Jetter AG Table of Contents

jxm-io-ew30_ba_2151_manual iii

Table of Contents

1 Introduction ......................................................................................................................................... 5

1.1 Information on this document .......................................................................................................5

2 Safety ................................................................................................................................................... 6

2.1 General information......................................................................................................................6

2.2 Purpose ........................................................................................................................................6

2.2.1 Intended use.....................................................................................................................6

2.2.2 Usage other than intended ...............................................................................................6

2.3 Warnings used in this document ..................................................................................................6

3 Product description ............................................................................................................................ 8

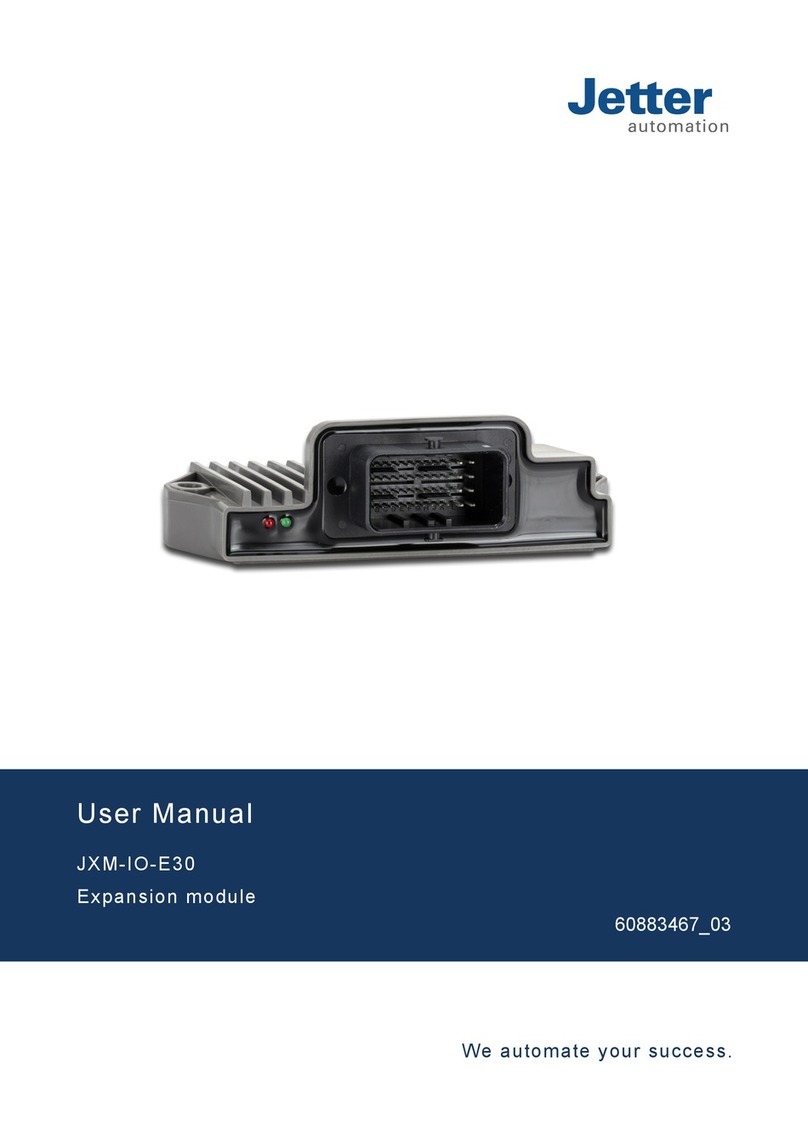

3.1 Design ..........................................................................................................................................8

3.2 Features .......................................................................................................................................9

3.3 Diagnostic capability via LEDs .....................................................................................................9

3.4 Nameplate ..................................................................................................................................10

3.5 Scope of delivery........................................................................................................................10

4 Technical specifications................................................................................................................... 11

4.1 Dimensions.................................................................................................................................11

4.2 Mechanical specifications...........................................................................................................11

4.3 Electrical properties....................................................................................................................12

4.4 Environmental conditions ...........................................................................................................12

4.5 EMC values ................................................................................................................................13

4.6 Outputs.......................................................................................................................................14

4.6.1 Current diagnostics at the outputs..................................................................................16

4.6.2 Overcurrent shutdown at outputs ...................................................................................16

4.7 Inputs..........................................................................................................................................16

5 Mechanical installation..................................................................................................................... 19

5.1 Requirements for the installation location ..................................................................................19

5.2 Allowed mounting orientations ...................................................................................................19

6 Electrical connection ........................................................................................................................ 20

6.1 Pin assignment...........................................................................................................................21

6.1.1 Printed Circuit Board ......................................................................................................21

6.1.2 DIP Switch......................................................................................................................24

6.1.3 5-pin male connector M12..............................................................................................25

7 Identification and Configuration...................................................................................................... 26

7.1 Identification ...............................................................................................................................26

7.1.1 Device information..........................................................................................................26