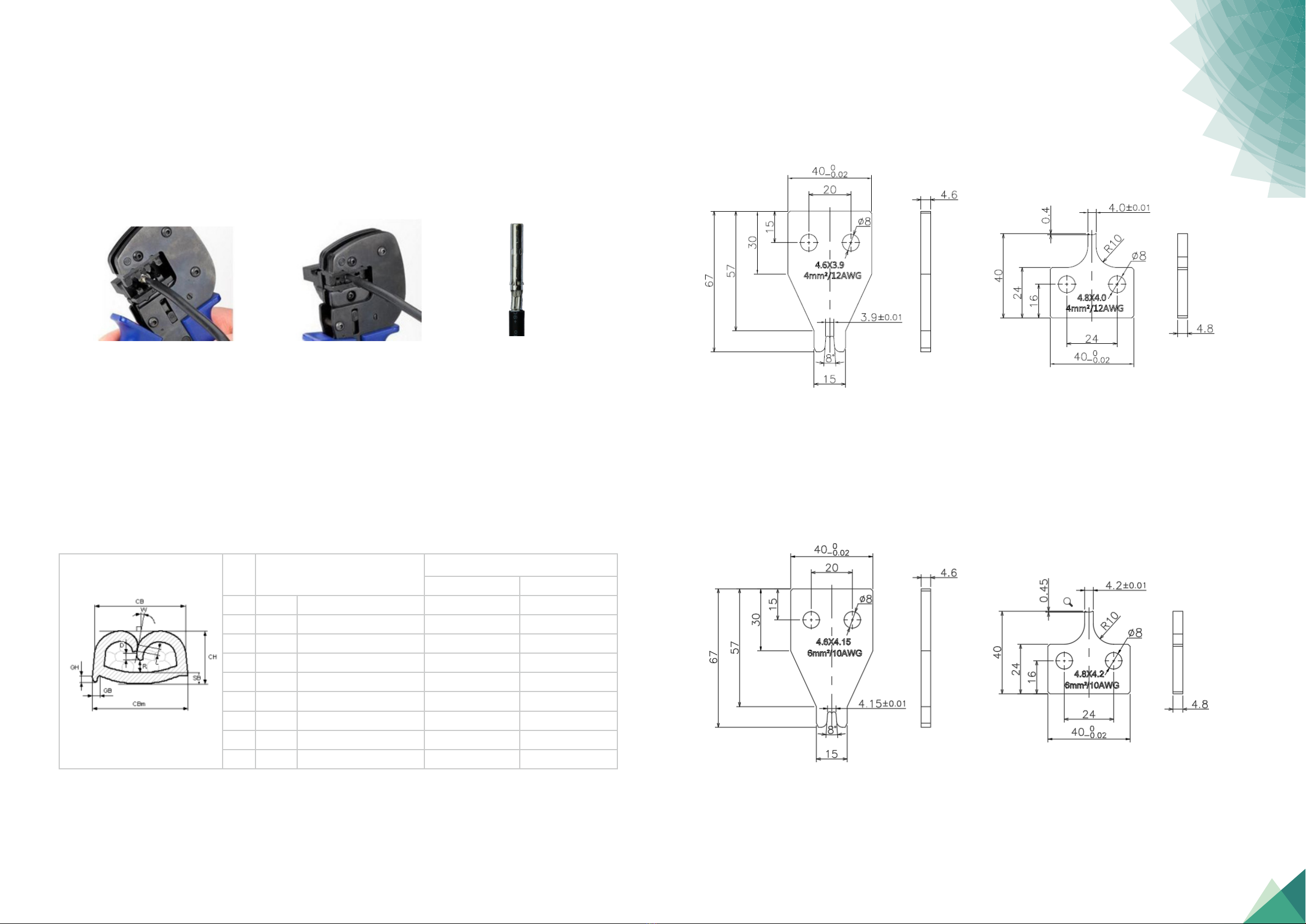

3.Technical Data 4.Tools Instruction

JKT-01:2.5mm²(14AWG)、4.0mm²(12AWG)、6.0mm²(10AWG)

The Stripping Tool-JKT-01 is applicable to 2.5mm²(14AWG) or 4.0mm²(12AWG) or

6.0mm²(10AWG) cable.

There is one stripping tool JKT-01 per tool set.

Function: Cutting the wire insulation (exposing the copper wire).

JKT-02:2.5mm²(14AWG)、4.0mm²(12AWG)、6mm²(10AWG)

The Crimping Tool-JKT-02 is applicable to 2.5mm²(14AWG) or 4.0mm²(12AWG) or 6.0mm²

(10AWG) cable.

There is one crimping tool-JKT-02 per tool set.

Function: The connection and crimping between the copper wire and metal terminals are

all made by the crimping tool.

Type Name or Model No.

Rated Voltage ( V DC)

PV-JK03M2-F/xy, PV-JK03M2-M/xy

1500 V DC

Rated Insulation Voltage

Rated Current (A DC)

Application Class Class A

Protection Class / Pollution Degree Class II / 2

Ambient Temperature -40℃to +85℃

Upper Limit Temperature 115℃

Over Voltage Category CAT III

Flammability Class

Degree of Protection, mated / unmated

UL94 V-0

Rewireable No

Cable Diameter 4.7mm to 8.0mm

Contact Resistance ≤ 0.2 m Ω

Contact material Copper, tin plated

Insulation Material PA

Existence of an enclosure Enclosed connector

Certification Standard IEC 62852 Edition 1.0 2014-11;

UL6703

IP65/ IP68 (1m, 2h) in mated condition

IP2X in unmated condition

8000 V (1500 V DC)

30 A (2.5mm²/14AWG)

45 A (4.0mm²/12AWG)

50 A (6.0mm²/10AWG)

60 A (10.0mm²/8AWG)

Wire Cross Section Area or Cross

Section Range

1X2.5mm²(14AWG) for x=1;

1X4.0-6.0mm² (12AWG/10AWG) for x =2;

1X10.0mm²(8AWG) for x=3;

Note: PV-JK03M2-F/xy ; PV-JK03M2-M/xy (x=1 or 2, y=B or C)

Stripping Tool - JKT-01

Crimping Tool- JKT-02

Assembly Tool -JKT-06

JKT-06:

Assembly Tool -JKT-06:There are two assembly tools per tool set.

Function: Used for assembling and disassembling connectors.

Installation Manual for PV-JK03M2/xy Series Cable Connector | 0706