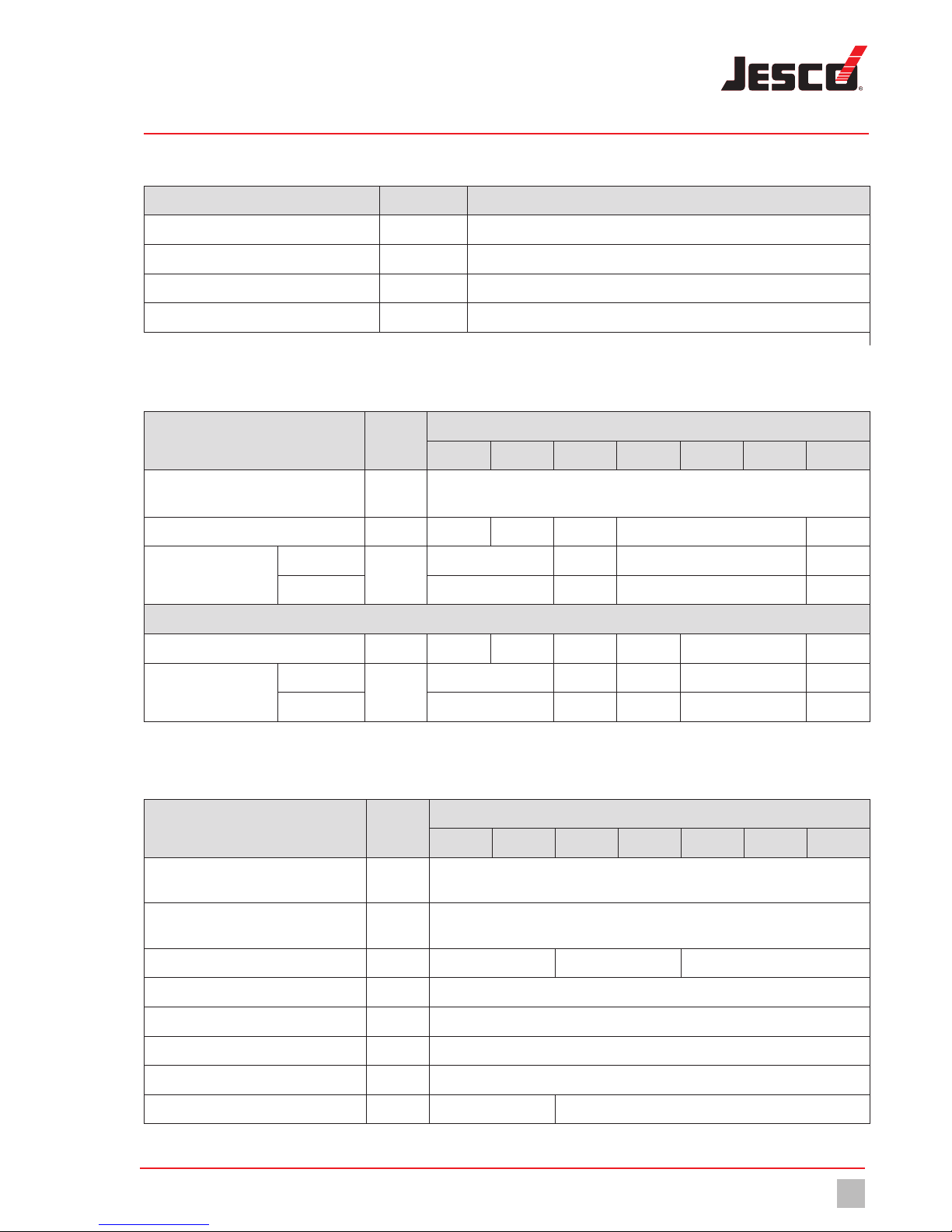

5.3 Electrical data

Information Value

MAGDOS LK size

05 1 2 4 6 10 15

Voltage supply 230 V AC ± 10 %, 50/60 Hz or

115 V AC ± 10 %, 50/60 Hz (refer to name plate)

Power consumption W 8 13 19 25 22

Max. current consump-

tion during dosing stroke

at 115 V AC

A

1,8 2,3 2,5 2,3

at 230 V AC 0,9 1,1 1,4 1,2

Eco-Mode 1

Power consumption W 6 9 14 16 18 17

Max. current consump-

tion during dosing stroke

at 115 V AC

A

1,6 1,9 2,2 2,3 2,0

at 230 V AC 0,8 0,9 1,0 1,1 0,9

Tab. 10: Electrical data

5.4 Other data

Information Value

MAGDOS LK size

05 1 2 4 6 10 15

Weight (with dosing head made of PVC, PP

or PVDF)

kg ~ 3.2

Weight (with dosing head made of stainless

steel (1.4571))

kg ~ 4.3

Diameter of diaphragm mm 24 33 39

Electrical cable m1.8 m (with mains plug)

Protection class IP65 (with covering caps on the connections)

Insulation class F

Valve connection G 5/8 external

Valve size DN3 DN4

Tab. 11: Other data

Dimensions

MAGDOS LK with dosing head made of PVC, PP or PVDF

14 © Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

6 Dimensions

6.1 MAGDOS LK with dosing head made of PVC, PP or PVDF

Fig. 5: Dimensioned drawing of MAGDOS LK with dosing head made of PVC, PP or PVDF (all dimensions in mm)

Connection Material Size Nominal diameter L

Hose clip PVC / PP / PVDF

4/6 mm DN4 31

1/4x3/8” 1/4“ 34

6/9 mm DN6 34

6/12 mm DN6 15

6.2 MAGDOS LK with dosing head made of stainless steel (1.4571)

Fig. 6: Dimensioned drawing of MAGDOS LK with dosing head made of stainless steel (1.4571) (all dimensions in mm)

Connection Material Size Nominal diameter L

Hose clip Stainless steel (1.4571) / PVDF 4/6 mm DN4 50

Hose clip Stainless steel (1.4571) / PVDF 6/9 mm DN6 54

Installing the Dosing Pump

Set up information 15

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

7 Installing the Dosing Pump

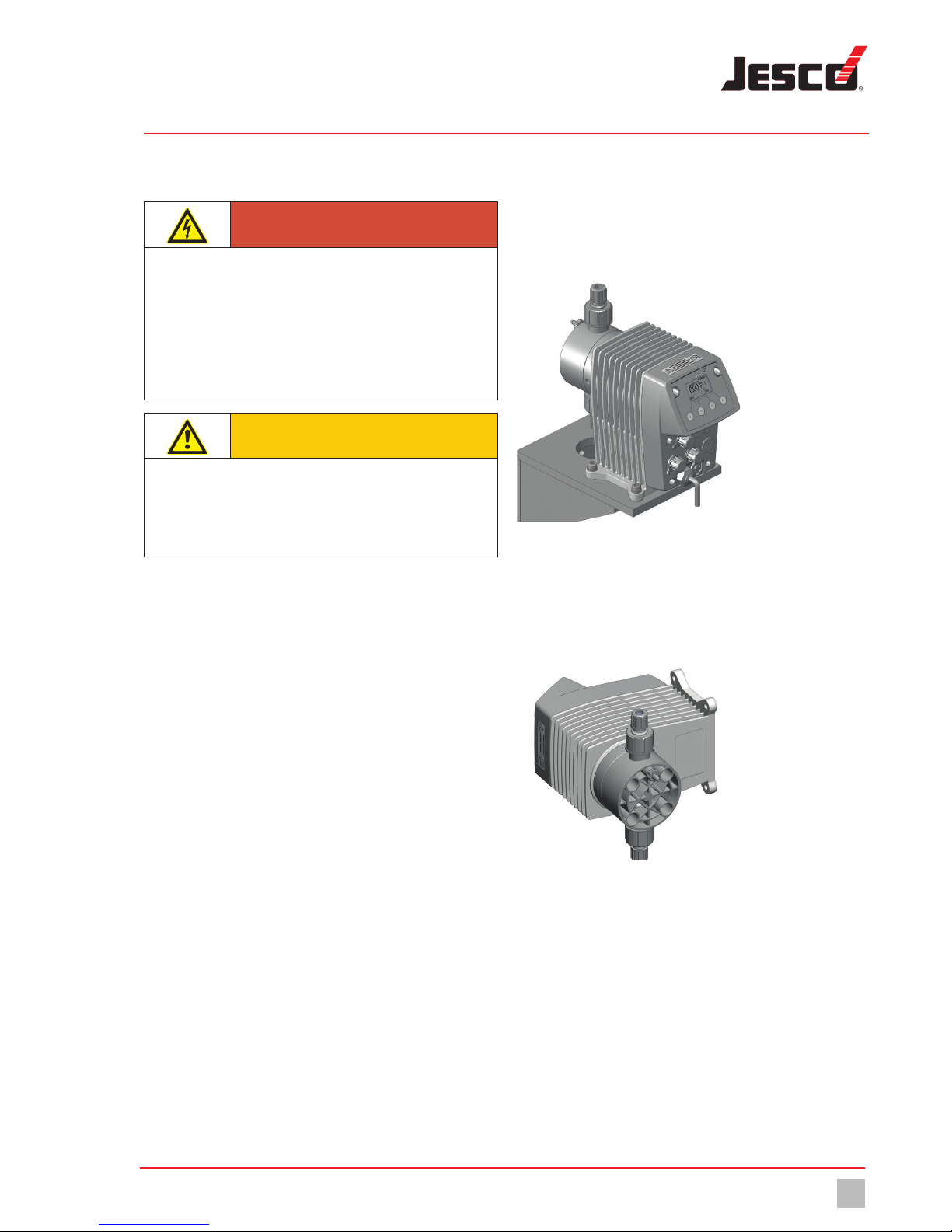

DANGER

Danger to life due to electric shock!

Electrically conductive liquid can enter pump housings, cable screw

connections and mains connectors.

ðMake sure that all protective measures comply at least with the

requirements of protection class IP65.

ðAlways set up the dosing pump such that water cannot enter the

housing.

CAUTION

Danger of personal injury and material damage!

A dosing pump that is difficult to access represents a danger due to

incorrect operation and faulty maintenance.

ðInstall the dosing pump such that it is accessible at all times.

7.1 Set up information

When installing, follow the basic principles below:

nThe valves must be vertical: Discharge valve at top, suction valve at

bottom. in this connection, pay attention to the arrow on the dosing

head. The dosing head must be aligned such that the arrow points

vertically upwards.

nYou should install the dosing pump at a convenient height for

operation.

nIt must not be installed under the ceiling.

nThe frame of foundation for fixing the dosing pump must not be

subjected to jolts. The pump must be vibration-free and stable.

nThere must be enough free space in the area of the dosing head and

the suction and discharge valves for these parts to be easily

dismantled if required. The entire space requirement for installation

and maintenance is approximately 1 m².

nThe distance from the sides of the dosing pump to the wall or other

dosing pumps or equipment must be at least 3 cm. There must be a

guaranteed flow of circulating air.

nThe maximum ambient temperature must be complied with, see

“Operating conditions and limits” on page12. If necessary, radiated

heat from surrounding equipment must be screened.

nAvoid exposure to direct sunlight.

nThe dosing pump is not intended for use out of doors unless

appropriate protective measures have been taken to prevent dust and

water from entering the housing.

nFor the dimensions of the fastening holes, refer to “Dimensions“ (see

page14).

nThe tightening torque for the fastening bolts is 1.5 - 2 Nm.

7.2 Installation examples

7.2.1 Installation on a wall bracket

Fig. 7: Installation on a wall bracket

To reduce the structure-borne noise, the dosing pump is bolted to the wall

bracket using rubber elements. The materials necessary for this are

included with the wall bracket.

7.2.2 Installation on the wall

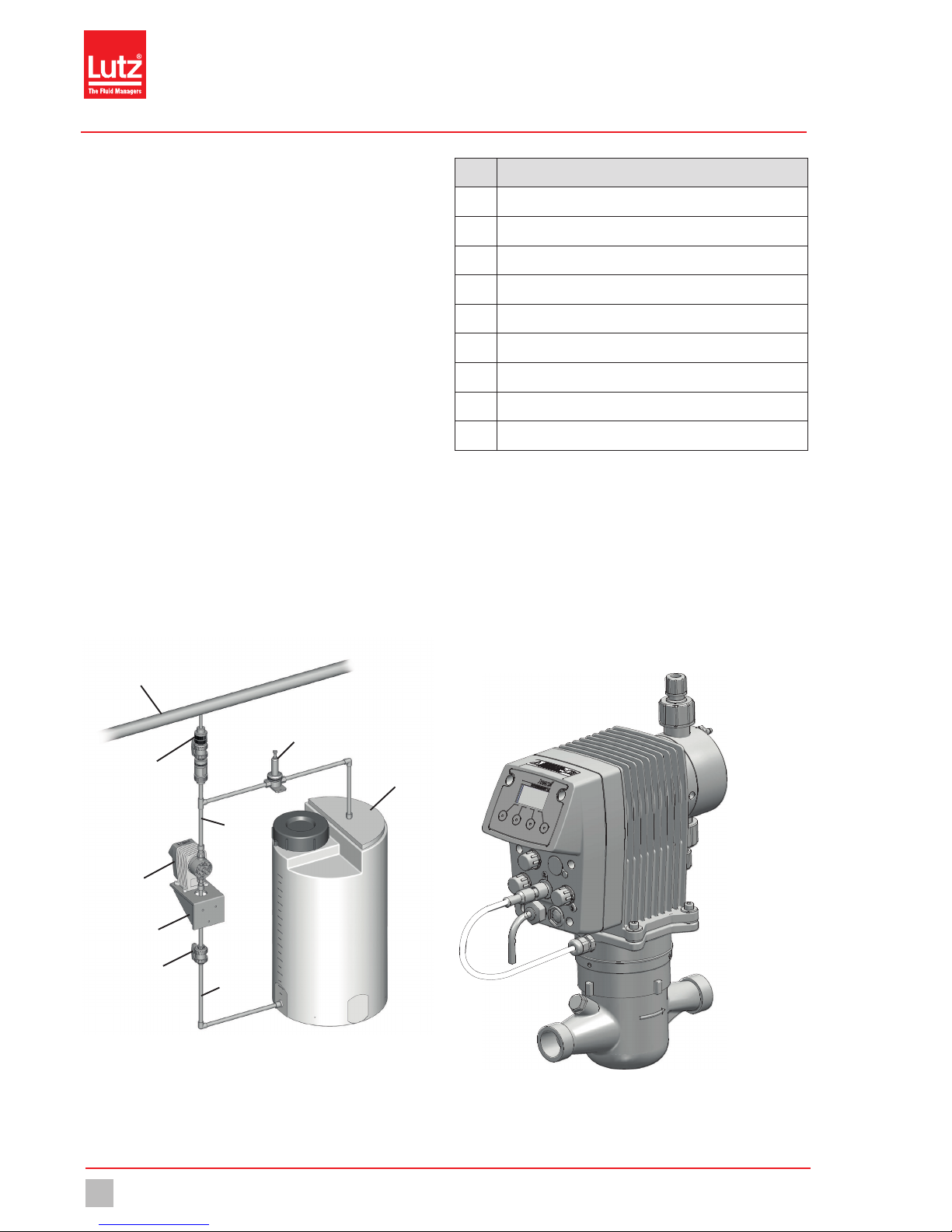

Fig. 8: Installation on the wall

The dosing pump can be mounted to the floor or directly to the wall

without the need for additional elements. Turn the dosing head appro-

priately to ensure the flow direction of the medium through the dosing

head.

Hydraulic installation

Dimensioning of the system

16 © Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

8 Hydraulic installation

In this chapter, you will find information about the hydraulic parts of a

system that you should install or that can install additionally. In many

cases, you must install hydraulic accessories to be able to use all the

functions that the dosing pump MAGDOS LK offers, to guarantee

functional safety or to achieve a high level of dosing precision.

WARNING

Caustic burns or other burns through dosing media!

The materials of the dosing pump and hydraulic parts of the system

must be suitable for the dosing medium that is used. Should this not

be the case, the dosing media may leak. Depending on the type and

hazardousness of the dosing medium, this can result in injury.

ðMake sure that the materials you are using are suitable for the

dosing medium.

ðMake sure that the lubricants, adhesives, sealants, etc. that you

use are suitable for the dosing medium.

WARNING

Caustic burns or other burns through dosing media!

If there is a diaphragm rupture, the dosing medium can escape in an

uncontrolled way. Depending on the type and hazardousness of the

dosing medium, this can result in injury.

ðInstall a leakage drain.

WARNING

Caustic burns or other burns through dosing media!

The dosing pump can generate a pressure that is many times the

rated one. A blocked pressure line can lead to dosing medium

escaping. Depending on the type and hazardousness of the dosing

medium, this can result in injury.

ðInstall pressure relief valves.

CAUTION

Danger of personal injury and material damage!

High peak pressures can lead to piping vibrating and cause them to

snap. This can result in injury due to uncontrollable piping or escaping

dosing media.

ðInstall pulsation dampeners.

NOTICE

Damage to drives due to overloading

The pressure conditions between the suction and discharge sides

must be balanced; otherwise, overloading can result. This can lead to

uncontrolled dosing processes, damage to the plant pipework and to

the dosing pump.

ðEnsure that the pressure on the discharge side is at least 1 bar

greater than on the suction side.

NOTICE

Locking of threads

Stainless steel and plastic parts (particularly those made of PVC) that

are bolted together in a detachable connection (e.g. the dosing head

and the valves) can lock. This makes them difficult to release.

ðBefore bolting, grease the corresponding parts with a lubricant

(e.g. PTFE spray). Ensure that the lubricant is compatible with the

dosing medium.

8.1 Dimensioning of the system

nThe dosing pump’s technical data (see “Technical Data“ on page12)

must be taken into account and the plant’s layout must be set up

appropriately (e.g. pressure loss when rating the lines with regard to

their nominal diameter and length).

nYou must design the entire plant and its integrated dosing pump such

that escaping dosing medium due to the failure of wearing parts such

as the diaphragm, or to burst hoses does not lead to permanent

damage to parts of the system or the premises.

nThe leakage opening of the dosing head must be visible so that you

can detect a diaphragm failure. It must be possible for the outflow

from the leakage drain to be on a free downwards gradient.

nIf you use hazardous dosing media, the installation must be designed

such that no disproportionately high consequential damages arise

due to dosing media escaping.

nTo avoid dosing errors after the end of the process, the dosing pump

must be locked hydraulically.

nTo allow you to easily inspect the pressure conditions in the system,

you should provide connections for pressure gauges close to the

suction and discharge valves.

Hydraulic installation

System piping 17

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

8.2 System piping

nThe system piping must not exert any force on the connections and

valves of the dosing pump.

nThis means that steel piping should be connected to the dosing pump

by means of flexible pipe sections.

nThe nominal diameters of the pipework and the installed fittings

should be rated the same as or greater than the nominal diameters of

the dosing pump‘s suction and discharge valves.

nThe suction line should be kept as short as possible.

nYou should avoid intertwined hoses.

nAvoid loops, since air bubbles can collect.

8.3 Aligning the dosing head

a

b

c

Fig. 9: Aligning the dosing head

When connecting the dosing lines to the dosing pump, you must observe

the direction of through-flow (see arrow b).The dosing head must be

aligned vertically.

The suction valve cmust always point downwards. Accordingly, arrow

band pressure valve falways point upwards. This is irrespective of

the positioning of the dosing head to the drive.

8.4 Hydraulic connections

8.4.1 Connecting hose clips

Choose the hose connection according to the condition of the hose

(material, inner diameter, wall thickness) in order to ensure maximum

pressure resistance.

8.4.1.1 Sizes 4/6 and 6/9

a

b

c

d

e

a

b

c

d

e

4/6 6/9

Fig. 10: Hose clips 4/6 and 6/9 (internal and external diameters in mm)

Perform the following working steps:

1. Cut the hose a to length neatly and at an exact right angle.

2. Place a gasket that is suitable for the dosing medium between the

connection e and the valve.

3. Screw the connecting piece eto the dosing pump‘s valve using the

union nut b.

4. Thread the union nut cand the clamping ring donto the hose.

5. Plug the hose aall the way in to the grommet of connection piece

e.

6. Push the clamping ring d onto the grommet of connection piecee

and screw it to the union nut c.

7. Carry out the same procedure with the connection to the dosing

pump‘s other valve.

üHose clip connected.

Hydraulic installation

Hydraulic connections

18 © Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

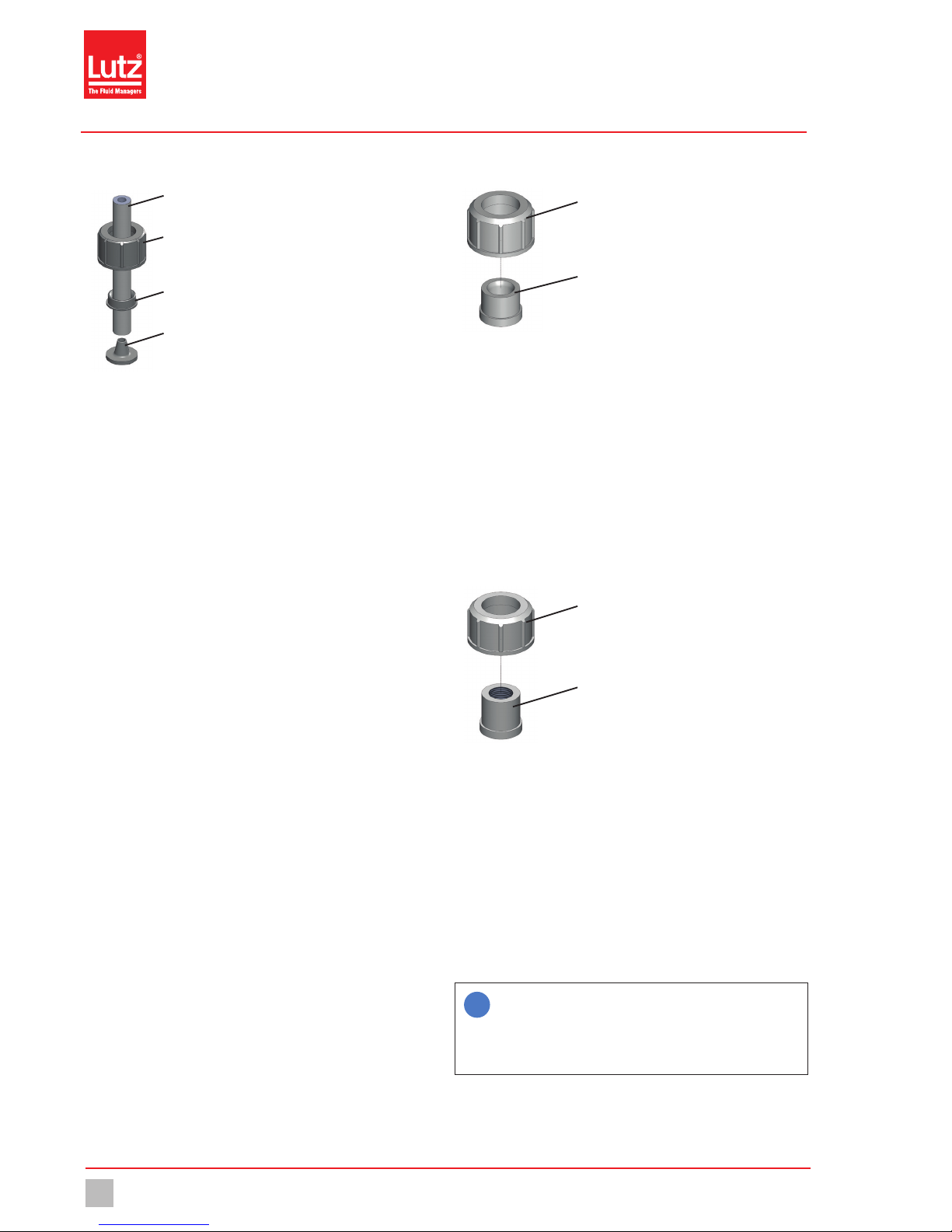

8.4.1.2 Size 6/12

a

b

c

d

Fig. 11: Hose clip 6/12 (internal and external diameter in mm)

Size 6/12 hose clips only have a union nut. It clamps the hose onto the

grommet of the connection piece and at the same time fastens on the

dosing pump‘s valve.

Perform the following working steps:

1. Cut the hose a to length neatly and at an exact right angle.

2. Place a gasket that is suitable for the dosing medium between the

connection d and the valve.

3. Push the union nut band the cutting ring cover the hose a.

4. Press the end of the hose aonto the grommet of connection

pieced.You can do this more easily by moistening the end of the

hose on the inside or applying some lubricant to the grommet in the

cone area. You should push at least two thirds of the hose onto the

grommet of the connection piece.

5. Push the cutting ring cover the hose ainto the cone area on the

grommet of connection piece d.

6. Screw the union nut bonto the valve of the dosing pump.

üHose clip connected.

8.4.2 Making the bonded connection

a

b

Fig. 12: Bonded connection

Perform the following working steps:

1. Cut the PVC tube to length.

2. Push the union nut a onto the tube.

3. Stick the bonded coupling sleeve b to the tube (follow the

instructions of the adhesive manufacturer).

4. Screw the union nut a onto the valve of the dosing pump. Use a

gasket that is suitable for the dosing medium.

üBonded connection made.

8.4.3 Making the cemented connection

a

b

Fig. 13: Cemented connection

Perform the following working steps:

1. Cut the tube to length.

2. Cut the thread b onto the end of the tube.

3. Push the union nut a onto the tube.

4. Seal the thread b. When choosing your sealing material, take into

account its resistance to material, temperature and pressure.

5. Screw the union nut a onto the valve of the dosing pump. Use a

gasket that is suitable for the dosing medium.

üCemented connection made.

i

Under normal conditions, you only need to screw the hydraulic

connections finger-tight. However, due to the material settling,

the pre-tension of the screw connection can slacken. This

means that you must re-tighten the screw connection before

carrying out commissioning.

Hydraulic installation

Connecting a leakage drain 19

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150225

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

8.5 Connecting a leakage drain

Lutz-Jesco GmbH dosing pumps are produced to the highest quality

standards and have a long service life. However, some parts are subject

to operational wear. This is the case particularly with the diaphragms that

are continuously subjected to forces during the suction and discharge

strokes and to the effects of the dosing medium.

If a diaphragm ruptures, the dosing medium starts to leak.This leakage is

drained via the leakage opening. On the flange of the dosing head, there

are three openings for this purpose. Depending on the alignment of the

dosing pump, the leakage is drained via the downward opening.

Fig. 14: Openings of the leakage drain

NOTICE

Damage to drives due to effervescent media

If a hose is connected to the leakage drain and it is routed back into

the dosing tank, effervescent media can enter the drive and damage

it.

ðCollect the leakage in a collecting pan.

ðAs an alternative, you can route the leakage back to to the dosing

tank using a funnel. You should install the funnel at an adequate

distance from the leakage opening.

8.6 Connecting the dosing head venting facility

The MAGDOS LK dosing heads have an integrated dosing head venting

facility (except for dosing heads made of stainless steel).

For the procedure when venting, refer to “Venting the dosing pump” on

page34.

Fig. 15: Dosing head venting facility with hose connection

Perform the following working steps:

1. Connect a 4/6 hose to the dosing head venting facility.

2. Route the other end of the hose into the dosing tank or a collecting

tank.

üDosing head venting facility connected.

Hydraulic installation

Hydraulic accessories

20 © Lutz-Jesco GmbH 2015

BA-10221-02-V03

Stepper Motor-driven Diaphragm Dosing Pump MAGDOS LK Operating Instructions

8.7 Hydraulic accessories

The following chapter is intended to give you an overview of installation

options.

Please note that these operating instructions are no substitute for the

instructions supplied with the accessories in each case. The corre-

sponding documentation supplied with the product applies to safety

information and provides exact instructions on assembly.

8.7.1 Injection nozzle

If the pressure line enters a main line, it is advisable to install an injection

nozzle.

Injection nozzles have three main functions:

nDosing the medium into a main line,

nPreventing flowback into the pressure line through a non-return valve.

Notes on assembly:

nDouble-ball injection nozzles must be installed into the main line

vertically from the bottom. You can install hose and spring-loaded

injection nozzles any way you like.

nWith dosing media that tend to crystallize, it is advisable to carry out

installation into the main line from the bottom. This prevents air

bubbles from being trapped.

nMany dosing media tend to contaminate the injection nozzles, which

can lead to blockages. In cases like this, it is advisable to install an

injection nozzle that is easy to dismantle and block off.

a

b

c

f

e

hi

d

g

Fig. 16: Installation with an injection nozzle

No. Description

aMain line

bInjection nozzle with shut-off valve

cPressure relief valve

dChemical tank

ePressure line

fMAGDOS LK dosing pump

gWall bracket

hShutoff valve

iSuction line

Tab. 12: Designation of components

8.7.2 Contact Water Meter

The contact-type water meter measures the throughflow in a pipe and

sends a pulse to the dosing pump, which then starts dosing. This means

that ideal proportional dosing is also possible with large throughflow

fluctuations.

The Contact Water Meter connects to connection socket 2 (see “Connec-

tion socket 2“ on page27).

You determine the ratio of throughflow and executed strokes of the

dosing pump in „Pulse input“ mode, (see “Water meter“ on page37).

Fig. 17: MAGDOS LK installation on contact-type water meter

Table of contents

Other Jesco Water Pump manuals

Jesco

Jesco Lutz PVC GF-2 User manual

Jesco

Jesco Peristaltic Pump 2.8 l/h Instruction Manual

Jesco

Jesco MIDIDOS E Series Instruction Manual

Jesco

Jesco 43-20406 Instruction Manual

Jesco

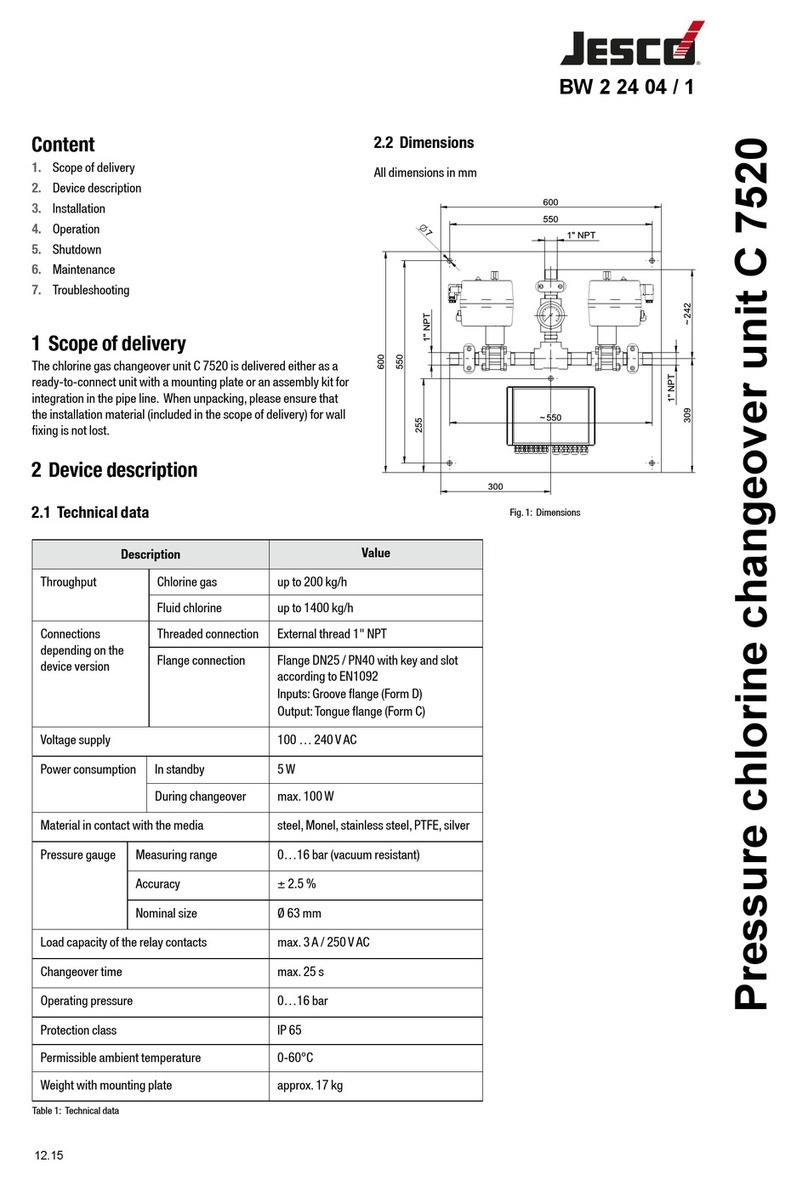

Jesco C7520 User manual

Jesco

Jesco MEMDOS E User manual

Jesco

Jesco SD 5 00 01/1 User manual

Jesco

Jesco MAGDOS E User manual

Jesco

Jesco EASYDOS Peristaltic V Manual

Jesco

Jesco MAGDOS LT Instruction Manual

Popular Water Pump manuals by other brands

Grundfos

Grundfos S2 Series Installation and operating instructions

Gardner Denver

Gardner Denver HD-2250 Operating and service manual

Hozelock

Hozelock cascade 450 Installation and operating insctruction manual

Binks

Binks MX1231 Series Service manual

Granit

Granit G280 operating instructions

Lumax

Lumax LX-1317 quick start guide