7

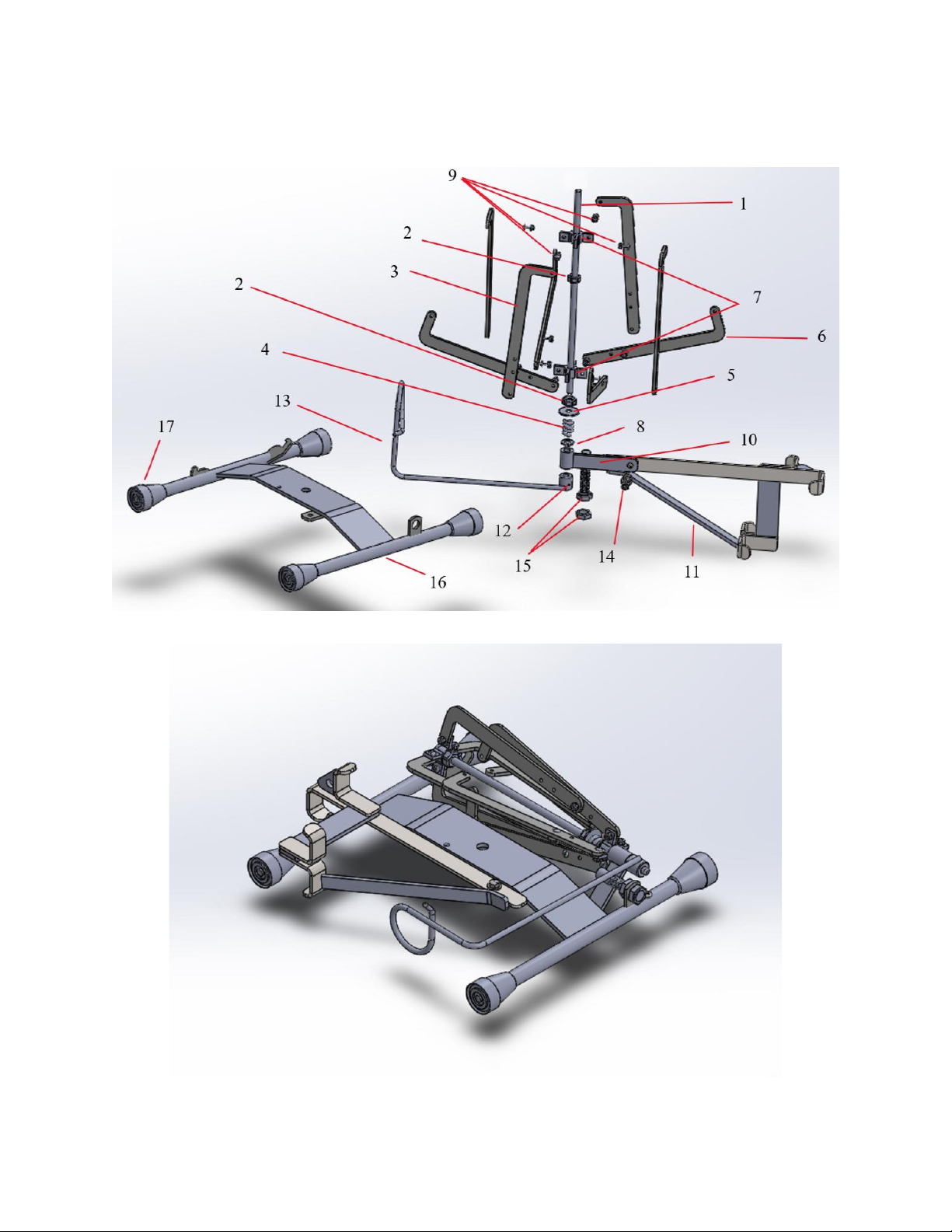

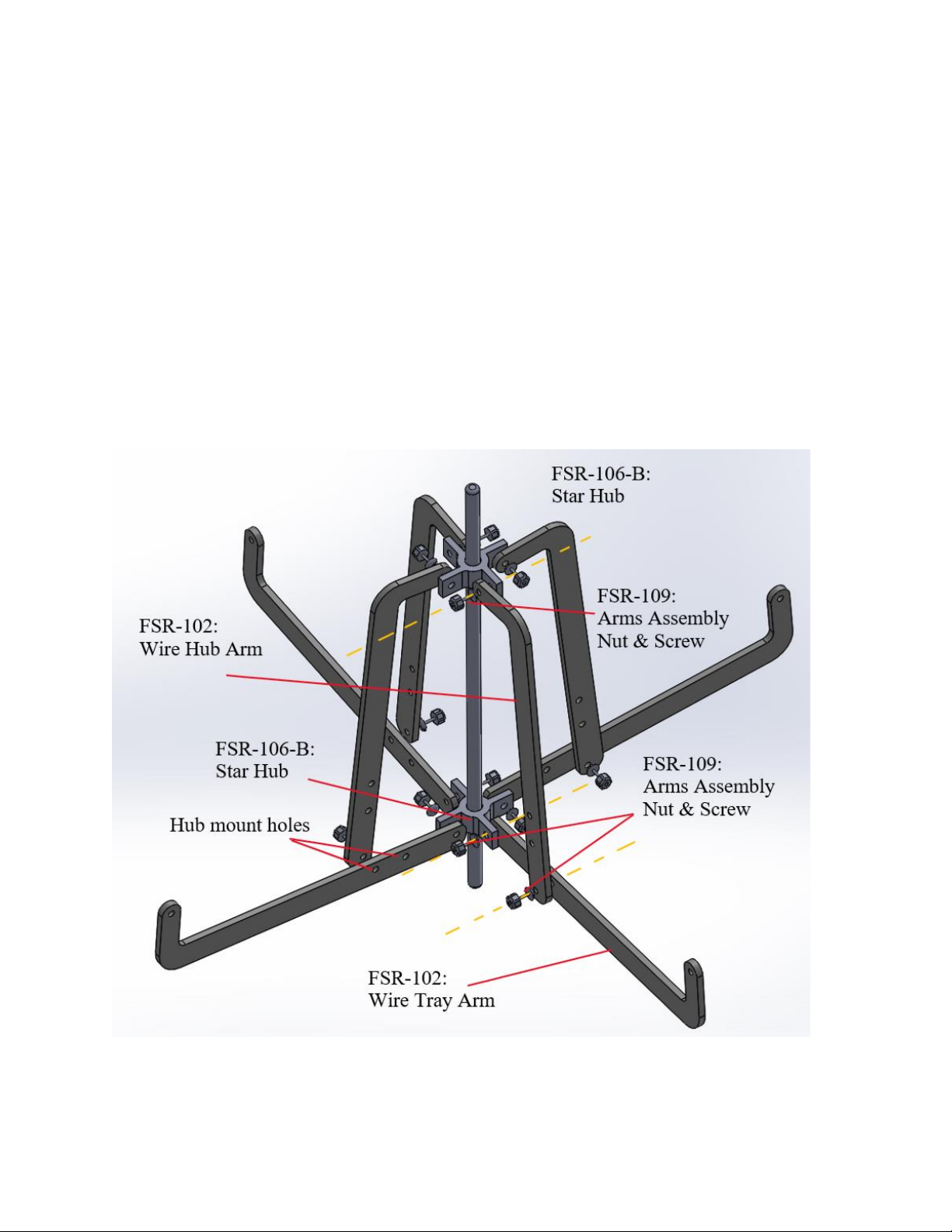

Underneath the swivel mount assembly weldment, the wire guide (FSR-116) should be

slid onto the spindle rod, seen in figure 3. To finish assembly, the set-screws in the wire guide

and hex set-screw bushings should be tightened to raise the wire tray arms to the preferred angle.

When this is achieved, the top het set-screw bushing should be snug with the top star hub, and

the bottom bushing, stop washer, spring and small washer should securely rest on the bottom star

hub. Instructions on adjusting the angle of the wire tray arms can be found on pages 12-13

Figure 3

The swivel mount assembly weldment and the spindle rod should slide on the spindle rod underneath the

rest of the arms assembly.

Dismounting the Stud Mount Assembly Weldment from the Floor Bracket

The stud mount assembly weldment will come attached to the floor bracket. In order to

use the floor bracket or the stud mount, they need to be separated. In order to do this, the 5/16”

bolt, washers & nut (FSR-117) need to be removed, which is shown in figure 4. The stud mount