Specifications

Model number..................................................................................................................................... JWBS-14DS

Stock number........................................................................................................................................10000237M

Motor and electricals:

Motor type....................................................................... totally enclosed fan cooled, induction, capacitor start

Horsepower ........................................................................................................................................... 0.75kW

Phase ....................................................................................................................................................... single

Voltage ...................................................................................................................................................... 230V

Cycle.......................................................................................................................................................... 50Hz

Listed FLA (full load amps)............................................................................................................................ 6A

Start capacitor .................................................................................................................................. 300/125uF

Run capacitor ..................................................................................................................................... 30/250uF

Power transfer .............................................................................................................................. Poly-V 200J5

On/off switch............................................................................................................................ KJD-12 NVR CE

Motor speed.......................................................................................................................................1420 RPM

Power cord ............................................................................................................VDE H05VV-F 3Cx1.0mm²

Power plug installed .................................................................................................................. VDE 16A/250V

Capacities:

Maximum cutting height/resaw capacity.......................................................................................... 6” (150mm)

Throat capacity .......................................................................................................................13-3/8” (340 mm)

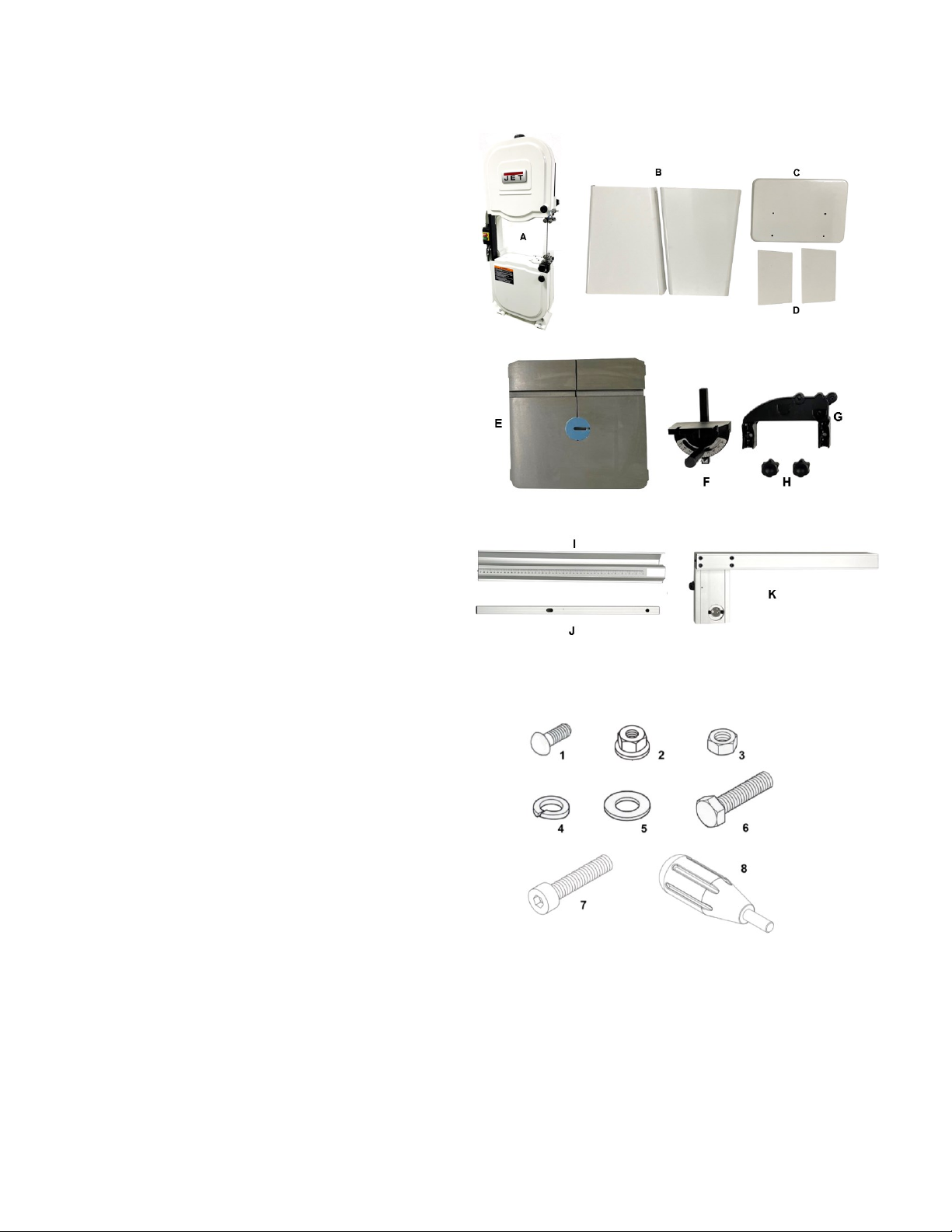

Minimum blade width..................................................................................................................... 1/8” (3.2mm)

Maximum blade width..................................................................................................................... 3/4” (19mm)

Blade length 2......................................................................................................................... 93½” (2375 mm)

Blade provided................................................................................................. hook type, 3/8” x 0.065” x 6 TPI

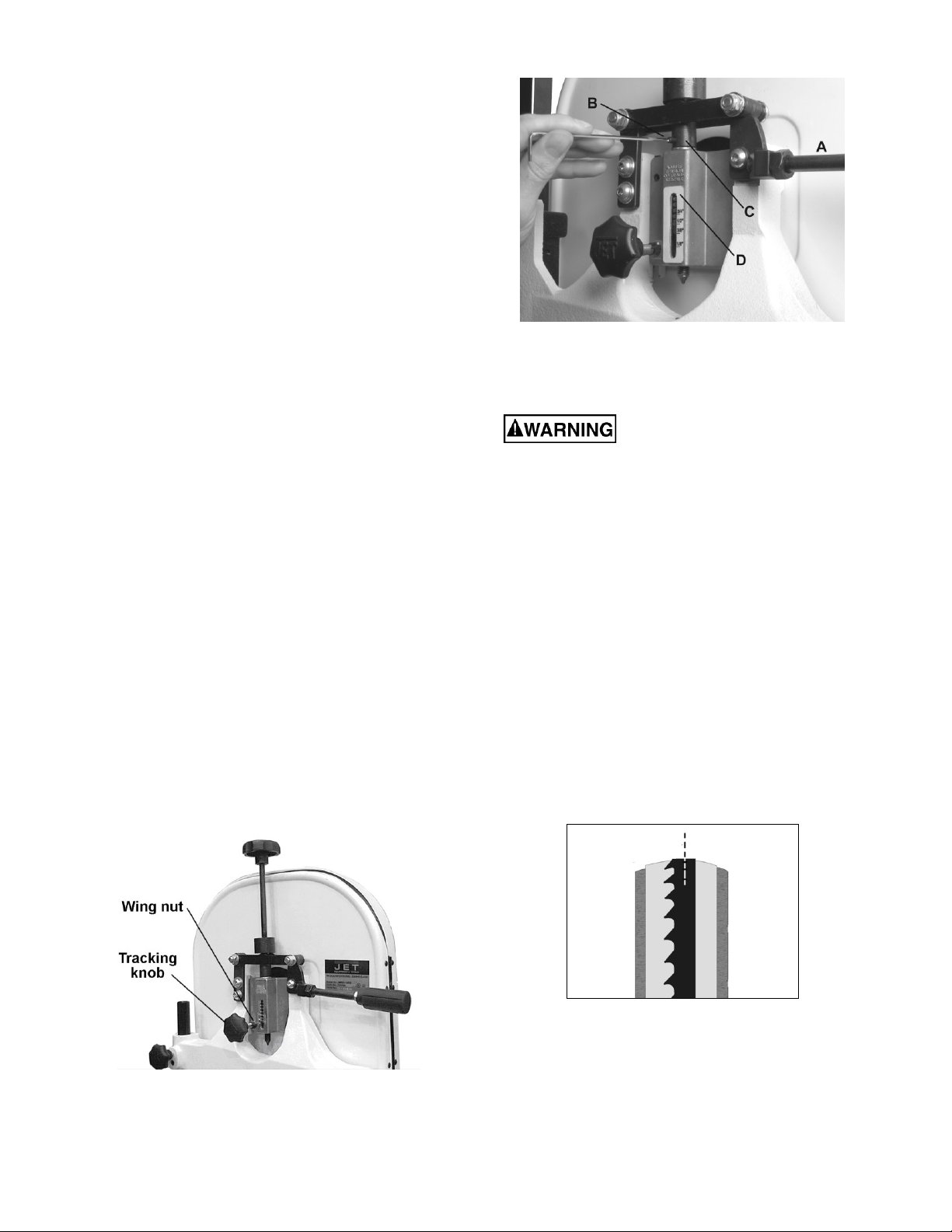

Blade speed...................................................................................................................2430FPM (742 M/min.)

Wheel diameter ............................................................................................................................. 14” (356mm)

Miscellaneous:

Fence plate.........................................................................................43.5x505x50.5 mm (standard equipped)

.......................................................................................................... 35.5X505X150 mm (high fence, optional)

Miter gauge positive stops.................................................................................................... Left 60°, Right 60°

Materials:

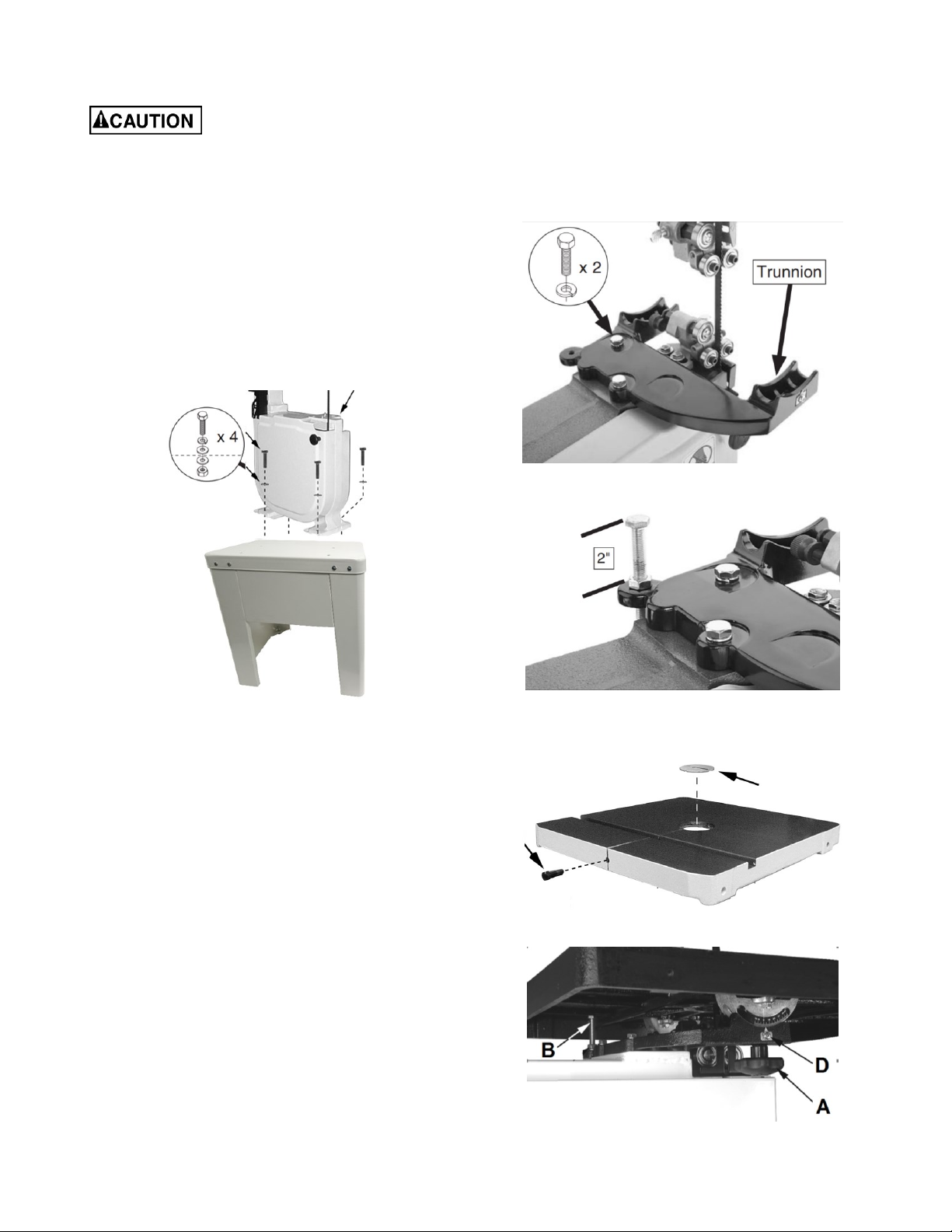

Table........................................................................................................................................ Ground cast iron

Trunnion .............................................................................................................................................. Cast iron

Saw Body .............................................................................. Steel (Cabinet and door) & Cast iron (Saw Bow)

Band wheels ........................................................................................................................................ Cast iron

Tires..................................................................................................................................... Black polyurethane

Blade guides....................................................................................................................................Ball bearing

Resaw fence........................................................................................................................Extruded aluminum

Handwheels............................................................................................................................................. Plastic

Paint finish ......................................................................................................................................Powder coat

Table:

Table dimensions .................................................................................................14”L x 14”W (356 x 356 mm)

Table tilt ...................................................................................................................................15° left, 45° right

Table height from floor at 90-degrees ..................................................................................... 43½” (1105 mm)

Miter T-slot.................................................................................................. 3/8”D; opening 3/4"W (9.5 x19mm)

Dust collection:

Dust port outside diameter ................................................................................................... two at 4” (100mm)

Weights:

Net weight (fully assembled) ..................................................................................................................83.1 kg

Shipping weight ......................................................................................................................................89.2 kg

Overall dimensions, assembled.......................................................................................... 28½ "Lx31½ "Wx65½ "H

Shipping Dimension........................................................................................................ 1120Lx530Wx495H mm