1

1. Summary of safety instructions:

1.1 These instructions must be read before use.

1.2 The lift should only be operated by persons authorised for this purpose.

1.3 Ensure that all electrical cables are undamaged at all times to avoid electric shocks.

1.4 Ensure that no bodily parts can be clamped or caught when raising and lowering the lift.

1.5 Stop any work on the lift immediately in the event of problems and contact the Matthies Workshop Service or your distri-

bution partner.

1.6 The lift must be installed on a rm, stable and level support surface.

1.7 The working area of the lift must be kept clean and clear.

1.8 Ensure when raising and lowering the lift that the vehicle is stably and safely secured. This can either be achieved with

an optional wheel clamp, an optional assembly stand or optional lashing straps. Raise the lift platform briey and ensure

that the vehicle is standing safely and correctly.

1.9 The operator must maintain visual contact with the lift during raising and lowering of the lift.

1.10 Persons should at no time be on the lift.

2. Important information for your safety

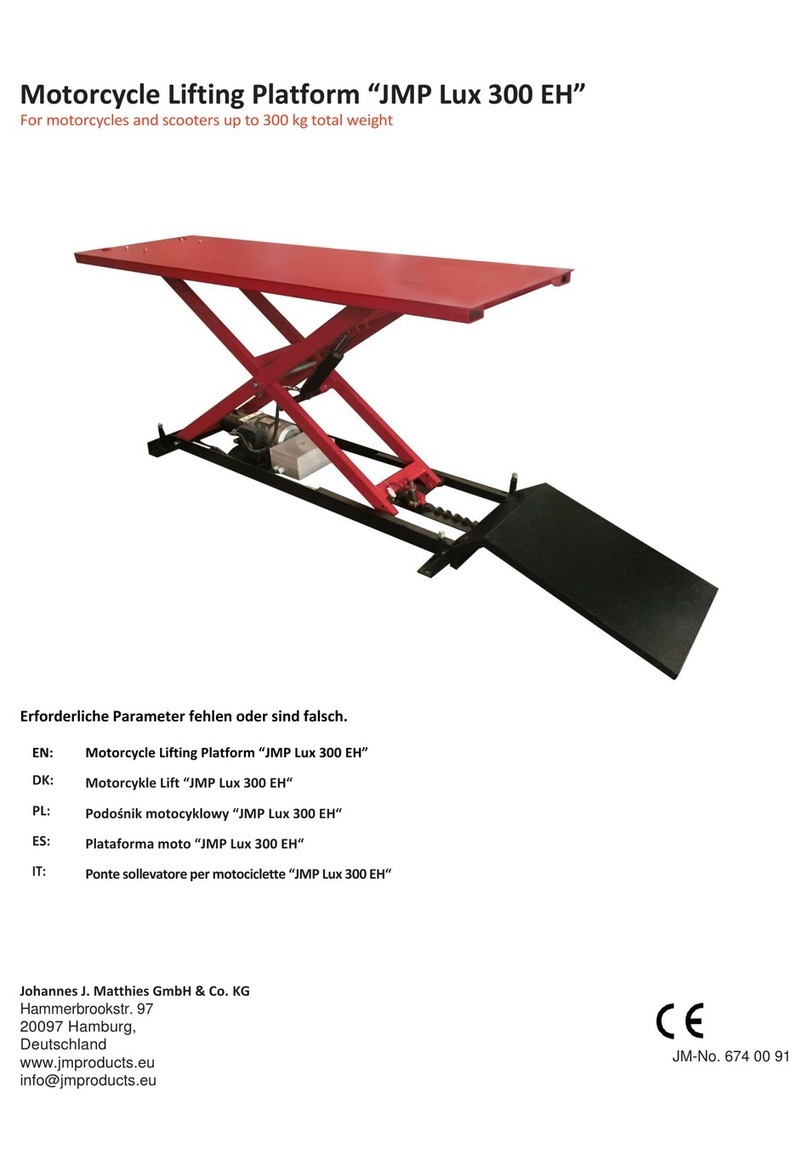

Please read these operating instructions carefully and follow the instructions in this manual prior to commissioning

the JMP Lux 300 EH lift. Please contact the Matthies Workshop Service in the event of questions.

Caution - electrical voltage. Only entrust installation to a specialist company.

3. Scope of supply

1x pre-assembled JMP Lux 300 EH lift

4. Technical data

Minimum height: 19 cm

Maximum height: 115 cm

Maximum carrying weight: 300 kg

Approx. dead weight: 200 kg

Complete raising: 30 sec

Complete lowering: 30 sec

Supply voltage: 230 VAC, 50 Hz

Power consumption: 0.75 KW

Work surface: 2000 x 650 mm

5. Area of use

The following areas of use are permitted:

5.1 The lift should only be used for raising motorcycles, scooters and other two-wheeled vehicles up to a weight of 300 kg.

5.2 The lift should be used exclusively in dry indoor spaces for this purpose.

5.3 The lift should only be used for briey lifting to realise maintenance or repairs.

5.4 The lift should only be operated by persons who have received intensive instruction in the operation of and safety inst-

ructions relating to the lift.

The following areas of use are prohibited:

5.5 Use outdoors.

5.6 Lifting of vehicles or other equipment that either exceed the permissible carrying weight of 300 kg or are unstable due to

their dimensions.

5.7 Stepping/climbing onto the lift.

5.8 Lifting of persons.

Original operating instructions