MSA V-TEC PFL User manual

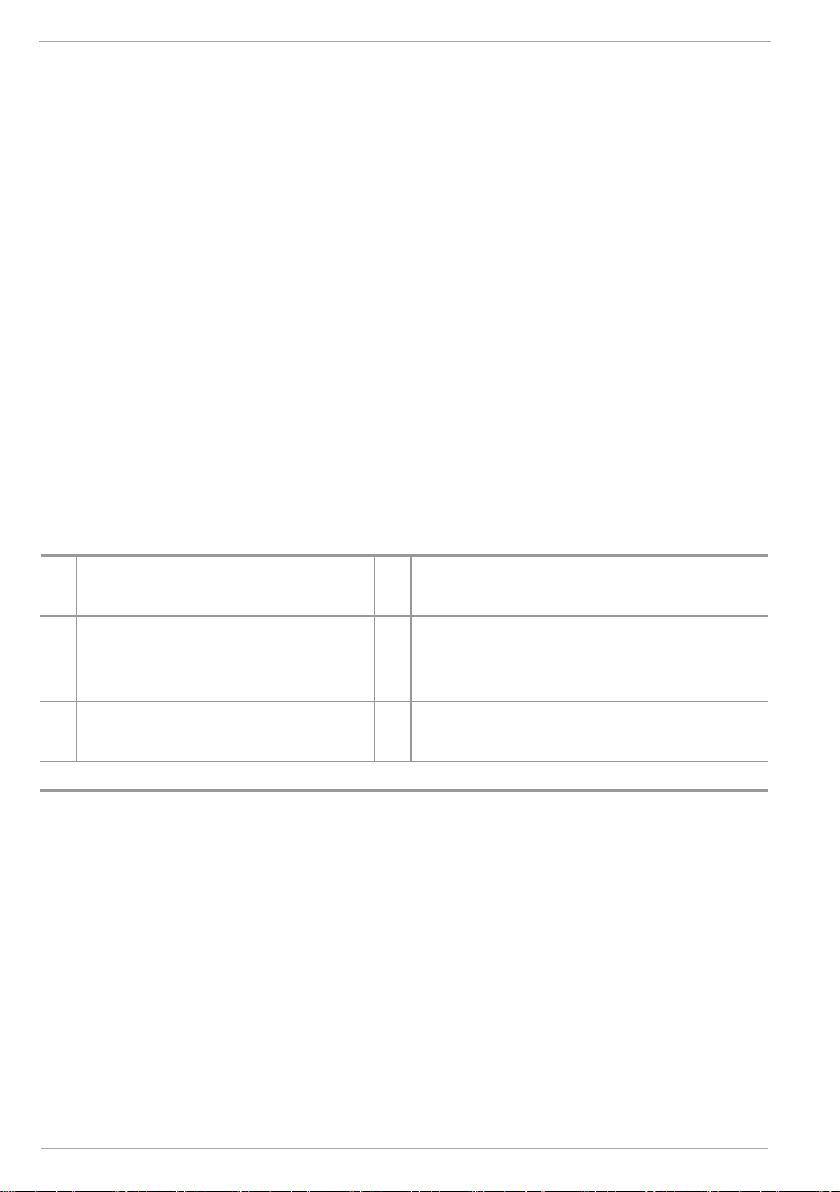

Other MSA Safety Equipment manuals

MSA

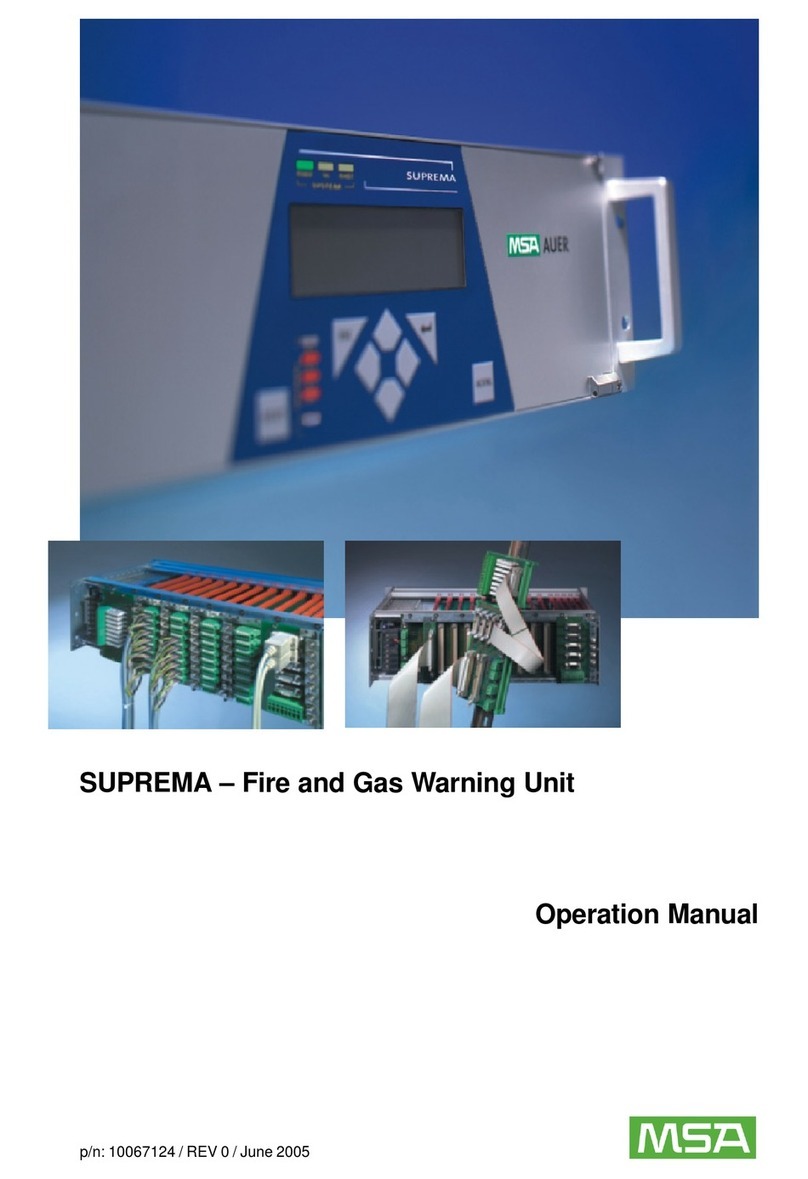

MSA SUPREMA User manual

MSA

MSA SavOx User manual

MSA

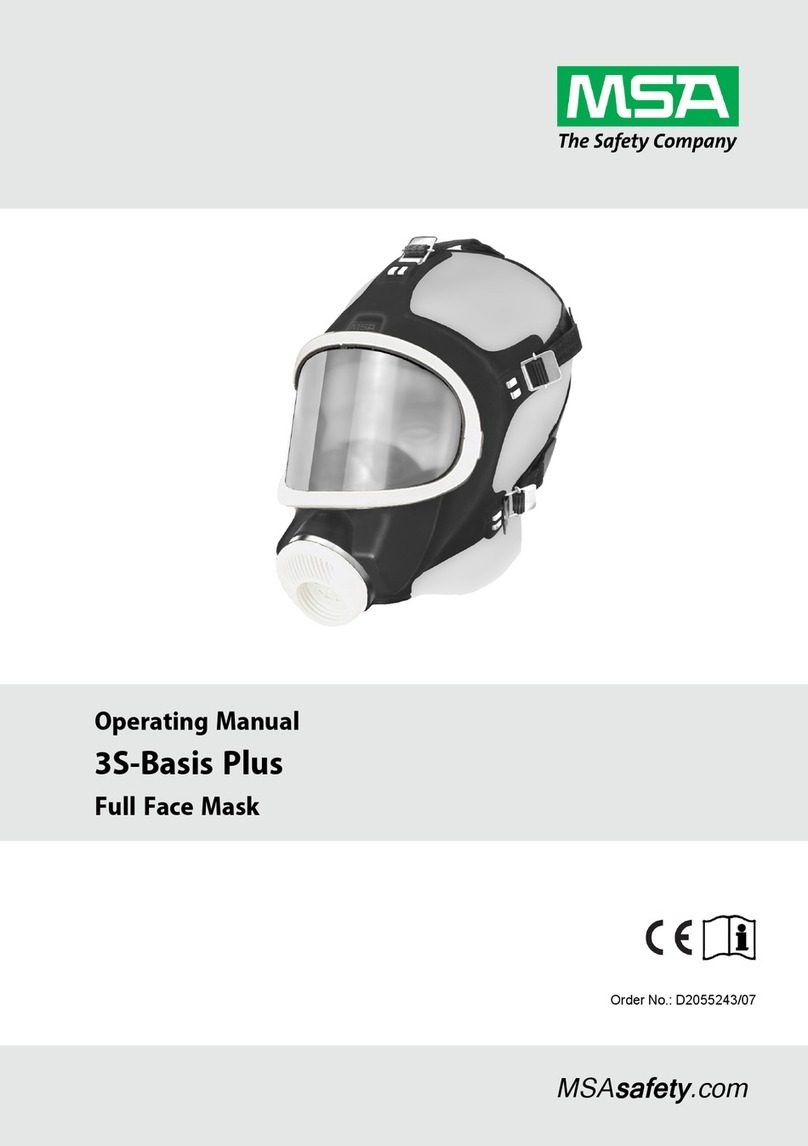

MSA AUER 3S-Basis Plus User manual

MSA

MSA Ultima X Series User guide

MSA

MSA SCBA Basic Apparatus AirGo User manual

MSA

MSA LUNAR User manual

MSA

MSA Aptura LT30 User manual

MSA

MSA GVC Series User manual

MSA

MSA Vautex Elite ET User manual

MSA

MSA 415865 User manual

MSA

MSA AirMaXX classic User manual

MSA

MSA SavOx TR User manual

MSA

MSA SavOx User manual

MSA

MSA VAUTEX ELITE 3S-L User manual

MSA

MSA M1 Installation guide

MSA

MSA Gravity Sure-Line Operation instructions

MSA

MSA fieldserver ProtoNode FPC-N54 User guide

MSA

MSA 10110162 Operation instructions

MSA

MSA Latchways SRL User manual

MSA

MSA HUB User manual

Popular Safety Equipment manuals by other brands

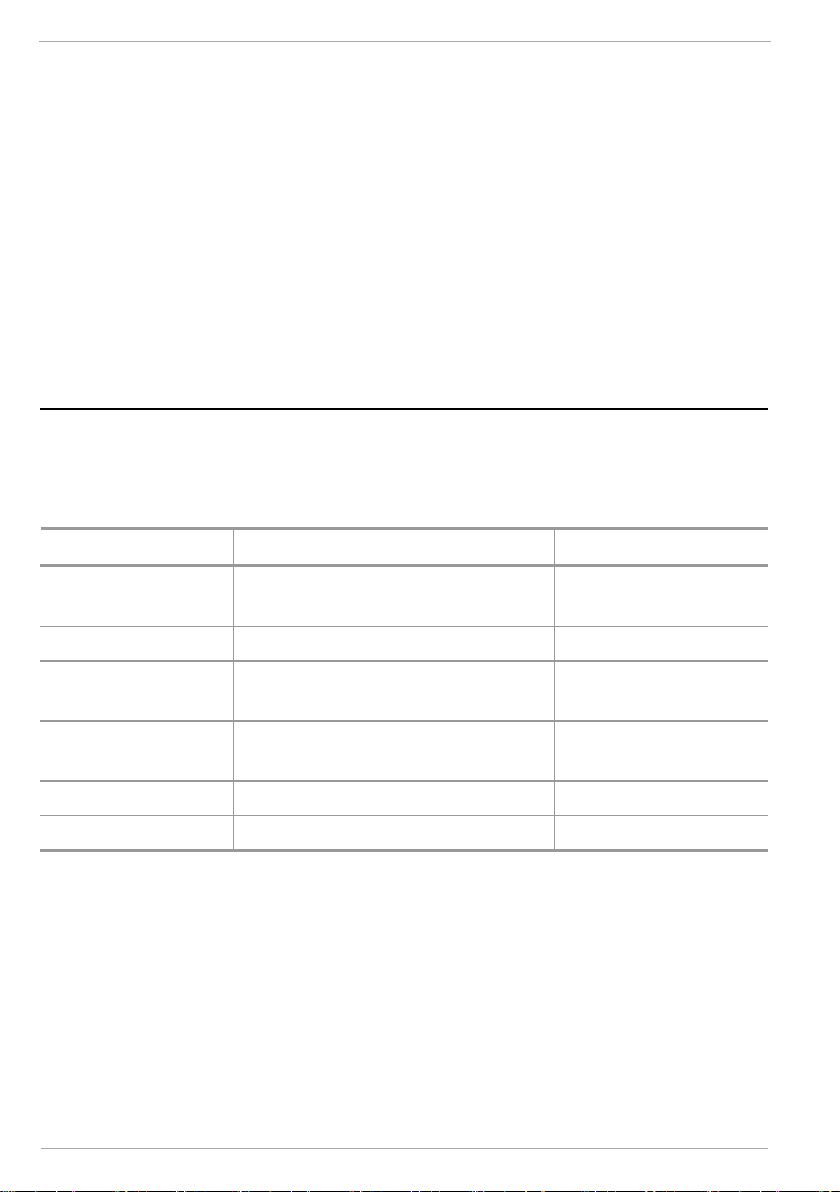

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual