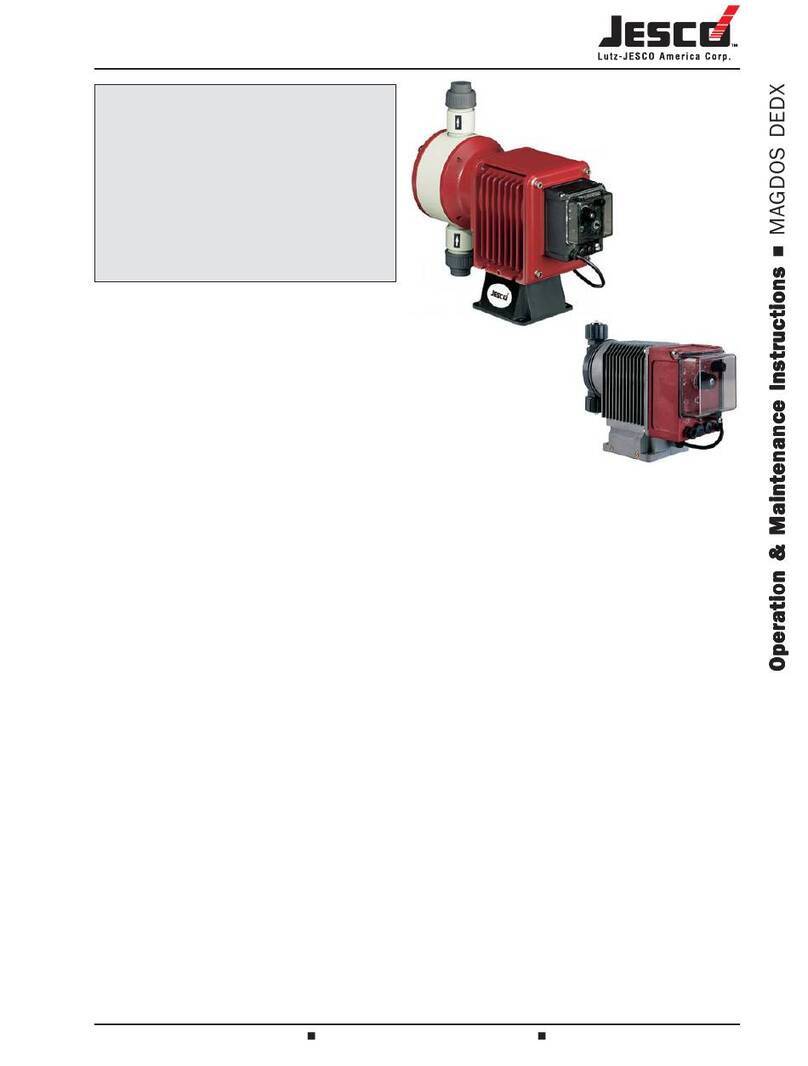

MAGDOS

BW 1 02 98 / 1

Lutz-Jesco GmbH

Improved changes are always reserved without notice.

Operating and Maintenance Instructions

meteringpumpfails.Werecommendinstallingleakage

probesandcontainmenttanks.

Meteringpumpsareproducedaccordingtohighest

quality standards and have a long service life.

Nevertheless some parts are subject to wear (e.g

diaphragm,valveseats,valveballs).Toensurelong

operating life, visual checks are required regularly.

Operatingandmaintenancepersonnelmustbeable

to access the pump easily. Periodic maintenance

protectsthe metering pumpagainstshutdowns.

Toincreasethemeteringaccuracyandreliability,we

recommendusingadditionalfittings.Theseinclude

backpressurevalves,reliefvalves,leakageprobes,

andchemicallowlevelindicators,asshowninfigures

1 to 3.

Always use appropriate tools for the installation of

plastic connecting parts. In order to avoid damage,

neverapplyexcessiveforce;plasticparts(especially

PVC parts) can be screwed and unscrewed more

easily if the thread is lubricated with vaseline or

siliconegreasebefore.

Note: For this purpose, the compatibility with the

chemical to be metered must be checked.

MAGDOS metering pumps with integrated level

controlfunctionareequippedwithashort-circuitjack

plug which must be removed before connecting a

level control by means of a jack plug. To keep the

protection class, screw a PG plastic sleeve on the

jackplug.TherequiredPGsleeveispartofthelevel

control (also in combination with a suction line).

Mounting the metering pump directly on the water

metermay result in noise levelamplification.Inthis

case, it is recommended to mount the pump on

separatewall brackets which,forthe same reason,

shouldbefixedtoouterwallsinsteadofinteriorwalls

with adjacent occupied rooms. It is also possible to

mount the pump directly on the metering supply

tank.

Ambient temperatures exceeding 40°C are not

permitted. Radiant heat of apparatus and heat

exchangersmustbekeptinlimitsallowingthepump

to sufficiently dissipate its own heat. Exposure to

directsunlightshouldbeavoidedespeciallyformete-

ringpumpswithplastichousingsbecausetheblack

plastic material can be damaged. If the pump is

installed outside, provide an enclosure to protect it

againstweather.

Wiring of the MAGDOS metering pump must be

carried out by a specialist according to the local

regulations. Normally the MAGDOS is connected

withasafetyplug.TheelectricaldataforallMAGDOS

data is listed in Table 14 "Technical data".

Note:TheMAGDOSmeteringpumpsarenotsuited

to be used in explosive environments.

Do not lay signal cables of water meters or

0(4)...20mAcontrolsparalleltohigh-voltagecurrent

Keeptheoperatinginstructionsofthemetering

pump and the accessories readily accessible.

List of contents

1. General

2. Scopeofdelivery

3. Installation

4. Injectionfittinginstallation

5. Safetyinstructions

6. Installationexample

7. Startup

8. Replacingthediaphragm

9. Drivesolenoids

10. Correctionofstroke lengthsetting

11. Controlpanel

12. Circuitdiagrams

13. Functionaloverview

14. Technicaldata

15. Troubleshooting

1. General

Solenoid metering pumps can be used in many

applications.Itisaparticularadvantagethattheycan

becontrolledproportionallytowatermetercontacts.

Theyarealsosuitedtobeusedasregulatingunitsin

automaticcontrolsystems.Seetable13forvarious

control types and monitoring facilities.

2. Scope of delivery

Becarefulwhenunpackingthemeteringpumpand

possible accessories in order not to miss small

parts.Comparethescopeofdeliverytothedelivery

note.Ifthereareanydiscrepancies,trytofindoutthe

reason.

3. Installation

Forselectionofapumpduringconstructionofaplant

as well as for installation and operation, the local

rulesmustbeobserved.Thisappliestotheselection

of suitable pump materials, the handling of the

chemicals and the electrical installation. At the

same time the technical data of the metering pump

according to table 12 must be considered, and the

plantmustbedesignedcorrespondingly(e.g.pressure

loss in lines depending on nominal diameter and

length).

Both, the designer and the user are responsible to

make sure that the whole plant including the mete-

ring pump is constructed so that neither plant

equipmentnorbuildingsareseverelydamagedinthe

case of chemical leakage due to the failure of wear

parts(e.g.diaphragmrupture)orbursttubing.When

constructing chemical plants, the installation must

be carried out so that no consequential damages

appear which are unreasonably high even if the