Jesco MAGDOS LT Instruction Manual

Dosing

Conveying

Control

Liquids

Gases

Systems

3

Operation & Maintenance Instructions .............................................................50

Subject to technical changes.

50

1. Safety .......................................................................................................................................................... 51

1.1 General........................................................................................................................................................ 51

1.2 Warnings used in this Operation & Maintenance Manual .............................................................................. 51

1.3 Qualification and training of personnel ......................................................................................................... 52

1.5 Hazards due to non-compliance with safety instructions .............................................................................. 52

1.6 Safe operation.............................................................................................................................................. 53

1.7 Safety instructions for the owner/operator.................................................................................................... 53

1.8 Safety instructions for installation, inspection, and maintenance .................................................................. 53

1.9 Unauthorized modification and production of spare parts ............................................................................. 53

1.10 Impermissible modes of operation................................................................................................................ 53

1.11 Dosing of Chemicals .................................................................................................................................... 54

1.12 Scope of delivery ......................................................................................................................................... 56

2. General........................................................................................................................................................ 56

3. Description .................................................................................................................................................. 57

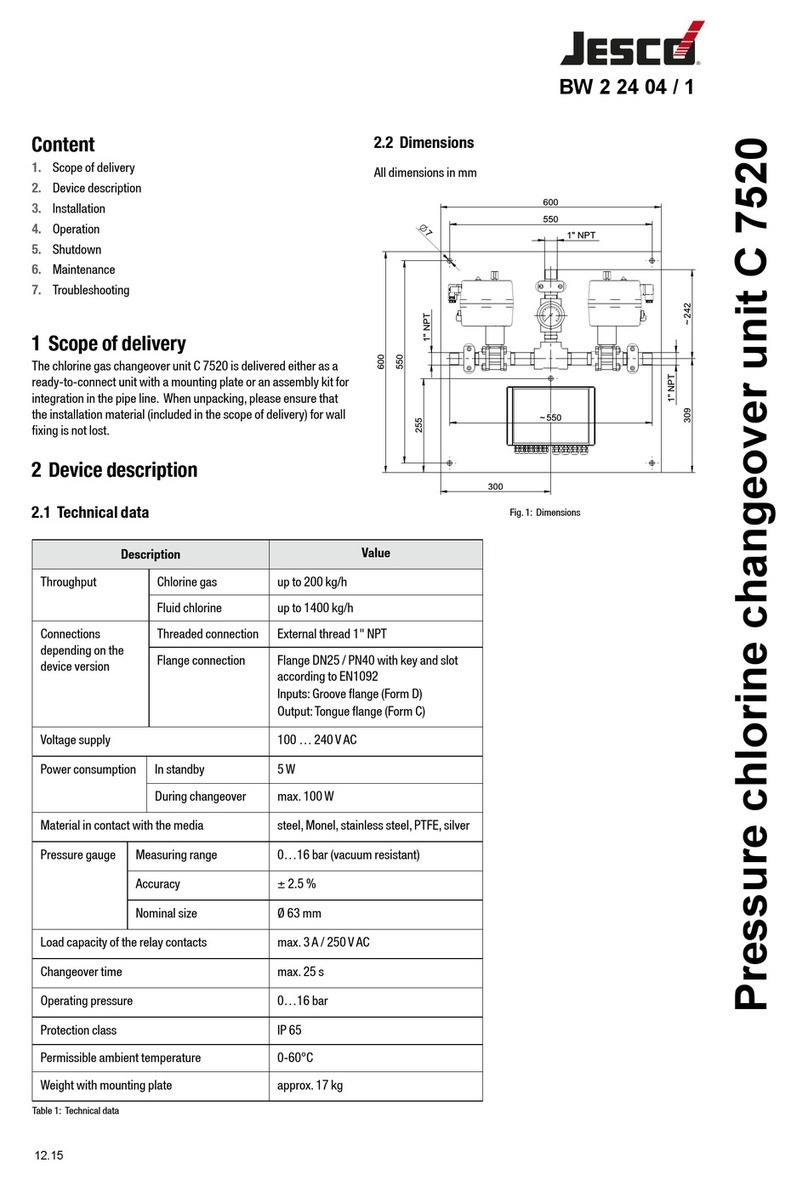

4. Dimensions.................................................................................................................................................. 57

5. Technical data.............................................................................................................................................. 58

6. Performance curves..................................................................................................................................... 59

7. Installation ................................................................................................................................................... 61

7.1 General notes of instruction.......................................................................................................................... 61

7.2 Installation location...................................................................................................................................... 61

7.3 Water meter installation ............................................................................................................................... 62

7.4 Electrical connection.................................................................................................................................... 62

7.5 Level control ................................................................................................................................................ 62

7.6 Pressure sustaining and safety valves.......................................................................................................... 63

7.7 Injection nozzles .......................................................................................................................................... 63

7.8 Installation examples ................................................................................................................................... 64

8. Operation..................................................................................................................................................... 66

8.1 Setting of flow rate....................................................................................................................................... 67

8.1.1 Selection of operating mode......................................................................................................................... 67

8.1.3 Factory setting ............................................................................................................................................. 68

8.1.2 Adjustment to pressure................................................................................................................................ 68

9. Start up........................................................................................................................................................ 69

10. Shutdown .................................................................................................................................................... 70

11. Maintenance................................................................................................................................................ 71

11.1 Replacing the diaphragm ............................................................................................................................. 71

11.2 Inspecting and replacing the deflector plate ................................................................................................. 74

11.3 Check Valves................................................................................................................................................ 75

11.4 Drive solenoid .............................................................................................................................................. 77

11.5 Correction of stroke length adjustment......................................................................................................... 78

11.6 Diagram of the circuit board MAGDOS LT ..................................................................................................... 79

12. Spare parts .................................................................................................................................................. 80

12.1 Spare parts list MAGDOS LT 02 ... 0680 ....................................................................................................... 81

12.2 Spare parts list MAGDOS LT 1 ...................................................................................................................... 82

12.3 Spare parts list MAGDOS LT 3...684 ............................................................................................................. 85

12.4 Spare parts list MAGDOS LT 10 .................................................................................................................... 86

12.5 Spare parts list MAGDOS LT 17 .................................................................................................................... 88

13. Troubleshooting ........................................................................................................................................... 90

14. Declaration of conformity............................................................................................................................. 92

15. Declaration of harmlessness ........................................................................................................................ 93

16. Warranty...................................................................................................................................................... 94

17. Dimensions for the USA................................................................................................................................ 95

18. Technical data for the USA ........................................................................................................................... 96

Contents

51

1. Safety

1.1 General

This Operation & Maintenance Manual contains basic information to be noted during

installation, operation and maintenance. It is therefore essential that the Manual is read

by the contractor before installing and commissioning the pump/system as well as by the

relevant operating personnel / owner of the pump/system. It must remain accessible at

the dosing pump/system for reference at all times.

In addition to the general safety instructions under this main heading Safety, the special

safety precautions outlined in other sections must also be observed.

1.2 Warnings used in this Operation & Maintenance Manual

This Operation & Maintenance Manual contains vital information, which may endanger

people, the environment and the dosing pump/system if disregarded. These statements

are identified by the following symbols:

DANGER!

Refers to an imminent danger.

Non-compliance can lead to death or extremely serious injury.

WARNING!

Refers to a potentially hazardous situation. Non-compliance can lead to death or serious

injury.

CAUTION!

Refers to a potentially hazardous situation. Non-compliance can lead to minor injury or

property damage.

NOTICE!

Appears in conjunction with safety instructions, which may endanger the pump/system

and its operation if disregarded.

IMPORTANT!

Draws attention to supplementary information to make the work easier and ensure trouble

free operation.

Markings which are affixed directly to the pump, such as

• Cable markings

• Markings for process fluid connections

must be observed without fail and must remain fully legible at all times.

52

1.3 Qualification and training of personnel

The personnel employed for installation, operation, inspection and maintenance must be

qualified for this work. The areas of responsibility, competence and supervision of the

personnel must be precisely defined by the owner. Personnel who do not have the required

knowledge must be duly trained and instructed. If necessary, this training can also be

provided by the manufacturer/supplier on behalf of the dosing pump’s owner. In addition,

the owner of the system must ensure that the relevant personnel are fully familiar with and

have understood the contents of this Operation & Maintenance Manual.

1.4 Important safety instructions

When installing and using this electrical equipment, basic safety

precautions should always be followed, including the following:

Read and follow all instructions!

WARNING!

To reduce the risk of injury, do not permit children to use this product unless they are

closely supervised at all times.

WARNING!

Risk of Electric Shock. Connect only to a grounding type receptacle protected by a ground-

fault circuit-interrupter (GFCI). Contact a qualified electrician if you cannot verify that the

receptacle is protected by a GFCI.

Do not bury cord. Locate cord to minimize abuse from lawn mowers, hedge trimmers,

and other equipment.

WARNING!

To reduce the risk of electric shock, replace damaged cord immediately.

WARNING!

To reduce the risk of electric shock, do not use extension cord to connect unit to electric

supply; provide a properly located outlet.

Save these instructions!

1.5 Hazards due to non-compliance with safety instructions

Failure to comply with the safety instructions may endanger not only people, but also the

environment and the dosing pump/system. Non-compliance with the safety instructions

can lead to the loss of all entitlement to damages.

The following hazards in particular may arise:

• Danger to people due to electrical, mechanical and chemical effects.

• Failure of dosing pump/system functions.

• Failure of specified methods for maintenance and repair.

• Danger to the environment due to leakage of hazardous substances.

WARNING!

WARNING!

WARNING!

WARNING!

53

1.6 Safe operation

The safety instructions contained in this Operation & Maintenance Manual must be observed.

The owner is responsible for ensuring compliance with local safety regulations.

1.7 Safety instructions for the owner/operator

• Leakages (e.g. due to diaphragm rupture) of hazardous substances (e.g. toxic, abra-

sive) must be discharged in such a way as to exclude all danger to people and the

environment. Statutory regulations must be observed.

• Danger due to electric current must be excluded (for further details,refer to the German

VDE standards as well as local rules and regulations or chapter 1.4).

1.8 Safety instructions for installation, inspection, and maintenance

The owner must ensure that all installation,inspection and maintenance work is undertaken

by authorized and duly qualified skilled personnel who have also studied this Operation

& Maintenance Manual.

The dosing pump must always come to a complete stop before starting any work on the

pump.The procedure specified in this Operation & Maintenance Manual for shutting down

the dosing pump/system must be observed without fail.

Dosing pumps or systems in contact with potentially harmful media must be decontami-

nated.

All safety mechanisms and guards must be refitted and reactivated as soon as the work

is completed.

The instructions outlined in chapter 7.2 „Installation location“ and 9. „Start up“ must be

observed before starting the pump/system.

1.9 Unauthorized modification and production of spare parts

The dosing pump may only be modified or converted in consultation with the manufacturer.

Genuine spare parts and accessories authorized by the manufacturer ensure greater safety.

Liability for damage or loss may be voided if non Lutz-Jesco parts are used.

1.10 Impermissible modes of operation

The operational safety of the pump supplied can only be guaranteed when it is used in

conformity with its intended use as specified in Lutz-Jesco contract documents especially

the order confirmation. The limit values specified in these documents must never be

exceeded.

54

1.11 Dosing of Chemicals

CAUTION!

• When working on dosing systems, the accident prevention regulations applicable

on-site must be observed and the specified personal protective equipment worn. The

following standard protective clothing is recommended, depending on the hazard as-

sociated with the metered medium:

Goggles Protective gloves Protective suit

All people responsible for installation and maintenance of pumps, piping, hoses and

accessories should wear this protective equipment.

• Before working on the dosing pump and plant, disconnect it from the power supply

and protect it against reconnection:

CAUTION!

• Any chemical still present in the dosing head may spray out when the power supply

is reconnected. This may lead to caustic or other burns to the face and hands. Dosing

lines must always be connected before starting the pump again.

• The chemical resistance of the pump’s materials of construction used must be verified

before dosing aggressive media!

• The dosing head of the dosing pump as well as connections and lines of the system

may be under pressure.Working on the dosing system requires special safety precau-

tions and may only be carried out by instructed technical personnel:

CAUTION!

• Chemical could spray out. This may lead to caustic or other burns. Always relieve the

system/pump pressure before starting work on the dosing pump.

• Before working on the dosing head, check valves and connections, flush the pump’s

wetted end with a harmless medium (mainly water) to avoid unintentional contact with

the metered medium.

WARNING!

• Never look into the open end of a clogged line or valve.

Chemical may emerge unexpectedly and cause caustic or other burns to face and

hands.

• Before start up, all connections must be inspected for correct tightness and, if neces-

sary, must be further tightened using appropriate tools.

WARNING!

CAUTION!

CAUTION!

CAUTION!

55

CAUTION!

• If connections at the dosing head are loosened during operation for venting or other

reasons,leaking chemical must be removed professionally.This is the only way to avoid

the danger of physical injury and corrosion at the dosing pump. Leaking chemical may

also damage the diaphragm at its mounting points.

NOTICE!

• When changing the chemical, check whether the pump’s and the system’s materials

of construction are chemically resistant. If there is the danger of a chemical reaction

between different media, a thorough cleaning first is mandatory.

IMPORTANT!

• After adjusting the stroke length, the locking screw must be retightened. Otherwise

the adjusting knob may change its position. Thus causing faulty flow rates.

• After changing the electrical connections, e.g. removing the level control,the threaded

cable joint must be tightened in order to ensure the protection class of the dosing

pump.

DANGER!

• Fire hazard. Pressure surge: parts may be catapulted off and cause fatal injury.

In no case is MAGDOS LT supposed to be used in explosive environment.

CAUTION!

• Hot metal parts may burn your hands.Always disconnect the mains power feeder before

opening the magnetic drive and let the dosing pump cool for at least one hour.

CAUTION!

Malfunctions may arise in

• Circuits

• Magnetic strips

• Mobile phones

if brought in direct vicinity of the stroking solenoid.

DANGER!

CAUTION!

CAUTION!

NOTICE!

IMPORTANT!

CAUTION!

56

IMPORTANT!

1.12 Scope of delivery

IMPORTANT!

Please unpack the dosing pump and ordered accessories carefully in order not to miss

small parts. Immediately compare the scope of delivery to the delivery note. If there are

any discrepancies, contact your local distributor.

2. General

Dosing pumps are used to add chemicals specifically in various processes. MAGDOS LT

can be flexibly used by the user thanks to its universal control system:

• external operation with stroke rate input

• internal operation with a stroking speed of 25% / 50% / 100% of the maximum stroke

frequency

• Energy adaption for pressures of up to 16 bar (232 psig)

Metering capacities range from 0.2 to 17 litres per hour ( 0.53 to 1.56 gph). The exact

metered capacities can be derived from the performance curves (chapter 6). All types are

available for testing in accordance with the German regulation DVGW-DIN 19635.

57

11.05.06 N.Lindemeyer

Maßbild Magdos LT

90

140~

O

77 70

84

O

6

L 108 L

100

100

120

211~

MB Magdos LT

233~

141~

Benennung

Zg.-Nr.

Ersatz für Ersetzt durch

Bl.

Blatt

Maßstab Werkstoff

gez.

gepr.

Datum Name

Allgemeintoleranzen

DIN ISO 2768 T.1 mittel

Index Änderung Datum Name

> 6 bis 30 +/-0,2

> 30 bis 100 +/-0,3

>100 bis 300 +/-0,5

>300 bis 1000 +/-0,8

bis 6 +/-0,1

Postfach 10 01 64 / D-30891 Wedemark

Lutz - Jesco GmbH

All dimensions in mm. For dimensions in inches

refer to page 95.

3. Description

Legend:

1 Solenoid coil

2 Solenoid armature

3 Stroke adjustment

4 Electronic unit

5 Drain pipe

6 Suction valve

7 Dosing head

8 Discharge valve

9 Diaphragm

10 Diaphragm return

spring

The solenoid coil of the drive solenoid is activated in a pulsating manner by the

electronic unit in the MAGDOS LT dosing pump. The solenoid armature forces

the diaphragm to the left and displaces the liquid in the dosing head . The liquid

escapes through the discharge valve into the discharge line. When the solenoid

armature is de-energized, the diaphragm return spring moves the solenoid armature

and diaphragm back to its original position. A negative pressure is produced in

the dosing head and liquid is drawn in through the suction valve . Leakages due to

a diaphragm rupture are discharged in a controlled manner through the drain .

4. Dimensions

Nominal Tubing Dim. L

width connection

DN 4 4/6 13 mm

DN 6 6/12 23 mm

6/9 34 mm

58

5. Technical data

Technical data for the USA refer to page 96.

MAGDOS LT 02 06 1 3 4 6 10 17

Max. pressure* [bar] 12 16 16 16 12 10 8 3

Flow rate at max. pressure* [l/h] 0.14 0.48 0.9 1.6 3.3 5.2 7.9 13.5

Medium pressure* [bar] 6 8 8 8 6 6 6 2

Flow rate at medium pressure* [l/h] 0.28 0.7 1.4 2.8 3.7 5.5 10.1 17

Max. stroke frequency [1/min] 80 120

Suction lift [m H2O] for non-effervescent media 3 2 1.2

Max. supply pressure [mbar] 800 700 400

Power supply 115 V AC or 230 V AC +/- 10 %, 50/60 Hz

24 V DC +/- 10 %

Power supply cable 2 m (230 V AC with shock-proof plug,

115 V AC with UL-/CSA-plug,

24 V DC 2-wire connecting cable)

Power consumption 30 W

Max. power consumption during dosing stroke 230 V AC: 2.9 A; 115 V AC: 4.3 A; 24 V DC: 17 A

Soldered fuse 230 V AC and 115 V AC: 3.15 A slow

24 V DC: 10 A slow

Protection class IP 65

Insulation class F

Input pulse duration > 10 ms

Voltage at level connection 5 VDC, for potential-free switching outputs

Voltage at pulse input 5 VDC, for potential-free switching outputs

Max. ambient temperature 45 °C (with PVC parts 40 °C)

Max. process fluid temperature 50 °C (with PVC parts 35 °C)

Weight approx. 2.7 kg

max. sound pressure level

[dB(A)] without pressure 58 66

max. sound pressure level

[dB(A)] at test pressure 60 68

* The exact metered capacities can be derived from the performance curves.

59

MAGDOS LT 3

The performance curves refer to water at 20 °C (68 °F). The performance of the dosing pump depends on the

viscosity of the process fluid and hydraulic installation conditions. Dosing pumps must therefore be gauged

in litres during application.

MAGDOS LT 02

MAGDOS LT 06

MAGDOS LT 1

Stroke length

ml / pulse

ml / pulse

ml / pulse

ml / pulse

6. Performance curves

Stroke length

Stroke length

Stroke length

60

MAGDOS LT 4

MAGDOS LT 6

MAGDOS LT 10

MAGDOS LT 17

ml / pulse

ml / pulse

ml / pulse

ml / pulse

Stroke length Stroke length Stroke length Stroke length

61

7. Installation

7.1 General notes of instruction

For the selection of a dosing pump when designing a system as well as for the installation

and operation, local rules and regulations must be obeyed. This applies to the selection

of appropriate materials of construction, the handling of the chemicals and the electrical

installation. At the same time the technical data of the dosing pump (chapter 5.) must be

taken into consideration.The system must be designed accordingly/properly (e.g.pressure

loss in lines depending on nominal diameter and length).

The designer and the user are responsible to make sure that the whole system including

the dosing pump is constructed so that neither plant equipment nor buildings are damaged

in the case of chemical leakage due to the failure of wear parts (e.g. diaphragm rupture)

or burst tubing. If the chemical plant represents a potential danger, the installation must

be carried out in a way that no unreasonably high consequential damages occur, even if

the dosing pump fails. Therefore we recommend the installation of leakage probes and

containment tanks.

The drain pipe of the dosing head must be visible in order for a diaphragm failure to be

detected. Drainage must be routed with a downward slope to the collecting tank.

To increase the dosing accuracy and to ensure the functional reliability, we recommend

the use of additional accessories! These include back pressure valves, relief valves, lea-

kage probes and low level indicators, as shown in the installation examples. Always use

appropriate tools for the installation of plastic connecting parts.

To avoid damage, never apply excessive force.

IMPORTANT!

Plastic parts (especially PVC parts) can be tightened and loosened more easily if the thread

is lubricated with slip additive (e.g. silicone grease).

Threaded stainless steel parts (i.e. dosing head and check valves) have to be lubricated

before assembled (i.e.PTFE-spray).This will make the disassembly easier when performing

maintenance on the pump.

NOTICE!

The slip additive must be compatible with the chemical to be metered.

7.2 Installation location

The installation location of the dosing pump must be easily accessible for the operating

and service staff.

The operation sound of the dosing pump might be transmitted to the piping and thus result

in a disturbing noise level. In this case, it is recommended to mount the dosing pump on a

wall bracket which, for the same reason, should be fixed to outer walls instead of interior

walls adjacent to occupied rooms.When installing the dosing pump below the storage level

of the process fluid, care must be taken to ensure that chemical leakages due to a broken

diaphragm cannot cause any damage (collecting pan, leakage sensor).

It is also possible to mount the pump directly on the chemical supply tank.

Please note the ambient temperature of the dosing pump (refer to technical data table).

Radiant heat of apparatus and heat exchangers must be shielded so that the dosing pump

NOTICE!

IMPORTANT!

62

can still dissipate its own heat sufficiently. Exposure to direct sunlight must be avoided. If

the dosing pump is installed outside, provide a roof to protect it against weather.

7.3 Water meter installation

The MAGDOS LT can be controlled by any standard contact water meter. To avoid inter-

ferences or faulty pulses,the dosing pump must not be mounted directly to the water meter.

Direct mounting is acceptable if a separator (Part No. 21801) is used, which provides the

required distance of 50 mm. Due to this fact the pump should be mounted on a chemical

supply tank or a wall bracket.The pulse sequence of the water meter must be tuned to the

maximum stroke frequency of the dosing pump (chapter 5. technical data).

7.4 Electrical connection

DANGER!

• Fire hazard. Pressure surge: parts may burst and cause fatal injury.

In no case is MAGDOS LT supposed to be used in explosive environment.

The electrical connection of the dosing pump must be made according to the local rules

and regulations and may only be carried out by technical personnel.

NOTICE!

The metering pumps has to be plugged into a grounded power outlet.

The 230 VAC version of the MAGDOS LT is connected via a grounded appliance plug con-

nector.The 115 VAC version is equipped with a UL/CSA plug connector.The 24 VDC version

has a 2-wire cable 2 x 1 mm².

NOTICE!

The metering pump is double-insulated and grounded.

Control cables must not be routed parallel to high-voltage current lines or supply mains.

Route supply and signal lines in separate channels. In the case of junctions, a 90° angle is

required. If lines are more than 2 meters (3feet) long, shielded cables must be used.

To avoid incorrect metering after the process is finished, the dosing pump must be locked

electrically and hydraulically.

7.5 Level control

If a level control is connected, the jack plug has to be covered by a plastic sleeve in order

to maintain the protection class. The required sleeve is part of the level control (also in

combination with a suction line).

A connected level control causes the dosing pump to stop if the chemical level in the supply

tank is low. Thus air bubbles are prevented from entering the suction line and the dosing

head. The red LED lights. As soon as the level input is closed again, the pump restarts.

The level sensor must be designed as a max. make / normally open contact.

The MAGDOS LT identifies automatically if the level input is connected. If no plug is con-

nected, the MAGDOS LT operates as if the contact was closed.

DANGER!

NOTICE!

NOTICE!

63

7.6 Pressure sustaining and safety valves

Pressure sustaining valves are accessories for optimizing the dosing process. They are

used

• to increase the dosing accuracy in the presence of fluctuating back pressure.

• with long dosing lines in order to prevent excess delivery, as the accelerated medium

continues moving on account of its own inertia even when the delivery stroke has

already ended.

• to prevent siphoning through the dosing pump if the suction pressure is higher than

the system pressure.

Safety and pressure relief valves protect the dosing pump and the associated accessories

and lines from overloads.Those prevent the system pressure from rising to an impermissible

high level on the discharge side of the dosing pump, what may be caused by the accidential

closing of valves while pump in operation or a clogged injector.

The PENTABLOC is an accessory that combines several functions:among others a pressure

sustaining valve as well as a safety valve. Such functions as anti-siphon, pressure relief

and flow indication and monitoring are also integrated.

7.7 Injection nozzles

Injection nozzles are used to mix the metered process fluid into a main stream and simul-

taneously fullfil a non-return function. The injection nozzle is usually installed in the main

line from above. Installation from below is only recommended in the case of media with a

tendency to crystallize. Thus entrapped air is able to leave.

In the case of media with a tendency to contaminate the injector, it is advisable to use an

injector which can be dismantled for maintenance and shut off.

Injection fitting

mounted from above

Injection fitting mounted from below

(for media with a tendency to crys-

tallize)

64

7.8 Installation examples

Legend

1 MAGDOS LT

2 Chemical tank

3 Suction line with integrated low level control

4 Multifunction valve PENTABLOC

5 Priming aid

This equipment allows easy start up of small dosing pumps in

particular. The entrapped air may serve as pulsation dampener.

6 Injection nozzle with non-return valve

7 Water meter with contact unit

8 Water meter spacer

The spacer is required to avoid that the drive solenoid affects

the water meter contact.

9 Wall bracket

10 Mounting Hardware MAGDOS Pump Riser Base (p/n 37558)

on chemical tank

on wall bracket

on water meter

65

Mounting of MAGDOS LT to Wall Bracket, Tank Mounting Plate, and Pump

Riser Base

Legend

1 Bolt M5

2Rod M5

Mounting Hardware consisting of

4 x Bolt

4 x Rod

(p/n 37558)

Installation example

Legend

1 MAGDOS LT

2Chemical tank

3 Suction line with integrated

low level control

4 Priming aid

5 Electric agitator

6 Pulsation dampener

7 Injection nozzle with non-return

and shutoff valve

8 Back pressure regulating valve

9 Pressure relief valve

(safety valve)

10 Throttle valve

Benennung

Zg.-Nr.

Ersatz für Ersetzt durch

Bl.

Blatt

Maßstab Werkstoff

gez.

gepr.

Datum Name

Allgemeintoleranzen

DIN ISO 2768 T.1 mittel

Index Änderung Datum Name

> 6 bis 30 +/-0,2

> 30 bis 100 +/-0,3

>100 bis 300 +/-0,5

>300 bis 1000 +/-0,8

bis 6 +/-0,1

Postfach 10 01 64 / D-30891 Wedemark

Lutz-Jesco GmbH

30.09.05 Krischker

Installationsbeispiel

Betriebsanleitung

Magdos LT

1:10

66

8. Operation

Control panel MAGDOS LT

Legend

1 Operating LEDs

1a level (red)

1b internal (green)

1c external (green)

2Push button for operating

mode and programming

3 Jack for level sensor connection

4 Pulse input cable

5 Mains cable

6 Stroke adjustment with

scale and locking screw

a b c

Table of contents

Other Jesco Water Pump manuals

Jesco

Jesco MIDIDOS E Instruction Manual

Jesco

Jesco Peristaltic Pump 2.8 l/h Instruction Manual

Jesco

Jesco MAGDOS 20-100 Instruction Manual

Jesco

Jesco MEMDOS E User manual

Jesco

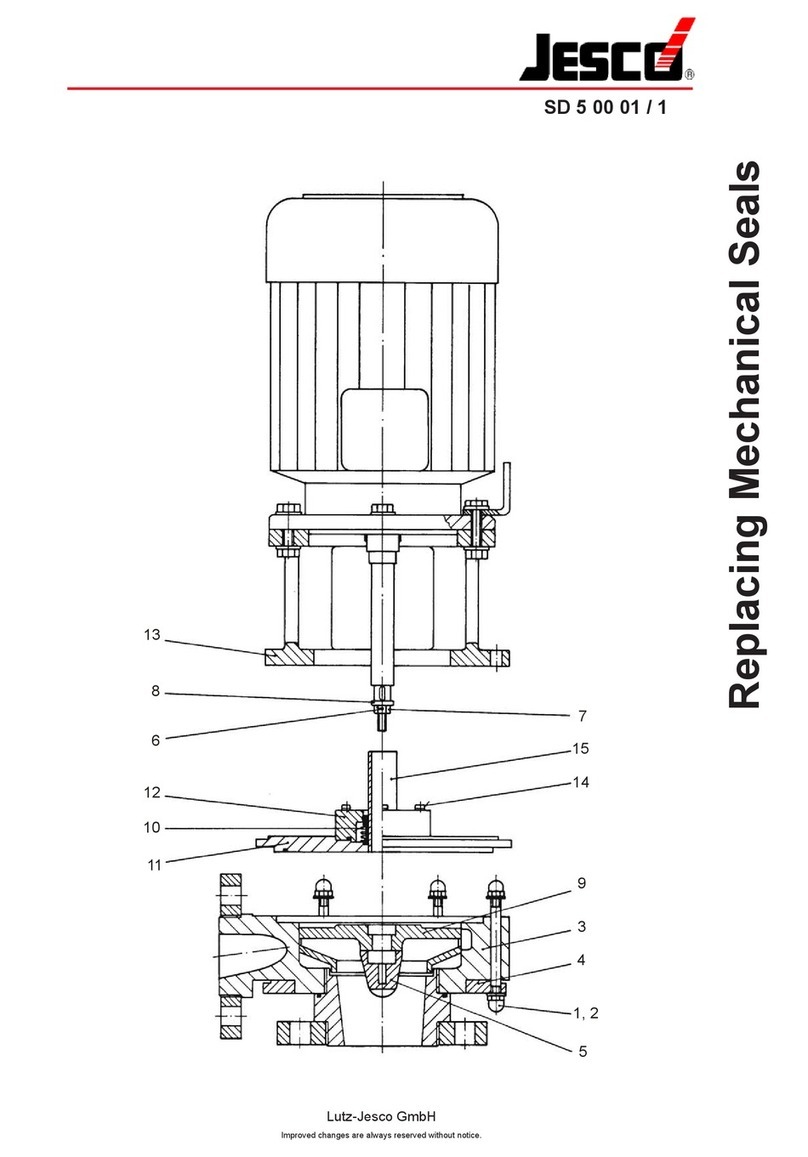

Jesco SD 5 00 01/1 User manual

Jesco

Jesco MAGDOS LB Guide

Jesco

Jesco FEDOS E 5 User manual

Jesco

Jesco Lutz PVC GF-2 User manual

Jesco

Jesco EASYDOS Peristaltic V Manual

Jesco

Jesco MIDIDOS E Series Instruction Manual