5.5 Installation Warning

If parts and tools used are not specified by JinKO or not prepared and assembled as

JinKO described during installation , the uniformity of safety and technical data on prod-

ucts are not guaranteed.

The connector is considered to be in compliance with UL 6703 only when assembled in

the manner specified by these assembly instructions.

During assembling, the connector must not be touched with any machine oil, grease, sol-

vent, with which connector would be out of action. Notice that the gloves the operators

used must not contain the substance above. The male cable connectors and the female

connectors must not plugged together when soiled.

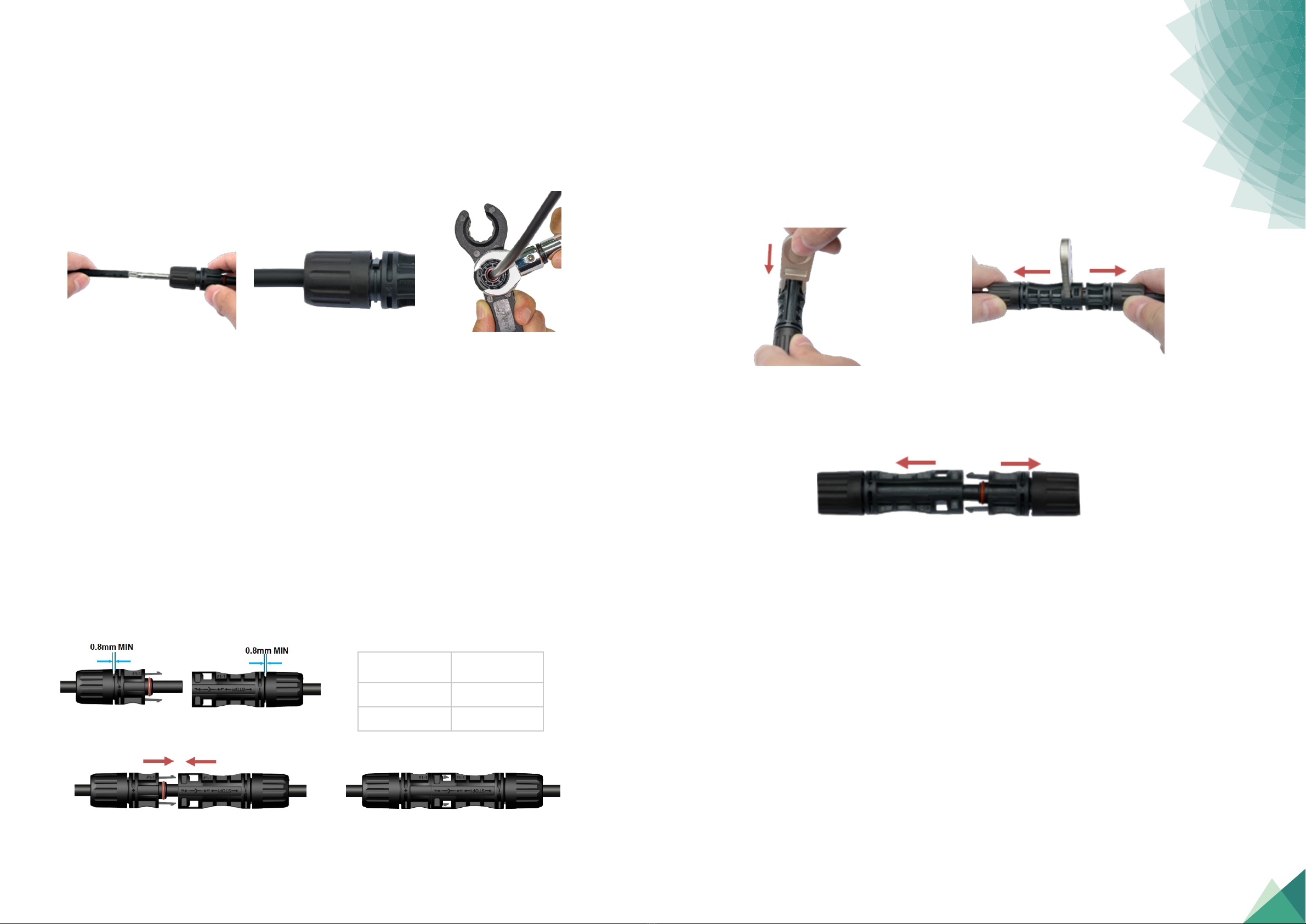

The work described here must not be carried out on live or load-carrying part.

Connectors must not be disconnected under load. Plugging and unplugging when volt-

age is permitted.

The dust plug(4JB03M31005/4JB03M31007)should be placed to avoid exposing the dust

and water when disconneted or disconnected after connected.

The plug connectors are watertight in accordance with IP68 protection class. However,

they are not suitable for continuous operation under water. Do not place the connectors

directly on the roof.

The plug connection must not be subjected to continuous mechanical tension. The cable

should be fixed with cable binders.

For safety reason, the use of either PVC cables or untinned cables are prohibited.

This connector is suitable for use only with Class B and C stranded copper conductors (See

NFPA NEC 70 Chapter 9, Table 10).

Notes: If you have any questions during installation, please feel free to contact us as follows:

Jiangxi Jinko PV Material Co., Ltd.

Add:No.10, Xingye Road, Economic Development Zone, Shangrao ,Jiangxi Province, P.R. China

Tel.:(+86)0793-8876086

Postcode:334100

Website:www.jinkopvm.com

Sales Contact Information

Tel.:(+86)0793-8876028

Technician Contact Information

Tel.:(+86)0793-8876018

Installation Manual for PV-JK03M/xy Series Cable Connector | 1514