JessEm POWRTEK SR User manual

FOR USE IN JESSEM ROUTER LIFT AND ROUTER TABLE APPLICATIONS ONLY (NOT FOR

HANDHELD USE)

Model #05302

x

TO REDUCE THE RISK OF INJURY, USER MUST READ OPERATORS

MANUAL

THANK YOU FOR CHOOSING

Thank you for choosing this product from JessEm Tool Company. We appreciate

your support and hope that our product serves you well. This product is designed

to provide many years of reliable service provided it is used as intended and taken

care of.

X

This user manual will assist you in assembly and general operaon of this product.

It is not our intent to teach you about woodworking. It is assumed that you are an

experienced woodworker with the basic skills and experience necessary to use this

product safely. If aer reading the following instrucons you are unsure or

uncomfortable about safely using this product, we urge you to seek addional

informaon through widely available woodworking books or classes.

X

As part of our Connuous Product Improvement Policy, JessEm products are always

advancing in design and funcon. Therefore, there may be dierences between

what is shown in our catalogs, website or at retail display and what is sold at me

of purchase. We reserve the right to make posive changes to our products at our

discreon.

If you have any quesons about our products or service, please call

Find us on social media

youtube.com/JessEmToolCompany

facebook.com/JessEmTools

instagram.com/jessemtoolcompany

324 Desbrisay Avenue

Moncton, New Brunswick,

E1E 0G8, Canada

Toll Free: 800-436-6799

Local Phone: 705-726-8233

Fax: 705-327-0295

Website: www. JessEm.com

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page1

CONTENT

WHATS IN THE BOX

2

WARRANTY

3

SAFETY INSTRUCTIONS

4

ASSEMBLY AND OPERATION

7

MAINTENANCE

10

ACCESSORIES

10

PARTS DIAGRAM

11

PARTS LIST

12

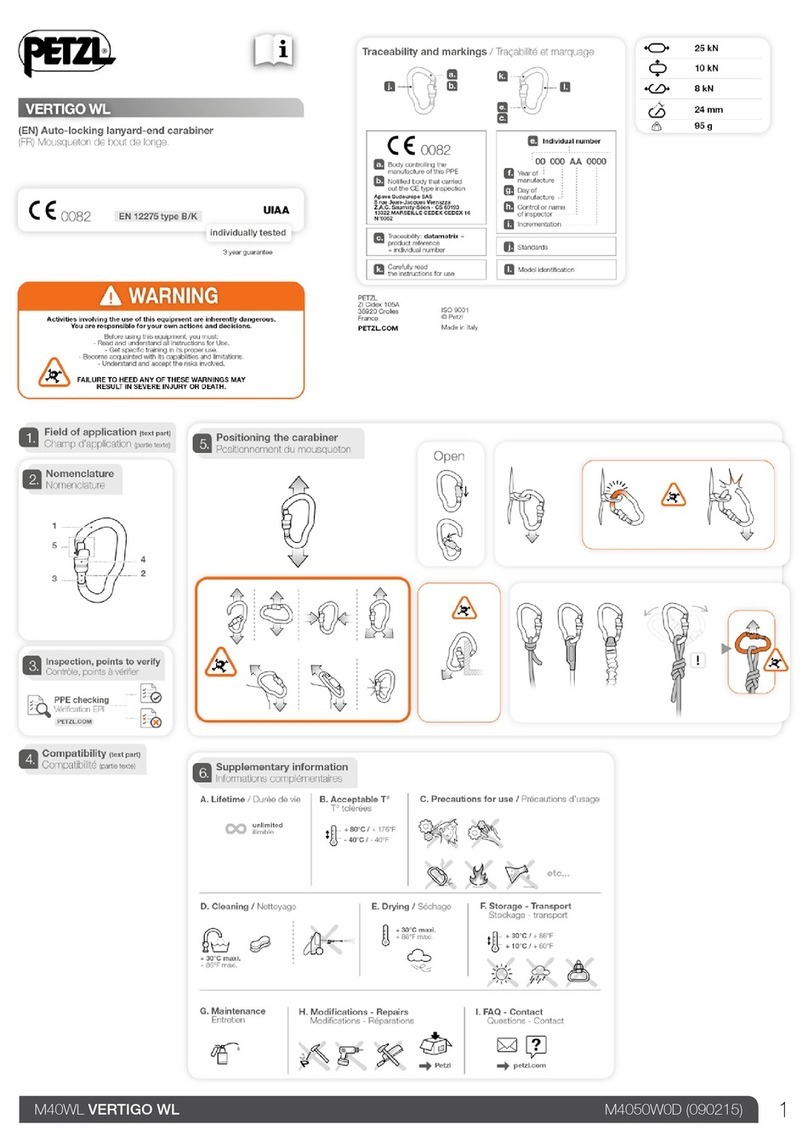

WARNING: Read and understand all

instrucons before using. Failure to follow all

instrucons listed below or to us the router in a safe

manor may result in electrical shock, re and/or

serious personal injury.

x

WARNING: This product can expose you to

chemicals including lead and/or chromium,

known to the State of California to cause cancer and

birth defects or other reproducve harm.

WARNING: Drilling, sawing, sanding or

machining wood products can expose you to

wood dust, a substance known to the state of

California to cause cancer. Avoid inhaling wood dust

or use a dust mask or other safeguards for personal

protecon.

WARNING: The wires of this product contain

chemicals known to the State of California to

cause cancer and birth defects or other reproducve

harm. Wash hands aer handling.

Operang a power tool can be extremely dangerous if operated incorrectly or in a manor other than what it

is intended to do. Read this manual and ensure all necessary precauons are taken for safe operaon. DO

NOT operate this machine if you do not fully understand how to use it and are not aware of its limitaons.

DO NOT modify this machine in any way.

This manual is not designed to teach you about woodworking. If aer reading this manual you sll do not

understand how to operate this machine safely, we urge you to seek addional informaon through widely

available books and woodworking classes.

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page2

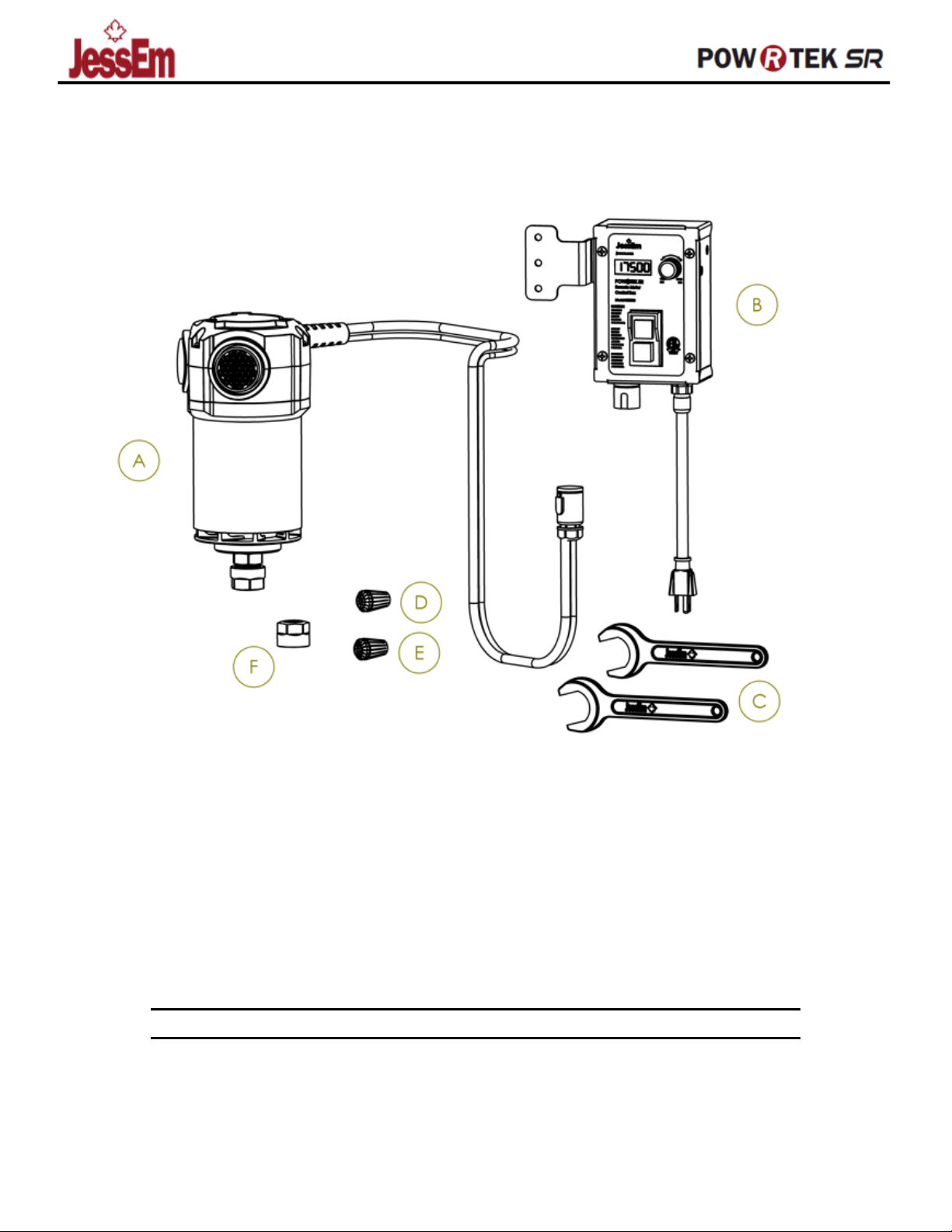

WHATS IN THE BOX

Figure 1 – What’s included with the POW-R-TEK SR ROUTER

SPECIFICATIONS

AC VOLTAGE

230 V (50 Hz)

POWER CONSUMPTION

2400 W (INPUT) 1800 W (OUTPUT)

NO LOAD RPM

10 000 – 22 000

A

ROUTER

D

½” ER-20 COLLET

B

SPEED CONTROL BOX

E

¼” ER-20 COLLET

C

WRENCHES

F

ER-20 COLLET NUT

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page3

WARRANTY

JESSEM TOOL LIMITED WARRANTY

All JessEm products are warranted to be free

from defects in material and workmanship.

JessEm will repair or replace any product which

upon inspecon proves to be defecve for a

period of (1) year from dated receipt and proof of

purchase. All warranty claims should be made

direct to JessEm Tool Company.

Contact JessEm for a warranty claim return

authorizaon and instrucons to proceed. The

consumer is responsible for shipping costs to

return product to JessEm Tool Company. We will

repair or replace the product at our discreon

and JessEm Tool will return shipment to you at no

charge.

WARRANTY LIMITATIONS

This warranty does not cover:

• Repairs or alteraons made or aempted by

anyone other than JessEm Tool Company or an

authorized JessEm service professional.

-Normal wear and tear

-Abuse, misuse or neglect.

-Improper care or maintenance.

-Connued use aer paral failure.

-Products that have been modied in any

way.

-Products used with improper accessories

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page4

GENERAL SAFETY

WORK AREA

1Keep work area clean and well lit. Cluer and dark

work areas invite accidents.

2Avoid dangerous environments. Do not use your

power tool in the rain, damp or wet locaons or in the

presence of an explosive atmosphere (gaseous fumes,

dust or ammable materials). Remove materials or

debris that may be ignited by sparks.

3Keep bystanders away. Children and bystanders

should be kept at a safe distance from the work area

to avoid distracng the operator and contacng the

tool or extension cord.

4Protect others in the work area from debris such as

chips and sparks. Provide barriers or shields as

needed.

5Make your workshop child proof with padlocks,

master switches, or by removing starter keys.

ELECTRICAL SAFETY

6Grounded tools must be plugged into an outlet

properly installed and grounded in accordance with all

codes and ordinances.

7Double insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug will

t in a polarized outlet only one way. If the plug does

not t fully in the outlet, reverse the plug. If it sll

does not t, contact a qualied electrician to install a

polarized outlet. Do not change the plug in any way.

Double insulaon eliminates the need for the three-

wire grounding power cord and grounded power

supply system.

8Guard against electrical shock. Prevent body contact

with grounded surfaces such as pipes, radiators,

ranges and refrigerators. When making blind or

plunge cuts, always check the work area for hidden

wires or pipes. Hold your tool by insulated nonmetal

grasping surfaces. Use a Ground Fault Circuit

Interrupter (GFCI) to reduce shock hazards.

9Do not expose to rain or use in damp locaons.

10 Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of

electrical shock.

PERSONAL SAFETY

11 Know your power tool. Read this manual carefully to

learn your power tool’s applicaons and limitaons as

well as potenal hazards associated with this type of

tool.

12 Stay alert, watch what you are doing, and use

common sense when operang a power tool. Do not

use tool while red or under the inuence of drugs,

alcohol, or medicaon. A moment of inaenon while

operang power tools may result in serious personal

injury.

13 Dress properly. Do not wear loose clothing or jewelry.

Wear a protecve hair covering to contain long hair.

These may be caught in moving parts. When working

outdoors, wear insulated non-skid footwear. Keep

hands away from moving parts. Do not wear gloves,

as they can potenally get caught in rotang parts and

pull your hand into the cuer.

14 Reduce the risk of unintenonal starng. Be sure your

tool is turned o before plugging it in. Do not use a

tool if the power switch does not turn the tool on and

o. Do not carry a plugged-in tool with your nger on

the switch.

15 Remove all adjusng keys and wrenches. Make a habit

of checking that adjusng keys, wrenches, etc. are

removed from the tool before turning it on.

16 Do not overreach. Maintain control. Keep proper

foong and balance at all mes.

17 Use safety equipment. Everyone in the work area

should wear safety goggles or glasses with side shields

complying with current safety standards. Everyday

eyeglasses are not safety glasses. Wear hearing

protecon during extended use and a dust mask for

dusty operaons. Hard hats, face shields, safety shoes,

etc. should be used when specied or necessary. Keep

a re exnguisher nearby.

18 Keep guards in place and in working order.

19 Never stand on tool. Serious injury could occur if the

tool is pped or if the cung tool is unintenonally

contacted.

20 Keep hands away from all cung edges and moving

parts.

21 Never touch the bit during or immediately aer use.

Aer use the bit may be hot enough to burn bare skin.

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page5

TOOL USE AND CARE

22 Secure work. Use clamps or a vise to hold work when

praccal. It is safer than using your hand and it frees

both hands to operate the tool.

23 Do not force tool. Your tool will perform best at the

rate for which it was designed. Excessive force only

causes operator fague, increased wear and reduced

control.

24 Use the right tool. Do not use a tool or aachment to

do a job for which it is not recommended. For

example, do not use a circular saw to cut tree limbs or

logs. Do not alter a tool.

25 Unplug tool when it is not in use, before changing

accessories or performing recommended

maintenance.

26 Store idle tools. When not in use, store your tool in a

dry, secured place. Keep out of reach of children.

27 Never leave the tool running unaended. Turn power

o. Do not leave the tool unl it comes to a complete

stop.

28 Check for damaged parts. Inspect guards and other

parts before use. Check for misalignment, binding of

moving parts, improper mounng, broken parts and

any other condions that may aect operaon. If

abnormal noise or vibraon occurs, turn the tool o

immediately and have the problem corrected before

further use. Do not use a damaged tool.

29 Use proper accessories. Consult this manual for

recommended accessories. Using improper

accessories may be hazardous. Be sure accessories are

properly installed and maintained. Do not defeat a

guard or other safety device when installing an

accessory or aachment.

30 Maintain tools carefully. Keep cung edges sharp and

clean. Follow instrucons for lubricang and changing

accessories. Periodically inspect tool cords and

extension cords for damage. Have damaged parts

repaired or replaced by a JESSEM.

31 Maintain labels & nameplates. These carry important

informaon.

32 Read, understand, and follow the instrucons

packaged with the router table and router li. Do not

plug in Remote Power unl Router Table Motor is fully

installed

33 Only use the following recommended router tables

and router lis with this motor.

-JessEm Mast-R-Li II #02120/21/23

-Incra Mast-R-Li II #02121

- JessEm Mast-R-Li Excel #02202

-JessEm Mast-R-Li Excel II #02203

Using tables and lis that are not specically

recommended may not properly secure the Router

Table Motor. An improperly secured Motor increases

the risk of injury or product damage.

34 Do not place motor in a router base or hold motor by

hand during use. Motor is designed only for use

properly secured in a recommended JessEm router li

or router table. This motor is not designed for use in a

router base.

35 Some woods contain preservaves that can be toxic.

Take extra care to prevent inhalaon and skin contact

when working with these materials. Request, and

follow, any safety informaon available from your

material supplier.

36 Always make sure the workpiece is free from nails,

screws and other foreign objects. Keep the working

edge away from the clamping surface. Cung these

objects can cause loss of control of the workpiece and

damage to the bit.

37 Never place hands near cung surface.

38 Never use dull or damaged bits. Sharp bits must be

handled with care. Damaged bits can break during

use. Dull bits require more force, which could cause

the bit to break. Damaged bits can throw carbide

pieces and burn the workpiece.

39 Never use dull or damaged bits. Sharp bits must be

handled with care. Damaged bits can break during

use. Dull bits require more force, which could cause

the bit to break. Damaged bits can throw carbide

pieces and burn the workpiece.

40 Never start the tool when the bit is in contact with the

material. The bit cung edge may grab the material

causing loss of control of the workpiece.

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page6

SERVICE

41 Service or maintenance performed by unqualied

personnel may result in a risk of injury.

42 When servicing a tool, use only idencal

replacement parts. Follow instrucons in the

maintenance secon of this manual. Use of

unauthorized parts or failure to follow

maintenance instrucons may create a risk of

shock or injury.

GROUNDING

43 Double insulated tools are constructed throughout

with two separate "layers" of electrical insulaon

between you and the tool's electrical system.

Tools built with this insulaon system are not

intended to be grounded. NOTE: Double insulaon

does not take the place of normal safety

precauons when operang this tool, the

insulaon system is for added protecon against

injury resulng from a possible electrical

insulaon failure within the tool.

44 If the tool is supplied with a 3-prong plug, it must

be plugged into a 3-contact electrical receptacle.

The 3rd prong is used to ground the tool and

provide protecon against accidental electric

shock.

EXTENSION CORDS

45 Grounded tools require a three-wire extension

cord. Double insulated tools can use either a two

or three wire extension cord.

46 As the distance from the supply outlet increases,

you must use a heavier gauge extension cord.

Using extension cords with inadequately sized

wire causes a serious drop in voltage, resulng in

loss of power and possible tool damage. Refer to

the table shown to determine the required

minimum wire size.

47 The smaller the gauge number of the wire, the

greater the capacity of the cord. For example, a

14-gauge cord can carry a higher current than a

16-gauge cord. When using more than one

extension cord to make up the total length, be

sure each cord contains at least the minimum wire

size required.

48 If you are using one extension cord for more

than one tool, add the nameplate amperes

and use the sum to determine the required

minimum wire size.

49 If using an extension cord outdoors, be sure it

is rated for outdoor use (Typically marked

with the sux “W-A” or “W” in Canada).

50 Be sure your extension cord is properly wired

and in good electrical condion. Always

replace a damaged extension cord or have it

repaired by a qualied person before using it

51 Protect your extension cords from sharp

objects, excessive heat and damp or wet

areas.

52 Avoid stepping on your extension cord.

53 If in Doubt about the rang or safety of an

extension cord, consult an electrician or other

qualied person.

READ AND SAVE ALL

INSTRUCTIONS FOR FUTURE USE

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page7

TOOL ASSEMBLY

WARNING: To reduce the risk of injury, always

unplug tool before aaching or removing

accessories or making adjustments. Use only

specically recommended accessories. Others

may be hazardous.

Snap the nut and collet together by rmly applying

downward pressure into the assembly with the palm of

your hand (Fig. 3).

To remove the collet from the nut, hold the nut rmly

with one hand and press the collet to one side with the

other hand (Fig. 4).

Collets

The collet must be aached to the collet nut before it is

put into the collet seat. Be sure that the size of the collet

matches the size of the bit shank being used. If the wrong

size bit shank is used, the collet may break. For aaching

or detaching the collet nut to the collet, follow the

illustrated instrucons on this page.

To aach the collet nut to the collet, place the narrow

end of the collet on an even surface. Take the nut and

place it over the collet (Fig. 1).

Posion the nut squarely over the collet with the smaller

opening of the nut facing up (Fig. 2).

WARNING: To reduce the risk of injury, always

wear eye protecon and all other applicable

personal protecve equipment when using or

performing maintenance on your tools.

INSTALLING THE MOTOR INTO A

LIFT

To install the motor into a router li, read, understand,

and follow the instrucons packaged with the router li.

To reduce the risk of injury, use only the following router

tables and lis with this motor.

-JessEm Mast-R-Li II™ #02120, #02121

-JessEm Mast-R-Li™ #02101, #02102

-JessEm Mast-R-Li Excel II™ #02202

-JessEm Mast-R-Li Excel™ #02201

Using other tables and lis may not properly secure the

Router Motor. An improperly secured motor increases the

risk of injury or product damage.

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page8

INSTALLING THE ROUTER BIT

It is not necessary to remove the motor from the li

to install a collet assembly or a bit. (If removal of

the motor is desired, see the li instrucons.) Raise

the motor as high as possible. Always wipe wood

chips, dust or other foreign materials from the collet

sha and collet assembly before assembling.

1. Insert the collet assembly into the collet seat.

2. Insert the bit shank into the collet as far as it will

go.

3. Back the bit shank out slightly to avoid

booming out.

Be sure there is a minimum of 1/16" between the

boom of the collet assembly and the radius to the

cung poron of the bit (Fig. 5).

4. Be sure that the collet is not clamped to a

uted secon on the bit shank. The collet

should be clamped to a solid part on the bit

shank.

5. To ghten the bit in the collet assembly, use

two wrenches (Fig. 6).

NOTE: Never ghten a collet assembly without

inserng a bit shank of the proper size. This may

damage the collet.

x

WARNING: To reduce the risk of injury, always

check for damage on your tools and cuers

before operang. Ensure collet is properly

ghtened to prevent the bit from moving or

coming out during operaon.

x

REMOVING THE ROUTER BIT

6. Loosen the collet nut from the collet seat using

two wrenches.

7. Once loose, unscrew the collet nut by hand unl it

feels ght again.

8. Return to using the wrenches unl the bit shank

can be pulled out.

OPERATION

x

WARNING: Do not use this router unless it is

securely installed into a recommended

JessEm li and table

x

THE VARIABLE SPEED DIAL

The variable speed dial allows the user to adjust the

rotang speed (RPM) of the tool. Variable speed dial

sengs range from 10,000 RPM to 21,000 RPM.

Higher numbers correspond to higher speeds and

lower number correspond to lower speeds. To change

the speed, set the variable speed control dial to the

desired number.

Use the following chart to determine the best speed for

the bit diameter.

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page9

STARTING AND STOPPING THE MOTOR

To start the motor, press the green start buon. It

will stay pressed unl the stop buon is pressed or

the incoming power is lost (power outage etc.). To

stop the motor, push the red stop buon.

ELECTRONIC OVERLOAD PROTECTION

Before the motor is overloaded, the electronic

overload protecon circuit will turn o the tool. If

the motor shuts o during use, push the o buon.

Wait at least three (3) seconds. This will reset the

electronics in the tool. Press the green start buon

to connue use.

SOFT START

The So-Start feature reduces the amount of torque

reacon to the tool. This feature gradually increases

the motor speed up from zero to the speed set by

the variable speed dial.

FEEDBACK CONTROL

The electronic speed control system allows the tool

to maintain constant speed between no-load and

load condions

MAKING THE CUT

The speed and depth of cut will depend largely on

the type of material being worked. Keep the cung

pressure constant but do not use excessive force so

the motor speed slows excessively. It may be

necessary on exceponally hard woods or problem

materials to make more than one pass to get the

desired depth of cut.

x

Before beginning the cut on the actual workpiece, it

is advisable to take a sample cut on a scrap piece of

lumber. This will show you exactly how the cut will

look as well as enable you to check dimensions.

x

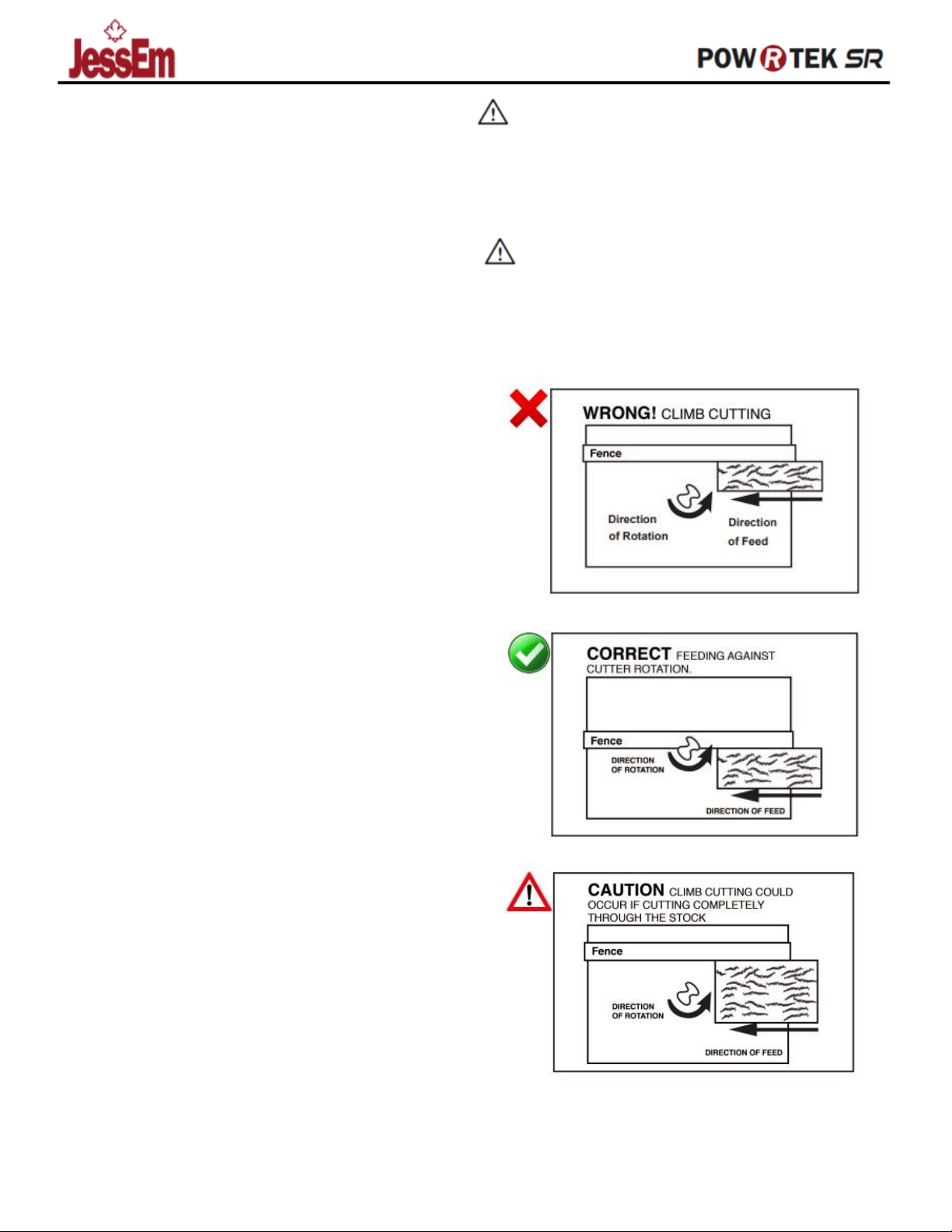

Posion the fence so that the workpiece feeds

against the cuer rotaon. Feeding the workpiece

with the cuer rotaon is called climb cung, which

is very dangerous. Climb cung can result in the

workpiece being thrown violently out of your control

at great speed.

WARNING: To reduce the risk of injury, avoid

“climb cung.” Climb cung can cause the

workpiece to be thrown violently out of your

control. Even small router bits can cause in

climb cung.

WARNING: To reduce the risk of injury, always

use feather boards, push scks or push blocks

with proper guarding. Keep hands away from

moving bit. Refer to the Router Table manual

for proper table setup and use.

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

Page10

MAINTENANCE

WARNING: To reduce the risk of injury,

always unplug your tool before performing

any maintenance. Never disassemble the

tool or try to do any rewiring on the tool's

electrical system.

WARNING: To reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to ow inside the tool

MAINTAINING TOOL

Keep your tool in good repair by adopng a regular

maintenance program. Before use, examine the

general condion of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounng, broken

parts and any other condion that may aect its safe

operaon. If abnormal noise or vibraon occurs, turn

the tool o immediately and have the problem

corrected before further use. Do not use a damaged

tool. Tag damaged tools “DO NOT USE” unl repaired

(see “Repairs”).

CLEANING

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use only

mild soap and a damp cloth to clean your tool since

certain cleaning agents and solvents are harmful to

plascs and other insulated parts. Some of these

include: gasoline, turpenne, lacquer thinner, paint

thinner, chlorinated cleaning solvents, ammonia and

household detergents containing ammonia. Never

use ammable or combusble solvents around tools.

ACCESSORIES

WARNING: To reduce the risk of injury,

always unplug the tool before aaching or

removing accessories. Use only specically

recommended accessories. Others may be

hazardous

For a complete lisng of accessories, including JessEm

router tables and lis, visit JessEm at www.jessem.com or

contact a distributor near you

The following JessEm lis accept the JessEm Motor with

Control Box.

-JessEm Mast-R-Li™ #02101, #02102

-JessEm Mast-R-Li II™ #02120, #02121

-JessEm Mast-R-Li™ Excel #02201

-JessEm Mast-R-Li™ Excel II #02202

1

2

3

45

6

7

8

9

10

11

12

13

14

15

16

17

18

19 20

21

23

24

25

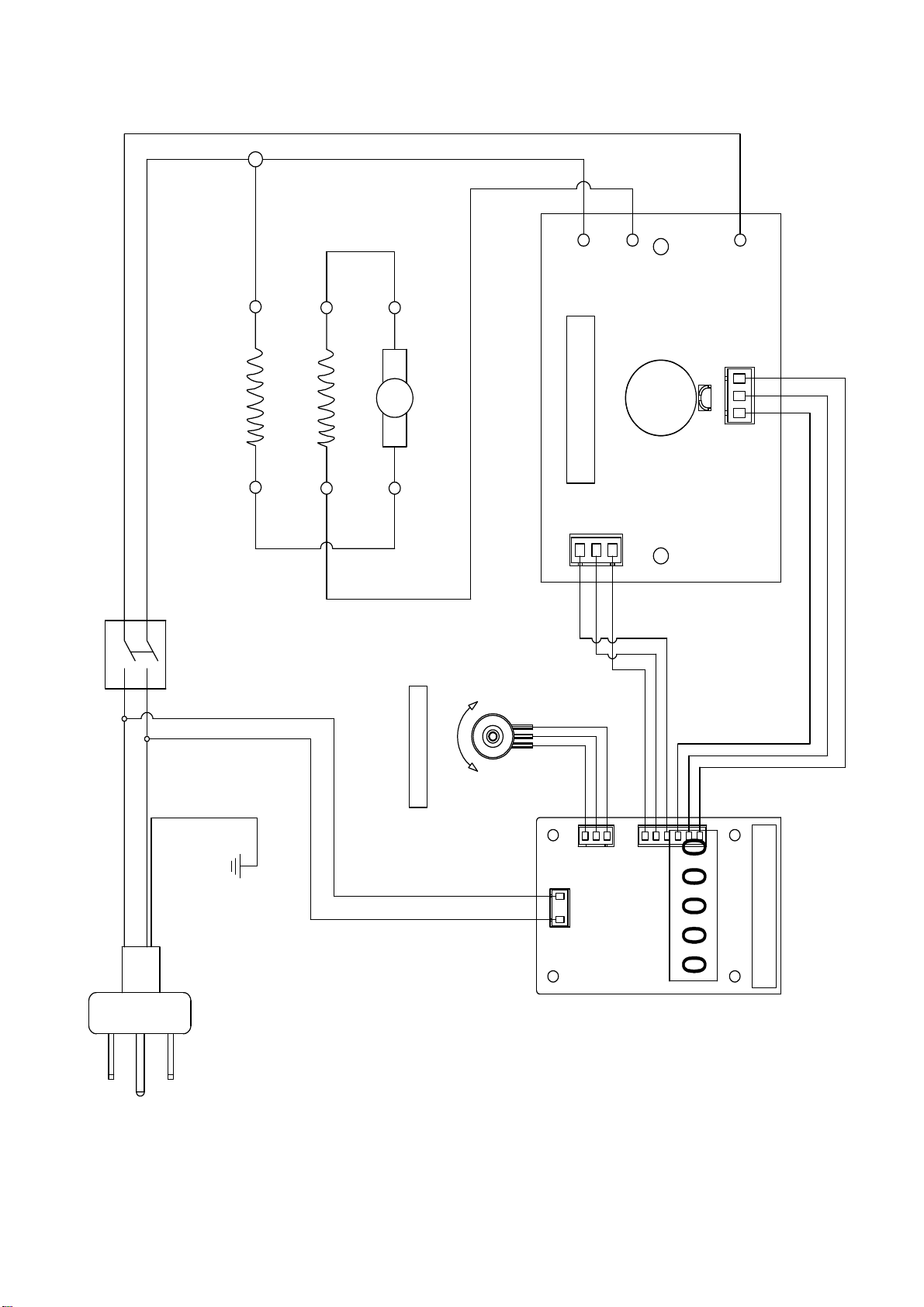

Exploded Drawing

Model No.: 05302

Parameters: 230V 50 Hz

No Load Speed: 10,000 - 21,000 RPM

22

26

27

28 29 30

31

32

33 34 35 36 37

38

39

40

41

42

05300 Router Motor Explosion view Parts List

Part No. Index Part No. Part Name QTY

1 05300-001 Collet Nut 1

2 05300-002 1/2" Collet 1

3 05300-003 Collet Seat 1

4 05300-004 Face Plate Screws 6

5 05300-005 Face Plate 1

6 05300-006 Angular contact Spindle Bearings 2

7 05300-007 Aluminum Housing 1

8 05300-008 Inner housing Sleeve 1

9 05300-009 Armature/fan assembly 1

10 05300-010 Upper Bearing Seat 1

11 05300-011 Bearing Seat Screws 4

12 05300-012 Upper Bearing 1

13 05300-013 Magnetic sensor screw 1

14 05300-014 Stator Winding Assembly 1

15 05300-015 Lower Plastic housing 1

16 05300-016 Air Intake port 2

17 05300-017 Brush Holder assembly 2

18 05300-018 Brush 2

19 05300-019 Brush Holder Screws 4

20 05300-020 Lower Plastic housing screws 3

21 05300-021 PCB Tray 1

22 05300-022 PCB tray screws 4

23 05300-023 Main PCB 1

24 05300-024 Upper Plastic Housing 1

25 05300-025 Upper Plastic housing screws 3

26 05300-026 Router to Controller Connection 1

27 05300-027 Control Box Face plate 1

28 05300-028 Mounting Bracket screws 2

29 05300-029 Mounting Bracket 1

30 05300-030 Control Box Face Plate Screws 4

31 05300-031 Ground Wire Mounting Screw 1

32 05300-032 Control Box 1

33 05300-033 Electromagnetic Saftey Switch 1

34 05300-034 Display Screws 1

35 05300-035 Speed display Board 1

36 05300-036 Plug mounting screws 4

37 05300-037 Wire mount Fitting 1

38 05300-038 Potentiometer 1

39 05300-039 Speed adjustment Knob 1

40 05300-040 Power Cord 1

41 05300-041 1/4" Collet 1

42 05300-042 Wrench 2

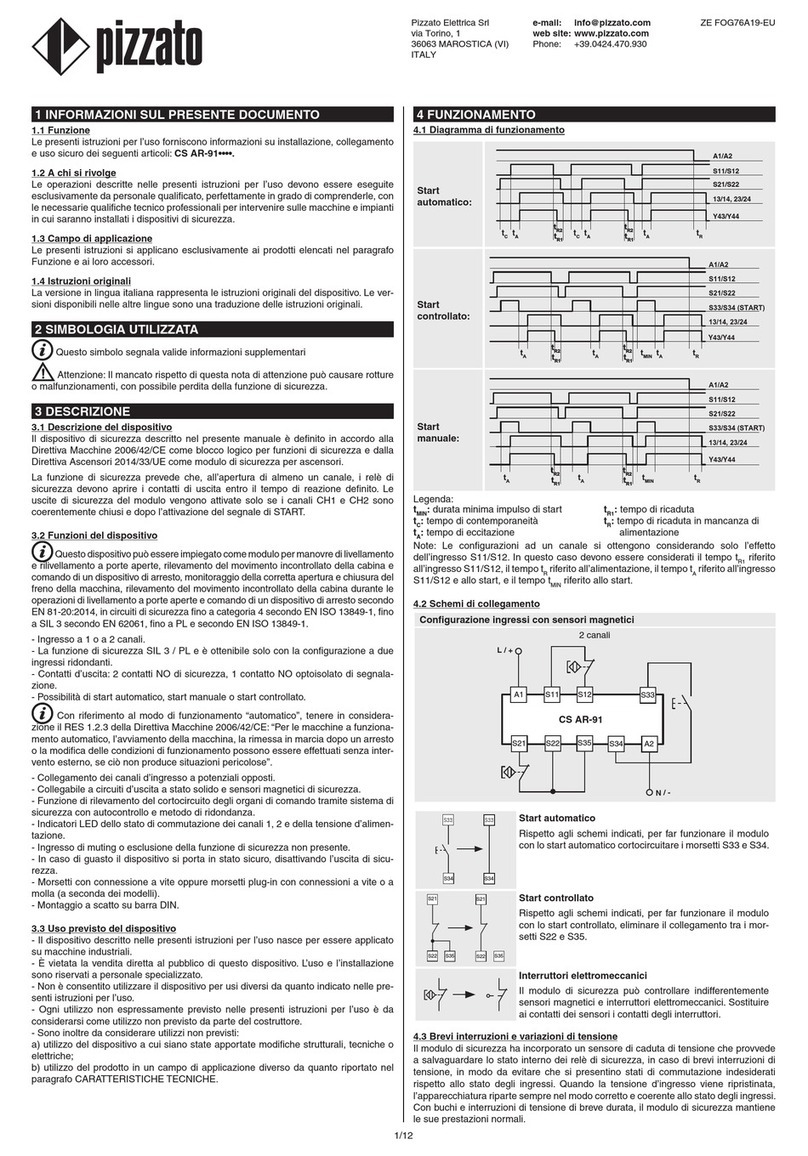

Model No.: 05300

Motor Parameters:

120V 60Hz 15A No

Load Speed:

10,000~21,000 RPM

Speed Adjustment

Potentiometer

5 34

HL

Motor Control PCB

M

main winding -R

Main winding-L

Brush-R Brush-L

3

4

65

7

8

3

4

5

5

4

3

L AC N

8 7 6

Power

ON/OFF

Speed Display PCB

Ground

This manual suits for next models

2

Popular Safety Equipment manuals by other brands

Save Phace

Save Phace I Series owner's guide

WISENT

WISENT 20826240 operating instructions

Berner

Berner 362968 operating instructions

Pizzato Elettrica

Pizzato Elettrica CS AR-91 Series operating instructions

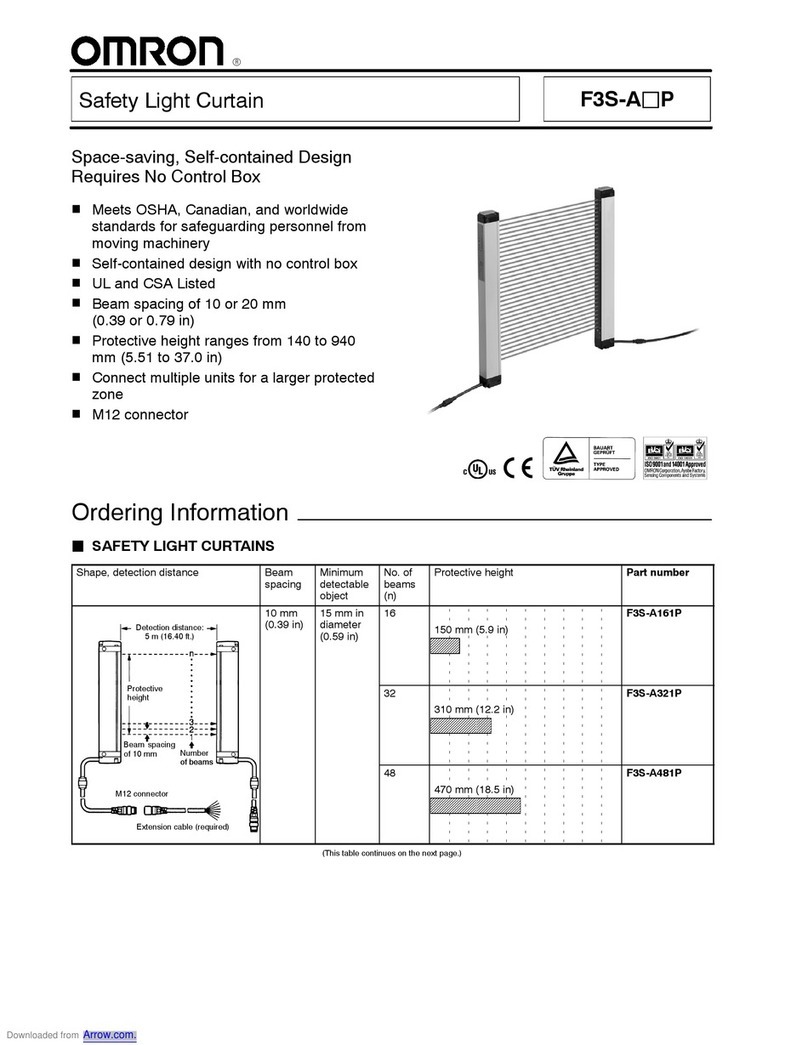

Omron

Omron F3S-AP Series manual

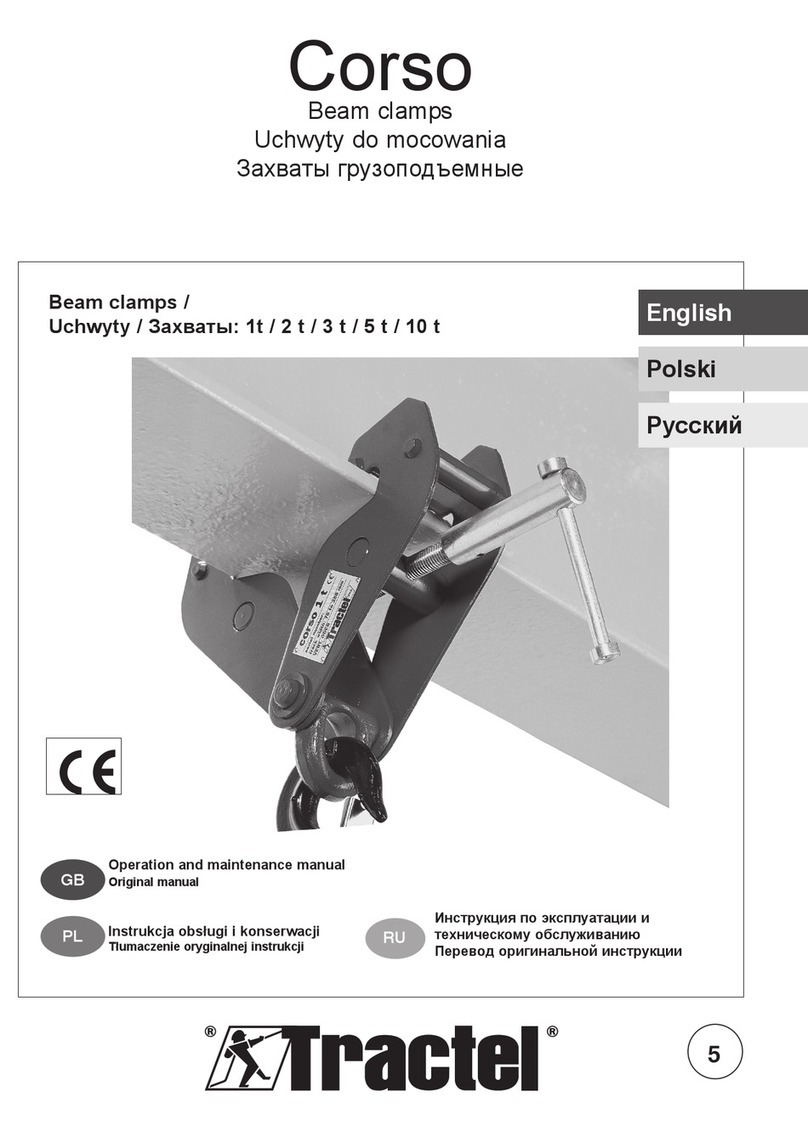

Tractel Group

Tractel Group Stopfor M Series Operating and maintenance instructions