JessEm Tool Mast-R-Fence Service manual

Operating

Instructions and Parts Manual

Mast

-

R

-

Fence and Rout

Models:

JessEm Tool Company

61 Forest Plain Road

Oro-Medonte, Ontario, Canada

L3V 0R4

Local: 705-726-8233

Fax: 705-327-0295

Toll Free: 1-866-272-7492 Website:

www.jessem.com Email:

Instructions and Parts Manual

Fence and Rout

-

R

-

Fence

Models:

04010 and 04100

Fence

Thank you for choosing this product from JessEm Tool Company. We appreciate your

support and hope thatour product serves you well. This product is designed to provide

many years of reliable service provided it is used as intended and taken care of.

This user manual will assist you in assembly and general operation of this product. It

is not our intent to teach you about woodworking. It is assumed that you are an

experienced woodworker with the basicskills and experience necessary to usethis

product safely. If after reading the following instructions, if you are unsure or

uncomfortable about safely using this product we urge you to seek additional

information through widely available woodworking books or classes.

As part of our Continuous Product Improvement Policy, JessEm products are

always advancing in design and function. Thereforethere may be differencesbetween

what is shown in our catalogs, website or at retail display and what is sold at time of

purchase. We reserve the right to make positive changes to our products at our

discretion.

JessEm Tool Company Warranty

All JessEm products are warranted tobe free from defects in material and

workmanship. JessEm will repairorreplaceanyproductwhich upon inspection proves to

be defective for aperiod of (1) yearfrom dated receipt and proof of purchase. All

warranty claims should be made direct to JessEm Tool Company. Contact JessEm

for a warranty claim return authorization and instructions to proceed. The consumer

is responsible for shipping costs to return product to JessEm Tool Company. We will

repair or replace the product at our discretion and JessEm Tool will return shipment to

you at no charge.

Warranty Limitations

This warranty does not cover:

Repairsor alterations madeor attempted byanyoneotherthanJessEmTool

Companyoranauthorized JessEm service professional.

Normal wear and tear

Abuse, misuse or neglect.

Improper careor maintenance.

Continued use after partial failure.

Products that have been modified in any way.

Products used with improper accessories.

Prematurethread-wearduetoadjusting height with electric or cordless drill.

Important Safety Precautions

Before operating any machinery or power tool,read andunderstand all safety

instructions in the owner’s manual for the tool or machine.

If you donot haveamanual,contact the manufacturer and obtain one before

using any tool or machine.

Always wear eye protection in compliance with ANSI safety standardswhen

operatinganypowertools or machinery.

Always use proper guards and safety devices when operating power tools and

machinery.

Carefully checkrouter bits before each use. Do not useif damageor defect is

suspected.

Donot exceedtherecommendedRPM for any router bit.

Do not wear loose clothing or jewelrythatmaycatch ontools, machineryor

equipment.

Unplug the tool or machine when mountingor makingany adjustmentsto

mechanical performance.

Routing Safety Precautions

Alwaysmakesurethefenceonyourrouter table is locked firmly into

position before each use.

Never force the bit or overload the routerbeyondthe expectations of thetool.

Be surethat atleast 3/4 oftheshank length is inserted securely in the router

collet.

Never bottom outthebit inthecollet. Allow 1/8” clearance between bottom of

sank and bottom of collet.

Always rout in two or more passes when large amounts of stock must be

removed.

Use reduced RPM speeds for larger diameter router bits.

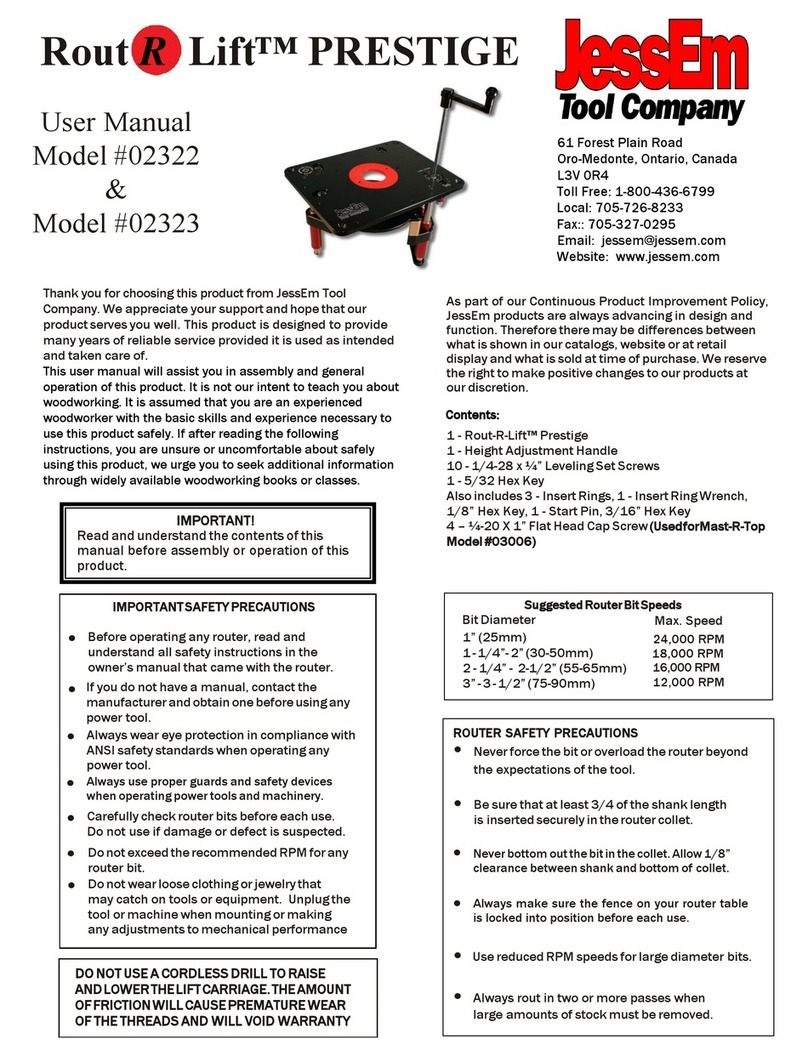

Suggested Router Bit Speeds

Bit Diameter Max. Speed

1” (25mm) 24,000 RPM

1-1/4”-2”(30-50mm) 18,000 RPM

2-1/4” - 2-1/2” (55-65mm) 16,000 RPM

3”-3-1/2”(75-90mm) 12,000 RPM

CALIFORNIA PROPOSITION 65

WARNING

This product contains lead known to the State

of California to cause cancer or reproductive

harm. Components made of brass are known

to contain lead. Wash hands after using this

product.

Tools Required for Assembly

Phillips screw driver

10 mm wrench or socket

3/16” Drill Bit*

1/16” Drill Bit*

*Note: This is required if you are not mounting to a Je

Assembling

the Fence Tracks

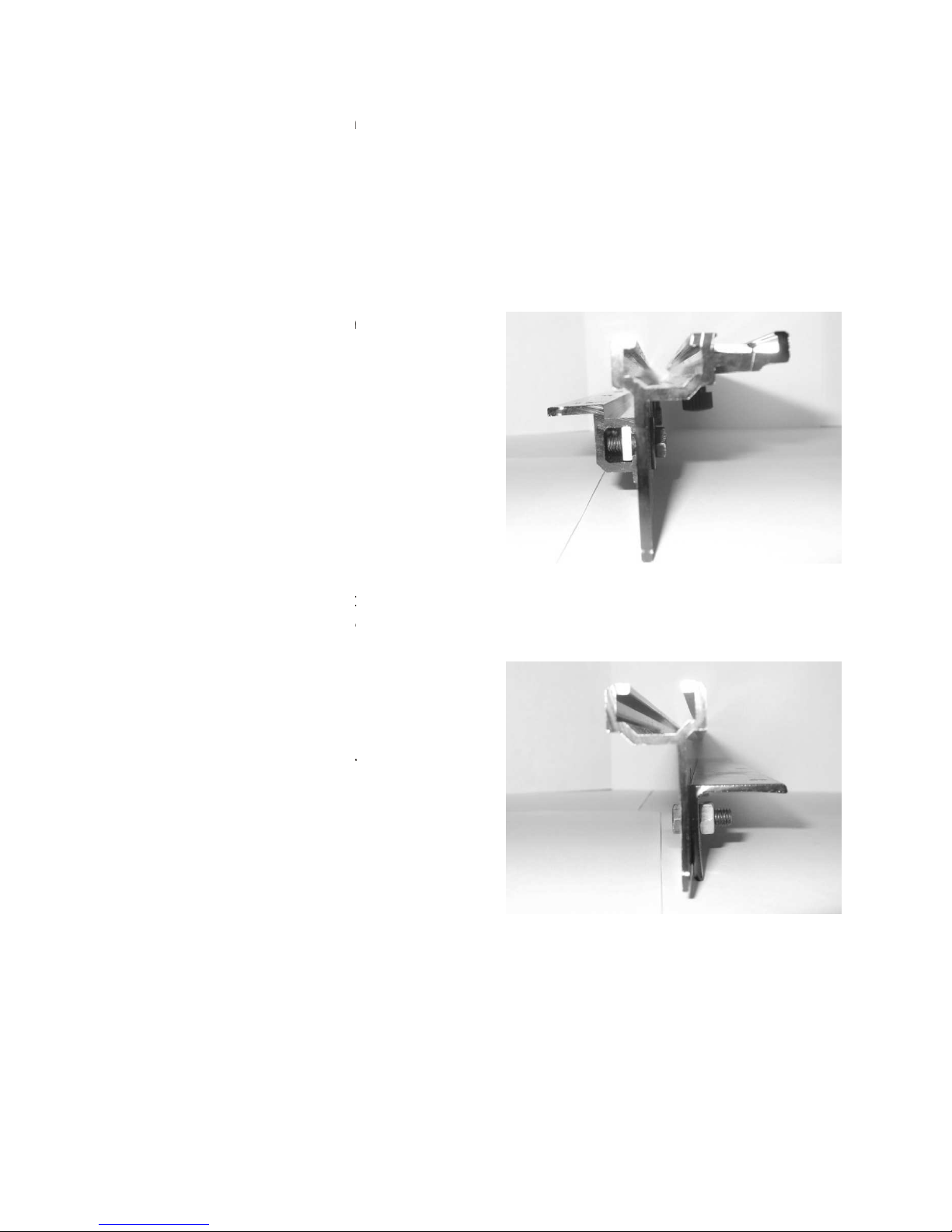

There are two different types of fence

tracks depending upon which model

fence you have purchased.

Fence model 04010 (Master Fence)

has a table mounting bracket provided

with a T-

nut slot for mounting

fence to the bracket (Fig 1)

. When

assembling the table mounting bracket

to the fence track use a 6mm hex bolt

with a flat washer and insert the bolt

into the lower slots on the fence track.

Screw the T-

nuts onto the bolts. Slide

the T-nuts into the T-

slot on the table

mounting bracket. Do not tighten this

assembly at this stage.

Fence model 04100 (Router Fence)

has a table mounting bracket but does

not have the T-

slot in the bracket as

Model 04010.

Mount the table bracket

directly to the fence track using 6mm

hex bolts

and flat washers (Fig. 2)

not tighten this assembly at this stage.

Tools Required for Assembly

10 mm wrench or socket

*Note: This is required if you are not mounting to a Je

ssEm table top.

the Fence Tracks

There are two different types of fence

tracks depending upon which model

fence you have purchased.

Fence model 04010 (Master Fence)

has a table mounting bracket provided

nut slot for mounting

the

. When

assembling the table mounting bracket

to the fence track use a 6mm hex bolt

with a flat washer and insert the bolt

into the lower slots on the fence track.

nuts onto the bolts. Slide

slot on the table

mounting bracket. Do not tighten this

Fence model 04100 (Router Fence)

has a table mounting bracket but does

slot in the bracket as

Mount the table bracket

directly to the fence track using 6mm

and flat washers (Fig. 2)

. Do

not tighten this assembly at this stage.

Figure 1

Figure 2

Figure 3

Figure 5

Note: If you are mounting the fence to a

JessEm table top proceed to the next

page section “For JessEm table”.

Measure the distance from the front edge of your

table to the center of the bit hole in the table top.

Transfer a mark the same distanced on both the

left and right edges of the table top. Then drawa

center line across

the top of the table from one

Take one of the fence track assemblies and

line it up with the mark you made in figure 4.

Make a mark on the underside of the table

top to locate the same position on the bottom

of the table (Fig. 5).

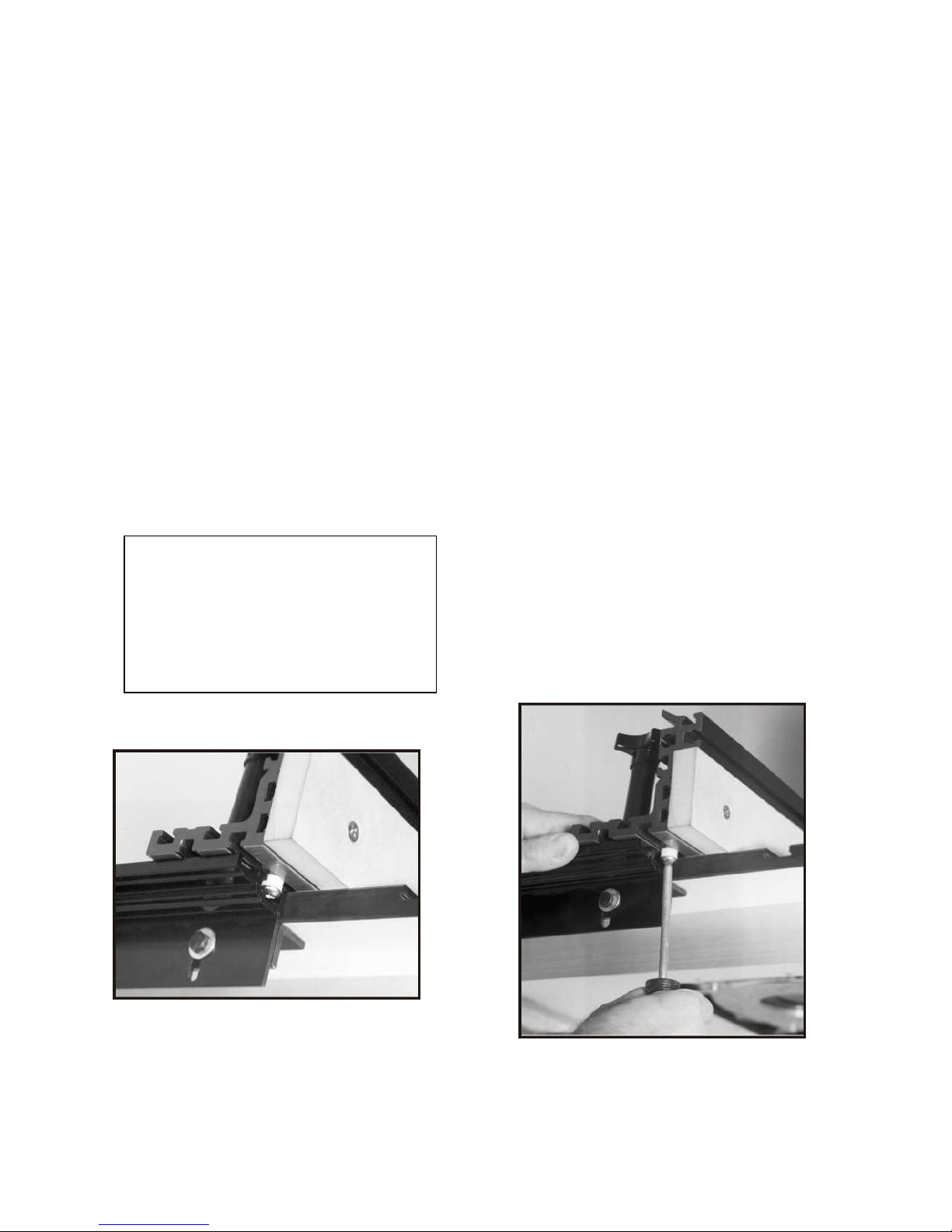

Mounting the Fence Tracks to the Table

Figure 4

Figure 6

From the center line you drew, come three

inchestoward thefront ofthe tableand mark a

small line on both the left and right sides of

the table (Fig. 4).

Flip the table top over and position the fence

bracket upside down and line up the frontedge

withthemarkyou made instep5.Using a

pencil or a 3/16” diameter drill bit mark the 4

holes for mounting the fence bracket. Pre-drill

the holes using a 1/16” diameter drill bit and

be sure you don’t drill through the table top

surface (Fig. 6). Using the #6 x ¾” wood

screws secure the fence track assembly to the

table. Repeat all steps for the second fence

bracket.

For JessEm Table Top

Leveling the Fence Track

If you are mounting the fence to aJessEm

table top the top is already pre- drilled for

the fence mounting angle brackets. With

the table upside down position the left and

right fence track assemblies andattach to

the table with the 6mm x45mmsocket head

cap screws for phenolic tablesand 4.8mm x

25mm wood screws forMDFtables and

proceed to the next step.

Figure 7

Move the fence back and use it to position the

rear end of the bracket in the same way and

tighten the rear bolt. Then tighten the center bolt

to complete the leveling of the fence track.

Repeat this process for the fence track on the

other side of the table.

When tightening the fence track mounting bolt on

Model 04010, the T-nut will tighten in the T-track

and hold the fence track securely. When

tightening the fence track mounting bolt on Model

04100 you will need a 10mm wrench to hold the

hex nut while tightening the hex bolt securely.

Mounting the Fence to the Tracks

Figure 8

Place the fence on the table top in its upright

position and allowittohang overthetable

edgeandlieacrossthefront endofthefence

track. Raise the fence track assembly sothat

it is positioned flush to the bottom of the fence

as it rests on the table top. With a 10mm

wrench or socket tighten the front bolt of the

fence assembly (Fig. 7).

Slide the ¾” hex T-nut for the extension

knob into the T- slot next to the scales on

the fence track (Fig. 8). The extension

knobs will thread into these nuts to hold the

fence in position. To do so, position the end

of the fence over the track and look directly

down through the open slot in the base of

the fence frame and visually line up the hole

in the rectangular T-nut.

Then insert the threaded tip of the

extension knob through theslot fence and

into the threaded hole inthe T- nut (Fig. 9).

Twisting the lock-down knob clockwise will

fasten the fence to the tracks andhold the

fence firmly in position.

Figure 9

The scales on the fence tracks are

adjustableforaddedversatility in

positioningthe fence. Toadjust the

scales loosen the knurled nut

underneath the fence track adjust the

scale and re-tighten the nut (Fig. 10).

You can use the scales as a zero

referencepoint byadjusting thescales to

“0”once your fence is set up in your

desiredposition relevant to the router

bit you are using. Please note that

fence scales are only available on

Model 04010. Fence scales are not

available for Model 04100.

Figure 10

Adjusting the Fence Track Scales

Figure 11

TheMast-R-Fenceoffersauniquemeans

of keeping the fence centered on the

table with a nylon bushing. Take the

6mm x 15mm bolt and insert into the

1/2”nylonspacerandthreadononeof the

square 6mm nuts. Do not thread the

square nut on all the way. Slide the

squarenut into the front T-slot under the

left end of the fence (Fig. 11). Leave

theassembly loose andapproximately 1”

in from the end of the fence.

Figure 12

Slide the fence with the nylon spacer

attached into the T-slot on the left

fence track (Fig. 12). Thenylon

spacershould be slightly loose to

allow for some movement.

Nowslide thefenceback andcenter the

fence left to right with the center of the

bit opening. Make sure it is parallel

with the front edge of the table or miter

track.

Note: Fence Model 04100 does not

come with the nylon bushing for

centering. Model 04010 is the only

fence equipped with this feature.

Now slide the fence, keeping it

square (use the scales on the fence

track to ensure you are square) to

thefront of the table, just until the

nylon spacer comes out of the

track. Then tighten the bolt on the

spacer being very careful not to

changeitsposition (Fig. 13).

Centering the Fence to the Table

Figure 13

Installing the Sub-

Fences

Locate the sub-fences in the

packaging. Place the sub-

fence

against the front of the fence

extrusion (Fig. 14). Align the holes in

the sub-

fence with the slots in the

fence

extrusion. Insert the 6mm x

45

mm screws through the hole in the

front of the sub-

fences (Fig. 15).

Place the 6mm washer over the sub

fence bo

lt. Screw the black knob

onto the sub-

fence bolt (Fig. 16).

Repeat these steps for the remaining

two holes. Repeat these for the other

sub-fence.

Slidethefencebacktothecenterofthe

table. Re-

check to see if the fence is

centeredonthe table.Ifnot repeatuntil

you

achieve your desired result.

Figure 14

Fences

fence

extrusion (Fig. 14). Align the holes in

fence with the slots in the

extrusion. Insert the 6mm x

mm screws through the hole in the

fences (Fig. 15).

Place the 6mm washer over the sub

-

lt. Screw the black knob

fence bolt (Fig. 16).

Repeat these steps for the remaining

two holes. Repeat these for the other

Slidethefencebacktothecenterofthe

check to see if the fence is

centeredonthe table.Ifnot repeatuntil

achieve your desired result.

Figure 14

Figure 15

Figure 16

Figure 17

Installing Sub-

Fence Offset Track

Fence Model 04010 and Model 04100 are both

equipped with sub-fence offse

t tracks. These

offset tracks are designed to be installed two

allow for a 1/32” or 1/16” offset of the sub

Notice the

female profile of the extrusion, you will

see that one side of the profile is deeper than the

other side. The small side is 1/32” and the

deeper side is 1/16”.

The sub-

fence offset tracks are located on the

backside of the fence in a specially designed

storage location (Fig. 17).

Remove one side of the fence sub-

fences by

unscrewing the black knob and removing the

sub-fence bolts (Fig. 18)

. Once the sub

has been removed, notice the end of the fence

extrusion. The fence extrusion is designed with

ma

ting male profiles designed to accept the

offset tracks (Fig. 19

). Side the offset tracks

onto the fence extrusion take care that you install

both o

ffsets on the same side (Fig. 20

offsets should always be installed on the same

side to insure the sub-

fence is offset the same

distance at the top and bottom of the sub

Once the offset tracks are securely in place,

reinstall the sub-fence with the sub

-

washer , and black locking knob.

Fence Offset Track

Fence Model 04010 and Model 04100 are both

t tracks. These

offset tracks are designed to be installed two

allow for a 1/32” or 1/16” offset of the sub

-fence.

female profile of the extrusion, you will

see that one side of the profile is deeper than the

other side. The small side is 1/32” and the

fence offset tracks are located on the

backside of the fence in a specially designed

fences by

unscrewing the black knob and removing the

. Once the sub

-fence

has been removed, notice the end of the fence

extrusion. The fence extrusion is designed with

ting male profiles designed to accept the

). Side the offset tracks

onto the fence extrusion take care that you install

ffsets on the same side (Fig. 20

). Both

offsets should always be installed on the same

fence is offset the same

distance at the top and bottom of the sub

-fence.

Once the offset tracks are securely in place,

-

fence bolt,

Figure 18

Figure 19

Figure 20

Attaching the Router Bit Guard

Take the clear polycarbonate guard

and two of the black knurled

knobs

andtwo1/4”squarenuts

. Insert each

knob through each

slot intheguard

andthread a square nut

onto each bolt

end.

Lineupthe nutontheguard assembly

slide each nut into the T-

slot starting from

the end of the fence (Fig. 21). Then

the guard to the center of the fence and

adjust the guard slightly higher than

abovetherouterbit.Besuretheguard

cle

ars the bit. Adjust and tighten securely

before each use and after all bit changes.

Attaching the Router Bit Guard

Take the clear polycarbonate guard

knobs

. Insert each

slot intheguard

onto each bolt

Lineupthe nutontheguard assembly

and

slot starting from

the end of the fence (Fig. 21). Then

slide

the guard to the center of the fence and

adjust the guard slightly higher than

and

abovetherouterbit.Besuretheguard

ars the bit. Adjust and tighten securely

before each use and after all bit changes.

Tools That Make A Difference!

Figure 21

Tools That Make A Difference!

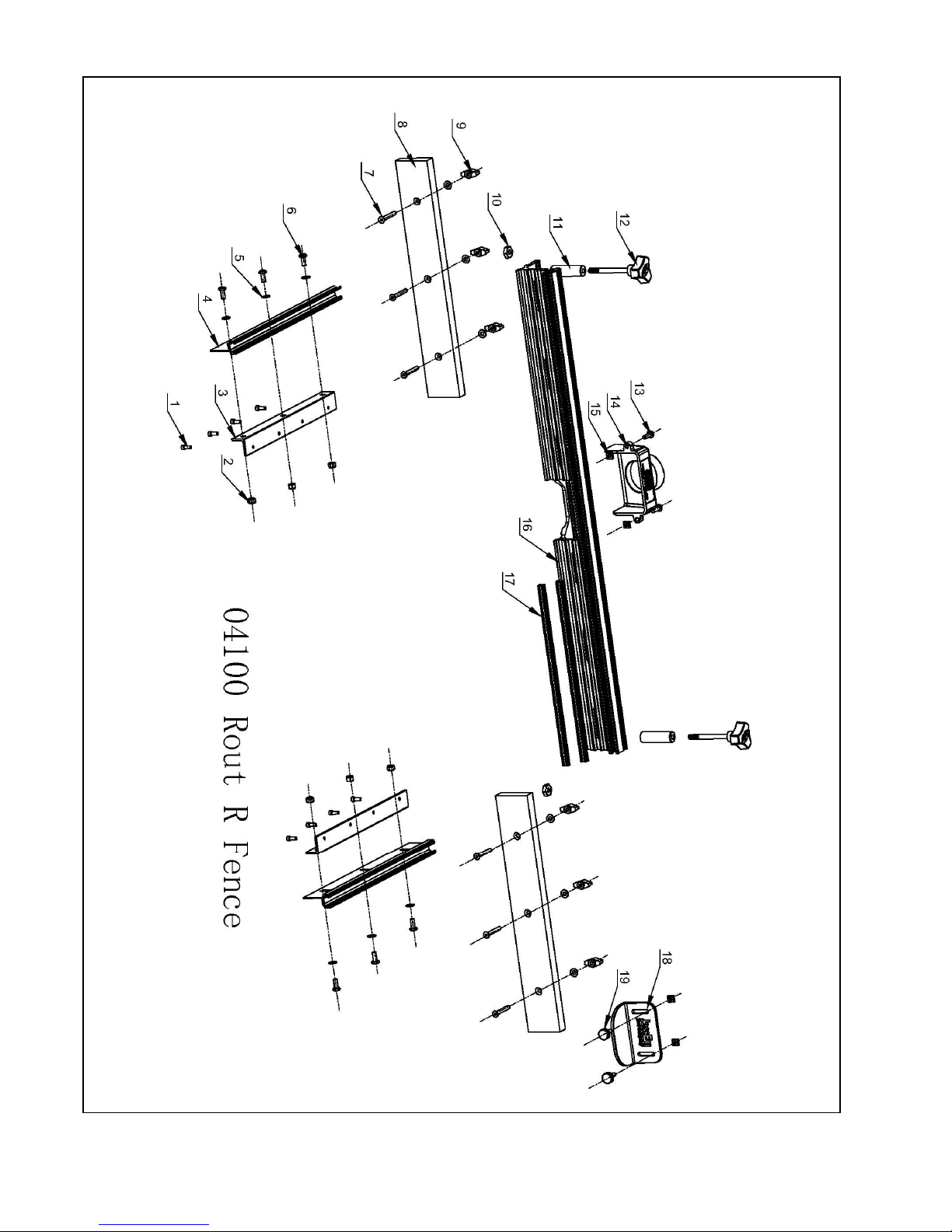

04100 Rout-R-Fence Parts List

Item No. Part No. Description Qty Part Specification

1 04100-001 Fence Track Mtg Angle Wood Screw 8 4.8MX25M

2 04100-002 Fence Track Mtg Nut 6 M6

3 04100-003 Fence Track Mtg Angle 2

4 04100-004 Fence Miter Track 2

5 04100-005 Fence Track Mtg Washer 6 6.5MX14.5MX1.2M

6 04100-006 Fence Track Mtg Bolt 6 M6X16

7 04100-007 Fence Face Mtg Bolt 6 M6X45

8 04100-008 Fence Face 2

9 04100-009 Fence Clamping Knob 2

10 04100-010 Fence Clamping Nut 2 M8

11 04100-011 Knob Extension 2

12 04100-012 Clamping Knob 6

13 04100-013 Vacuum Port Mtg Screw 2 M6X20

14 04100-014 Vacuum Port/Dust Chute 1

15 04100-015 Vacuum Port Square Nut 4 M6

16 04100-016 Fence Extrusion 1

17 04100-017 Fence Shimming Bar 2

18 04100-018 Fence Guard 1

19 04100-019 Fence Guard Locking Knob 2

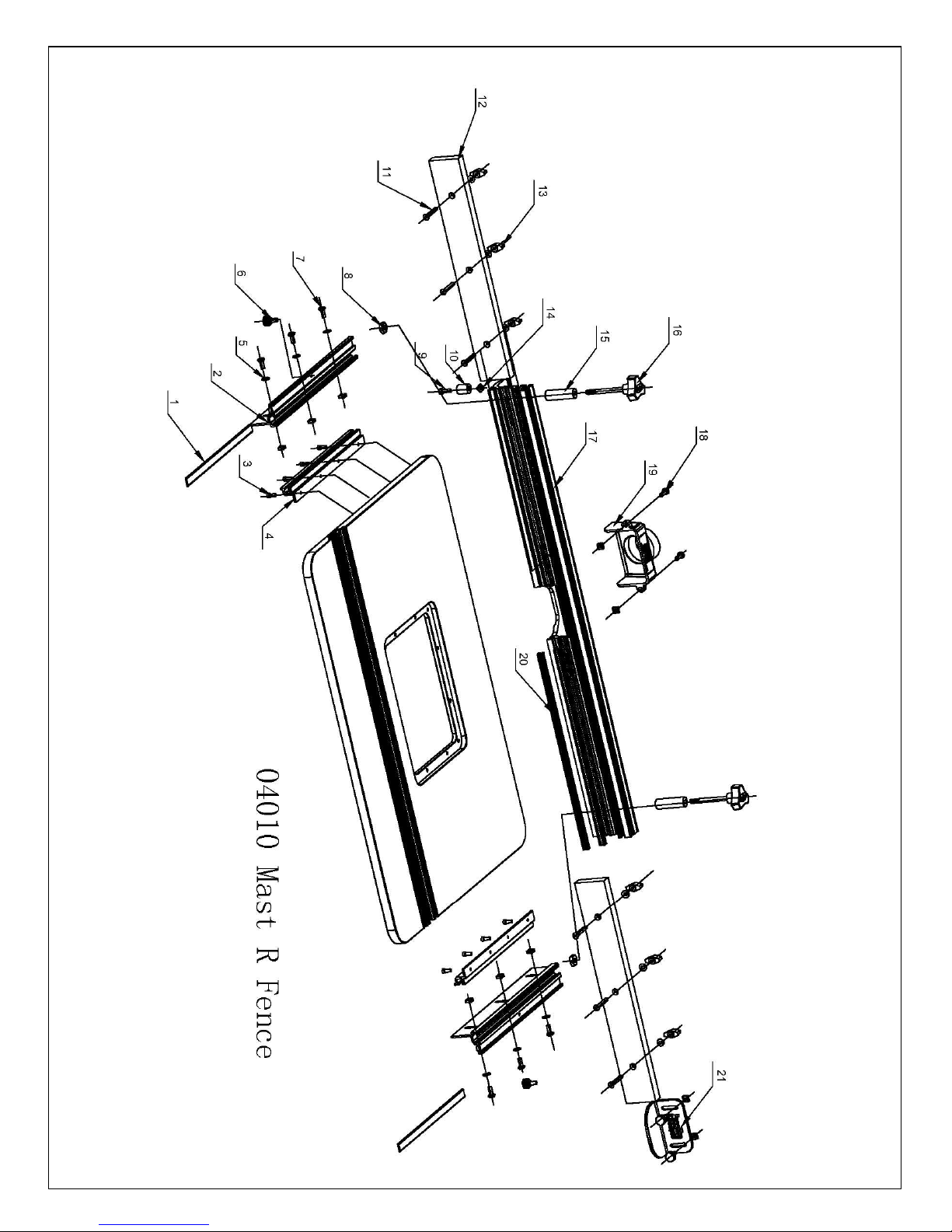

04010 Mast-R-Fence II Parts List

Item No. Part No. Description Qty Specification

1 04010-001 Scale Mounting Bar and Scale 2

2 04010-002 Fence Track 2

3 04010-003 Fence Bracket Mtg Track Screw 8 M5X12

4 04010-004 Track Mounting Angle 2

5 04010-005 Flat Washer 12 6.5X14.5X1.2

6 04010-006 Fence Track Scale Locking Knob 4

7 04010-007 Fence Track Mtg bolt 6 M6X16

8 04100-010 Fence Clamping Nut 2 M8

9 04010-009 Centering bushing bolt 1 M6X15

10 04010-010 1/2" Nylon Spacer 1

11 04100-007 Fence Face Bolt 6 M6X45

12 04010-012 Fence Face 2

13 04100-012 Clamping Knob 6

14 04100-015 Centering bushing nut 11 M6

15 04100-011 Knob Extension 2

16 04100-009 Fence Clamping Knob 2 M8

17 04010-017 Fence Extrusion 1

18 04100-013 Vacuum Port/Dust Chute Screw 2 M6X20

19 04100-014 Vacuum Port/Dust Chute 1

20 04010-020 Fence Shimming Bar 2

21 04100-018 Fence Guard 1

04100-015 Vacuum Port/Dust Chute nut 2

04010-023 Fence Scale 1

This manual suits for next models

1

Table of contents

Other JessEm Tool Power Tools manuals

JessEm Tool

JessEm Tool Mast-R-Lift 02101 User manual

JessEm Tool

JessEm Tool MITE-R-SLIDE II User manual

JessEm Tool

JessEm Tool CLEAR CUT-TS User manual

JessEm Tool

JessEm Tool mast-r-lift II User manual

JessEm Tool

JessEm Tool Mite R Slide User manual

JessEm Tool

JessEm Tool TA FENCE User manual

JessEm Tool

JessEm Tool Rout R Lift PRESTIGE 02322 User manual

Popular Power Tools manuals by other brands

IKH

IKH 6021 instruction manual

Clarke

Clarke Strong-Arm CSA50FPB Operation & maintenance instructions

Opus

Opus Goldpress Plus OPERATING, MAINTENANCE AND SAFE USAGE

Beveler USA

Beveler USA B15 Operation manual

Matatakitoyo Torque Tools

Matatakitoyo Torque Tools MOT2 Operation manual

HART

HART HPIF50 Operator's manual